Thingiverse

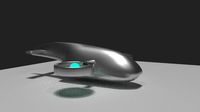

Speedy "Red Mini Wing" RC Plane by wersy

by Thingiverse

Last crawled date: 3 years ago

Here is a brood to the bird family. Related to the wingspan, it is a crossbreed of the

"Red Duck" http://www.thingiverse.com/thing:407766

and the

"Red Swan" http://www.thingiverse.com/thing:453090

Still small, but speedy and pretty manoeuvrable - a big fun for a real pilot.

Anyhow, Marcel, member of the ACNE http://www.aero-club-nieder-eschbach.de/

who piloted the maiden flight, had a lot of fun and this is his first impression:

"The small model is already very good, but some model flying experience is needed. For a wing type of this small size it flies even damned good. It’s not a plane for circling through thermics, of course it’s to small for that. The performance is shown when one flies it speedingly".

Uwe Heuer - experienced flying wing designer and Horton specialist - says about this square form of a flying wing, which he loves to call "panel plane":

"They do have a low damping and flight stability around the pitch axis (elevator), therefore you can fly snags in curves. This is why I love these “panel-planes”, these are also good-tempered against tilting to one side. But on the other side you pay that with the high sensitivity regarding wrong trimming of the CG and the elevator. During stall the wings stay level but for recovery they need a long dive to speed up again".

Besides my other planes it was flying at the InterEx 2016 in Versiox/Genevahttp://jivaro-models.org/interex_2016/index.html

They were very enthusiastic about of the speed which is possible.

But we dicovered that it is also posssible to land it slowly.

Here you can see how it flies:https://youtu.be/d8cFB1equikhttps://youtu.be/QrYqn8kItYM

This small plane is quickly printed.The biggest parts are 220mm high to print, but I also sliced them in half.

Wing fixating

Additional to fasten the wing with rubber band, it is important to secure it against sliding sidewards. You can do this by simply fixiating it with a short tape at front and at back to the fuselage.

Update 11.23.2015

Uploaded smaller wing segments:

wing middle left 110

wing middle right 110

wind left right 110

And smaller front fuselage segments:

fuselage front 1

fuselage front 2

fuselage interface front

Update 12.14.2015

Uploaded smaller back fuselage segments:

fuselage back 1

fuselage fback 2

fuselage interface back

Update 01.04.2016

Uploaded

winglet test 1 (1.5mm thick)

winglet 0.9 (0.9mm thick) which is successfully tested by "wytti"

print setting: three 0.3 solid layers

Update 01.07.2016

Wing fixiating and centering

"Scorpio 9999" made a good suggestion for improvement: Centering the wing by two little ribs on the bottom side of the middle wing part.

Thank you Scorpio!

I uploaded the files:

wing middle left 110 centered

wing middle right 110 centered

Additional I let the first files online in case anybody wants to extend the wingspan by simply add a wing section in the middle.

Update 01.21.2016

"Scorpio9999" published two parametric servo inserts for those who have different servos.http://www.thingiverse.com/thing:1264902

Update 1. August 2017

Uploaded bigger stabilizer. They are 14% bigger

base 90 mm

top 66 mm

hight 140 mm

Specifications

airfoil: ClarkYS

wing span: 794 mm

wing chord: 160 mm

aerodynamic center 27 mm

wing overall weight: 270 g

wing area: 12.7 dm²

fuselage empty weight 75 g

fuselage overall weight 270 g

wing loading: 42.5 g/dm²

longitudinal stability (Thies) STFs:

motor: Turnigy 2632 Brushless Motor 1000kv

motor camber: -3°

side pull: 2° right

propeller: Aeronaut CAM Aeronaut Carbon Classic 9 x 6.5" / 23 x 16.5 mm

static thrust: 500 g (3S Lipo)

battery: Turnigy nano-tech 950mah 3S 25~50C Lipo Pack

ESC: HobbyKing YEP 30A (2~4S) SBEC Brushless Speed Controller

receiver: OrangeRx R615X DSM2/DSMX Compatible 6Ch 2.4GHz Receiver w/CPPM

servos: Hitec HS-55

Print Settings

Attention

The wings are designed to print with 0.5 width, 0.3 hight and 2 bottom and top layer, NO infill.

If you print thinner, the perimeter of the upper side will not merge with the perimeter of the inner spars.

If you print thicker, the perimeter will not be printed continuesly in one turn.

The print must go as if you print in spiral vase mode. So you reach at least a smooth surface on the upper side.

If needed, you must try with 0.49 or 0.48 width. It depends on which slicer you use.

The second thing is, if you print with less layer hight, the inner spars will not connect the top and the bottom layer. There will be a gap inbetween.

All parts: layer height =0,3mm, width =0.5 mm, NO infill

wing

1 perimeter, 2 bottom layer, 2 top layer, hollow

wing servo: 3 bottom layer, spiral vase mode

aileron base: 5 bottom layer, spiral vase mode

aileron end: 2 bottom layer, spiral vase mode

aileron appendix: 1 perimeter, hollow

aileron interface: no bottom layer, spiral vase mode

fuselage

Note: The extrusion width must be thick enough to prevent printing infill between the two perimeters of the 1mm hull. You must try out and check it in the preview.

I had to set the width to 0.53mm.

fuselage front: 7 bottom layer, 3 top layer, 2 perimeter, extrusion width 0.53mm, 20% infill

fuselage back: 3 bottom layer, 3 top layer, 2 perimeter, extrusion width 0.53mm, 20% infill

fuselage interface: 2 perimeter 0.4 no bottom/top layer, holow

fin: 4 bottom layer, spiral vase mode

fin cover plate: 2 bottom layer, hollow

The bigger fin:

0.3 layer hight

0.5 width

3 solid bottom layer, spiral vase mode

The bigger fin plate:

3 solid bottom layer

1 perimeter

10% infill

"Red Duck" http://www.thingiverse.com/thing:407766

and the

"Red Swan" http://www.thingiverse.com/thing:453090

Still small, but speedy and pretty manoeuvrable - a big fun for a real pilot.

Anyhow, Marcel, member of the ACNE http://www.aero-club-nieder-eschbach.de/

who piloted the maiden flight, had a lot of fun and this is his first impression:

"The small model is already very good, but some model flying experience is needed. For a wing type of this small size it flies even damned good. It’s not a plane for circling through thermics, of course it’s to small for that. The performance is shown when one flies it speedingly".

Uwe Heuer - experienced flying wing designer and Horton specialist - says about this square form of a flying wing, which he loves to call "panel plane":

"They do have a low damping and flight stability around the pitch axis (elevator), therefore you can fly snags in curves. This is why I love these “panel-planes”, these are also good-tempered against tilting to one side. But on the other side you pay that with the high sensitivity regarding wrong trimming of the CG and the elevator. During stall the wings stay level but for recovery they need a long dive to speed up again".

Besides my other planes it was flying at the InterEx 2016 in Versiox/Genevahttp://jivaro-models.org/interex_2016/index.html

They were very enthusiastic about of the speed which is possible.

But we dicovered that it is also posssible to land it slowly.

Here you can see how it flies:https://youtu.be/d8cFB1equikhttps://youtu.be/QrYqn8kItYM

This small plane is quickly printed.The biggest parts are 220mm high to print, but I also sliced them in half.

Wing fixating

Additional to fasten the wing with rubber band, it is important to secure it against sliding sidewards. You can do this by simply fixiating it with a short tape at front and at back to the fuselage.

Update 11.23.2015

Uploaded smaller wing segments:

wing middle left 110

wing middle right 110

wind left right 110

And smaller front fuselage segments:

fuselage front 1

fuselage front 2

fuselage interface front

Update 12.14.2015

Uploaded smaller back fuselage segments:

fuselage back 1

fuselage fback 2

fuselage interface back

Update 01.04.2016

Uploaded

winglet test 1 (1.5mm thick)

winglet 0.9 (0.9mm thick) which is successfully tested by "wytti"

print setting: three 0.3 solid layers

Update 01.07.2016

Wing fixiating and centering

"Scorpio 9999" made a good suggestion for improvement: Centering the wing by two little ribs on the bottom side of the middle wing part.

Thank you Scorpio!

I uploaded the files:

wing middle left 110 centered

wing middle right 110 centered

Additional I let the first files online in case anybody wants to extend the wingspan by simply add a wing section in the middle.

Update 01.21.2016

"Scorpio9999" published two parametric servo inserts for those who have different servos.http://www.thingiverse.com/thing:1264902

Update 1. August 2017

Uploaded bigger stabilizer. They are 14% bigger

base 90 mm

top 66 mm

hight 140 mm

Specifications

airfoil: ClarkYS

wing span: 794 mm

wing chord: 160 mm

aerodynamic center 27 mm

wing overall weight: 270 g

wing area: 12.7 dm²

fuselage empty weight 75 g

fuselage overall weight 270 g

wing loading: 42.5 g/dm²

longitudinal stability (Thies) STFs:

motor: Turnigy 2632 Brushless Motor 1000kv

motor camber: -3°

side pull: 2° right

propeller: Aeronaut CAM Aeronaut Carbon Classic 9 x 6.5" / 23 x 16.5 mm

static thrust: 500 g (3S Lipo)

battery: Turnigy nano-tech 950mah 3S 25~50C Lipo Pack

ESC: HobbyKing YEP 30A (2~4S) SBEC Brushless Speed Controller

receiver: OrangeRx R615X DSM2/DSMX Compatible 6Ch 2.4GHz Receiver w/CPPM

servos: Hitec HS-55

Print Settings

Attention

The wings are designed to print with 0.5 width, 0.3 hight and 2 bottom and top layer, NO infill.

If you print thinner, the perimeter of the upper side will not merge with the perimeter of the inner spars.

If you print thicker, the perimeter will not be printed continuesly in one turn.

The print must go as if you print in spiral vase mode. So you reach at least a smooth surface on the upper side.

If needed, you must try with 0.49 or 0.48 width. It depends on which slicer you use.

The second thing is, if you print with less layer hight, the inner spars will not connect the top and the bottom layer. There will be a gap inbetween.

All parts: layer height =0,3mm, width =0.5 mm, NO infill

wing

1 perimeter, 2 bottom layer, 2 top layer, hollow

wing servo: 3 bottom layer, spiral vase mode

aileron base: 5 bottom layer, spiral vase mode

aileron end: 2 bottom layer, spiral vase mode

aileron appendix: 1 perimeter, hollow

aileron interface: no bottom layer, spiral vase mode

fuselage

Note: The extrusion width must be thick enough to prevent printing infill between the two perimeters of the 1mm hull. You must try out and check it in the preview.

I had to set the width to 0.53mm.

fuselage front: 7 bottom layer, 3 top layer, 2 perimeter, extrusion width 0.53mm, 20% infill

fuselage back: 3 bottom layer, 3 top layer, 2 perimeter, extrusion width 0.53mm, 20% infill

fuselage interface: 2 perimeter 0.4 no bottom/top layer, holow

fin: 4 bottom layer, spiral vase mode

fin cover plate: 2 bottom layer, hollow

The bigger fin:

0.3 layer hight

0.5 width

3 solid bottom layer, spiral vase mode

The bigger fin plate:

3 solid bottom layer

1 perimeter

10% infill

Similar models

thingiverse

free

Speedy "Red Swept Wing" RC by wersy

...after the other, and see that you can get them out again, if needed. if both pipes are inside, the wings can not be pulled apart!

thingiverse

free

Flying Wing Buratinu by wersy

...ve designed a special fuselage nose.

fuselage 1 rear-mounted mc3

firewall rear-mounted

it has already integrated 3° motor camber.

thingiverse

free

Speedy Red Midi Wing by wersy

... in the slicer.

the cylinder must be printed hollow, with only 2 or 3 perimeters.

then you have to re-cut the bushing with a tap.

thingiverse

free

Delta Wilde Hummel by wersy

...se no solid bottom/top layers

acces panel brackets: print width 0.5mm, layer height 0.2mm, spiral vase no solid bottom/top layers

thingiverse

free

Speedy "Red Swept Wing 2" RC by wersy

...ery: turnigy 1800 mah 3s 40~50c lipo

motor camber: -4°

side pull: no

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

thingiverse

free

Vase by MrNlCE

...d in abs

0.3 mm layer hight

spiral vase mode failed but managed to do it with 3 perimeters, 3 bottom layers, 0 top and 0% infill.

thingiverse

free

Speedy "Red Midi Swept Wing" by wersy

...0 mah 3s 40~50c lipo

motor camber: tilted -4 degrees

side pull: none

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

cults

free

Speedy "Red Midi Swept Wing"

...0 mah 3s 40~50c lipo

motor camber: tilted -4 degrees

side pull: none

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

thingiverse

free

Simple Vase by vikram31

...nozzle and set the layer height to 0.6 mm and line width to 1.0 mm)

for solid mode:

top layer - 0

infill - 0%

wall line count - 3

thingiverse

free

Simple Vase by vikram31

...nozzle and set the layer height to 0.6 mm and line width to 1.0 mm)

for solid mode:

top layer - 0

infill - 0%

wall line count - 3

Wersy

thingiverse

free

Fan 80 mm.stl by wersy

...fan 80 mm.stl by wersy

thingiverse

just a fan 80 mm for your planning.

thingiverse

free

LED Ring Mount for Printrbot by wersy

...led ring mount for printrbot by wersy

thingiverse

this mount can be fastened on one side of the extruder.

thingiverse

free

Penholder Tubes by wersy

...one for the kids with some more tubes.

it is by far not so artfully because i am just an engineer - though i hope you like it :-)

blendswap

free

WERSI Galaxis

...ocal z direction, the lights will switch on or of. for moving the hole organ there is a squared empty.

have fun with this peace.

thingiverse

free

Carrier to carry the Printrbot by wersy

...ty small and not so heavy it is a bit cumbersome to transport because the only stiff parts are the bases connected with the rods.

thingiverse

free

Prusa I2 holder for wersy's case for RRD full graphic LCD by byteborg

...i like the rrd smart lcd and have it integrated in wersy's case. i needed a way to mount it on my prusa i2, so here it is :)

thingiverse

free

Mount for the Full Graphic Smart LCD Controller Case by wersy 2020 3030

...ing for wersy's case holes... so i designed this mount parts for this great lcd case https://www.thingiverse.com/thing:87250.

thingiverse

free

Turbo Car RC (experimental) by wersy

...be/6tzpffwsd0q

tires:http://www.makeblock.com/tire-68-5x22mm-4-packhttps://www.kiwi-electronics.nl/band-68-5x22mm-4-stuks?lang=de

thingiverse

free

Case for the Full Graphic Smart LCD Controller by wersy

...is a case for the full graphic smart lcd controller. http://www.reprapdiscount.com/home/34-full-graphic-smart-lcd-controller.html

thingiverse

free

Mini Buratinu LW PLA by wersy

...m for this if the rear tubes are shortened. therefore i upload a remix of the modified rear fuselage.

fuselage rear 860 lwpla.stl

Speedy

3d_export

$15

Speedy Gonzales 3D Model

... duck silvester cat low poly

speedy gonzales 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl buncic 107350 3dexport

turbosquid

$6

Speedy Envy MKII Wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Speedy Envy MK V Wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Speedy Envy MK V - low poly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Стіл компютерний

...стіл компютерний 3ddd speedy , стол стіл компютерний speedy disegno 085 al-6-m. ...

archive3d

free

Table 3D Model

...table 3d model archive3d table desk furniture table speedy disegno 085 al-6-m n100612 - 3d model (*.3ds) for...

3d_export

$15

Slowpoke Rodriguez 3D Model

...mouse looney tunes toon cartoon low poly mexico mexican speedy gonzales cat slow fast slowpoke rodriguez 3d model download...

3d_export

$65

locomotive pm 36

...locomotive pm 36 3dexport pm 36-1. speedy steam engine of polish construction from 1937. equipped with...

thingiverse

free

speedy on chart by Syzguru11

...speedy on chart by syzguru11

thingiverse

speedy on chart

thingiverse

free

Speedy the Snail by O3D

...speedy the snail by o3d

thingiverse

speedy the snail was printed on the da vinci color

Rc

3ddd

$1

RC Helicopter

...rc helicopter

3ddd

вертолет

mini rc helicopter

93.329 polys

3d_export

$7

rc helicopter model

...rc helicopter model

3dexport

rc helicopter model

3d_ocean

$25

RC F1

...rc f1

3docean

auto car control f1 formula race rc remote speed

remote control f1 car

turbosquid

$10

rc plane

...lane

turbosquid

free 3d model rc plane for download as blend on turbosquid: 3d models for games, architecture, videos. (1295828)

turbosquid

$100

RC Helicopter

...free 3d model rc helicopter for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298511)

turbosquid

$59

Drone with RC

...3d model drone with rc for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1363601)

turbosquid

$75

RC buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

RC Plane001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

RC Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Rc airplane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Wing

3ddd

$1

The Wing

...the wing

3ddd

wing , appledesign

the wing seating by appledesignstudio

3d_export

$5

wings

...wings

3dexport

beautiful wings model.

archibase_planet

free

Wing

...wing

archibase planet

wing decoration ornament

wing angel n180215 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3ddd

$1

Wing Chair

...wing chair

3ddd

baker , wing

wing chair

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Кушетка WING

...кушетка wing

3ddd

flexform , wing

модель дкушетки wing

производитель: flexform

turbosquid

free

A-Wing

...id

free 3d model a-wing for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1164828)

3ddd

$1

Кресло Wing

...кресло wing

3ddd

wing

кресло wing из каталога в двух сочетаниях конфигурации.

3d_export

$5

wing nut

...wing nut

3dexport

wing nut

Plane

3d_export

$5

Plane

...plane

3dexport

unusual plane)

archibase_planet

free

Plane

...plane

archibase planet

plane lath slat

plane n011207 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$11

Plane

...plane

designconnected

tom dixon plane computer generated 3d model. designed by dixon, tom.

turbosquid

$20

Plane

...lane

turbosquid

royalty free 3d model plane for download as on turbosquid: 3d models for games, architecture, videos. (1214347)

turbosquid

$50

Plane

...e

turbosquid

royalty free 3d model plane for download as fbx on turbosquid: 3d models for games, architecture, videos. (1290318)

turbosquid

$20

Plane

...e

turbosquid

royalty free 3d model plane for download as max on turbosquid: 3d models for games, architecture, videos. (1214127)

turbosquid

$15

Plane

...e

turbosquid

royalty free 3d model plane for download as c4d on turbosquid: 3d models for games, architecture, videos. (1413357)

turbosquid

$5

plane

...ne

turbosquid

free 3d model plane for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1424281)

turbosquid

free

plane

...ne

turbosquid

royalty free 3d model plane for download as ma on turbosquid: 3d models for games, architecture, videos. (1655587)

turbosquid

free

Plane

...osquid

free 3d model plane for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1385376)

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Red

3ddd

$1

red bull

...red bull

3ddd

red bull

red bull can

3d_ocean

$4

Red brick

...red brick

3docean

brick low poly red

red brick

3d_export

$40

red panda

...red panda

3dexport

red panda

3d_export

$5

eggchair red

...eggchair red

3dexport

a red eggchair

3ddd

$1

Red curtain

...red curtain

3ddd

red curtain

3d_export

$5

Red barrel

...red barrel

3dexport

its a red barrel

3ddd

$1

Red bicycle

...red bicycle

3ddd

велосипед

red bicycle

3ddd

$1

RED COLLECTION

...red collection

3ddd

витрина

red collection

3ddd

$1

RED COLLECTION

...red collection

3ddd

обеденный

red collection

3ddd

$1

RED COLLECTION

...red collection

3ddd

витрина

red collection