Thingiverse

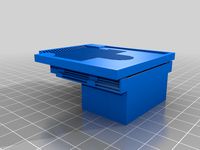

Solidoodle Jigsaw Extruder Replacement w/ Fan Shroud and Receiver - MK5 Compatible for Hexagon and Other Hotends. by GoatCheez

by Thingiverse

Last crawled date: 3 years ago

This is meant to replace and accompany another thing:

lawsy's Mk5 parts (http://www.thingiverse.com/thing:111213)

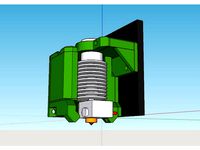

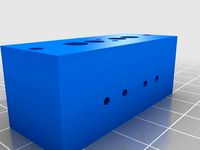

I have two replacement bases for the above parts, in addition to fan mounts and a receiver. My bases are designed to help extruding softer filament. Sometimes softer or more flexible filament can bend a little bit instead of trying to extrude. My bases try to alleviate extrusion issues for those types of filament by constricting the distance from the stepper to the hotend opening. .

Base3 is more aggressive than Base2 as far as guiding the filament is concerned. Base2 should be the default option unless you are having issues with your filament.

The bases are meant for groove mount hotends and give enough heatsink room to support the size of the hexagon hotend, That was the intention with them, however they should also work for many other hotends. You will probably want to loosen the hobbed pulley/gear attached to the extruder stepper motor when mounting to ensure it aligns correctly with the directed filament guide..

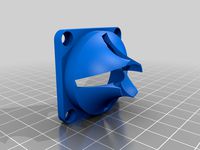

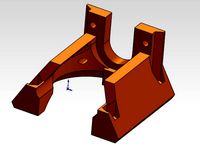

The directed fan mount and receiver are sized for the hexagon hotend, but they may work with others. The directed fan mount should work with most hotends, and will definitely work with any j-head style. The receiver, however, has a piece that extends past the filament guide and would run into either the heat block or heatsink of any non-hexagon hotend. If you want to try the receiver without a hexagon anyway, you could probably just snap off that part of the piece if your hotend ends up running into it.

There is support material included for all pieces. If you need to use a knife to remove the support material, you might want to revisit your printing settings. The bases have support for the tension arm mount, as well as support for the spacing of the stepper motor. The directed fan mount has support for its accessory clips. You should be able to apply force against the print direction, then slide them out. The directed fan mount receiver has two tiny supports for the mounting hole bulges.

As far as testing goes, only base 3 is untested as of this writing. Base 2 has served me well enough for everything other than ninjaflex, so I haven't had a need to switch just yet.

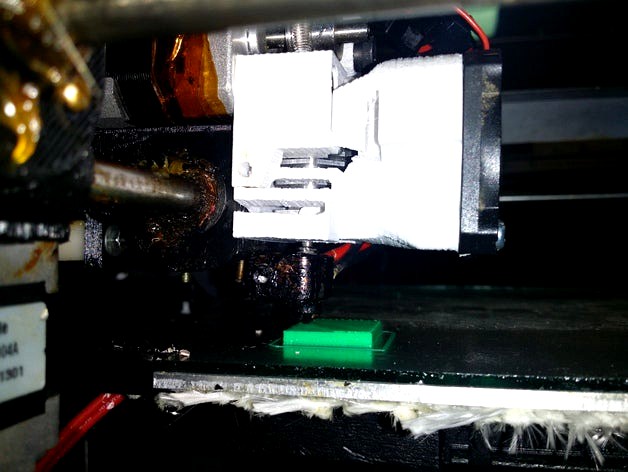

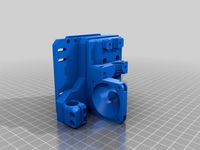

The pictures are of the complete assembly using Base2 - Base2, Receiver, Fan Mount. There is an action picture of the assembly whilst in the process of printing a PET+ calibration cube. I plan on replacing all extruder parts with PET+ due to the strength, temperature, and print quality characteristics.

This thing is close to being finalized. All pieces (outside potentially base3) are very much in fully working order.

Please excuse how dirty my hexagon is in the pictures. I have very much been abusing it. I went through 3 J-Head MK V-BVs before going all-metal. I feel dumb now. All metal hotends are the way to go. Lining ends up limiting temperatures and is really just a cost-saving manufacturing means in most cases. All metal is the way to go. I have a spare cartridge and thermistor for the hexagon. I don't think I will need them any time soon.

One major issue with the J-Heads I had purchased was that the cartridge was "glued" in with cement. Additionally, the thermistor leads were very weak. Hexagon kits come with really solid and reliable parts that exhibit neither of those weaknesses. I'm not trying to sell the Hexagon, but to me it's obvious why it's popular, versatile, cheap to produce, and above all, very usable for a variety of filaments.

lawsy's Mk5 parts (http://www.thingiverse.com/thing:111213)

I have two replacement bases for the above parts, in addition to fan mounts and a receiver. My bases are designed to help extruding softer filament. Sometimes softer or more flexible filament can bend a little bit instead of trying to extrude. My bases try to alleviate extrusion issues for those types of filament by constricting the distance from the stepper to the hotend opening. .

Base3 is more aggressive than Base2 as far as guiding the filament is concerned. Base2 should be the default option unless you are having issues with your filament.

The bases are meant for groove mount hotends and give enough heatsink room to support the size of the hexagon hotend, That was the intention with them, however they should also work for many other hotends. You will probably want to loosen the hobbed pulley/gear attached to the extruder stepper motor when mounting to ensure it aligns correctly with the directed filament guide..

The directed fan mount and receiver are sized for the hexagon hotend, but they may work with others. The directed fan mount should work with most hotends, and will definitely work with any j-head style. The receiver, however, has a piece that extends past the filament guide and would run into either the heat block or heatsink of any non-hexagon hotend. If you want to try the receiver without a hexagon anyway, you could probably just snap off that part of the piece if your hotend ends up running into it.

There is support material included for all pieces. If you need to use a knife to remove the support material, you might want to revisit your printing settings. The bases have support for the tension arm mount, as well as support for the spacing of the stepper motor. The directed fan mount has support for its accessory clips. You should be able to apply force against the print direction, then slide them out. The directed fan mount receiver has two tiny supports for the mounting hole bulges.

As far as testing goes, only base 3 is untested as of this writing. Base 2 has served me well enough for everything other than ninjaflex, so I haven't had a need to switch just yet.

The pictures are of the complete assembly using Base2 - Base2, Receiver, Fan Mount. There is an action picture of the assembly whilst in the process of printing a PET+ calibration cube. I plan on replacing all extruder parts with PET+ due to the strength, temperature, and print quality characteristics.

This thing is close to being finalized. All pieces (outside potentially base3) are very much in fully working order.

Please excuse how dirty my hexagon is in the pictures. I have very much been abusing it. I went through 3 J-Head MK V-BVs before going all-metal. I feel dumb now. All metal hotends are the way to go. Lining ends up limiting temperatures and is really just a cost-saving manufacturing means in most cases. All metal is the way to go. I have a spare cartridge and thermistor for the hexagon. I don't think I will need them any time soon.

One major issue with the J-Heads I had purchased was that the cartridge was "glued" in with cement. Additionally, the thermistor leads were very weak. Hexagon kits come with really solid and reliable parts that exhibit neither of those weaknesses. I'm not trying to sell the Hexagon, but to me it's obvious why it's popular, versatile, cheap to produce, and above all, very usable for a variety of filaments.

Similar models

thingiverse

free

Solidoodle Pico Hot-End Cooling Fan Duct (with mk5 mount) by eckerj

...onnectors, etc) but the 40mm fan that comes with the pico fits in nicely, and the duct mounts nicely to lawsy's mk5 extruder.

thingiverse

free

Nema 11 Extruder by Rektinator

...th-nema-11-stepper-motor-11hs200674spg5-p-33.html

note: download version 2.1 if you're planning to print flexible filament

thingiverse

free

Extruder Base with Dual Fan Mount by atntias

...(0.7 lines designed for 0.35 but should be ok anyways)

this should fit jheads but im not sure about makergears since its shorter.

thingiverse

free

BLTouch mount for the Tevo Black Widow with Titan Extruder by dot_bob

...1537971

this design is a remix of the following but centers the hotend in the fan shroud:http://www.thingiverse.com/thing:1543232

thingiverse

free

Hexagon Hotend 40mm Fan Mount by LucasCalvert

... hexagon hotend. it is designed connect to the hotend without relying on other parts of the printer so that it is more universal.

thingiverse

free

4010 fan support for direct all metal BMG extruder by salvogi

...mg extruder by salvogi

thingiverse

this is a support for replace the 3010 fan with a 4010 fan for direct all metal bmg extruder.

thingiverse

free

Extruder Hotend Bowden for 1.75mm/3mm Filament Fan holder by 3DShah

...he cooling blocks ...

may 14. 2017

this work's but needs lot to be don with it yet... like the size needs to be scaled down..

thingiverse

free

e3d direct drive extruder by obdiy

...e3d direct drive extruder by obdiy

thingiverse

simple direct drive extruder for e3d hotend or j-head with fan (45mm)

thingiverse

free

Delta direct extruder E3D/MK8 by pindemand

...version

note. v1 with back space for the nema stepper motor

note. v2 with filament support. adjust of screw holes. work great

thingiverse

free

E3D Hotend mount for CTC Prusa i3 DIY with 40mm fan and filament cooling by MartinHoffmann

...xisting screw holes in the ctc diy where the extruder was mounted.

for mounting you need six 15 mm m3 screws and six square nuts.

Mk5

turbosquid

free

Sten mk5

...ee 3d model sten mk5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1472891)

humster3d

$75

3D model of Magnum MK5 2014

...y a detailed 3d model of magnum mk5 2014 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$99

Volkswagen Golf Mk5 3door 2004 3D Model

...2006 2007 2008 2009 3-door hatchback compact family city germany

volkswagen golf mk5 3door 2004 3d model humster3d 70274 3dexport

cg_studio

$99

Volkswagen Golf Mk5 3-door 20043d model

...x .lwo .max .mb .obj - volkswagen golf mk5 3-door 2004 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of Volkswagen Golf Mk5 3-door 2004

...model of volkswagen golf mk5 3-door 2004 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$75

3D model of Volkswagen Golf Mk5 5-door 2004

...model of volkswagen golf mk5 5-door 2004 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$89

Volkswagen Golf Mk5 3-door 2004

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_ocean

$89

Volkswagen Golf Mk5 5-door 2004

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_export

$70

toyota supra mk5 a90 fast and furious

... was rendered at 3dsmax 2017 with vray3.6<br>saved for max 2014<br>toyota supra 3d model clean topology with interior

vizpark

$15

HDRI Skydome 30

...scenes. the exposure images were taken with a canon mk5 camera. all images were manually adjusted and corrected with...

Solidoodle

thingiverse

free

Solidoodle by diogo_manuel

...solidoodle by diogo_manuel

thingiverse

solidoodle souporte tools

thingiverse

free

solidoodle toolkeeper by ali55

...solidoodle toolkeeper by ali55

thingiverse

solidoodle tool keeper

thingiverse

free

Solidoodle Logo by kepster

...solidoodle logo by kepster

thingiverse

a logo i created for my solidoodle 2

thingiverse

free

Solidoodle logo by SLAM-ER

...hing to the front of the print bed. all rights belong to solidoodle, i am not affiliated with or a representitive of solidoodle.

thingiverse

free

Solidoodle clip by pesce

...dle clip by pesce

thingiverse

this is a simple clip, that you can use to attach various things to the frame of the solidoodle...

thingiverse

free

GoPro Solidoodle Clip by boulderbuff64

...gopro solidoodle clip by boulderbuff64

thingiverse

this is a gopro bracket that clips to a solidoodle frame

thingiverse

free

Solidoodle Z-Endstop by frankcusano

...solidoodle z-endstop by frankcusano

thingiverse

replacement z-endstop for solidoodle 2 or 3.

thingiverse

free

Solidoodle Spool Holder by frankcusano

...solidoodle spool holder by frankcusano

thingiverse

replacement spool holder for a solidoodle 2 or 3.

thingiverse

free

Solidoodle tool holder by _steezy_

...solidoodle tool holder by _steezy_

thingiverse

simple tool holder for standard tools that came with my solidoodle 4

thingiverse

free

Recup box for solidoodle by FOmenal

...recup box for solidoodle by fomenal

thingiverse

i make this full parametrique box for my solidoodle to make clean.

Jigsaw

turbosquid

$22

Jigsaw

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

jigsaw

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

JIGSAW

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Jigsaws

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$2

Jigsaw Puzzle

...s puzzle tiles toy

simple jigsaw puzzle model. modeled nicely in 3ds max and include mulitiple format (.obj, .max, .3ds and.fbx).

turbosquid

$16

Jigsaw Seat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Minion jigsaw model

...royalty free 3d model minion jigsaw model for download as obj on turbosquid: 3d models for games, architecture, videos. (1193713)

turbosquid

$30

Toy Castle Jigsaw

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Circle jigsaw puzzle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

jigsaws --- dekupaj

...jigsaws --- dekupaj

3dexport

it consists of 18 pieces<br>cannot be used in production<br>you can use in games

Shroud

3d_export

$500

Centrifugal pump volute casing with impeller

...casing with impeller 3dexport volute casing with impeller and shroud ...

3d_export

$35

The Holy Face base relief 3D Model

...the holy face base relief 3d model 3dexport shroud turin veronica veronica's veil gospel ikon jesus holy face...

3d_export

$20

present car cloth presentation transport transportation shape concepts show celebration cover showro

...transportation shape concepts show celebration cover showroom covered revealin shroudd cover covering tarp draped fabric cloth showroom reveal revealing...

3d_export

$5

Lockheed F-117 Nighthawk lowpoly stealth bomber

...initial operating capability status in 1983. the aircraft was shroudd in secrecy until it was revealed to the public...

3d_export

$49

kriss vector gen 2 sub-d

...rear flip sight.<br>- vector ejection port.<br>- vector crb square shroud / 16"" sliencer.<br>- ds150 stock.<br>- .ma (maya 2020 ascii)<br>-...

3d_export

$10

vichy dining table

...in oak, sycamore and walnut marquetry.<br>even if the restaurant shroud the vichy in a long table cloth, two slender...

3d_export

$500

us navy pcu sterett ddg-104 arleigh burke class destroyer flight iia max

...the position has been shifted.<br>q. where are the exhaust shroud for the stacks?<br>a. since ddg-89, the exhaust system was...

thingiverse

free

shroud by samshay317

...shroud by samshay317

thingiverse

shroud

thingiverse

free

Fan Shroud

...fan shroud

thingiverse

this is a fan shroud for a 140mm fan

thingiverse

free

40mm fan shroud

...40mm fan shroud

thingiverse

40mm fan shroud

Hotends

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Receiver

archibase_planet

free

Receiver

...receiver

archibase planet

receiver receiving set radio set

receiver n170311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Receiver

...receiver

archibase planet

receiver equipment

receiver - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Receiver

...receiver

archibase planet

radio tuner receiver

receiver n120108 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Receiver

...receiver

archibase planet

receiver denon

denon avr3805- 3d model for interior 3d visualization.

turbosquid

$62

RECEIVER

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Receiver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

Receiver for 20m3

...receiver for 20m3

3dexport

receiver for 20m3 of compressed air

archive3d

free

Receiver 3D Model

...iver receiving set radio set

receiver n170311 - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$6

DVD Receiver

...yer. can also be used as a receiver. original design dvd player or stereo design with exceptional detail. dvd receiver 3d models.

3d_ocean

$25

Television receiver

...cial plugin needed to open scene. - correctly scaled accurate representation of the original objects. - model is all materials...

Hexagon

3ddd

$1

Hexagon

...ная лампа 'hexagon'. на рендере, матовое черное основание с черным абажуром. в36xш28см.http://www.boconcept.com

3ddd

$1

Hexagon metal

...hexagon metal

3ddd

журнальный

журнальный стол "hexagon metal"

3d_export

$15

hexagonal map

...hexagonal map

3dexport

13 hexagonal forts, temples, villages, pyramids, volcanos , tombs ... for 3d printing

design_connected

$13

Hexagon Tables

...hexagon tables

designconnected

tribù hexagon tables computer generated 3d model. designed by maes, pieter.

3d_export

$5

hexagonal shaft knob

...hexagonal shaft knob

3dexport

hexagonal shaft knob

3d_export

$5

hexagonal needle knob

...hexagonal needle knob

3dexport

hexagonal needle knob

3d_export

$5

hexagonal screwed knob

...hexagonal screwed knob

3dexport

hexagonal screwed knob

turbosquid

$10

hexagonal ring

...uid

royalty free 3d model hexagonal ring for download as stl on turbosquid: 3d models for games, architecture, videos. (1236985)

turbosquid

$10

hexagonal ring

...uid

royalty free 3d model hexagonal ring for download as stl on turbosquid: 3d models for games, architecture, videos. (1236984)

turbosquid

$5

Hexagon Tiles

...squid

royalty free 3d model hexagon tiles for download as ma on turbosquid: 3d models for games, architecture, videos. (1240815)

Compatible

turbosquid

$3

Genesis 8 Clothing 1 dForce Compatible

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Genesis 8 Clothing Top 1 dForce Compatible

...nesis 8 clothing top 1 dforce compatible (2) for download as on turbosquid: 3d models for games, architecture, videos. (1217671)

turbosquid

$50

Screwdriver Latch Type CSC Torx compatible with Straumann

...sc torx compatible with straumann for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1370064)

3d_export

$9

cad compatible casual woman hand model f1p3d1v1hand

...s: stl, obj, fbx<br>models with quad-topology (1100 quads) are also included (f1p3d1v1hand_quad.obj, f1p3d1v1hand_quad.fbx)

3d_export

$38

uzaki rigify

...uzaki rigify 3dexport compatible-blender ...

3d_export

$5

cloud lowpoly 3d

...cloud lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

flower lowpoly 3d

...flower lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

rocks lowpoly 3d

...rocks lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$10

pots

...pots

3dexport

pots<br>modeled in blender<br>compatable with evee and cycels

3d_ocean

$95

Mr Techny

...for 3ds max 2010 and later – biped (2010 compatible and cat (2011 compatible) versions incluided. for maya 2012...

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Replacement

3d_export

$12

replaceable bristle

...replaceable bristle

3dexport

this is 3d printable replaceable bristle toothbrush.

3d_export

$34

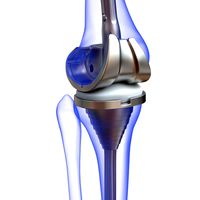

Knee Replacement

...h meets the lower leg. ... during a total knee replacement, the end of the femur bone is removed and replaced with a metal shell.

3d_export

$44

Hip Replacement

...omponents. the damaged femoral head is removed and replaced with a metal stem that is placed into the hollow center of the femur.

turbosquid

$59

Hip replacement

...el hip replacement for download as ma, c4d, lwo, lxo, and obj on turbosquid: 3d models for games, architecture, videos. (1520195)

turbosquid

$10

Module replacment station

...alty free 3d model module replacment station for download as on turbosquid: 3d models for games, architecture, videos. (1271271)

3d_export

$8

tool replacement gearbox

...tool replacement gearbox

3dexport

eccentric lifting mechanism, you can process according to available drawings.

turbosquid

$7

Globe Oil Atomizer Replacement Housing

... oil atomizer replacement housing for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1253839)

turbosquid

free

SLICE Ceramic Scapel (Replaceable Blade)

... (replaceable blade) for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1363525)

3d_export

$19

Knee Replacement Implant

...ntimeter<br>__________________________<br>poly count :<br>polygon count - 217440<br>vertex count - 108776

turbosquid

$19

(Project) Bad odor filtering sytem with support rail and pulley that assure a comfortable gel filter element replacement.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

W

3ddd

$1

chair W

...chair w

3ddd

chair w

3ddd

$1

кресло w

...кресло w

3ddd

капитоне

кресло w

3ddd

$1

KUTEK (W) W-ZW-5

...kutek (w) w-zw-5

3ddd

kutek

3d модель люстри (w) w-zw-5 фабрики kutek. в архиве: max2012, obj, fbx, mat.(два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-3

...kutek (w) w-zw-3

3ddd

kutek

3d модель люстри (w) w-zw-3 фабрики kutek. в архиве: max2012, obj, fbx, mat. (два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-1

...kutek (w) w-zw-1

3ddd

kutek

3d модель люстри (w) w-zw-1 фабрики kutek. в архиве: max2012, obj, fbx, mat (два варианта металла).

3ddd

free

aneken W&W

...aneken w&w

3ddd

2 женских манекена, ценники и фолио. материалы и текстуры прилагаются.

design_connected

$9

KTribe W

...ktribe w

designconnected

ktribe w computer generated 3d model. designed by starck, philippe.

design_connected

$16

Troy W

...troy w

designconnected

magis troy w computer generated 3d model. designed by wanders, marcel.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Other

design_connected

$16

ST12 Other

...signconnected

photo-realistic 3d models of the st12 other stool from e15 for 3d architectural and interior design presentations.

turbosquid

$26

Oar and Other

...quid

royalty free 3d model oar and other for download as fbx on turbosquid: 3d models for games, architecture, videos. (1473409)

turbosquid

$5

chair with other

...id

royalty free 3d model chair with other for download as ma on turbosquid: 3d models for games, architecture, videos. (1171468)

3ddd

$1

parfume and other

...parfume and other

3ddd

тумбочка

create by sametyuzer

turbosquid

$79

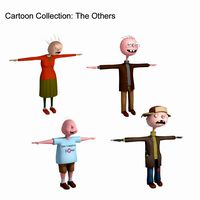

The Others Collection

...others collection for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1480228)

turbosquid

$25

Other Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

other car.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Other Mothers Hand

... 3d model other mothers hand for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1663825)

turbosquid

$8

other sport wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

pool and other elements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.