Thingiverse

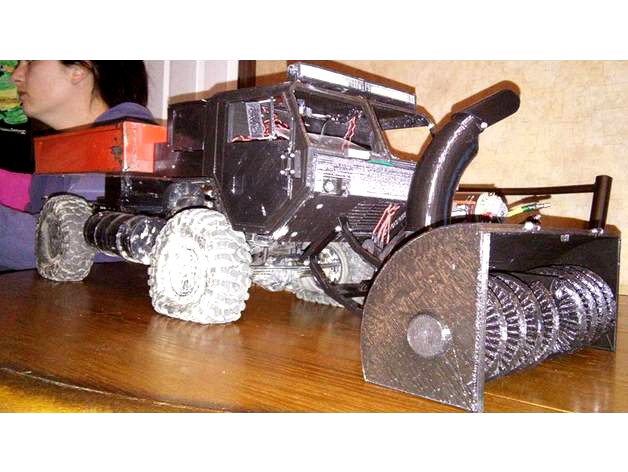

Snowblower for 1/10 Scale Oshkosh 4x4 RC Body by Aldrich_will

by Thingiverse

Last crawled date: 3 years ago

So after months and months of designing and printing and wasting PLA, I have finally made a semi-working snow blower for my Oshkosh SCX10 body. I say semi working because I have only operated it once and broke after 30 seconds. I have, since the failure, redesigned and reprinted the failed parts. However I have not yet tested due to a few engineering limitations of my imagination. One issue that I am having is making a belt for the pulleys in the back. I started testing with extra 3d printer timing belt. So far its working, but haven't given it any stress or duration of run time. So any pointers would only benefit anyone who wants to print this. So I will be uploading STL files once I get a few more things figured out and once a final live test has been done. Their calling for some dry snow over the next few days so expect the STLs to show up soon.

Update 2/19/2018

All File to make this are uploaded

I'm unsure how much support I will be able to give but I'll do my best. The main front auger uses a STRAIGHT 1/4" steel brake line that slide into the two halves. You will also need 3 fidget spinner bearings. Two for either side of the auger (brake line) and one goes into rear to hold the spur pulley. Basically its powered by a 550 rc motor that turns a belt connected to the secondary drive pulley. I used a stepper motor pinion pulley with a printed adapter to fit onto the 550 motor shaft. The secondary drive uses a (16/1) worm gear to turn the primary auger. The belt is just a 3d printer timing belt. Making a belt out of the a straight piece of timing belt was the main holdup of the whole build. This is how i did it. Measured around the pulleys, cut diagonally so the ribs match up. Then I superglued it together. Got a very tiny drillbit to drill holes in the the ribs. Then used screws from a 9g servo to go into the ribs. I only used about 4-5 ribs. and then superglue again and...boom, you have a belt. The mounts are designed for the unimog and would use a body mounted winch servo to pull the blower up and down, however, it is really heavy so I had to hard mount it to the body and drive really slow. Now for a few suggestions, after most is assembled, glue the primary pulley to the secondary shaft before screwing it together. There only a 4mm hex turning the primary shaft. Mine striped out after a little. And I wouldnt used a brushless motor to power it all. I use a 55t crawler motor and that seems to spin fast enough to throw snow. Well, enjoy printing and I will do my best to answer questions. Oh...the whole thing is put together with M3 screws.

Update 2/19/2018

All File to make this are uploaded

I'm unsure how much support I will be able to give but I'll do my best. The main front auger uses a STRAIGHT 1/4" steel brake line that slide into the two halves. You will also need 3 fidget spinner bearings. Two for either side of the auger (brake line) and one goes into rear to hold the spur pulley. Basically its powered by a 550 rc motor that turns a belt connected to the secondary drive pulley. I used a stepper motor pinion pulley with a printed adapter to fit onto the 550 motor shaft. The secondary drive uses a (16/1) worm gear to turn the primary auger. The belt is just a 3d printer timing belt. Making a belt out of the a straight piece of timing belt was the main holdup of the whole build. This is how i did it. Measured around the pulleys, cut diagonally so the ribs match up. Then I superglued it together. Got a very tiny drillbit to drill holes in the the ribs. Then used screws from a 9g servo to go into the ribs. I only used about 4-5 ribs. and then superglue again and...boom, you have a belt. The mounts are designed for the unimog and would use a body mounted winch servo to pull the blower up and down, however, it is really heavy so I had to hard mount it to the body and drive really slow. Now for a few suggestions, after most is assembled, glue the primary pulley to the secondary shaft before screwing it together. There only a 4mm hex turning the primary shaft. Mine striped out after a little. And I wouldnt used a brushless motor to power it all. I use a 55t crawler motor and that seems to spin fast enough to throw snow. Well, enjoy printing and I will do my best to answer questions. Oh...the whole thing is put together with M3 screws.

Similar models

thingiverse

free

HTD 3M Pulleys for Stepper and CNC by Area51

...pulley is for the 10mm key indexed mill shaft.

the pulleys is used for driving the y axis on my opti bf20 mill (grizzly g0704).

cg_trader

$2

Pulley Belt

...shaft to another. the speed ratio between the drive shaft and the driven shaft depends on the ratio of the pulley diameters used.

thingiverse

free

Drive shaft support by AdrianR52

...port by adrianr52

thingiverse

drive shaft support for kossel xl, so that the shaft is supported on both sides of the belt pulley

grabcad

free

Belt and Pulley system

...ts are generally made from a soft, flexible material such as rubber. grooves on the pulleys and belts help them to grip and turn.

thingiverse

free

Timing gear M8 T2.5 64 tooth 50mm by tmackay

...n, so the pulley was the only new component to print.

though i did have to order in the timing belt, t2.5 - 6mm wide, 200mm long.

grabcad

free

Pulley and Belt

...ts are generally made from a soft, flexible material such as rubber. grooves on the pulleys and belts help them to grip and turn.

grabcad

free

Two 32 teeth pulleys

...search for <i>drive belt 3m 12</i>).

i can upload the step files on request (parts created in autocad inventor).

grabcad

free

Linear Actuator/Slide Belt Driven

...:

nema 34 stepper motor

550 teeth 1inch timing belt

20 teeth 1inch pulley

custom motor and pulley mounts

a custom belt teeth mesh

grabcad

free

TIMING PULLEY

...timing pulley

grabcad

timing pulley used for rotating of belt to shaft or part

grabcad

free

V-Belt

...two points. the belt drive can also be used to change the speed of rotation, either up or down, by using different sized pulleys.

Aldrich

3ddd

$1

Savoy House/ Aldrich 4 Light Foyer

...savoy house/ aldrich 4 light foyer

3ddd

savoy house

http://www.savoyhouse.com/4-light-foyer-3-4500-4-69.html

3d_sky

free

Savoy House / Aldrich 4 Light Foyer

...savoy house / aldrich 4 light foyer

3dsky

savoy house

http://www.savoyhouse.com/4-light-foyer-3-4500-4-69.html

thingiverse

free

Milliporesigma Logo Deskart by PhoenixShepherd

...fidgets i made her a little something-something. milliporesigma / sigma-aldrich retains full rights to their logo, but i'd prefer...

thingiverse

free

Head of a Bodhisattva by met

...(19.1 cm) classification: sculpture credit line: gift of abby aldrich rockefeller, 1942 accession number: 42.25.12 versions captured and edited...

thingiverse

free

Tilted PCR rack/plate holder by WaveSupportApparatus

...15 mm tall: the pictured example is sold by sigma-aldrich but the same basic design is sold as a...

cg_trader

$10

Pottery Barn Potterybarn Aldrich Stool

... the sturdy construction an airy feel. this piece is ideal for an entry or as additional seating in a living room or dining area.

cg_trader

$3

ALDRICH uppercase and lowercase 3D Letters STL FILE | 3D

...ercase letters written with the aldrich font individually saved each as .stl file plus a .stl file containing the entire alphabet

cg_trader

$39

Aldrich Side Table

... contemporary unique realistic cozy classic modern hi res detailed furniture other bar counter bar stool realistic tree tree root

grabcad

free

Component Holders for MakerBeam

...project includes: 125mm x 125mm fresnel lens holder sigma aldrich 96 well plate holder sg90 micro servo wheel adapter...

cg_trader

$5

Carew Tower | 3D

...designed by w.w. ahlschlager & associates and delano & aldrich this highrise was the tallest building in cincinnati for...

Snowblower

thingiverse

free

Custom Snowblower Wheel by madwrench

...custom snowblower wheel by madwrench

thingiverse

just some bling wheels for my snowblower.

thingiverse

free

Husqvarna snowblower key

... but the keys for snowblowers are pretty much universal.

i also haven't printed one yet as i'm waiting for more filiment.

thingiverse

free

N scale Tractor with snowblower by Areg7

...n scale tractor with snowblower by areg7

thingiverse

n scale tractor with snowblower

thingiverse

free

Snowblower Ski by te_3D

...snowblower ski by te_3d

thingiverse

fits the big red snow blowers

thingiverse

free

Snowblower Ignition Key by roboto

...a plastic ignition key for a mtd yardmachines snowblower 24 inch 2 stage. it may also fit other brands with same 4 cycle engines.

thingiverse

free

Batteriecase for Snowblower by Uzzi

...batteriecase for snowblower by uzzi

thingiverse

this is a battery protector for a snow blower sg 110 from china.

thingiverse

free

v formed snowblower 1/32 tracktor by jan1cato

...v formed snowblower 1/32 tracktor by jan1cato

thingiverse

!!!! untested !!!!

v formed snowblower for 1 32 scale tracktors

thingiverse

free

Snowblower Part by homeautomationguru

...wblower model number i built it for, but i'm posting for people to be able to follow along with the steps in the above posts.

thingiverse

free

MTD Snowblower Key

...with my settings, it prints in about 8 minutes.

i suggest printing extra hot and with 4 walls so that it has plenty of strength.

thingiverse

free

SNOWMOBILE/ SNOWBLOWER PULL CORD HANDLE by camaroboy383

...art handle designed for snowmobiles, but can be used on snowblowers as well... print on its side in abs with 100% infill... enjoy

Oshkosh

3d_export

$80

oshkosh m1070

...oshkosh m1070

3dexport

cg_studio

$100

Oshkosh HEMMT3d model

...io

cars oshkosh hemmt heavy truck

.max - oshkosh hemmt 3d model, royalty free license available, instant download after purchase.

turbosquid

$130

Oshkosh HET

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Oshkosh M-ATV

...lty free 3d model oshkosh m-atv for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1699177)

turbosquid

$45

Oshkosh M-ATV

...yalty free 3d model oshkosh m-atv for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1544733)

turbosquid

$30

OSHKOSH ALPHA SWAT

... free 3d model oshkosh alpha swat for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1441940)

3d_export

$119

Oshkosh Sand Cat 3D Model

...sh sand cat sandcat army military vechicle israel transporter plasan armored hmmwv

oshkosh sand cat 3d model squir 51469 3dexport

turbosquid

$30

OSHKOSH ALPHA CHICAGO POLICE

...odel oshkosh alpha chicago police for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1441938)

cg_studio

$139

Oshkosh MTVR Mk233d model

...rt truck army navy usa supply

.max - oshkosh mtvr mk23 3d model, royalty free license available, instant download after purchase.

cg_studio

$129

Oshkosh JLTV 20143d model

...dio

.c4d .3ds .obj .max .lwo .fbx - oshkosh jltv 2014 3d model, royalty free license available, instant download after purchase.

4X4

turbosquid

$12

4x4 Bundle

...bosquid

royalty free 3d model 4x4 bundle for download as obj on turbosquid: 3d models for games, architecture, videos. (1243408)

turbosquid

$6

4x4 Pickup

...bosquid

royalty free 3d model 4x4 pickup for download as obj on turbosquid: 3d models for games, architecture, videos. (1243410)

turbosquid

$6

4x4 SUV

...turbosquid

royalty free 3d model 4x4 suv for download as obj on turbosquid: 3d models for games, architecture, videos. (1243409)

turbosquid

$5

4x4 Car

...rbosquid

royalty free 3d model 4x4 car for download as blend on turbosquid: 3d models for games, architecture, videos. (1545830)

turbosquid

$1

4X4 ROOM

...urbosquid

royalty free 3d model 4x4 room for download as max on turbosquid: 3d models for games, architecture, videos. (1415863)

turbosquid

$29

Military 4X4

... free 3d model military 4x4 for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1339605)

turbosquid

$20

Military 4X4

...ty free 3d model military 4x4 suv for download as 3ds and obj on turbosquid: 3d models for games, architecture, videos. (1340520)

turbosquid

$10

Bookshelf (4x4)

... model bookshelf (4x4) for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410538)

turbosquid

$75

trabant 4x4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$57

4x4-max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Rc

3ddd

$1

RC Helicopter

...rc helicopter

3ddd

вертолет

mini rc helicopter

93.329 polys

3d_export

$7

rc helicopter model

...rc helicopter model

3dexport

rc helicopter model

3d_ocean

$25

RC F1

...rc f1

3docean

auto car control f1 formula race rc remote speed

remote control f1 car

turbosquid

$10

rc plane

...lane

turbosquid

free 3d model rc plane for download as blend on turbosquid: 3d models for games, architecture, videos. (1295828)

turbosquid

$100

RC Helicopter

...free 3d model rc helicopter for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298511)

turbosquid

$59

Drone with RC

...3d model drone with rc for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1363601)

turbosquid

$75

RC buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

RC Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Rc airplane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

RC-Car

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Body

3d_ocean

$39

Heart and body

...heart and body

3docean

blood body heart human organ

heart and body highpoly heart inside human body.

3ddd

$1

body

...body

3ddd

маникен

corona mtl

turbosquid

$50

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

bodies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

design_connected

$11

Domino 10

...domino 10

designconnected

zanotta domino 10 computer generated 3d model. designed by progetti, emaf.

Scale

turbosquid

$20

Weight scale or Bathroom Scale

...ght scale or bathroom scale for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1664576)

turbosquid

$19

Scale

...e

turbosquid

royalty free 3d model scale for download as fbx on turbosquid: 3d models for games, architecture, videos. (1411722)

turbosquid

$5

Scales

...s

turbosquid

royalty free 3d model scales for download as ma on turbosquid: 3d models for games, architecture, videos. (1393439)

turbosquid

$40

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

of scales

...s have a flat point of support. the samples are rendered in the standard cinema 4d renderer. enjoy your use and creative success.

3d_export

$5

scale knob

...scale knob

3dexport

scale knob

3d_export

$20

cartoon weight scale or bathroom scale

...cartoon weight scale or bathroom scale

3dexport

texture size:512px number of texture:1 texture format: png

3d_ocean

$4

Bathroom scale

... the model is ready to import and render in all formats. it comes with a .tif diffuse texture. for other cool stuff check out ...

1

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

turbosquid

$50

door 1 darkwood 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.