Thingiverse

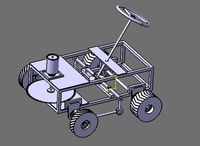

Slider for 2040 Openbuilds v-cut by FabianFriethjoph

by Thingiverse

Last crawled date: 3 years, 1 month ago

After encountering serious wobble in the X beam of my TronXY X1, I thought I might need something akin to the bed tightener by PB2000 ( http://www.thingiverse.com/thing:2203872 ). However, this piece is designed to work on on 2020 openbuild V-Slot following the documentation ( http://www.thingiverse.com/thing:69333 ), and the Z-Axis of the TronXY X1 is made from a 2040. So, spacing couldn't be taken over.

The Version 0 test type took the measurements of Press Reset's brackets ( http://www.thingiverse.com/thing:2120675 ), but the spacing of the print was off. WAY off. I had to cut it up, using them as spacers to be screwed on. Back to field 1: start from scratch, grab the documentation.

Taking the measurements of the metal piece, the openbuilds documentation (measurements of the V-Slot beam and matching 23.9mm wheels), the ISO norms (M4 & M5 machine screws), I startet to design the piece from scratch with set goals in mind:

the bend should leave space for the M4 screw that holds the actual X-Beam on the TronXY X1

it should act as spacer just as much as tightener

two pieces shall clamp it in position around the 2040 beam

After dissembly to check the measurements, I noticed that the wobble did not originate in a lack of tightening, but my failure: a single screw was not pulled tight enough.

5 Versions are available:

75% plastic thread - this variant is designed to carry a thread for M5 cut into it and has holes of 4.2 mm diameter. The part will act like connected nuts, keep this in mind in assembly, like when you want to clamp the beam between two!

Close Fit - This variant is meant to leave no wriggle for the screws, but it does not bite down on them either. 5.25 mm diameter holes.

Standard Fit - somewhat more loose, this is the diameter of the holes in the metal plate I took the original measurements from.

75% plastic thread and Standard fit on the two back holes with a hole to hold the 7.11mm cylinder of an Openbuild eccentric nut, allowing adjustment of the tightener

EDIT:

After encountering, that the walls of the threaded variant can bend a bit while cutting the thread, all variants were updated with thicker walls.

The Version 0 test type took the measurements of Press Reset's brackets ( http://www.thingiverse.com/thing:2120675 ), but the spacing of the print was off. WAY off. I had to cut it up, using them as spacers to be screwed on. Back to field 1: start from scratch, grab the documentation.

Taking the measurements of the metal piece, the openbuilds documentation (measurements of the V-Slot beam and matching 23.9mm wheels), the ISO norms (M4 & M5 machine screws), I startet to design the piece from scratch with set goals in mind:

the bend should leave space for the M4 screw that holds the actual X-Beam on the TronXY X1

it should act as spacer just as much as tightener

two pieces shall clamp it in position around the 2040 beam

After dissembly to check the measurements, I noticed that the wobble did not originate in a lack of tightening, but my failure: a single screw was not pulled tight enough.

5 Versions are available:

75% plastic thread - this variant is designed to carry a thread for M5 cut into it and has holes of 4.2 mm diameter. The part will act like connected nuts, keep this in mind in assembly, like when you want to clamp the beam between two!

Close Fit - This variant is meant to leave no wriggle for the screws, but it does not bite down on them either. 5.25 mm diameter holes.

Standard Fit - somewhat more loose, this is the diameter of the holes in the metal plate I took the original measurements from.

75% plastic thread and Standard fit on the two back holes with a hole to hold the 7.11mm cylinder of an Openbuild eccentric nut, allowing adjustment of the tightener

EDIT:

After encountering, that the walls of the threaded variant can bend a bit while cutting the thread, all variants were updated with thicker walls.

Similar models

thingiverse

free

Tronxy X1 X-Axis adjustabel slider by 3D_Dane

... printet and used for my tronxy x1

i hope you find this useful.

you will need a 3mm bolt and nut. i had spares from the assembly.

thingiverse

free

Tronxy X1 x-Axis Stabilizer by mitterberger

...m5x19 headless screw (axis for the bearing, cut a longer one)

and you'll have to tap m5 threads into the inner and outer part

thingiverse

free

Tronxy X1 bed tightener by volka

... is a m5 nut + a m5 screw with 25mm length (without part c+d) or 30mm length (with part c+d)

suggestions or requests are welcome!

thingiverse

free

Tronxy X1 8mm Z-Nut Adapter - M3 Srew wheel tightener by Blosters

...les on the third wheel screw to put an m3 screw and nut to tighten more the wheel on the 2040 aluminium extrusion, not tested yet

thingiverse

free

spacer for openbuilds carriage by GrafZahl_12345

...giverse.com/thing:43394 the v-wheel used on photo

http://www.thingiverse.com/thing:24886 used for basic idear

thx to all have fun

thingiverse

free

Ultimate bed stiffener for Tronxy X1

...base plate assembly.

now tighten the m5 nut using a 8 mm wrench.

reassembly the bed and re-adjust levelling.

enjoy better prints!

thingiverse

free

easy and efficient bed tightener for Tronxy X1 by MoonCactus

...e footprint for the wheels as https://www.thingiverse.com/thing:2854095 (which already reduces wobbles to almost zero by itself).

thingiverse

free

TronXY X1 Necessities by Caverntwo

...https://www.thingiverse.com/thing:2020468 belt tightener less wobbly. m5 angeled pillar pretty similar to the other m5 pillar, this one comes with...

thingiverse

free

bed tightener for Tronxy X2

...ightener for tronxy x2

thingiverse

i made bed tightener for tronxy x2

i use this modelhttps://www.thingiverse.com/thing:2854082

thingiverse

free

Tronxy X1 Z-axis Cap by jjfs85

... spool holder!

pay special attention to your infill and layer height as those two settings directly affect usability of the part.

Fabianfriethjoph

thingiverse

free

Dummyhead for modeling by FabianFriethjoph

...pe to work with that is easily adjusted to your head. this was made in fusion360 to allow such by simply altering the parameters.

thingiverse

free

Harmonograph by FabianFriethjoph

...lorful art. in higher classes the same object could be used in its original idea: as an example of a dampened harmonic oscilator.

thingiverse

free

Von Koch Snowflake by FabianFriethjoph

...h of the sides of the resulting star, turning this into a snowflaky object. in this case, there are 4 repetitions of this proces.

thingiverse

free

TronXY X1 Electronics Box LCD Cover by FabianFriethjoph

...ronxy x1.

2 variants: single piece & split into a tronxy x1 printable set of two with a 30mm overlap and grooves for the glue

thingiverse

free

Coinbox-Lock by FabianFriethjoph

... lugs of the disk and... voila! a simple but effective lock that can be set into a standard hole and prevent coins from escaping.

thingiverse

free

20x20x20mm Test Cube by FabianFriethjoph

..., 1.2 mm, walls, and a pair of resin-escape holes in the z-cover, and a little air intake hole on the x sides to prevent cupping.

thingiverse

free

TronXY X1 Hotend Adapter for 12V Fan by FabianFriethjoph

...uts has to be pressed into the holes first, then a pair of m3 in 20mm or longer can grab them and provide good hold on the block.

thingiverse

free

Tronxy X1 X-Axis adjustabel slider by 3D_Dane

...even i printet the closefit one. i still use fabianfriethjophs on the side closest to the screw heads, and...

thingiverse

free

Tronxy X1 radial fan mount and nozzle. by fessyfoo

...this. all credit goes to: it's the mount from fabianfriethjoph https://www.thingiverse.com/thing:2330698/#files and the nozzle from louiscooper https://www.thingiverse.com/thing:2184575 also i...

Openbuilds

3d_export

free

openbuilds lead cnc laser mount for opt lasers

...nload at:<br>to learn more about engraving and cutting cnc lasers that can be mounted with this item, click the link below:

thingiverse

free

OpenBuilds LEAD by OpenBuilds

...nyone to modify it to make it longer/taller or add attachments for adding a diode laser, a plasma an extruder among other things.

thingiverse

free

Openbuilds logo by olo2000pm

...openbuilds logo by olo2000pm

thingiverse

openbuilds logo

thingiverse

free

OpenBuilds Standard Spacer by TheMadScientist

...emadscientist

thingiverse

spacer with no offset and a 7.1mm hole for mounting openbuild slider wheels to openbuild mount plates.

thingiverse

free

Openbuilds aluminum profiles by Artu66

...openbuilds aluminum profiles by artu66

thingiverse

aluminum profiles openbuilds

thingiverse

free

Openbuilds Filament Filter by olo2000pm

...openbuilds filament filter by olo2000pm

thingiverse

openbuilds filament filter

thingiverse

free

Openbuilds Nut Block

...erted it to stl for who ever would like to use it ..again this is openbuilds not mine... use at your own risk...happy printing :)

thingiverse

free

Openbuilds CBeam End Plate

... end mount plate that was converted from grabcad.com to an stl this is openbuilds not mine use at your own risk happy printing ;)

thingiverse

free

Openbuilds M5 T-Nut

...openbuilds m5 t-nut

thingiverse

openbuilds slim t-nut with one m5 thread

thingiverse

free

Openbuilds Mountplate by TheMadScientist

...plate with regulation spaced/sized holes for openbuilds v slot rails

untested - if anyone prints, please let me know if it works!

2040

turbosquid

$15

human-2040

...turbosquid

royalty free 3d model human-2040 for download as on turbosquid: 3d models for games, architecture, videos. (1175771)

3ddd

$1

Настольный светильник Essa 2040

...ки — накаливания

регулировка направления света

регулировка направления света — нет

высота — 65 см

ширина — 35 см

3ddd

free

Odeon Light Essa 2040/8

... и придаст уют вашей квартире, дому или офису.

страна: италия

материалы: хрусталь,текстиль

цоколь: e14

габариты: d1000 x h680 мм

3ddd

$1

люстра серии Essa 2040/8

...люстра серии essa 2040/8

3ddd

odeon light

основание металл, цвет хром, материал плафона из белой ткани.

3ddd

$1

бра серии Essa 2040/1W

...бра серии essa 2040/1w

3ddd

odeon light

основание металл, цвет хром, материал плафона из белой ткани.

3ddd

$1

Люстра Essa 2040/5

...иль: модерн

вес: 5

объем (м3): 0,073

длина (см): 70

цвет металла (арматура): хром/бел

цвет плафона: белый

артикул фабрики: 2040/5

3ddd

$1

Odeon Light Essa бра 2040/1W

... и придаст уют вашей квартире, дому или офису.

страна: италия

материалы: хрусталь,текстиль

цоколь: e14

габариты: 500x250xh150 мм

3ddd

$1

люстра коллекции Essa 2040/5

... коллекции essa 2040/5

3ddd

odeon light

материал основания из металла цвета хром прекрасно гармонирует с плафоном из белой ткани.

3ddd

free

настольная лампа Essa 2040/1T

...ssa 2040/1t

3ddd

odeon light

основание цвета хром отлично сочетается с плафоном из белой ткани. может осветить площадь до 2 кв.м.

3ddd

$1

Lam Lee WALL ART

...lam lee wall art 3ddd c2905-2040 ...

Slider

3d_export

$5

slider

...slider

3dexport

slider

3d_export

$5

Camera Slider

...camera slider

3dexport

camera slider toy

turbosquid

$10

SLIDER RAW

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Slider V1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Vitrocsa3001-Slider-Fixed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ЭКМИ-МЕБЕЛЬ / Регина-slider

...er

3ddd

угловой , экми-мебель

диван "регина-slider". производитель экми-мебель

3d_ocean

$12

Bolt Cutter (Xpresso Slider Controlled)

...are to use slider controller. you can see how to use slider in preview video. render system and materials are ready. c4d and o...

3ddd

free

Шкатулка-держатель для фотографий Slider

...рмы umbra. вмещает три фотографии размером 8 х 8 см, 10 х 10 см и 10 х 15 см.http://www.umbra.com/usd/slider-photo-dis

3d_ocean

$9

Seats with Automatic Adding Slider (Xpresso)

... / images and read description carefully before you buy. thanks. you need cinema 4d software to use slider controller or just ...

turbosquid

$15

Computer Camera Slider, closes and opens camera view

...der, closes and opens camera view for download as skp and stl on turbosquid: 3d models for games, architecture, videos. (1331206)

Cut

design_connected

$11

e15 Cut Cutting Boards

...e15 cut cutting boards

designconnected

e15 cut cutting boards computer generated 3d model.

design_connected

$16

Cut

...cut

designconnected

lapalma cut computer generated 3d model. designed by rota, francesco.

3d_export

$5

cutting machine

...cutting machine

3dexport

crop cutting machine

3d_export

$5

cutting board

...cutting board

3dexport

12 models for cutting boards

3d_export

$20

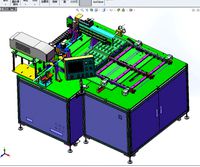

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3ddd

$1

Lapalma CUT

... cut

фабрика: lapalma

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, ткань, кожа, дерево.

сайт: www.lapalma.it

3ddd

$1

стул lapalma cut

...стул lapalma cut

3ddd

lapalma , cut

стул lapalma cut

3ddd

$1

Lapalma CUT

...

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, порошковое покрытие, черный, белый, ткань, пластик.

сайт: www.lapalma.it

design_connected

$16

Hi Cut

...hi cut

designconnected

kartell hi cut computer generated 3d model. designed by starck, philippe.

3ddd

$1

Vorwerk Cut

...vorwerk cut

3ddd

ковер

vorwerk cut

прямоугольный:

размеры : 2400mm x 3200mm

круглый:

размеры : 2400mm

V

design_connected

$16

V Chair

...v chair

designconnected

v chair computer generated 3d model.

design_connected

$11

V Hanglamp

...v hanglamp

designconnected

arturo alvarez v hanglamp computer generated 3d model. designed by alvarez, arturo .

turbosquid

$25

Borbet V

...v

turbosquid

royalty free 3d model borbet v for download as on turbosquid: 3d models for games, architecture, videos. (1381618)

turbosquid

free

Saturn V

...rn v

turbosquid

free 3d model saturn v for download as blend on turbosquid: 3d models for games, architecture, videos. (1651098)

turbosquid

$40

V motor

...turbosquid

royalty free 3d model v motor for download as max on turbosquid: 3d models for games, architecture, videos. (1379483)

turbosquid

$7

V for Van

...rbosquid

royalty free 3d model v for van for download as max on turbosquid: 3d models for games, architecture, videos. (1695889)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408535)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408534)

turbosquid

$15

BonePile V

...oyalty free 3d model bonepile v for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546310)

turbosquid

$2

FONT V

...quid

royalty free 3d model font v for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549450)