Thingiverse

SLA Printer FDM Parts by KT421

by Thingiverse

Last crawled date: 2 years, 12 months ago

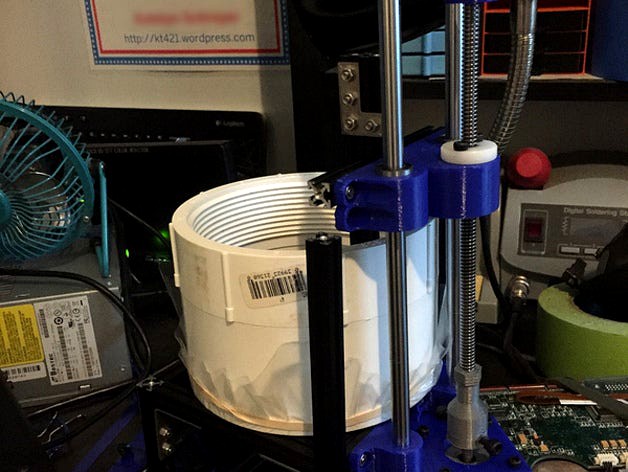

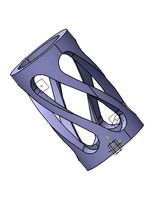

These are the FDM printed parts used in my WIP SLA build. It's currently unfinished and non functional.

Full build notes #1: https://kt421.wordpress.com/2015/06/28/my-newest-project-an-sla-printer-wip/

Modifying a projector: https://kt421.wordpress.com/2015/07/07/modifiying-a-dlp-projector-for-use-in-an-sla-printer/

These parts are designed for the materials I have on hand: the gutted remains of my Printrbot Simple Maker's Kit after I upgraded to a Printrbot Simple Metal.

All FDM parts printed at .3mm layer height, either 10% or 30% infill depending on if the part is load bearing or not.

FDM Parts in this thing:

Mirror Bracket (only one side, mirror it in your slicer for the other side)

Z assembly

Motor Mount & smooth rod block

Knurled knob (unmodified from source)

Z-coupler (unmodified from source)

Vat walls

Gasket Mold (I used RTV gasket maker to create the gasket. Mold is lightly larger than needed as I found the gasket maker shrinks.)

FDM part yet to be designed:

Shutter for projector

Vitamins:

MakerBeam kit

RAMPS/Mega

Nema 17 motor (PB Simple)

Vat (cut from acrylic if you have access to a laser cutter; otherwise use the STL above to 3D print it)

Vat bottom - FEP Film

(http://projectsinterestsandetcetera.com/store/) or potentially Reynold's Oven Wrap?

Small C-clamps to hold vat assembly together

First Surface Mirror (http://www.sciplus.com/p/MIRROR-FIRST-SURFACE15MM-X-15MM-X-1MM-THKVERY-SMALL_248)

DLP Projector

Aluminum build plate (http://www.metalremnants.com/product/aluminum-discs/)

2x 8mm Smooth rods (PB Simple)

5/16" Threaded rod (PB Simple)

2x LM8UU Linear Bearings (PB Simple)

M3 hardware (PB Simple)

Delrin Acme Nut (PB Simple)

Servo for shutter

Firmware/Software:

Marlin; modified to remove extruder code and temperature failsafes, and to enable 1 servo

Creation Workshop to slice and control printer (http://www.envisionlabs.net/)

WARNINGS:

DO NOT USE ABS FOR SLA PRINTER PARTS. If you have a resin spill, the resin dissolves ABS. It will literally melt your printer. Not fun. I'm using PLA, because I have lots of it. If I need to, I'll reprint parts in PET or Nylon. I'll update this if PLA doesn't work out for any reason. Likewise, PVC is not a good material. The PVC vat in the pic is just a placeholder while I make my acrylic vat.

You'll have to get a DLP projector and likely have to modify it a bit to make it work. Void warranties at your own risk.

Full build notes #1: https://kt421.wordpress.com/2015/06/28/my-newest-project-an-sla-printer-wip/

Modifying a projector: https://kt421.wordpress.com/2015/07/07/modifiying-a-dlp-projector-for-use-in-an-sla-printer/

These parts are designed for the materials I have on hand: the gutted remains of my Printrbot Simple Maker's Kit after I upgraded to a Printrbot Simple Metal.

All FDM parts printed at .3mm layer height, either 10% or 30% infill depending on if the part is load bearing or not.

FDM Parts in this thing:

Mirror Bracket (only one side, mirror it in your slicer for the other side)

Z assembly

Motor Mount & smooth rod block

Knurled knob (unmodified from source)

Z-coupler (unmodified from source)

Vat walls

Gasket Mold (I used RTV gasket maker to create the gasket. Mold is lightly larger than needed as I found the gasket maker shrinks.)

FDM part yet to be designed:

Shutter for projector

Vitamins:

MakerBeam kit

RAMPS/Mega

Nema 17 motor (PB Simple)

Vat (cut from acrylic if you have access to a laser cutter; otherwise use the STL above to 3D print it)

Vat bottom - FEP Film

(http://projectsinterestsandetcetera.com/store/) or potentially Reynold's Oven Wrap?

Small C-clamps to hold vat assembly together

First Surface Mirror (http://www.sciplus.com/p/MIRROR-FIRST-SURFACE15MM-X-15MM-X-1MM-THKVERY-SMALL_248)

DLP Projector

Aluminum build plate (http://www.metalremnants.com/product/aluminum-discs/)

2x 8mm Smooth rods (PB Simple)

5/16" Threaded rod (PB Simple)

2x LM8UU Linear Bearings (PB Simple)

M3 hardware (PB Simple)

Delrin Acme Nut (PB Simple)

Servo for shutter

Firmware/Software:

Marlin; modified to remove extruder code and temperature failsafes, and to enable 1 servo

Creation Workshop to slice and control printer (http://www.envisionlabs.net/)

WARNINGS:

DO NOT USE ABS FOR SLA PRINTER PARTS. If you have a resin spill, the resin dissolves ABS. It will literally melt your printer. Not fun. I'm using PLA, because I have lots of it. If I need to, I'll reprint parts in PET or Nylon. I'll update this if PLA doesn't work out for any reason. Likewise, PVC is not a good material. The PVC vat in the pic is just a placeholder while I make my acrylic vat.

You'll have to get a DLP projector and likely have to modify it a bit to make it work. Void warranties at your own risk.

Similar models

thingiverse

free

Heart Pendant (DLP/SLA) by Beezen

...printer.

there are 3 version.

version 1 is without support. version 2 is with minimal support. version 3 is with maximum support.

thingiverse

free

Battletech Glass Spider / Galahad

.../sla printers, no guarantee that this will print on fdm. scaled in line with the mw:da figures. mirror parts for the other sides.

thingiverse

free

Battletech Neanderthal

.../sla printers, no guarantee that this will print on fdm. scaled in line with the mw:da figures. mirror parts for the other sides.

thingiverse

free

Battletech Puma / Adder

.../sla printers, no guarantee that this will print on fdm. scaled in line with the mw:da figures. mirror parts for the other sides.

thingiverse

free

SLA/DLP Flex VAT 4:3 aspect ratio by roubledainbow

... version of the flex vat by ameralabs, the print area on this one is ~152x114mm to better work with my 4:3 aspect ratio projector

thingiverse

free

FLE-17 Flea for Battletech (Custom Sculpt)

...h (custom sculpt)

thingiverse

this is meant for dlp/sla resin printers, there's no guarantee it will work on an fdm printer.

thingiverse

free

Battletech Scorpion

.../sla printers, no guarantee that this will print on fdm. scaled in line with the mw:da figures. mirror parts for the other sides.

thingiverse

free

LEGO NXT/EV3 Custom Sensor Case by chansheunglong

...nxt/ev3 custom sensor case by chansheunglong

thingiverse

recommend using sla/dlp, it will be very hard to print on a fdm printer

thingiverse

free

Monoprice Mini-SLA Resin vat tray by wpski

...ki

thingiverse

a tray to keep my mini-sla resin vat off of the table when i'm inspecting and cleaning the vat or the printer

thingiverse

free

Battletech Blitzkrieg

.../sla printers, no guarantee that this will print on fdm. scaled in line with the mw:da figures. mirror parts for the other sides.

Kt421

thingiverse

free

XCOM:EW Insignia by KT421

... post for more information: https://kt421.wordpress.com/2015/04/10/3d-printed-xcom-stuff-or-how-to-make-3d-models-from-2d-images/

thingiverse

free

28mm scale firepit by KT421

...h acrylic paints.

remixed from two existing designs. i seriously just plopped them down together and saved. nothing fancy here.

thingiverse

free

LED insert for steampunk goggles by KT421

...an go to a switch or to an arduino if you're a fancypants.

step 6 (not shown): glue some gears on it and call it steampunk.

thingiverse

free

Medication Supplies Organizer for IVF by KT421

...rinted at 60mm/sec on a printrbot metal simple, but would probably increase those speeds to 80mm/sec if i were to print it again.

thingiverse

free

XCOM EU:EW Logos by VideogameEnthusiast

...from the enemy within expansion from xcom. inspired by kt421#39;s xcom:ew insignia thing. you can find it at: https://www.thingiverse.com/thing:763167....

Sla

3ddd

$1

CILEK SL ACTIVE

...sl active 3ddd cilek cilek active (sl active white) sla1304 кровать...

3ddd

$1

Cilek SL ACTIVE

...3ddd cilek , стеллаж cilek active (sl active white) 1501-sla стеллаж...

3d_export

$5

ring-love norian-54-64 mm 4pcs

...norian-54 ring-love norian-56 ring-love norian-60 ring-love norian-64 suitable for sla and sls and similar printing...

3d_export

$10

cute kitten v2 stl 3d print model

...print model 3dexport solid type (fdm) and hollow type (sla & dlp)<br>stl file for 3d print<br>size :<br>x : 66...

3d_export

$5

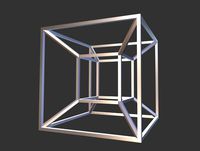

tesseract hypercube

...each diagonal has 6 faces. you can use sls, sla and other technologies to print it. moreover different textures...

3d_export

$23

the last engineer 3d printing figurine

...will also receive "assembly manual" for fff/fdm 1.0 and dlp/sla 1.0 versions in pdf format. the figurine is saved...

3d_export

$5

groot con grabadora

...enabled, however you can also use a dlp or sla printer with resin as well. for small scale printouts,...

3d_export

$5

deer christmas 3

...enabled, however you can also use a dlp or sla printer with resin as well. you should use a...

3d_export

$5

deer christmas 2

...enabled, however you can also use a dlp or sla printer with resin as well. you should use a...

3d_export

$5

deer christmas

...enabled, however you can also use a dlp or sla printer with resin as well. you should use a...

Fdm

3d_export

$15

old brick wall with corner version

...texture + corner version. miniatures printing - resin & fdm ...

3d_export

$5

shutter shade sunglasses

...shutter shade sunglasses 3dexport this model suitable for fdm printer, the gaps between two dynamic part is 0.4...

3d_export

$5

toggle clamp

...model to your favorite size. this model design for fdm 3d printing plus it design with standard sheet metal...

3d_export

$10

cute kitten v2 stl 3d print model

...kitten v2 stl 3d print model 3dexport solid type (fdm and hollow type (sla & dlp)<br>stl file for 3d...

3d_export

free

Articulated centipede

...actual scale is the smallest scale i've tried for fdm with perfect results. you can scale it up with...

3d_export

$5

groot con grabadora

...is recommended to print these models with a good fdm printer by using some supports enabled, however you can...

3d_export

$5

deer christmas 3

...is recommended to print these models with a good fdm printer by using some supports enabled, however you can...

3d_export

$5

deer christmas 2

...is recommended to print these models with a good fdm printer by using some supports enabled, however you can...

3d_export

$5

deer christmas

...is recommended to print these models with a good fdm printer by using some supports enabled, however you can...

3d_export

$5

deer christmas 5

...is recommended to print these models with a good fdm printer by using some supports enabled, however you can...

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Parts

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)

turbosquid

$8

Drum parts

...bosquid

royalty free 3d model drum parts for download as max on turbosquid: 3d models for games, architecture, videos. (1631178)