Thingiverse

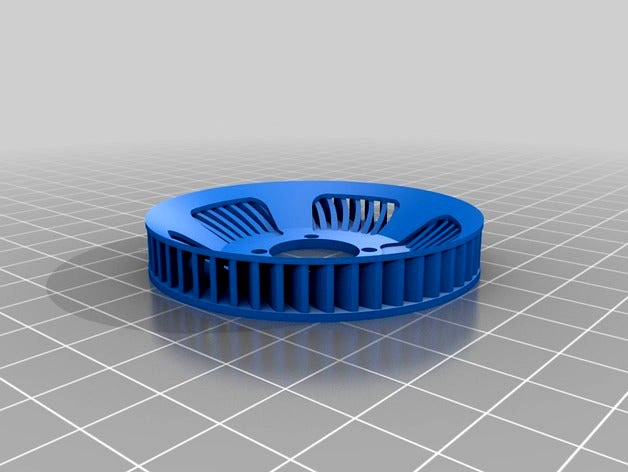

Sk3 63mm Motor fan cover by JohnAlbrecht

by Thingiverse

Last crawled date: 3 years ago

Here is a work in progress. The goal was to create a cover for the huge holes on the back of the 63mm sk3 motors (6354, 6364, or 6374). But why have a cover when you could make a fan to help cool the motors? I have yet to test the fluid dynamics of how the fan helps, but it seems to help on my first tests. Im using these in a dual surf rods setup, so im really tight on space. The cover doesn't stick out past the cans button, so with the right 3mm screws nothing will stick out past the and of the axle. There are two fans uploaded of each design so determine which side your motor will be mounted and get the corresponding fan. (one is designed for turning left and one right). here are the specs for each design: make sure you align the fan correctly, the cut outs should match the motor as well as have the screw holes line up.

Design v1.1

-30 blades mounted in a Backward-curved way so rocks are deflected off when spinning. the gap for a rock to get in is only 3.28mm by 5.2mm.

-Just needs about 10-12 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)very strong design, less obstruction of holes on back of motor... only positive is less stringing of filament on your 3D printer

Design v2.1

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 5.2mm on these blades.

-Just needs about 10-12 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)This is a very good air flow fan, won't let any rocks in and is strong enough to take a few hits without breaking

Design V2.2 recommended

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 7.2mm on these blades.

-Just needs about 10 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)this is the design with the best airflow, but least strong so don't use if you have underside mounted Sk3 motors

Design v3.1 recommended if space isn't an issue

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 7.4mm on these blades.

-Just needs about 12 grams of plastic and would probably be better to use a higher temp plastic.

-needs 4 3mm screws between 6 and 12mm long (any longer and will hit windings)This is the design with the best airflow, and also just as strong as the others. It does extend to the end of the axle though so its better where space isn't a concern

Design v1.1

-30 blades mounted in a Backward-curved way so rocks are deflected off when spinning. the gap for a rock to get in is only 3.28mm by 5.2mm.

-Just needs about 10-12 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)very strong design, less obstruction of holes on back of motor... only positive is less stringing of filament on your 3D printer

Design v2.1

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 5.2mm on these blades.

-Just needs about 10-12 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)This is a very good air flow fan, won't let any rocks in and is strong enough to take a few hits without breaking

Design V2.2 recommended

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 7.2mm on these blades.

-Just needs about 10 grams of plastic and would probably be better to use a higher temp plastic. (Im just using regular PLA and will see how that works)

-needs 4 3mm screws between 4 and 10mm long (any longer and will hit windings)this is the design with the best airflow, but least strong so don't use if you have underside mounted Sk3 motors

Design v3.1 recommended if space isn't an issue

-52 blades mounted in a Backward-curved way so rocks are deflected off when spinning. The gap for a rock to get in is only 1.7mm by 7.4mm on these blades.

-Just needs about 12 grams of plastic and would probably be better to use a higher temp plastic.

-needs 4 3mm screws between 6 and 12mm long (any longer and will hit windings)This is the design with the best airflow, and also just as strong as the others. It does extend to the end of the axle though so its better where space isn't a concern

Similar models

thingiverse

free

Turnigy Aerodrive SK3 3536 1400kV Motor Mounts

...orts, print 100% fill (solid)

also just added a couple of more rounded off versions of the mounts; so they are a bit less draggy.

thingiverse

free

CR10s_Mounting_Plate_BL_Touch 3mm mounting plate by life4of9

...inal 6mm so that 2 of the mounting screws from the original can be used, slightly longer is still needed for the fan mount though

thingiverse

free

Turnigy SK3 6374 192kv fan for longitudinal operation by iPeel

...otor doesn't overheat.

this may well fit other 6374 size turnigy motors but has only been tested to fit on the 192kv variant.

thingiverse

free

Nema 23 Stepper Motor Fan Shroud / Mount by RockChalk846

...es require four screws. i used 1/2 inch long #4 screws (about 2.5mm diameter, 10mm long). the fans are standard 40mm case fans.

thingiverse

free

Heatsink Motor Fan Cage for Hot Racing Clip-On Two-Piece Motor Heat Sink with fan by luisfjdesigner3d

...nstalling the

heat sink motor fan cage. and then the photos should give you an idea how to

install it. so enjoy this new upgrade.

thingiverse

free

Motor mount for Turnigy SK3 Fandrive - 3659-1900kv

...erse

custom engine mount for a turnigy sk3 fandrive - 3659-1900kv (inrunner)

you need to use the aluminum cross to fix the motor

thingiverse

free

80mm Brushless Outrunner Motor Fan Cover by JohnAlbrecht

...t from scooping up debris.

requirements:

-31 grams of abs or petg (motors get too hot for pla)

-4 m5 screws, preferably 8mm long

thingiverse

free

30mm fan mount for Carten M210R M-TC

... a motor cooling fan on to the carten m210r chassis you will need some 3mm mounting screws and nuts also a couple of 10mm spacers

grabcad

free

MOTOR FAN

...motor fan

grabcad

plastic fan blade

thingiverse

free

Makergear M2 Extruder Motor Fan Mount 60mm by Easybotics

...eo covering my various makergear m2 mods:https://youtu.be/jd6ztccd0j8

by - http://www.easybotics.com/

and - http://hilo90mhz.com/

Johnalbrecht

thingiverse

free

Surf Rods 200mm Hanger by JohnAlbrecht

... 200mm hanger by johnalbrecht

thingiverse

step file of 200mm surf rods rkp hangers. can make other formats available on request.

thingiverse

free

FOCbox Mount (for two) by JohnAlbrecht

... mounting holes. the focbox mounts are in a good position so both mount and don't touch, and don't overlap off the sides.

thingiverse

free

36 tooth Abec 11 wheel pulley by JohnAlbrecht

...esigned for evolve supercarve trucks so a 10x22mm bearing fits perfectly in this.

needs

-50g filament

-6 m3x20mm screws

-bearing

thingiverse

free

43 tooth Abec 11 wheel pulleys by JohnAlbrecht

... they are made to use an integrated bearing so they need longer axle trucks.

needs

-60g filament

-6 m3x20mm screws

-skate bearing

thingiverse

free

Dc power supply, fully enclosed by JohnAlbrecht

...8mm screws (around that size would work best)

-300 grams of filament

-some wiring (22awg and 16awg)

-nonslip pads for the bottom

thingiverse

free

48 Tooth Abec 11 Flywheel 97mm Wheel pulley by JohnAlbrecht

.... the 9mm belt won't need any supports, but the 12 an 15mm ones probably need supports.

new: 21mm pulley files added 11/26/17

thingiverse

free

80mm Brushless Outrunner Motor Fan Cover by JohnAlbrecht

...t from scooping up debris.

requirements:

-31 grams of abs or petg (motors get too hot for pla)

-4 m5 screws, preferably 8mm long

Sk3

turbosquid

$7

In Between SK3 Table

...oyalty free 3d model in between sk3 table for download as max on turbosquid: 3d models for games, architecture, videos. (1629239)

3d_export

$5

bench

...страна производитель: беларусь артикул ск3 poly: 22236 verts: 22344 https://vishop.by/catalog/tovary-dlya-dachi-i-otdyha/skami-dlya-dachi/skameyka-sk3 ...

3dbaza

$2

In Between SK3 Table (343936)

...in between sk3 table (343936)

3dbaza

in between sk3 table 3d model

thingiverse

free

SK3 Compatible arms for Hovership MHQ2 by MORP

...ded by nilz. the arm now fits motors that use m2 screws that are placed 7mm from the heart of the motor (e.g. aeroquad sk3 2118).

thingiverse

free

Motor mount for Turnigy SK3 Fandrive - 3659-1900kv

...erse

custom engine mount for a turnigy sk3 fandrive - 3659-1900kv (inrunner)

you need to use the aluminum cross to fix the motor

thingiverse

free

Spacer/standoff for Turnigy Aerodrive SK3 type outrunner by Motorpixiegimbals

...pacer for turnigy aerodrive sk3 outrunner.

44 mm between holes diagonally.

used for graupner taxi ii glow to electric conversion.

thingiverse

free

Turnigy Aerodrive SK3 3536 1400kV Motor Mounts

...orts, print 100% fill (solid)

also just added a couple of more rounded off versions of the mounts; so they are a bit less draggy.

thingiverse

free

Turnigy SK3 6374 192kv fan for longitudinal operation by iPeel

...otor doesn't overheat.

this may well fit other 6374 size turnigy motors but has only been tested to fit on the 192kv variant.

thingiverse

free

Turnigy SK3 Dust / Dirt plug TPU by xsynatic

...eady. the file is really tight and you need a tool to press the sides in, optionally print it at 99 or 98% on the y axis (length)

thingiverse

free

DIY E-Bike with EXT600 & Turnigy Aerodrive SK3 - 6374-192kv by cashilysh

... lipo and a 100a esc with an arduino and throttle grip.

note: you need to split the "ebike holder.stl" into two pieces!

63Mm

3d_export

$19

Gingerbread cookie 009

...vertex with more than 5 edges: 0<br>object:<br>- dimension mm: 63mm x 71mm x 8mm<br>- dimension cm: 6.3cm x 7.1cm...

3d_export

$19

Cupcake wave

...vertex with more than 5 edges: 0<br>object:<br>- dimension mm: 63mm x 66mm x 91mm<br>- dimension cm: 6.3cm x 6.6cm...

3d_export

$19

Canned food round tin metal aluminum can 10

...5 edges: 0<br>object:<br>- dimension mm: 84mm x 84mm x 63mmlt;br>- dimension cm: 8.39cm x 8.39cm x 6.3cm<br>- dimension m:...

thingiverse

free

Impeller 63mm

...impeller 63mm

thingiverse

63mm impeller

thingiverse

free

Pipe Clip 63mm by gastondamian

...pipe clip 63mm by gastondamian

thingiverse

i nelarge the paul_tibble clip to fit 63mm pipe.

thingiverse

free

Katsu router 63mm hose adaptor

...katsu router 63mm hose adaptor

thingiverse

hose adaptor 37mm to 63mm

thingiverse

free

Circuit Board Mount 63mm by DeviantSpark

...circuit board mount 63mm by deviantspark

thingiverse

this is a mount for a 63mm circuit board.

thingiverse

free

63mm servicetransit template

...63mm servicetransit template

thingiverse

swedish standard template for servicetransits

thingiverse

free

DIN Clip for 63mm PCB by wt4y

...din clip for 63mm pcb by wt4y

thingiverse

i lengthened the clip to accommodate a 63mm power supply pcb

thingiverse

free

Impeller 63mm V2

...sin.

the impeller runs in my jetdrive with sss56114 motor.

impeller give me a thrust of around 12kg with 6s lipo and pulling 60a.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Cover

archibase_planet

free

Cover

...cover

archibase planet

cover place setting

cover n170807 - 3d model for interior 3d visualization.

3ddd

$1

cover

...cover

3ddd

ковер , круглый

cover decor

archibase_planet

free

Cover

...cover

archibase planet

cover place setting setting

servis-cafe1930 - 3d model for interior 3d visualization.

turbosquid

free

Coverings

...rings

turbosquid

free 3d model coverings for download as dwg on turbosquid: 3d models for games, architecture, videos. (1279391)

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

turbosquid

$25

Covers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

manhole cover

...manhole cover

3dexport

manhole cover gost, stl, step

turbosquid

$5

Street Gas Cover Manhole Cover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Bed cover

...bed cover

3ddd

постельное белье

very useful bed cover

3d_export

$5

cpu cover

...cpu cover

3dexport

cpu cover, cpu box, sheet metal container