Thingiverse

Single cylinder steam engine by hberg32

by Thingiverse

Last crawled date: 3 years ago

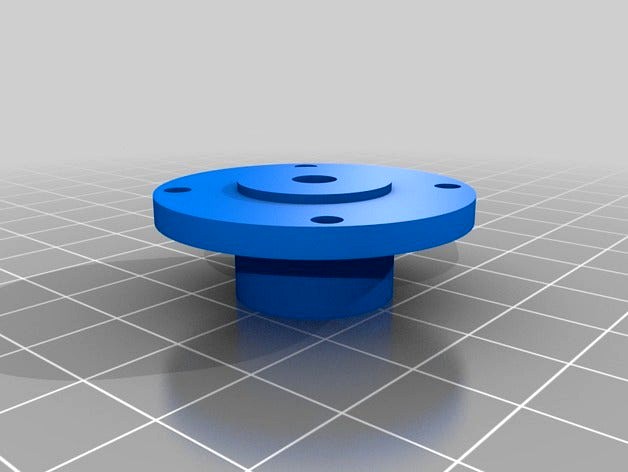

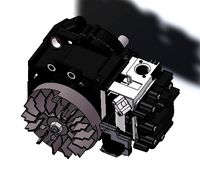

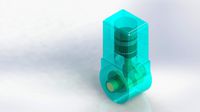

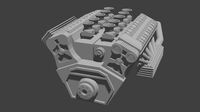

This is a vertical single cylinder model steam engine translated from the plans posted at http://www.john-tom.com/MyPlans/SteamPlans3/GermanSingleVertical/BP-Dampf.pdf. Aside from an assortment of M3 bolts you'll want some basic machine tools to make this run. The piston rod, crank shaft, crank pin, and valve rod are included here for completeness but I'd really recommend cutting these from brass rod unless you have a mini-lathe to turn them accurately. Brass rod can be cut quite easily with the same sort of cutter that plumbers use to cut copper pipe. The parts here are all transcribed exactly from the plans with no tolerances added for printing.

Cutting gaskets for the steam chest and cylinder heads is recommended. I don't know yet if piston rings or o-rings are a good idea. Mine is leaking past the piston a good bit so rings will probably be required.

I've printed mine in pla with default .2mm settings for slic3r with the exception of bumping perimeters to 6 and setting "seam position" to random. This last setting in particular is helpful as each layer will be started from a different position so you don't get those vertical seams throwing all the holes off center. So far I can get about a half-turn with lung power but haven't been able to turn it over yet as I don't have a compressor.

The crosshead turning guide is a sacrificial part to make it easier to sand/turn down the crosshead without rounding the edges and to make it easier to keep it round. Print the two parts of the turning guide and fit them to the crosshead to form one cylinder. Turn down the cylinder to fit, give it a polish and then remove and discard the two turning guide pieces.

Eccentric rod - There are two versions of this. Use eccentric_rod_solid if you want to print the whole rod as one piece. Use eccentric_rod if you want to cut and thread your own brass rod. Cutting your own rod would let you adjust the rod length a little while fitting the engine. I don't think this is actually necessary, there seems to be enough room for adjustment of the crossbar on the valve rod.

Brass rod sethttps://www.amazon.com/gp/product/B0748DCBHQ/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

Metric drill bit sethttps://www.amazon.com/gp/product/B071ZRMWBN/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

Metric tap and die sethttps://www.amazon.com/gp/product/B0000DD4KV/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

Metric reamer sethttps://www.amazon.com/gp/product/B074M3WJC5/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Comically terrible expanding reamer set (theoretically usable for boring the cylinder to precisely 17mm)https://www.amazon.com/gp/product/B01CEJG0AS/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

Here's a discussion and pictures of the source model Stehende Einzylinder - Dampfmaschine (I don't speak German but the pictures are helpful.): http://modell-dampf-forum.info/wbb4/index.php?thread/6768-stehende-einzylinder-dampfmaschine/&pageNo=4

Cutting gaskets for the steam chest and cylinder heads is recommended. I don't know yet if piston rings or o-rings are a good idea. Mine is leaking past the piston a good bit so rings will probably be required.

I've printed mine in pla with default .2mm settings for slic3r with the exception of bumping perimeters to 6 and setting "seam position" to random. This last setting in particular is helpful as each layer will be started from a different position so you don't get those vertical seams throwing all the holes off center. So far I can get about a half-turn with lung power but haven't been able to turn it over yet as I don't have a compressor.

The crosshead turning guide is a sacrificial part to make it easier to sand/turn down the crosshead without rounding the edges and to make it easier to keep it round. Print the two parts of the turning guide and fit them to the crosshead to form one cylinder. Turn down the cylinder to fit, give it a polish and then remove and discard the two turning guide pieces.

Eccentric rod - There are two versions of this. Use eccentric_rod_solid if you want to print the whole rod as one piece. Use eccentric_rod if you want to cut and thread your own brass rod. Cutting your own rod would let you adjust the rod length a little while fitting the engine. I don't think this is actually necessary, there seems to be enough room for adjustment of the crossbar on the valve rod.

Brass rod sethttps://www.amazon.com/gp/product/B0748DCBHQ/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

Metric drill bit sethttps://www.amazon.com/gp/product/B071ZRMWBN/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

Metric tap and die sethttps://www.amazon.com/gp/product/B0000DD4KV/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

Metric reamer sethttps://www.amazon.com/gp/product/B074M3WJC5/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Comically terrible expanding reamer set (theoretically usable for boring the cylinder to precisely 17mm)https://www.amazon.com/gp/product/B01CEJG0AS/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

Here's a discussion and pictures of the source model Stehende Einzylinder - Dampfmaschine (I don't speak German but the pictures are helpful.): http://modell-dampf-forum.info/wbb4/index.php?thread/6768-stehende-einzylinder-dampfmaschine/&pageNo=4

Similar models

thingiverse

free

Desk Fan by NebNorse

...lpages04?ie=utf8&psc=1

motor control: https://www.amazon.com/gp/product/b01cnl6imc/ref=od_aui_detailpages04?ie=utf8&psc=1

thingiverse

free

MuriDron by inakimurillo

...i_detailpage_o03_s00?ie=utf8&psc=1https://www.amazon.es/gp/product/b016eqqpra/ref=oh_aui_detailpage_o04_s00?ie=utf8&psc=1

thingiverse

free

PICman MK1 by Scorch1262

...tps://www.amazon.de/gp/product/b00ok9fauw/ref=oh_aui_detailpage_o03_s00?ie=utf8&psc=1

haupt prozessor: microchip pic 18f46k20

thingiverse

free

Positionsleuchte MK2 by Scorch1262

...o07_s00?ie=utf8&psc=1

li-ion akku:https://www.amazon.de/gp/product/b06xpdv15r/ref=oh_aui_detailpage_o07_s00?ie=utf8&psc=1

thingiverse

free

Glotzkowsky MK1 by Scorch1262

...=oh_aui_detailpage_o00_s00?ie=utf8&psc=1

prozessor: microchip pic 18f1330

"reifen": gummibänder (ca: ø100mm x 10mm)

thingiverse

free

HC-12 Fernbedienung Mini MK1 by Scorch1262

...o00_s00?ie=utf8&psc=1

li-ion akku:https://www.amazon.de/gp/product/b06xpdv15r/ref=oh_aui_detailpage_o07_s00?ie=utf8&psc=1

thingiverse

free

Toolbox by jbialek

...o03_s00?ie=utf8&psc=1

countersink:https://www.amazon.de/gp/product/b00nvpmv5i/ref=oh_aui_detailpage_o03_s00?ie=utf8&psc=1

thingiverse

free

Sonoff Enclosure by JeffLZ

...title_o00_s00?ie=utf8&psc=1

https://www.amazon.com/gp/product/b00qvb6qpu/ref=ox_sc_saved_title_1?smid=atvpdkikx0der&psc=1

thingiverse

free

12 Function Deep Dish Button Box by coyoteyz13

..._title_o03_s00?ie=utf8&psc=1

https://www.amazon.com/gp/product/b07vhcb1q4/ref=ppx_yo_dt_b_search_asin_title?ie=utf8&psc=1

thingiverse

free

rc 12v led lights by derrick84

...ingiverse

heres the led bulbs i used http://www.amazon.com/gp/product/b00b2yhfo2/ref=oh_aui_detailpage_o07_s00?ie=utf8&psc=1

Hberg32

thingiverse

free

Cape Hatteras Lighthouse Masking Guide by hberg32

...use tower and tie on some string or fishing line to help align the masking tape. each string should wrap around the tower twice.

thingiverse

free

Hotas Cougar Gimbal Redesign by hberg32

...don't let the magic smoke out.

influences

https://www.thingiverse.com/thing:2496028https://www.shapeways.com/shops/debolestis

Steam

3d_export

$28

steam locomotive

...steam locomotive

3dexport

## steam locomotive

turbosquid

$1

Steam

...m

turbosquid

royalty free 3d model steam for download as obj on turbosquid: 3d models for games, architecture, videos. (1626376)

3d_ocean

$15

Steam iron

...ign made by me. you can use it for your projects and games as you want. iron, steam iron, philips,siemens, clothes,ironing, tefal

3d_export

$5

steam locomotive

...steam locomotive

3dexport

road. low-poly model steam train

3d_export

$10

bitron steam press

...bitron steam press

3dexport

bitron steam press

3d_export

$5

sauna steam room

...sauna steam room

3dexport

sauna steam room

3d_export

$10

steamed buns

...steamed buns

3dexport

3d_export

$7

steam locomotive

...steam locomotive

3dexport

turbosquid

$100

Steam Train

...osquid

royalty free 3d model steam train for download as fbx on turbosquid: 3d models for games, architecture, videos. (1166089)

turbosquid

$49

Steam machine

...quid

royalty free 3d model steam machine for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486836)

Cylinder

turbosquid

$1

Piston - Cylinder Cylinder Engine

...nder cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1235278)

3ddd

$1

sofa cylinder

...sofa cylinder

3ddd

круглый

sofa cylinder

turbosquid

$1

Cylinder Head - Single Cylinder Engine

...ngle cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1222618)

turbosquid

$16

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$120

Four cylinder

...four cylinder

3dexport

four cylinder render 3d modelling

3d_export

$5

piston cylinder

...piston cylinder

3dexport

piston cylinder arrangement sketched in solidworks

3ddd

$1

Cylinder Lamp A

...cylinder lamp a

3ddd

cylinder form lamp for loft interior

archive3d

free

Cylinder 3D Model

... model

archive3d

cylinder drum

cylinder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Cylinder 3D Model

...odel

archive3d

drum cylinder

cylinder 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Single

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single fastener

...single fastener

3dexport

single fastener

3ddd

$1

Single FLOU

... sofa , трансформер

диван-трансформер single от итальянского производителя flou

3ddd

$1

bed single

...bed single

3ddd

постельное белье

bed single 190cm*90cm

3ddd

$1

Single Flou

...single flou

3ddd

качественная моделька дивана-трансформера single flou.

3d_ocean

$9

Single sofa

...le sofa

3docean

modern sofa single sofa sofa white sofa.comfortable sofa

single sofa,sofa,modern sofa,white sofa.comfortable sofa

3d_export

free

Single Knife

...single knife

3dexport

a single knife, presumably it was used as one of the throwing knives.

3d_export

free

couch - single

...couch - single

3dexport

low poly single couch with .psd file for personal customization

3d_ocean

$5

Single Sofa

...single sofa

3docean

single sofa made by fabric , wood frame & ss leg

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

turbosquid

$1

ENGINE

...y free 3d model engine for download as max, 3ds, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1673703)