Thingiverse

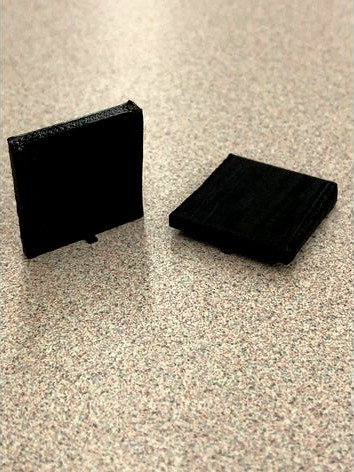

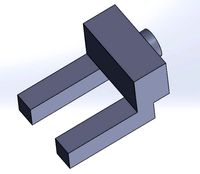

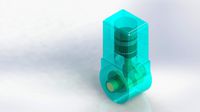

Simple Connector Lab - Bearing/Compression Failure Test by SDstate_Civil_Engineering

by Thingiverse

Last crawled date: 3 years ago

Simple Connector Lab

This simple connector was designed by students at SDSU for an experiment. The connector is designed to break at a specific compressive force to obtain the ultimate bearing/compressive strength of the 3D printed material. From our testing we found the average ultimate bearing/compressive strength of 3D printed PLA to be 34.3 MPa (5000 psi).

To calculate the ultimate bearing/compressive strength of the material the follow equation can be used:

B = P / A

Where:

P = the load at which the specimen broke

-The connector is designed to break between 2.8 kgs to 3.0 kgs or 6.2 to 6.6 lbs

A = area of failure surface = (Thickness of layer below block)*(perimeter)

-The failure surface for the bearing/compressive connector is the area at the bottom of the small peg – The dimensions are designed to be 2 mm x 0.4 mm; however, you should measure the dimensions with a caliper to check these values.

This lab is designed to give students experience with basic engineering design and provide students with the mechanical properties of 3D printed material, which can be used in design for later labs.

More information on this lab and other labs will be available soon in the form of a lab manual from South Dakota State University.

This simple connector was designed by students at SDSU for an experiment. The connector is designed to break at a specific compressive force to obtain the ultimate bearing/compressive strength of the 3D printed material. From our testing we found the average ultimate bearing/compressive strength of 3D printed PLA to be 34.3 MPa (5000 psi).

To calculate the ultimate bearing/compressive strength of the material the follow equation can be used:

B = P / A

Where:

P = the load at which the specimen broke

-The connector is designed to break between 2.8 kgs to 3.0 kgs or 6.2 to 6.6 lbs

A = area of failure surface = (Thickness of layer below block)*(perimeter)

-The failure surface for the bearing/compressive connector is the area at the bottom of the small peg – The dimensions are designed to be 2 mm x 0.4 mm; however, you should measure the dimensions with a caliper to check these values.

This lab is designed to give students experience with basic engineering design and provide students with the mechanical properties of 3D printed material, which can be used in design for later labs.

More information on this lab and other labs will be available soon in the form of a lab manual from South Dakota State University.

Similar models

thingiverse

free

Simple Connector Lab - Tensile Failure Test by SDstate_Civil_Engineering

...ore information on this lab and other labs will be available soon in the form of a lab manual from south dakota state university.

thingiverse

free

Simple Connector Lab - Shear Failure Test by SDstate_Civil_Engineering

...ore information on this lab and other labs will be available soon in the form of a lab manual from south dakota state university.

thingiverse

free

Project: Strength of Materials by insane66

...h break test and a compression strength break test. in this project we will do some material testing.https://youtu.be/4dgdbdbmbte

thingiverse

free

Prestressed Beam Lab - Mold and Rebar by SDstate_Civil_Engineering

...more information on this lab and other labs will be available soon in the form of a lab manual from south dakota state university

thingiverse

free

Truss Design Challenge Experiment - Group 2 by SDstate_Civil_Engineering

...a link to the handout in this description when it is complete, so you can perform this experiment yourself or with your students.

grabcad

free

Fatigue testing machine cover

...can be extremely dangerous because such a test is a destructive test. this cover is designed to act as a protector to the machine

grabcad

free

ALLGO crane

...both on the ground and on any other horizontal surface, for example, on the roof of the cargo module.

all inside the zip archive.

thingiverse

free

Truss Design Challenge Experiment - Group 3 by SDstate_Civil_Engineering

...a link to the handout in this description when it is complete, so you can perform this experiment yourself or with your students.

thingiverse

free

russ Design Challenge Experiment - Group 5 by SDstate_Civil_Engineering

...a link to the handout in this description when it is complete, so you can perform this experiment yourself or with your students.

grabcad

free

Universal Testing Machine

...is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.

Failure

3d_export

$60

morane saulnier ms-760 paris

...earlier proposed trainer aircraft, the ms.755 fleuret. following the failure of the french air force to select the fleuret,...

3d_export

$40

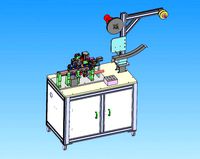

90 cam quick transplanting manipulator 12 models in total

...to 1s 2. no maintenance, reliable and durable, low failure rate, long-term stable operation 3. compact mechanism, simple debugging...

3d_export

$14

design of arc welding workstation with single robot and double fixture

...of single robot dual fixture arc welding workstation. the failure rate of the system is low. however, the robot...

3d_export

$40

hsp-ae series quick cam manipulator picking manipulator 12 specifications

...to 1s 2. no maintenance, reliable and durable, low failure rate, long-term stable operation 3. compact mechanism, simple debugging...

3d_export

$60

bell boeing v-22 osprey

...cruise performance of a turboprop aircraft. in 1980, the failure of operation eagle claw (during the iran hostage crisis),...

3d_export

$75

VT-4 Tank

...eventually proved to be unsuccessful, said to have high failure rate on the transmission system resulting in breakdowns during...

3d_export

$5

OLD RUSTY CAR

...decades of the 20th century also simply meant "a failurequot;.[9] other early terms for a wreck of a car...

3d_export

$250

3d drawings bom list for fully automated pocket packing machines

...and high efficiency.convenient operation and maintenance, stable performance, low failure rate and reliable operation.the pneumatic gripper device automatically bag,...

thingiverse

free

Failure Plaque by Anubis_

...failure plaque by anubis_

thingiverse

failure will never

overtake me if my

determination to

succeed is

strong enough.

thingiverse

free

Blobbed Failure by Tictorus

...blobbed failure by tictorus

thingiverse

fml

Civil

3d_export

$250

CIVIL AIRCRAFT

...civil aircraft

3dexport

turbosquid

$15

Roman civilization

... model roman civilization for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1545732)

turbosquid

$15

Roman civilization

... model roman civilization for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1545704)

turbosquid

$40

Civil Transport

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Civil man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Ancient Sheba civilization

...ent sheba civilization for download as 3ds, obj, dxf, and fbx on turbosquid: 3d models for games, architecture, videos. (1689945)

turbosquid

$150

Civil War Child

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$79

Civil War Cannon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

Loft civil interior

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

Civil Servants Bundle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Compression

turbosquid

$20

compresser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression Tap

...for download as blend, gltf, obj, stl, dae, fbx, wrl, and usd on turbosquid: 3d models for games, architecture, videos. (1650763)

turbosquid

$7

Compression reducing tee

...ty free 3d model compression reducing tee for download as max on turbosquid: 3d models for games, architecture, videos. (1540313)

3d_export

$5

Mustang Compressed blend

...mustang compressed blend

3dexport

turbosquid

$19

Compression hips trainer

... compression hips trainer for download as , fbx, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1684685)

turbosquid

$10

Compressed air station

...compressed air station for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1598414)

turbosquid

$35

Compressed-air Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Concrete Compression Tester

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression TAP worn

...for download as blend, usd, dae, gltf, fbx, obj, stl, and wrl on turbosquid: 3d models for games, architecture, videos. (1652641)

turbosquid

$49

Compressed Gas Cylinder and Regulator

...odel compressed gas cylinder and regulator for download as ma on turbosquid: 3d models for games, architecture, videos. (1170670)

Lab

3ddd

$1

Lab

...lab

3ddd

hkliving , lab

lab 13x13x17cm,

lab xl 36x36x32cm

3ddd

$1

Смеситель Lab

...смеситель lab

3ddd

barazza , lab

кухонный смеситель barazza;

модель lab.

3d_export

$5

Lab Tray

...lab tray

3dexport

lab tray 3d model that can be used in movies and games.<br>suitable for lab and hospital environments.

3ddd

$1

Lab Line

...lab line

3ddd

turbosquid

$149

Computer Lab

...squid

royalty free 3d model computer lab for download as lwo on turbosquid: 3d models for games, architecture, videos. (1676076)

turbosquid

$90

Crashed lab

...osquid

royalty free 3d model crashed lab for download as max on turbosquid: 3d models for games, architecture, videos. (1426371)

turbosquid

$5

Lab Table

...rbosquid

royalty free 3d model lab table for download as obj on turbosquid: 3d models for games, architecture, videos. (1703851)

turbosquid

$99

Kids Lab

...alty free 3d model kids lab for download as c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1699149)

turbosquid

$19

Lab Flask

...y free 3d model lab flask for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1245982)

turbosquid

free

Lab bench

...ree 3d model lab bench for download as jpg, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1472590)

Connector

turbosquid

$5

Connector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Connector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Connector 3D Model

...connector 3d model

3dexport

connector штекер 3d

connector 3d model manch111 83121 3dexport

3d_export

$14

connector production equipment

...connector production equipment

3dexport

connector production equipment

3d_export

$10

connector xt60

...e designing, and will help save your precious time. the scale of the model is 1:1. the dimensions are for reference in the image.

turbosquid

free

Audio connectors

...del audio connectors for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1424706)

3d_export

$20

car connectors dj70

...quot; connector 9-pin "dj7091a-2.8-11/21" terminal (male) "dj611-2.8" terminal (female) "dj622-2.8"

turbosquid

$30

Cinch connector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Jumper Connector

...umper connector for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1494917)

turbosquid

$15

RCA Connector

...l rca connector for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1376648)

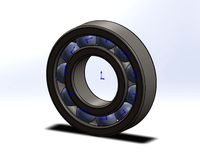

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Test

turbosquid

$99

test

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1251637)

turbosquid

$63

TEST

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1446233)

turbosquid

$1

test

...st

turbosquid

royalty free 3d model test for download as fbx on turbosquid: 3d models for games, architecture, videos. (1360941)

3d_export

free

johnny test

...johnny test

3dexport

johnny test 3d

turbosquid

$15

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

gripper test

...gripper test

3dexport

robot gripper test model

Simple

turbosquid

$1

Simple goblet (Taca simples)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

simple bench

...simple bench

3dexport

the simple bench which can be used in simple projects or video-games.

3d_export

$5

simple knob

...simple knob

3dexport

simple knob

3d_export

$5

simple handle

...simple handle

3dexport

simple handle

3d_export

$5

simple button

...simple button

3dexport

simple button

3d_export

$5

simple spindle

...simple spindle

3dexport

simple spindle

3d_export

$5

simple wheel

...simple wheel

3dexport

simple wheel

3d_export

$5

simple chair

...simple chair

3dexport

simple blue chair

3d_export

free

Simple room

...simple room

3dexport

here is a simple but beautiful room

3ddd

free

SIMPLE | Кресло

...io cianfarra , simple

производитель area declic дизайн giulio cianfarra коллекция simple

Engineering

3d_export

$5

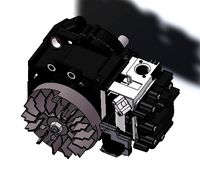

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

turbosquid

$1

ENGINE

...y free 3d model engine for download as max, 3ds, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1673703)