Thingiverse

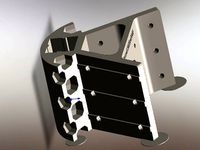

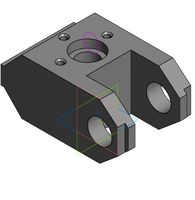

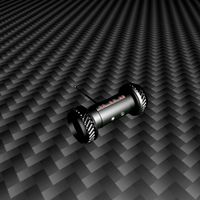

Simple adjustable slider clamp for He3D K200, K280 and similar kossel deltas by Nanocube

by Thingiverse

Last crawled date: 3 years, 1 month ago

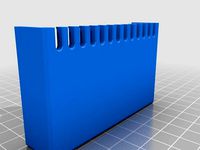

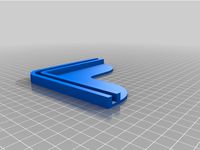

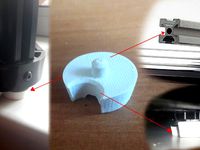

Replaces the stock injection moulded slider clamps of my He3D K280 kossel delta; the stock item is actually fine, but this version has a simple adjuster mechanism, and is sized for a 9mm belt upgrade I made.

Updated with 4 new Models (March 2020) - This is a updated design with thicker pin supports and 4mm more adjustment travel.

Models are provided for 40 and 42mm pins, plus 6 and 9mm belts: A stock K280 has 6mm belts and 40mm pins.

The stock He3D 4 roller carriage backplate design is actually quite good, and I think the 20x20mm spacing for the mount bolts is common to a whole bunch of Kossel designs.

Printing:

Use support for the pin arms and slider bracket. I originally printed these in PLA and they worked fine for a year, But I re-made them in PC-ABS (horrible material to print with, but very strong and stable) when I updated the design.

Fitting;

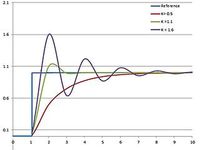

fit both pieces but only fully tighten the upper bolts, leave the lower loose enough so the slider can slide. Then fit the belt, making it tight'ish on the clamp. Finally tension the two pieces with a thumb and finger on the ends to a firm tension on the belt, don't go mad.. but it's OK to squeeze reasonably hard, the belt should thrumm like a double base when plucked.. Finally tighten the lower bolts while maintaining the tension; and after a few hours of printing and settling in it's a good idea to re-tighten and check everything.

Good:

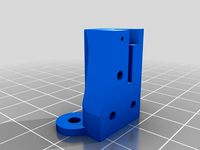

8mm of tensioning adjustment possible via slider, allowing final tension to be set after the belt is fitted.

Standard 4 mounting holes on 20x20 grid, uses original bolts

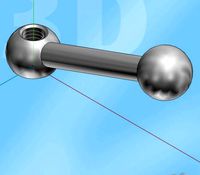

Arm pin width is 40mm; matching the stock k280 part, this is parameterized in the scadfile and I have also uploaded 42mm wide versions.

Up to 9mm belt, also parameterized, I have uploaded 6mm versions of the model, these are probably lighter; but not printed or tested

Extends to the top of the carriage plate to hit the standard K280 endstop

(is is important that you check this before the first homing move!)

IR blade cutout at the top, I, however, use it to mount a magnet and have magnetic reedswitch endstops.

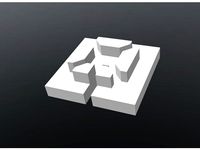

Simple and strong shell, none of the detail is random; there are elements of the wall layout etc designed to help the resultant print be strong where needed.

I tap the hols for the arm bolts, there is no nut recess, the hex-shaped hole will grip the original bolt very firmly and my experience of using an identical fitting on the effector end of the arms for the last few months has been good.

Arm clearance appears to be as good as, if not better than, the original

Ungood

The lower mount bolts really need a washer to allow you to tighten them enough, make sure it is 1mm or less in thickness or you may foul the belts.

Approx 5g heavier than the original, I think this isn't tooo bad considering this also has adjustment. ymmv.

The slider part will need support to print.I played with a supportless design but it was heavier and fouled the rods more easily.

Finally; The scad file is also there if you want to remix, laugh at my mistakes, etc. OpenScad 2016.11 or later is needed for the clamp to render properly.

Updated with 4 new Models (March 2020) - This is a updated design with thicker pin supports and 4mm more adjustment travel.

Models are provided for 40 and 42mm pins, plus 6 and 9mm belts: A stock K280 has 6mm belts and 40mm pins.

The stock He3D 4 roller carriage backplate design is actually quite good, and I think the 20x20mm spacing for the mount bolts is common to a whole bunch of Kossel designs.

Printing:

Use support for the pin arms and slider bracket. I originally printed these in PLA and they worked fine for a year, But I re-made them in PC-ABS (horrible material to print with, but very strong and stable) when I updated the design.

Fitting;

fit both pieces but only fully tighten the upper bolts, leave the lower loose enough so the slider can slide. Then fit the belt, making it tight'ish on the clamp. Finally tension the two pieces with a thumb and finger on the ends to a firm tension on the belt, don't go mad.. but it's OK to squeeze reasonably hard, the belt should thrumm like a double base when plucked.. Finally tighten the lower bolts while maintaining the tension; and after a few hours of printing and settling in it's a good idea to re-tighten and check everything.

Good:

8mm of tensioning adjustment possible via slider, allowing final tension to be set after the belt is fitted.

Standard 4 mounting holes on 20x20 grid, uses original bolts

Arm pin width is 40mm; matching the stock k280 part, this is parameterized in the scadfile and I have also uploaded 42mm wide versions.

Up to 9mm belt, also parameterized, I have uploaded 6mm versions of the model, these are probably lighter; but not printed or tested

Extends to the top of the carriage plate to hit the standard K280 endstop

(is is important that you check this before the first homing move!)

IR blade cutout at the top, I, however, use it to mount a magnet and have magnetic reedswitch endstops.

Simple and strong shell, none of the detail is random; there are elements of the wall layout etc designed to help the resultant print be strong where needed.

I tap the hols for the arm bolts, there is no nut recess, the hex-shaped hole will grip the original bolt very firmly and my experience of using an identical fitting on the effector end of the arms for the last few months has been good.

Arm clearance appears to be as good as, if not better than, the original

Ungood

The lower mount bolts really need a washer to allow you to tighten them enough, make sure it is 1mm or less in thickness or you may foul the belts.

Approx 5g heavier than the original, I think this isn't tooo bad considering this also has adjustment. ymmv.

The slider part will need support to print.I played with a supportless design but it was heavier and fouled the rods more easily.

Finally; The scad file is also there if you want to remix, laugh at my mistakes, etc. OpenScad 2016.11 or later is needed for the clamp to render properly.

Similar models

thingiverse

free

HE3D K280 Filament Mount

...he3d k280 filament mount

thingiverse

he3d k280 filament mount

thingiverse

free

HE3D K280 - K200 Basic Effector by christtian

...h makes arms perfecly parallel (it is not for the one in the box).

printed in pla or petg to have the good result (no abs at all)

thingiverse

free

Belt Lock (HE3D K280) by the3der

...giverse

frustrated that my belts would occasionally adjust themselves, i decided to make some locks to keep them in their slots.

thingiverse

free

Ender 3 X axis short belt tensioner (Stock Parts only)

...ioner bolt allows tightening of the bolt onto the bearings with no issue

-stronger bolt

-different bolt and case alignment method

grabcad

free

ShapeOko2 Belt Tensioners

...ension is 4mm hex m5 30mm long

the bolt for the clamp is a 2.5mm hex m3 14mm long

reverse side of clamp 2 locking hex 5mm m3 nuts

thingiverse

free

HE3D K280 PSU MOUNT

...he3d k280 psu mount

thingiverse

he3d k280 psu mount

designed to hold the power supply on the backside or where ever you choose.

thingiverse

free

Belt tensioner / tightener for 2020 delta / Kossel 3D printer

...lide carriage is not ideal. i designed for 6mm gt2 belt, inspired by atziano. belt tension can easily regulated by a knurled nut.

thingiverse

free

Armed Slider for Mini Kossel by bjbsquared

...us long enough for open or closed belts. these have not been used for printing yet but fit and belt alignment appears to be good.

thingiverse

free

X-axis belt clamp'n'tension by carbonoid84

...ting the belt is a bit awkward.

note 2: you may need to turn your x-axis limit switch to stop it catching on the tensioner block.

thingiverse

free

42mm Remix of Anycubic Kossel Linear Plus Carriage Tensioner by pfjason

...tifully to remove the echos i was seeing in the prints due to insufficient belt tension provided by the stock spring tensioners.

Nanocube

thingiverse

free

nanocube rgb hood by ejpsx

...nanocube rgb hood by ejpsx

thingiverse

nanocube rgb ledhood

thingiverse

free

Nanocube light hood by ejpsx

...nanocube light hood by ejpsx

thingiverse

nanocube led light hood

thingiverse

free

NanoCube 6 Aquarium Overflow by jdebriyn

...nanocube 6 aquarium overflow by jdebriyn

thingiverse

simply overflow for small nanocube 6 gal aquarium

thingiverse

free

nanoCUBE by varykap

...tar.

dimensiones 280x280x280

volumen 130x140x140

estructura openbeam

https://www.peakapic.com/

http://varykap.blogspot.com.es/

thingiverse

free

Aquarium Edge Cover (Dennerle Nanocube)

...rle nanocube 60l but should also fit on the other models of dennerle.

also suitable as bear seat :-d

freecad files are included.

thingiverse

free

Simple Key Rack by Nanocube

...imple key rack by nanocube

thingiverse

a simple key rack with 3d lettering.

prints easily with 10% infill and no support needed.

thingiverse

free

NanoCube Flow Diverter by CopabX

...s made for a filter head of .78" diameter and is made at .8" to compensate for the small amount of error during prints.

thingiverse

free

eenvoudig sleutelrek by Nanocube

...telrek

afdrukken met 10% vulling, geen ondersteuning.

de 'dikke' versie was een mk1, ik geef de voorkeur aan de slankere.

thingiverse

free

DC05-nFurminator by Nanocube

...very crudely) replaced the connector with a simple cylinder and tapered cone sized for the nozzle adapter on my dc05. works well.

thingiverse

free

Low Poly Sphere by Nanocube

...aximum rule).

might need a big brim and/or a raft if your bed level or adhesion is poor.

update: improved version with scad file!

K280

thingiverse

free

HE3D K280 Filament Mount

...he3d k280 filament mount

thingiverse

he3d k280 filament mount

thingiverse

free

he3d k280 bed level test

...he3d k280 bed level test

thingiverse

he3d k280 bed level test

thingiverse

free

HE3D K280 PSU MOUNT

...he3d k280 psu mount

thingiverse

he3d k280 psu mount

designed to hold the power supply on the backside or where ever you choose.

thingiverse

free

K280 FAN MOUNT by kissmuch

...k280 fan mount by kissmuch

thingiverse

it's fan-mount for delta 3d printer (k280)

24v dual fan mount

i think not bad

thingiverse

free

HE3D K280 equipment by AbsolutBeginner

...on: case for powersupply with switch, for use with the both holder.

switch-hole 11x30mm (www.kopp.eu ..... switch nr. 1928.1208.7

thingiverse

free

Hemera K280 Delta

...arly most so that i get the attribution of the model i remixed it from. i plan on trying to get it up and running by jan 7, 2020

thingiverse

free

HE3D K280 Bed Bracket by prahjister

...w.cnx-software.com/2017/12/06/he3d-k280-3d-printer-review-part-1-build-tweaks-and-first-prints/

use this article for instructions

thingiverse

free

Belt Lock (HE3D K280) by the3der

...giverse

frustrated that my belts would occasionally adjust themselves, i decided to make some locks to keep them in their slots.

thingiverse

free

he3d k200/k280 delta cooling fan mount by Curado

...ature fault

print on the long flat side with support enabled.

pla might work but abs is best.

see my other k200/k280 accessories!

thingiverse

free

He3D K280 Glass-bed Bracket by the3der

...lass down with masking tape. so i came up with some small brackets that fit every other hole around the bed and hold it in place.

K200

humster3d

$75

3D model of Kenworth K200 Tractor Truck 2010

...odel of kenworth k200 tractor truck 2010 in various file formats. all our 3d models were created maximally close to the original.

thingiverse

free

Keyboard foot for logitech k200 by agarajag

...keyboard foot for logitech k200 by agarajag

thingiverse

a replacement foot for keayboard logitech k200

thingiverse

free

for He3d K200 cool fan by he3d2016

...giverse

for he3d k200 cool fan, according to your own situation, adjust the nozzle height if it have to.

hope you will enjoy it!

thingiverse

free

he3d k200 Z sensor limit switch by Passion

...he3d k200 z sensor limit switch by passion

thingiverse

he3d k200 z sensor limit switch

thingiverse

free

Delta filament holder HE3D K200 by KassyARF

...r he3d k200 by kassyarf

thingiverse

filament holder optimized for the delta he3d k200-280 quick release or quick change printer.

thingiverse

free

HE3D K200 Layer 40mm Fan Duct by tERB0

...he3d k200 layer 40mm fan duct by terb0

thingiverse

this is a remix of e3d v6 layer fan duct to fit he3d k200 delta printer.

thingiverse

free

K200 Fan Duct by DeLan_Design

...chamber.

this modification boost the performance of the overall cooling system.

please rotate on x axis to print on right plane.

thingiverse

free

K200 Keyboard Foot Replacement by jmacdissi

...it works with the keyboard.

there is a possibility this works with more than just the k200 keyboard. i will work to confirm this.

thingiverse

free

Logitech K200 keyboard replacement foot by selectnone

... keyboard.

i designed this when one of mine snapped off.

the rubber pad from the broken part can be reused with this replacement.

thingiverse

free

He3D K200 delta printer cooling for 40 mm cooler by sharanchius

...he3d k200 delta printer cooling for 40 mm cooler by sharanchius

thingiverse

he3d k200 delta printer cooling for 40 mm cooler

He3D

thingiverse

free

HE3D K280 Filament Mount

...he3d k280 filament mount

thingiverse

he3d k280 filament mount

thingiverse

free

HE3D Mods by prahjister

...iverse

https://www.cnx-software.com/2018/02/03/he3d-k280-delta-3d-printer-review-part-2-upgrades-calibration-and-more-3d-prints/

thingiverse

free

he3d k280 bed level test

...he3d k280 bed level test

thingiverse

he3d k280 bed level test

thingiverse

free

Plate for endstop switch (He3D) by Gudini

...plate for endstop switch (he3d) by gudini

thingiverse

plate for endstop switch. for 3d printer he3d

thingiverse

free

HE3D K280 PSU MOUNT

...he3d k280 psu mount

thingiverse

he3d k280 psu mount

designed to hold the power supply on the backside or where ever you choose.

thingiverse

free

cool fan for HE3D EI3 dual by he3d2016

...cool fan for he3d ei3 dual by he3d2016

thingiverse

for he3d printer, cool fan & m12 sensor rack

thingiverse

free

HE3D MKS Faceplate 40mm Fan by ausfranko

...he3d mks faceplate 40mm fan by ausfranko

thingiverse

he3d faceplate for mks base 1.4 with 40mm fan mount

thingiverse

free

HE3D MKS Faceplate 50mm Fan by ausfranko

...he3d mks faceplate 50mm fan by ausfranko

thingiverse

he3d faceplate for mks base 1.4 with 50mm fan mount

thingiverse

free

Y Axis Front plates for HE3D by ausfranko

...y axis front plates for he3d by ausfranko

thingiverse

custom badged front axis plates for he3d 6mm thickness

thingiverse

free

for He3d K200 cool fan by he3d2016

...giverse

for he3d k200 cool fan, according to your own situation, adjust the nozzle height if it have to.

hope you will enjoy it!

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Slider

3d_export

$5

slider

...slider

3dexport

slider

3d_export

$5

Camera Slider

...camera slider

3dexport

camera slider toy

turbosquid

$10

SLIDER RAW

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Slider V1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Vitrocsa3001-Slider-Fixed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ЭКМИ-МЕБЕЛЬ / Регина-slider

...er

3ddd

угловой , экми-мебель

диван "регина-slider". производитель экми-мебель

3d_ocean

$12

Bolt Cutter (Xpresso Slider Controlled)

...are to use slider controller. you can see how to use slider in preview video. render system and materials are ready. c4d and o...

3ddd

free

Шкатулка-держатель для фотографий Slider

...рмы umbra. вмещает три фотографии размером 8 х 8 см, 10 х 10 см и 10 х 15 см.http://www.umbra.com/usd/slider-photo-dis

3d_ocean

$9

Seats with Automatic Adding Slider (Xpresso)

... / images and read description carefully before you buy. thanks. you need cinema 4d software to use slider controller or just ...

turbosquid

$15

Computer Camera Slider, closes and opens camera view

...der, closes and opens camera view for download as skp and stl on turbosquid: 3d models for games, architecture, videos. (1331206)

Deltas

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

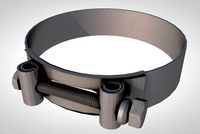

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

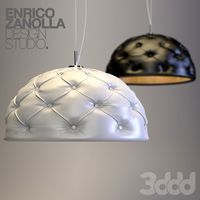

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Similar

3d_export

$20

sports car similar to a chevrolet

...sports car similar to a chevrolet

3dexport

a sports car similar to a chevrolet. high-poly and low-poly models

turbosquid

$10

2 Similar Cutlery Sets

...odel 2 similar cutlery sets for download as c4d, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1609168)

turbosquid

$49

Gun similar to Colt Peacemaker

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Gun similar to Jericho 941

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Gun similar to Colt 1911

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

The girl similar to Mandy 3D Model

...autiful sexy

the girl similar to mandy 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl iasha3d39286 103194 3dexport

3d_export

$10

coffee machine similar lavazza tiny

...commended for photorealistic rendering of domestic environments, the model is in real scale and has dimensions of 29.6x11xh 25 cm

turbosquid

$49

Gun similar to Desert Eagle .44 Magnum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

The girl similar to Mandy

...real-world scale and is centered at 0,0,0.

objects, materials, textures use meaningful names.

mapping is only overlapping in hair

turbosquid

$35

Ground Surveillance Drone (Similar to Tom Clancy's Rainbow Six: Siege drone)

...om clancy's rainbow six: siege drone) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1341540)

Adjustable

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$1

Adjustable Wrench

...free 3d model adjustable wrench for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1446736)

turbosquid

$1

Adjustable Wrench

...y free 3d model adjustable wrench for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1379022)

3d_export

$5

Adjustable key

...adjustable key

3dexport

Simple

turbosquid

$1

Simple goblet (Taca simples)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

simple bench

...simple bench

3dexport

the simple bench which can be used in simple projects or video-games.

3d_export

$5

simple knob

...simple knob

3dexport

simple knob

3d_export

$5

simple handle

...simple handle

3dexport

simple handle

3d_export

$5

simple button

...simple button

3dexport

simple button

3d_export

$5

simple spindle

...simple spindle

3dexport

simple spindle

3d_export

$5

simple wheel

...simple wheel

3dexport

simple wheel

3d_export

$5

simple chair

...simple chair

3dexport

simple blue chair

3d_export

free

Simple room

...simple room

3dexport

here is a simple but beautiful room

3ddd

free

SIMPLE | Кресло

...io cianfarra , simple

производитель area declic дизайн giulio cianfarra коллекция simple