Thingiverse

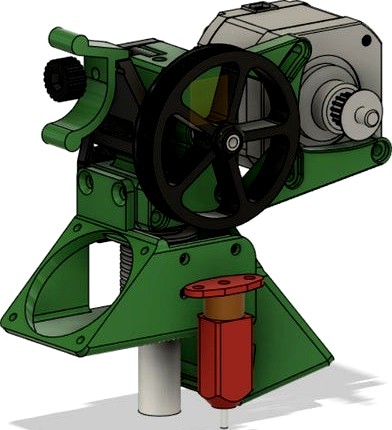

SILVIUS extruder: Belted 1:5 BMG dual gear by Baltojikale

by Thingiverse

Last crawled date: 3 years ago

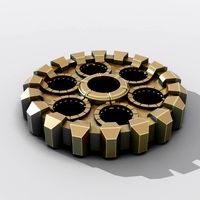

SILVIUS extruder: Belted with 1:5 reduction and BMG dual gear.

https://discord.gg/nKkq2rkG for discussion and suggestion on upgrades.

I was inspired by direct drive extruders like Orbiter, fliexishaft remote extruders and Voron M4. Though had personal view on all listed extruders:

Orbiter: Small gears not printable with standard 0.4mm nozzles, even though I have resin printer did not wanted to print as resin is somehow brittle.

Flexshaft remote direct drive extruder (thing:4009262): Have printed and used (1:10 ratio) gearbox until worm gear worn out. Too high reduction (1:10 or 1:30) as worm gears works with high friction. Prolonged printing times as extruder retraction speed, acceleration speed and max speed has to be much slower. Also did not like sound of flex shaft during retractions.

Voron M4: Design on paper looks quite heavy. Very nice design but look over engineered. Odd belt size.

What inspired in those named extruder:

Orbiter – lightweight extruder without motor ~60g. Moderate reduction 1:7 (

Remote direct drive flex shaft – simple lock mechanism, and small footprint.

Voron M4 – 3 plate design (back plate, midsection and face plate), as it easy to print.

Requirements: Direct drive, Light weight, easy to print, moderate reduction, pancake motors (nema 14/ nema 17), BMG dual gears, micro bearing, mounting holes for horizontal or vertical attachment, simple and light lock mechanism, E3D V6 heat break mounting hole.

Few requirements ware dictated by the parts I had at the moment (namely Triangle labs volcano clone). So came up with this design after third iteration:

Features:

-1:5 reduction. 16t vs 80t pulley system wired with 200mm gt2 belt

-BMG dual gear filament griping system

-Light weigh: extruder with nema17 pancake stepper weights 196 g (while stepper with wires weights 129.5g). So using nema 14 extruder weight should be like Orbiters (140g).

GT2 80t gear is easily printable. whole design easily printable.

Satisfying filament locking system

Easily adaptable for mounting to various printers as only one part should be edited (back plate)

Easily adaptable to nema 14 or 17 motors as only face plate should be chosen

-Can be made into vertical or horizontal motor mounting position.

Disadvantages: Design could use more refinement: filament guide to hot end from BMG gears, 80t pulley fixing to shaft works well but don’t like looks of wood screw, quite large footprint of pulley system.

Hardware:

1x set of BMG style filament dual gears (8mm)

1x set of E3D style hot end

1x gt2 200x6 mm belt

1x 16t gt2 pulley

1x nema14 or 17

1x 4x2 PTFE tube ~50mm

2x MR95zz bearings (5x9x3)

1x 50x 5 mm round aluminum tube for shaft

3x round headed M3 x 30 mm screws (Philips)

3x round headed M3 x 6 mm screws (Philips)

1x round headed M3 x 40 mm screw (Philips)

7x M3 x 4mm heat set inserts

1x 20x5 or 20x6 mm spring

1x M3 nut

2x M3 washers

1x wood screw (12-16 mm length, 2.5 mm OD (threads included))

1x 22x3 mm rod/ pin or M3 screw

Tools:

2 and 3 mm drill bits and Cordless drill;

Solder iron with tip for a heat set inserts;

Files and sand paper (optional to clean up prints).

Assembly:

Most of the assembly is straight forward. Only heat set inserts and extruder shaft require additional attention. Shaft requires one small hole/ indentation for BMG set screw and one pass through hole which is needed for key of 80T gt2 pulley. Spacing between holes approx. 28 mm. Spacers go on shaft. Other than that may some cleanup of 3d printed parts require as sanding or hole cleanup with 3 mm drill bit.

Printing:

Some parts require small supports (mid plate, fan ducts). Other than that 0.2 - 0.3 resolution is enough.

Print quality using Silvius extruder:

first print layer consistency. 60mm/s, 0.2 mm layer height. no additional calibration. Due to 1:5 reduction extruder is capable of high extrusion rates (only simple extrusion test was performed)

Heat dissipation systems:

As this post is about extruder not about fan system I chose to go with simple 40x40x20 24v fans. Locally Sunon brand fans are quite available thus fan duct system was adapted for them. Suggestion to uses whatever you like or you have. I went with those as they were available and runs quite at 21 dBa. Current extruder design involves 4 mounting holes for fan systems also back plate or front plate can be expanded to accommodate any fan duct systems. E3D style fan which was included in triangle labs volcano hot end clone kit was not used as it was louder. Thus designed that “monstrosity” which is present in photos.

https://discord.gg/nKkq2rkG for discussion and suggestion on upgrades.

I was inspired by direct drive extruders like Orbiter, fliexishaft remote extruders and Voron M4. Though had personal view on all listed extruders:

Orbiter: Small gears not printable with standard 0.4mm nozzles, even though I have resin printer did not wanted to print as resin is somehow brittle.

Flexshaft remote direct drive extruder (thing:4009262): Have printed and used (1:10 ratio) gearbox until worm gear worn out. Too high reduction (1:10 or 1:30) as worm gears works with high friction. Prolonged printing times as extruder retraction speed, acceleration speed and max speed has to be much slower. Also did not like sound of flex shaft during retractions.

Voron M4: Design on paper looks quite heavy. Very nice design but look over engineered. Odd belt size.

What inspired in those named extruder:

Orbiter – lightweight extruder without motor ~60g. Moderate reduction 1:7 (

Remote direct drive flex shaft – simple lock mechanism, and small footprint.

Voron M4 – 3 plate design (back plate, midsection and face plate), as it easy to print.

Requirements: Direct drive, Light weight, easy to print, moderate reduction, pancake motors (nema 14/ nema 17), BMG dual gears, micro bearing, mounting holes for horizontal or vertical attachment, simple and light lock mechanism, E3D V6 heat break mounting hole.

Few requirements ware dictated by the parts I had at the moment (namely Triangle labs volcano clone). So came up with this design after third iteration:

Features:

-1:5 reduction. 16t vs 80t pulley system wired with 200mm gt2 belt

-BMG dual gear filament griping system

-Light weigh: extruder with nema17 pancake stepper weights 196 g (while stepper with wires weights 129.5g). So using nema 14 extruder weight should be like Orbiters (140g).

GT2 80t gear is easily printable. whole design easily printable.

Satisfying filament locking system

Easily adaptable for mounting to various printers as only one part should be edited (back plate)

Easily adaptable to nema 14 or 17 motors as only face plate should be chosen

-Can be made into vertical or horizontal motor mounting position.

Disadvantages: Design could use more refinement: filament guide to hot end from BMG gears, 80t pulley fixing to shaft works well but don’t like looks of wood screw, quite large footprint of pulley system.

Hardware:

1x set of BMG style filament dual gears (8mm)

1x set of E3D style hot end

1x gt2 200x6 mm belt

1x 16t gt2 pulley

1x nema14 or 17

1x 4x2 PTFE tube ~50mm

2x MR95zz bearings (5x9x3)

1x 50x 5 mm round aluminum tube for shaft

3x round headed M3 x 30 mm screws (Philips)

3x round headed M3 x 6 mm screws (Philips)

1x round headed M3 x 40 mm screw (Philips)

7x M3 x 4mm heat set inserts

1x 20x5 or 20x6 mm spring

1x M3 nut

2x M3 washers

1x wood screw (12-16 mm length, 2.5 mm OD (threads included))

1x 22x3 mm rod/ pin or M3 screw

Tools:

2 and 3 mm drill bits and Cordless drill;

Solder iron with tip for a heat set inserts;

Files and sand paper (optional to clean up prints).

Assembly:

Most of the assembly is straight forward. Only heat set inserts and extruder shaft require additional attention. Shaft requires one small hole/ indentation for BMG set screw and one pass through hole which is needed for key of 80T gt2 pulley. Spacing between holes approx. 28 mm. Spacers go on shaft. Other than that may some cleanup of 3d printed parts require as sanding or hole cleanup with 3 mm drill bit.

Printing:

Some parts require small supports (mid plate, fan ducts). Other than that 0.2 - 0.3 resolution is enough.

Print quality using Silvius extruder:

first print layer consistency. 60mm/s, 0.2 mm layer height. no additional calibration. Due to 1:5 reduction extruder is capable of high extrusion rates (only simple extrusion test was performed)

Heat dissipation systems:

As this post is about extruder not about fan system I chose to go with simple 40x40x20 24v fans. Locally Sunon brand fans are quite available thus fan duct system was adapted for them. Suggestion to uses whatever you like or you have. I went with those as they were available and runs quite at 21 dBa. Current extruder design involves 4 mounting holes for fan systems also back plate or front plate can be expanded to accommodate any fan duct systems. E3D style fan which was included in triangle labs volcano hot end clone kit was not used as it was louder. Thus designed that “monstrosity” which is present in photos.

Similar models

thingiverse

free

Nema 17 belted reduction gear by D14

...earance for bolt and bearing to sit tighter. so, you need to adjust them.

links:

gt2-80t http://www.thingiverse.com/thing:1812138

thingiverse

free

NEMA17 Universal Belted 2:1 Reduction Drive by mildw4ve

...rews

2x m3x25 socket hex screws

4x m3x25 or longer socket hex screws for mounting the top plate and anything that might be on it.

grabcad

free

GT2 80T 5mm Bore Pulley for 6mm Belt

...5mm bore pulley for 6mm belt

grabcad

gt2 80t 5mm bore pulley for 6mm belt with set screw holes.

includes step and sldprt files.

grabcad

free

GT2 80T 8mm Bore Pulley for 10mm Belt

...mm bore pulley for 10mm belt

grabcad

gt2 80t 8mm bore pulley for 10mm belt with set screw hole.

includes step and sldprt files.

grabcad

free

GT2 80T 8mm Bore Pulley for 6mm Belt

...bore pulley for 6mm belt

grabcad

80t 8mm bore pulley for 6mm belt with set screw holes.

included are the step and sldprt files.

thingiverse

free

UM reduced extruder for 3.0mm filament by EazyBreezy

... bearing 3x10x4

2x - 625 bearings 5x16x5

5x - m3 nuts

5x - m3x30 screws

1x - m3x12 screw

1x - little spring to the clamp filament

grabcad

free

Voron 80T 5mm Bore Pulley

...voron 80t 5mm bore pulley

grabcad

80t 5mm bore pulley for voron with set screw holes.

included are step and sldprt files.

thingiverse

free

backlash free gearbox for nema 17 stepper motor by hamid8Sadra

...(or cnc) for 2mm iron bracket (or plexiglass)

video in youtube channel "learn,make,forget"https://youtu.be/mpu_jl-h0qi

thingiverse

free

Belt Reduction Drive direct extruder stock Ender Eplate by NDCSR

...assortment

1x extruder spring (optional)https://tinyurl.com/extruder-spring

4x 625zz bearingshttps://tinyurl.com/625zz-bearing

thingiverse

free

Pulley 20 mm for gt2 by Anything_3D

...pulley 20 mm for gt2 by anything_3d

thingiverse

this is a simple gt2 belt pulley. the m3 screw was used as the axis.

Baltojikale

thingiverse

free

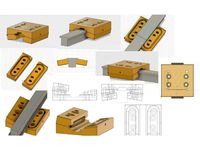

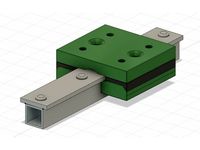

3DP linear bearing (recirculating) and DIY linear rail 6mm bb by Baltojikale

...as reference only. too much wrong operations.

https://www.thingiverse.com/thing:4662854

https://www.thingiverse.com/thing:4671314

thingiverse

free

Neopixel progress bar CURA plugin for klipper by Baltojikale

...ted in voron standarts: 4 perimeters, 5 tops and bottoms and 40 infill. ( for thin parts likethese it unintentionaly becomes 100%

thingiverse

free

3DP linear bearing (recirculating) and DIY linear rail V2 (old version) by Baltojikale

...s as elephant foot.

current design could be aplicable in 3d printers.

also working on 6 mm bb version. posible cnc aplications.

thingiverse

free

3DP linear bearing (recirculating) and DIY linear rail (old version) by Baltojikale

...ounting mechanism thus one cannot over tighten mounting screw as they can possible deform part and interfere with bb circulation.

thingiverse

free

3DP linear bearing (recirculating) and DIY linear rail 4.5mm bb (Final version) by Baltojikale

...e/ryh3psujley

further development

application in cnc project. currently working on test model of corexy laser cnc. still testing.

Silvius

thingiverse

free

Silviu by paul1891

...silviu by paul1891

thingiverse

basically silviu (0>0)

thingiverse

free

Unveiling Gift Box by Silviu-Stefan

...g for a cool gift box, check this out!

when you pull the drawer, the upper part slides back into the case, unveiling the content.

thingiverse

free

Ultimaker handle by Silvius

...m not responsible for any damage (falling um's) caused by using this!

use handle_straight if you want a straight bottom edge.

thingiverse

free

Ultimaker heavy-duty handle by jwags55

...handle by jwags55 thingiverse i modified the ultihandle by silvius increased thickness by 5 mm (now 20 mm). reduced...

thingiverse

free

Handle "Ultimaker Style" without text

...mount on the i3m, and the "ultimaker handle" by silvius was great. but i didn't like the "ultimaker" text...

thingiverse

free

Rangement pour télécommandes by Ecologeek

...eanu from www.flaticon.com is licensed by cc 3.0 by

icons made by webalys freebies from www.flaticon.com is licensed by cc 3.0 by

grabcad

free

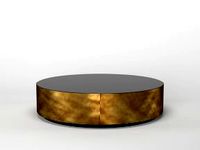

COFFEE TABLE SET Silviu Silion

...coffee table set silviu silion

grabcad

this nodel is dedicated to my dear friend silviu silion

c4d 3dsmax dwg stl obj

cg_trader

$8

Bernhardt Silvius Round Cocktail Table

...d cocktail table

wooden table base with glass top

overall dimensions

h: 16-5/8 in

diameter: 48 in

h: 42.23 cm

diameter: 121.92 cm

grabcad

free

Face Mask with Cotton Pads v2

... cotton pads v2

grabcad

this is a 3d printable face mask.

i use cotton pads as a filter and used the mask shape of silviu stroe.

Bmg

turbosquid

$3

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

50 BMG Cartridge

...e 3d model 50 bmg cartridge for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1303035)

turbosquid

$30

Sniper 50 bmg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cal 50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$25

.50 BMG Cartridge3d model

...odel

cgstudio

.3ds .max .obj .wrl - .50 bmg cartridge 3d model, royalty free license available, instant download after purchase.

3d_export

$5

50 caliber BMG round 3D Model

...d 3d model

3dexport

50cal caliber 50 round bullet bmg cartridge browning rifle

50 caliber bmg round 3d model csw92 27660 3dexport

3d_export

$22

.50 BMG Cartridge 3D Model

...ectile rifle round pistol cartridge m2 hb 127x99mm nato browning barrett m82a1

.50 bmg cartridge 3d model plutonius 8091 3dexport

turbosquid

free

LAR Grizzly .50 BMG Sniper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

cartrige m50 bmg

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Belted

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Square

...belt square

designconnected

meridiani belt square computer generated 3d model. designed by parisio, andrea.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

3d_export

$13

extruded table

...ed to give you the highest possible quality for up to 4k renders. there is no post-production used on any of the renders you see.

3d_export

$13

extruded chair

...for high-quality render results. no extra plugins are required for this model. lights and cameras are not included in the scenes.

3d_export

$13

extruded table 2

...for high-quality render results. no extra plugins are required for this model. lights and cameras are not included in the scenes.

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

5

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.

3d_ocean

$9

chanel 5

...chanel 5

3docean

books chanel

quality models perfum chanel 5 and books.

1

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

turbosquid

$50

door 1 darkwood 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.