Thingiverse

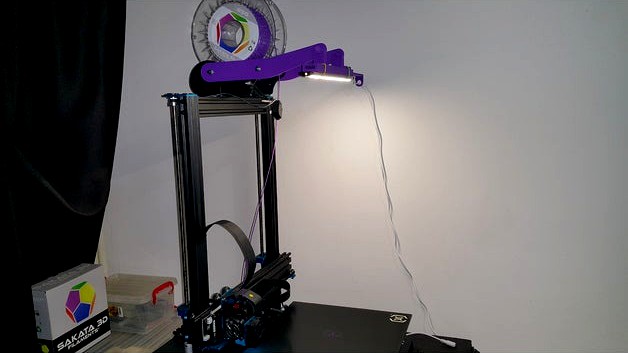

Sidewinder X1 Spool Holder And LED Stick Support

by Thingiverse

Last crawled date: 4 years, 2 months ago

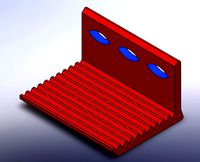

I created this spool holder for the obvious reason to not move the printer's stock holder every time I change the filament from a different brand and the LED stick support was just an additional idea when I saw 2 unused holes in the stock spool holder.

I made these little things with Fusion 360 (beautiful thing by the way) with a level of knowledge in 3D design around zero and keeping in mind that I have that printer just from 5 weeks ago.

The tubes for spool holder are 20 mm in diameter and 100 mm long and they suppose to fit on the 14 mm bearings.Well,my printer printed the 20 mm diameter but the 14 mm,the inner diameter was just about 13.70 so I made another tube with 20 mm on the outside diameter and 14.32 on the inside diameter and it fits great,not tight not loose,the spool rolls nice.

For the "boomerang" like arms (LED light support and mirror LED light support) I used just 2 M5x30 mm screws and 2 M5 nuts for the front side (screw from outside,nut from inside) and for the back side on the unused holes I used the M5 screws and nuts (screw from inside,nut from outside,otherwise the spool will touch the screw) the printer had at the bearings.You can print both at a time or just one as you wish.

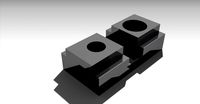

The T profile (250x30.5x15.5) I printed vertically with no raft,no support,just slow overnight.

The T connector has 0.5 mm clearance from T profile.

The wire holder 175 mm (50 mm profile and 125 mm long arm ending a lip with a 12 mm diameter hole) is the only piece printed with support,vertically cos I thought that is the way for less post-printing work and a functional/good looking piece.The same 0.5 clearance like the T connector,slides back and forth as you need.

The pin(s) connecting the arms and the T connectors are the "weak link" in all that design cos I wasn't able to make a M7 (the holes already printed about 7.7 mm in diameter)screw and nut to fit in Fusion 360 and print with 0.4 nozzle,so that remains a work-in-progress after I'll learn on YT how to make custom thread (coil).

The LED stick lamp is hanged with rubber band,I could use zip tie,not elegant at all I know that but patience is not my thing you know ( I want it all and I want it now).

So that being said,take it,enhance it,use it if you like,comment about it...etc.

Live long and prosper.

I made these little things with Fusion 360 (beautiful thing by the way) with a level of knowledge in 3D design around zero and keeping in mind that I have that printer just from 5 weeks ago.

The tubes for spool holder are 20 mm in diameter and 100 mm long and they suppose to fit on the 14 mm bearings.Well,my printer printed the 20 mm diameter but the 14 mm,the inner diameter was just about 13.70 so I made another tube with 20 mm on the outside diameter and 14.32 on the inside diameter and it fits great,not tight not loose,the spool rolls nice.

For the "boomerang" like arms (LED light support and mirror LED light support) I used just 2 M5x30 mm screws and 2 M5 nuts for the front side (screw from outside,nut from inside) and for the back side on the unused holes I used the M5 screws and nuts (screw from inside,nut from outside,otherwise the spool will touch the screw) the printer had at the bearings.You can print both at a time or just one as you wish.

The T profile (250x30.5x15.5) I printed vertically with no raft,no support,just slow overnight.

The T connector has 0.5 mm clearance from T profile.

The wire holder 175 mm (50 mm profile and 125 mm long arm ending a lip with a 12 mm diameter hole) is the only piece printed with support,vertically cos I thought that is the way for less post-printing work and a functional/good looking piece.The same 0.5 clearance like the T connector,slides back and forth as you need.

The pin(s) connecting the arms and the T connectors are the "weak link" in all that design cos I wasn't able to make a M7 (the holes already printed about 7.7 mm in diameter)screw and nut to fit in Fusion 360 and print with 0.4 nozzle,so that remains a work-in-progress after I'll learn on YT how to make custom thread (coil).

The LED stick lamp is hanged with rubber band,I could use zip tie,not elegant at all I know that but patience is not my thing you know ( I want it all and I want it now).

So that being said,take it,enhance it,use it if you like,comment about it...etc.

Live long and prosper.

Similar models

thingiverse

free

Spool Holder by protagonist

...just another spool holder for bearings of skateboards:

inside diameter: 8 mm

outside diameter: 22 mm

overall width: 7 mm

thingiverse

free

NeoPixel Stick Led Holder for 6mm T-Nut Profile by Wampo

... aluminium profiles. i used short m4 screw to mount it with the hammerheadscrews. stick holds with clip or double adheasive tape.

thingiverse

free

Wall mounted stick holder for filament spool by Shange

...le to attach the stick in place on the holder.

size: 20.0 x 45.0 x 20.9 mm

material used: 4 g

print time: 28 minutes with anet a6

thingiverse

free

Filament Roll holder 54mm / 52 (Herz filament) by 7eggert

...files should be the same as the obj files. i used the obj files for printing.

see also: https://www.thingiverse.com/thing:3335750

thingiverse

free

CR10 Spool shaft bushing update by Smamula

...e bushing. once the bushing is installed into roll it should spin freely on original tube with original retaining nut hand tight.

thingiverse

free

Spool Holder (4th try)

...ead of a point.

[[[ don't seem to be able to get the pictures right side up. ]]] fixed thanks to help from the community.

thingiverse

free

Filament Spool Holder for 2020 Aluminum by spool3d_canada

...be used anywhere there is a 2020 profile aluminium bar. just attach with m4 screws and t-nuts.

printer sold at http://spool3d.ca

thingiverse

free

filament spool holder by a69291954

... screws and nuts (for mounting the holder)

2x m3 12mm screws for the endcamp (these are designed for an inner diameter of 7.7mm)

thingiverse

free

Umpteenth Samla spool holder by mordr3d

...ww.thingiverse.com/thing:2198955 ).

the stick diameter is about 1.4cm

used some screw to mount the stick holder to the container.

thingiverse

free

Rostock Max V2 simple spool holder by niklaswik

...ameters.

using this part the spool turns smoothly, eliminating any "sticking and jerking" that the stock holder causes.

Sidewinder

turbosquid

$20

Missile sidewinder

...

royalty free 3d model missile sidewinder for download as obj on turbosquid: 3d models for games, architecture, videos. (1407825)

turbosquid

$10

Aim 9 Sidewinder

...del aim 9 sidewinder for download as blend, stl, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1639038)

turbosquid

$3

AIM_9B Sidewinder Missle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Sidewinder Submachine Gun

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

AIM-9 Sidewinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

AIM-9L-M SIDEWINDER

...royalty free 3d model aim-9l-m sidewinder for download as fbx on turbosquid: 3d models for games, architecture, videos. (1638522)

3d_export

$10

sidewinder missile

... height, rough, and metal.<br>https://stgbooks.blogspot.com/<br>please note: this may, or may not 3d print. untested.

humster3d

$75

3D model of Vetex Sidewinder ATX 3000 Forklift 2011

... vetex sidewinder atx 3000 forklift 2011 in various file formats. all our 3d models were created maximally close to the original.

cg_studio

$30

aim-9 missle3d model

...aim-9 missle3d model cgstudio military aim-9 aim sidewinder missle air usaf f-15 f-16 f-14 f-117 amraam bomb...

cg_studio

$29

Matra R550 Magic 23d model

...cgstudio matra r550 r.550 magic 2 ii missile air sidewinder jet military aircraft force navy europe .3ds .lwo .max...

X1

design_connected

$11

X1

...x1

designconnected

dränert x1 chairs computer generated 3d model. designed by oswald mathias ungers.

3ddd

$1

Leica X1

...leica x1

3ddd

leica , фотоаппарат

leica x1 profi

turbosquid

$15

sofa x1

...turbosquid

royalty free 3d model sofa x1 for download as max on turbosquid: 3d models for games, architecture, videos. (1283096)

3ddd

$1

Francis Francis X1

...francis francis x1

3ddd

кофемашина

кофемашина francis francis x1

3d_export

$5

X1 3D Model

...x1 3d model

3dexport

x1

x1 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 106035 3dexport

turbosquid

$55

Nokia X1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

Nokia X1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

X1 Airplane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$55

Nokia X1 3D Model

...nokia x1 3d model

3dexport

nokia x1 phone smartphone mobile

nokia x1 3d model fedia 45159 3dexport

3ddd

$1

Wood x1

...wood x1

3ddd

размер 1024-1024 бесшовная 8-)

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Stick

3d_ocean

$5

Deodorant Stick

...deodorant stick

3docean

deodorant stick

deodorant stick. product label included.

3ddd

$1

Stick Lamp

...stick lamp

3ddd

stick

stick бра

раз. 330*280*650mm

3d_ocean

$5

Usb Stick

...usb stick

3docean

flash stick usb usb memory usb stick

usb stick created using 3ds max 2015 and rendered on mental ray.

turbosquid

$29

Stick

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Stick

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Stick

...ee 3d model stick for download as 3ds, obj, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1443003)

3d_ocean

$6

USB Stick

...tick

3docean

32 gb flash ram gigabyte memory metal nand plug ram stick usb usb 3 usb stick

usb stick with texture and normal map.

3d_ocean

$5

USB Stick

...usb stick

3docean

32gb computer memory plug plugin protection usb usb stick

an usb stick with built-in plug protection

3d_export

$5

stick with leaf

...stick with leaf

3dexport

i made a stick or branch with an oak leaf on it.

3ddd

$1

F23 Stick

...f23 stick

3ddd

fabbian

http://www.fabbian.com/en/f23-stick-2#.vkobhfmswsr

86000 полигонов

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Support

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon