Thingiverse

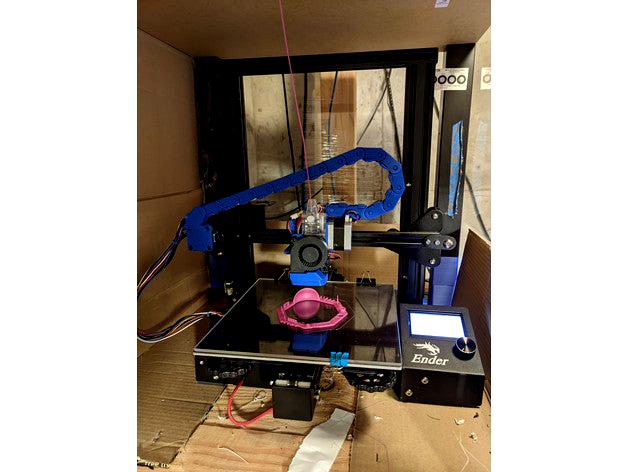

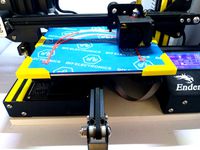

Shortest Filament Path Drive for Ender 3 + Bondtech Direct Drive + E3D V6 Gantry Toolhead Mount With Cable Drag Chains by darkpoet

by Thingiverse

Last crawled date: 2 years, 10 months ago

This is for tinkerers who have a junk box ideally. I may not have described exactly all the extra parts needed. Maybe someone who builds it can do a better job than I in the comments.

So, why? Well...

When I bought my first Bondtech geared direct drive (good quality clones run about $15US), I was like "wow" this thing fits right on top of my e3d v6 hotend (of which good clones run about $15US also). I won't need anything else. But every design added a chunk of PTFE tubing and the associated couplers, adding additional points of failure. When I found the parent of my design (see remixed from) I was thrilled. It just clamps on.

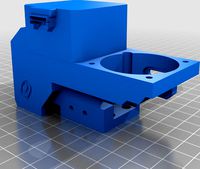

Brilliant! It tucks the hotend fan under the extruder motor, helping to cool that motor AND push the air harmlessly to the left without the same likelihood that it will draft onto the build plate that is evident in all other designs I've tried (and that's most of them). It sticks the part cooling fan out front where you can SEE it. And it uses a 5015 which will exceed your expectations for rapid printing/cooling power.

The reason for the remix is that I did want to use my own design of cable chain with it, so I modified that design. My cable chain design allows you to snap off the top to re-run a cable, so you don't have to disassemble the entire thing every time you need to change a cable. See my other designs for additional options there. You will almost certainly need to run new longer cables to your hotend to make this work. I recommend silicone, and everything that enters the cable chain onward should be silicone or ptfe stranded wire if you want it to never break down.

If your hotend is the bowden type (big gape on the top instead of just a hole for the filament), you will need to run a short length of PTFE between the point where it contacts the extruder and where it rests against the throat. If you haven't set up a V6 before, hit youtube, or you will likely find it confusing. The idea here is to have no point at which filament can wiggle out of its path while under high pressure.

You will lose about 1CM in the Y axis by using this as it is. That's because it pushes the nozzle contact point ahead about that far. Worth it. Do adjust your slicer and firmware as needed.

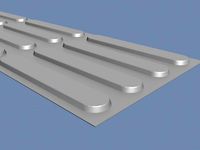

You DO need to print the 5mm spacers to run two of your M3 screws through. The plate of this does sit about 5mm off the x gantry plate of the Ender 3. The two screw holes that usually hold on the stock hotend should now have a few short rounded top M3 screws to hold this on. If your junk box lacks these, many cheap assortment boxes are out there. You also will need 4 M3x40 bolts for the receiver.

I'll add more as thoughts occur to me. Overall this is the most simple but brilliant design that meets my needs now that the drag chain has been added.

So, why? Well...

When I bought my first Bondtech geared direct drive (good quality clones run about $15US), I was like "wow" this thing fits right on top of my e3d v6 hotend (of which good clones run about $15US also). I won't need anything else. But every design added a chunk of PTFE tubing and the associated couplers, adding additional points of failure. When I found the parent of my design (see remixed from) I was thrilled. It just clamps on.

Brilliant! It tucks the hotend fan under the extruder motor, helping to cool that motor AND push the air harmlessly to the left without the same likelihood that it will draft onto the build plate that is evident in all other designs I've tried (and that's most of them). It sticks the part cooling fan out front where you can SEE it. And it uses a 5015 which will exceed your expectations for rapid printing/cooling power.

The reason for the remix is that I did want to use my own design of cable chain with it, so I modified that design. My cable chain design allows you to snap off the top to re-run a cable, so you don't have to disassemble the entire thing every time you need to change a cable. See my other designs for additional options there. You will almost certainly need to run new longer cables to your hotend to make this work. I recommend silicone, and everything that enters the cable chain onward should be silicone or ptfe stranded wire if you want it to never break down.

If your hotend is the bowden type (big gape on the top instead of just a hole for the filament), you will need to run a short length of PTFE between the point where it contacts the extruder and where it rests against the throat. If you haven't set up a V6 before, hit youtube, or you will likely find it confusing. The idea here is to have no point at which filament can wiggle out of its path while under high pressure.

You will lose about 1CM in the Y axis by using this as it is. That's because it pushes the nozzle contact point ahead about that far. Worth it. Do adjust your slicer and firmware as needed.

You DO need to print the 5mm spacers to run two of your M3 screws through. The plate of this does sit about 5mm off the x gantry plate of the Ender 3. The two screw holes that usually hold on the stock hotend should now have a few short rounded top M3 screws to hold this on. If your junk box lacks these, many cheap assortment boxes are out there. You also will need 4 M3x40 bolts for the receiver.

I'll add more as thoughts occur to me. Overall this is the most simple but brilliant design that meets my needs now that the drag chain has been added.

Similar models

thingiverse

free

Gantry Cover Cable chian side mount with filament guide by Suidog

...lament dryer so i can't run the filament from the top. this allows me to still have it on the side but in front of the rail.

thingiverse

free

MakerGear M2 E3D v6 Filament drive by cmenard

...rsilvers e3d v5 filament drive. provisions have been made for the ptfe tube and bowden connector on the 1.75mm universal hotend.

thingiverse

free

TronXY X5SA Direct Drive Mount for Stock Extruder by Dropwire

...ounting and attachments, and print settings for slicing the parts.

this is my first design on thingiverse, hope it helps you out.

thingiverse

free

Anet A8 Direct Drive E3D v6/lite cable chain adapter. by ggppjj

...e different parts in tinkercad and here we are. you need 30 or so chain parts, and two m4 x20 screws to mount it to the carriage.

thingiverse

free

Bondtech BMG extruder mount for C-Bot by AK_Eric

...bottom, with a bowden tube in-between. this was most similar to my original setup. frontplatealt : this is designed...

thingiverse

free

BMG Bondtech e3D v6 Hevo Hypercube Hotend Mount Extruder direct drive

...se

i remixed the hotend mount to have a bmg as a direct drive and the extruder screw isnt crashing the extrusion on the front ;)

thingiverse

free

5015 Cooler for Bondtech BMG + Stock Style Hotend Direct Drive

...tch.

i didn't much like the cooler included (prusa style i think?) so modded my old design to give more wrap around cooling.

thingiverse

free

M2 Dual Extruder for M2 and E3D by Xezerk

...goes over some details.https://youtu.be/qaheea26nsm

i have a single hotend version here http://www.thingiverse.com/thing:824655

thingiverse

free

Direct Drive BMG Anycubic i3 Mega

...

thingiverse

bondtech direct drive for anycubic i3 mega. include bltouch holder (optimized for v6 hotend), pcb and chain holder.

thingiverse

free

Ender 3 Cable Chain Gantry Mount by TTalkington

...rate a bit.

the first chain link is backwards from the rest of the chain, this is so that portion doesn't bend as sharply up.

Darkpoet

thingiverse

free

Waterfall Showerhead for Lower Pressure by darkpoet

...ure situations, and i also removed some of the lower non-threaded portion of the stem to more easily fit more curved faucet taps.

thingiverse

free

8x10 Mobius Photo Picture Frame For Big Printers by darkpoet

...es down if you're unsure.

only will fit on a 300mm wide bed as-is, though you can certainly scale it in your slicer for less.

thingiverse

free

Reinforced Bondtech BMG V6 Mount For Ender 3 / CR10 by darkpoet

...ence.

it can print fine as-is without supports if your cooling is good enough but i suggest using tree supports for best results.

thingiverse

free

Heavy Duty Cable Drag Chain Snap Top Openable with Voron Logo by darkpoet

... i can no longer find it to link back and give credit where credit is due. if you find it please post a comment so i can do that.

thingiverse

free

Ender 3 Front Side Cable Chain Mounts for Hydra Fan and Hotend Mount by darkpoet

... want to reuse their stock screws. apparently it can be hot-glued to the right spot, though i would hesitate to do so personally.

thingiverse

free

CR-10 Ender 3 (pro/normal) Blower Hotend Assembly With Light Shield (petsfang bullseye alternative) by darkpoet

...ing the abs part a brief acetone bath to strengthen it up, particularly if you use low infill, which i recommend. (20% should do)

Toolhead

thingiverse

free

FLUX TOOLHEAD by yaoalen

...flux toolhead by yaoalen

thingiverse

you can put toolhead hear

thingiverse

free

RL550B toolhead by xxbombamanxx

...rl550b toolhead by xxbombamanxx

thingiverse

toolhead for dillon rl 550 b.

thingiverse

free

Olmec Toolhead by 3DPrinthings

...erse

olmec toolhead holds small tools like screwdrivers and hex keys ...

printed with matteforge filament (www.3dprinthings.eu).

thingiverse

free

Dillon 550 Toolhead Stand by RPR308

...dillon 550 toolhead stand by rpr308

thingiverse

toolhead stand for dillon 550

thingiverse

free

FLUX Toolheads BOX by wyp8711

...8711

thingiverse

flux delta+ toolheads box

※uploaded files are optimized

flux tools box:http://www.thingiverse.com/thing:2282697

thingiverse

free

Simple and Double Dillon XL 650 Toolhead stand

...ble stand for dillon xl 650 toolhead.

simple toolhead stand is 100mm x 120mm x 30mm

double toolhead stand is 200mm x 120mm x 30mm

thingiverse

free

Snapmaker 2 Toolhead Holder by gatonero

...r snapmaker 2. i designed it in freecad. it works with snapmaker 2.0 quick tool changer https://www.thingiverse.com/thing:4700986

thingiverse

free

Lulzbot TAZ 5 Sharpie/Pen Toolhead by wrvn97

...lulzbot taz 5 sharpie/pen toolhead by wrvn97

thingiverse

toolhead for holding writing utensils on a taz 5.

thingiverse

free

Creality E3D V6 Toolhead

...ns are compatable with bltouch.

to be honest i made this a while ago so i'm not entirely sure whats required on installation.

thingiverse

free

Snapmaker 2.0 ToolHead holder by JH1616

...ng downwards. wich leads to laser lense are not getting dirty / dusty. and you can leave the filament in when changing toolheads.

Shortest

3d_export

$5

Frigidaire aappliance microwave and oven

...closed doors, you will get the result in the shortest possible...

thingiverse

free

Brachistocrone by roytotten

...a model of a brachistochrone curve/track. it shows the shortest route from point a to point...

artstation

$1

Calendary 3D

...available so you can develop your projects in the shortest possible...

thingiverse

free

Abstract Pencil Holder by MooreDesigns

...pencils 2.5in by 2.5in base tallest point is 4in shortest point is...

artstation

$5

Plastic Container with Lid

...available so you can develop your projects in the shortest possible...

artstation

$5

Battery 3D Object Charging

...available so you can develop your projects in the shortest possible...

artstation

$5

Mail Box 3D Object

...available so you can develop your projects in the shortest possible...

thingiverse

free

Cable pipe holder ender 6 by jan141282

...so the tube to the hotend can take the shortest way to the...

artstation

$5

Basketball Object 3D

...available so you can develop your projects in the shortest possible time. #blender...

thingiverse

free

Brachistochrone Curve Demonstration by Taimoor98

...gravitational field to a given end point in the shortest ...

Bondtech

thingiverse

free

x5s bondtech

...x5s bondtech

thingiverse

this allow using a bondtech dual drive on x5s machines

thingiverse

free

Bondtech mount by Nicoande99

...bondtech mount by nicoande99

thingiverse

custom bondtech mount for my velleman k8200 3d printer.

thingiverse

free

Trex2+ Bondtech adpter by fong504

...trex2+ bondtech adpter by fong504

thingiverse

bondtech makerbot 2 clone adapter for the trex2+.

thingiverse

free

Bondtech PTFE tube Holder

...bondtech ptfe tube holder

thingiverse

adjusted a bit to fit my bondtech clone.

thingiverse

free

Bondtech DDX by sebbzor

...of the ddx incase you want to build adapters for it. original stepfile can be found on bondtechs website, all credits go to them.

thingiverse

free

Support BONDTECH Anet_A8 By SergioFPV by SergioFPV

...support bondtech anet_a8 by sergiofpv by sergiofpv

thingiverse

support bondtech anet_a8

thingiverse

free

CR-10S-Bondtech-Mosquito_Mount_Bl_Touch by enoblk

...cr-10s-bondtech-mosquito_mount_bl_touch by enoblk

thingiverse

cr-10s-bondtech-mosquitomount-_bl_touch

thingiverse

free

Bondtech Flying mount by Yakandu

...du

thingiverse

lightweight flying extruder mount for the bondtech bmg with design centred around filament path.

this is a remix.

thingiverse

free

Bondtech Oiler by bamhm182

...t a piece of sponge and put it in the hole. oil it up and you're good to go! been using it for a few months with no problems.

thingiverse

free

RatRig V-Core Pro Bondtech Carriage (Prusa MK3S Bondtech Extruder)

...dtech can be mounted 1:1 :)

i have the mk3s with bondtech and mosquito magnum. i'll try out if my ratrig arrives...

have fun!

Gantry

turbosquid

$349

Gantry crane

...alty free 3d model gantry crane for download as ige and sldas on turbosquid: 3d models for games, architecture, videos. (1476278)

3d_export

free

firestone advertising gantry

...rs premises and<br>these advertisement gantries, were very popular in the 30-70's at grand prix races advertising tyres

turbosquid

$30

Derelict Launch Gantry

...alty free 3d model derelict launch gantry for download as fbx on turbosquid: 3d models for games, architecture, videos. (1669952)

turbosquid

$129

Gantry Crane RTG

...e 3d model gantry crane rtg for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1491933)

turbosquid

$120

Gantry stacker Assembly

...try stacker assembly for download as sldas, fbx, 3ds, and ige on turbosquid: 3d models for games, architecture, videos. (1648516)

turbosquid

$19

Train Signals Gantry

...l train signals gantry for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1462242)

turbosquid

$5

STS Gantry Crane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$160

Bulk carrier with gantry crane

...carrier with gantry crane for download as lwo, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1285258)

3d_export

$50

RMG Gantry Crane 3D Model

...t hoist rail rubber tyre tire rtg eot beam portal heigh tonne shipyard port

rmg gantry crane 3d model 5starsmodels 42860 3dexport

3d_export

$29

gantry crane

...istic model that will enhance the detail and realism of any of your rendering projects.<br>file formats: max, obj, fbx, 3ds

Drag

turbosquid

$30

Drag Pack Centerline Auto Drag Wheels

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Drag Pack Centerline Auto Drag Wheels

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Drag Car

...r

turbosquid

royalty free 3d model drag car for download as on turbosquid: 3d models for games, architecture, videos. (1613195)

turbosquid

free

drag strip

...free 3d model drag strip for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1486232)

turbosquid

$8

drag bike.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Raven drag red

...uid

royalty free 3d model raven drag red for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486830)

turbosquid

$199

Pro Stock Drag Car

...y free 3d model pro stock drag car for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1341240)

turbosquid

$38

BFGoodrich Auto Drag Combo

...l bfgoodrich auto drag combo for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1457166)

turbosquid

$199

Funny Car Drag Car

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Centerline Auto Drag Wheels

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Path

3d_export

$3

path in wood

...path in wood

3dexport

path

3d_export

$5

Stone Path

...export

stone path stylized stone path texture painted in blender game asset tested in unity low poly polygons-1513 vertices-1588

turbosquid

$80

path finder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

wild path

...wild path

3dexport

simple rendering of the scene file

3d_ocean

$6

Ground. Gravel path.

...d textures. in this case, the texture of gravel paths. there are three maps in this archive: 1. 5000×5000 ground texture for c...

turbosquid

$3

Walk Path With Grasses

...alty free 3d model walk path with grasses for download as max on turbosquid: 3d models for games, architecture, videos. (1663041)

turbosquid

$10

Path Bross barstool

...free 3d model path bross barstool for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1493360)

3d_export

$25

Cobblestone Path 3D Model

...t

cobblestone stone path rock brick element pavement street lump road roading

cobblestone path 3d model polypower 52120 3dexport

turbosquid

$4

Naruto Six Path

... model naruto six path for download as c4d, c4d, c4d, and c4d on turbosquid: 3d models for games, architecture, videos. (1627248)

3ddd

free

Profoffice / path

...d

profoffice , sitland

в архиве файлы мах, fbx, obj. текстуры. габариты: 25 кг, 61x75x71

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Chains

archibase_planet

free

Chain

...chain

archibase planet

chain chain link chain loop

chain n020708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

chain

...chain

3dexport

3d model chain

3d_export

$5

chain

...chain

3dexport

chain. obj,fbx,blend

archibase_planet

free

Chain

...se planet

chain circuit catena

chain - archicad parametrical gdl 3d model (*.gsm). regulation of the length, curvature and angle.

archibase_planet

free

Chain

...n

archibase planet

chain circuit catena

chain - archicad parametrical gdl 3d model(*.gsm). regulation of the length and angle xyz

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

turbosquid

$10

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1329200)

turbosquid

$9

chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1549461)

turbosquid

$2

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1148668)

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

$30

Cable Reels

...osquid

royalty free 3d model cable reels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439507)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder