Thingiverse

sg6042 RCM&E panther autogyro blade by WRudy

by Thingiverse

Last crawled date: 3 years, 3 months ago

EDIT!

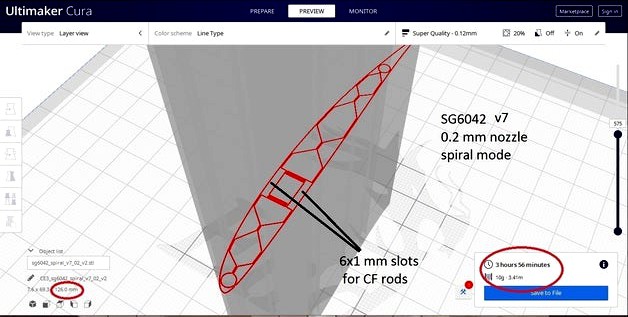

v7 available for 0.2 mm nozzle and hidden slots for 6x1 mm CF spars:

10g/126 mm span, uploaded gcode for 126mm span print with PETG at 235/90degC (4 prints per blade), longer span means low quality surface at one end due to printer vibrations (ender 3 pro with direct drive mod)

settings for printing with 0.2 nozzle at spiral mode:

<35 mm/s

0.115-0.119 layer height

100-105% flow

at least 6 mm brim

end of EDIT

A bit tired of playing with cura settings to print the available autogyro blades with acceptable quality I made my own version with sg6042 aerofoil. It was designed for Panther autogyro (from RCM&E magazine) so the chord is 68 mm (slicer cuts additional 2 mm of trailing edge). I have not checked it yet in the air.

IMPORTANT!

IT IS DESIGNED TO BE PRINTED WITH SPIRAL MODE (or VASE MODE).

Your slicer might ignore the geometry and wants to print only one perimeter! In Cura I am using rotating the blade with chord along Y axis helps, playing with the Z-seam position also changes the Cura's approach for slicing ;)

EDIT!

Cura seems to be quite random in loosing some layers in vase mode of such geometry, it took me some time to get best results by:

1) placing the airfoil with chord along Y-axis and rotate few deg to find 'sweet spot'

2) playing with the layer height (0.195-0.199 instead of default 0.2 mm for 0.4 mm nozzle and 0.115-0.119 layer height for 0.2 mm nozzle)

3) increasing the flow to 100-105% to provide some connection between neighbouring layers (flow in my ender 3 pro was initially calibrated to 94% flow with cube wall test)

4) 6mm brim

end of EDIT

The idea was to get as good quality of surface as possible and keep the aerofoil stiffness. Needs 2 carbon fibre 6x1 mm spars with your favourite adhesive ;)

I have uploaded only 50 mm span blade but you can extend it in your slicer to any dimension your printer accepts.

Hole in the leading edge is for balancing with 2 mm dia. wire (I am using spokes as cheap and accessible in any bicycle shop)

Shimming controlled with two caps (per blade), uploaded caps with 0, -1, -1.5 and -2 deg of shimming. Can upload different angles, just let me know in comments

Printing with PLA (205/ 55) at 0.2 layer (0.4 mm nozzle) and 25 mm/s takes 3,5 h/ 200mm span

Weight is around 14g/100 mm,

use at least 6mm brim!

v7 available for 0.2 mm nozzle and hidden slots for 6x1 mm CF spars:

10g/126 mm span, uploaded gcode for 126mm span print with PETG at 235/90degC (4 prints per blade), longer span means low quality surface at one end due to printer vibrations (ender 3 pro with direct drive mod)

settings for printing with 0.2 nozzle at spiral mode:

<35 mm/s

0.115-0.119 layer height

100-105% flow

at least 6 mm brim

end of EDIT

A bit tired of playing with cura settings to print the available autogyro blades with acceptable quality I made my own version with sg6042 aerofoil. It was designed for Panther autogyro (from RCM&E magazine) so the chord is 68 mm (slicer cuts additional 2 mm of trailing edge). I have not checked it yet in the air.

IMPORTANT!

IT IS DESIGNED TO BE PRINTED WITH SPIRAL MODE (or VASE MODE).

Your slicer might ignore the geometry and wants to print only one perimeter! In Cura I am using rotating the blade with chord along Y axis helps, playing with the Z-seam position also changes the Cura's approach for slicing ;)

EDIT!

Cura seems to be quite random in loosing some layers in vase mode of such geometry, it took me some time to get best results by:

1) placing the airfoil with chord along Y-axis and rotate few deg to find 'sweet spot'

2) playing with the layer height (0.195-0.199 instead of default 0.2 mm for 0.4 mm nozzle and 0.115-0.119 layer height for 0.2 mm nozzle)

3) increasing the flow to 100-105% to provide some connection between neighbouring layers (flow in my ender 3 pro was initially calibrated to 94% flow with cube wall test)

4) 6mm brim

end of EDIT

The idea was to get as good quality of surface as possible and keep the aerofoil stiffness. Needs 2 carbon fibre 6x1 mm spars with your favourite adhesive ;)

I have uploaded only 50 mm span blade but you can extend it in your slicer to any dimension your printer accepts.

Hole in the leading edge is for balancing with 2 mm dia. wire (I am using spokes as cheap and accessible in any bicycle shop)

Shimming controlled with two caps (per blade), uploaded caps with 0, -1, -1.5 and -2 deg of shimming. Can upload different angles, just let me know in comments

Printing with PLA (205/ 55) at 0.2 layer (0.4 mm nozzle) and 25 mm/s takes 3,5 h/ 200mm span

Weight is around 14g/100 mm,

use at least 6mm brim!

Similar models

thingiverse

free

Arrma Notorious Rear Wing Version 1.0

...nt speed : 30 mm/s

infill pattern : cubic

bottom/top thickness : 0.6

flow : 105%

initial layer flow : 120%

generate support : yes

thingiverse

free

Nozzle on the washing vacuum cleaner Thomas

...m cleaner thomas

thingiverse

print vertically on the part with the tube. pla, d 0.5 mm, layer 0.2 mm, with supports, brim wider.

cg_trader

$3

Nozzle on the washing vacuum cleaner Thomas | 3D

...leaner thomas | 3d

cg trader

print vertically on the part with the tube. pla, d 0.5 mm, layer 0.2 mm, with supports, brim wider.

grabcad

free

NASA/Langley HSNLF(1)-0213 Aerofoil Blade

...d

l/d = ~3 at ~20 m/s flow

as used in http://grabcad.com/library/rotor-fan-for-stuff and http://grabcad.com/library/quadrotor--1

thingiverse

free

Robot 'RB' v2.0 by witchtail

...al: abs / layer height : 0.1mm

print speed : 30 mm/s

slicer : cura

brim/support option : none

'rb v1' is here :)

thingiverse

free

Chain By Alok by alokjoshi

...mm nozzle.

i printed this with 10 layers of brim/skirt for good bed adhesion.

layer height : 0.1 or 0.2 (made using 0.2mm nozzle)

thingiverse

free

308 & 260Rem Powder funnels 15cm drop tube

...designed to print in vase mode without top and bottom layers.

print with brim and funnel against bed.

0.2 layer height

0.4 nozzle

thingiverse

free

Spiral lampshade (vase mode) by etsugo

...n the steeper surfaces.

print with brim to prevent falling over as it gets quite tall.

designed in fusion 360 with the form mode.

thingiverse

free

Fan with aerofoil blades by Texasbelle

...fan with aerofoil blades by texasbelle

thingiverse

played a bit with fan design using aerofoils for the blades

thingiverse

free

bed level tes by hafidz

...bed level tes by hafidz

thingiverse

bed leve tes only 2 layer print

use

0.2 mm layers

0.4 mm nozzle

120 mm x 120 mm

Wrudy

thingiverse

free

try square by WRudy

...pload different sizes, just pm me or leave a comment. print flat with 3-4 walls for superb stiffness (in pla) and angle accuracy.

thingiverse

free

ring for beehive candle mold by WRudy

...walls and 3mm brim no infill required with 4 walls as ring thickness is 3.2 mm. ring geometry extracted from the original mold.

thingiverse

free

Matek f405 wing plate by WRudy

...d to remove memory card before sliding in flight controller.

designed in freecad 0.18, source file included, feel free to modify.

thingiverse

free

beehive candle remix by WRudy

...e wax will shrink slightly while solidification process and needs calm conditions. fast cooling might cause cracks, be patient...

thingiverse

free

Panther autogyro head with commutator for RGB LEDs by WRudy

... i will try to help :)

source file provided (freecad), feel free to modify but please post your remix for other autogyro nuts :).

Autogyro

turbosquid

$79

Soviet Autogyro TsAGI A-4

...soviet autogyro tsagi a-4 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1323651)

turbosquid

$7

Toy helicopter based on Kamov Autogyro

... kamov autogyro for download as blend, obj, 3ds, dae, and fbx on turbosquid: 3d models for games, architecture, videos. (1532635)

thingiverse

free

Learner autogyro by davesurace

...es are to build an autogyro for beginners. everything is connected via arrow shafts. designed around arroshafts of .291 diameter.

thingiverse

free

Autogyro Gaslands / hotwheels

...e on weapons/ bits.

small nubbin under the cockpit is the tip for the pusher prop, points towards the rear.

no supports required.

thingiverse

free

Panther autogyro disc H1 by Plattekerre

...panther autogyro disc h1 by plattekerre

thingiverse

this is disc h1 for the rcm&e panther autogyro (march free plan)

thingiverse

free

Panther autogyro disc H2 by Plattekerre

...panther autogyro disc h2 by plattekerre

thingiverse

this is disc h2 for the rcm&e panther autogyro (march free plan)

thingiverse

free

Panther autogyro disc H3 by Plattekerre

...panther autogyro disc h3 by plattekerre

thingiverse

this is disc h3 for the rcm&e panther autogyro (march free plan)

thingiverse

free

Naked Autogyro gaslands/ hotwheels

...naked autogyro gaslands/ hotwheels

thingiverse

no supports needed.

3dcadbrowser

free

Autogyro Bushman

...software.this 3d object can be downloaded in .max, .obj, .3ds, .fbx, .dxf, .lwo, .stl, .wrl, .ma, .dae, .x and .asc file formats.

thingiverse

free

C30 or Similiar Autogyro Head Control by radioman

...ead control by radioman

thingiverse

c30 or medium size autogyro head control. something the size of the whippit, revolver2, c30.

Rcm

thingiverse

free

RCMS Bench by coach_garcia

...rcms bench by coach_garcia

thingiverse

scale model for math class

thingiverse

free

NINTENDO SWITCH RCM JIG CAT5

...nintendo switch rcm jig cat5

thingiverse

simplified version of jig

thingiverse

free

RCM&E Panther Cowling by Emanuel_Stassar

...eatured in uk magazine rcm&e. its designer is richard harris.

i printed it in abs. the raw weight before sanding is 40 grams.

thingiverse

free

RCM Jig Cartridge Adapter by Bruckyboy

...ts on either part, and aside from the insertion of the paperclip, the prints should be ready to go once they are off the printer.

3dfindit

free

LCM(Basic+Lite), RCM(Basic+Lite), Blind controller (zc-blind)

...lcm(basic+lite), rcm(basic+lite), blind controller (zc-blind)

3dfind.it

catalog: zencontrol

thingiverse

free

Small Nintendo Switch RCM Jig by Nooble

...pringy.

this model is a redesign/alteration/remix of the rcm jig designed by yahnbaron. https://www.thingiverse.com/thing:2892320

thingiverse

free

Yet Another Switch RCM Joycon Jig with Keyring by smx

...rcm joycon jig with keyring by smx

thingiverse

added a keyring opening so it can be attached to my switch case for safe keeping.

thingiverse

free

Switch RCM Jig by yahnbaron

...t and try to create a bend in the wire after you clip it flush to provide a gentle spring function against the joy-con connector.

thingiverse

free

Nintendo Switch RCM Jig SD card Game Cartridge Adapter by Cryzzgrantham

...nintendo switch rcm jig sd card game cartridge adapter by cryzzgrantham

thingiverse

remixed to add sd card slot

thingiverse

free

Swiss Switch micro SD cards and RCM Jig Insert by Wolfpup5456

... sd card are for labels. the micro sd cards that i personally put in there are for an android boot as well as my normal cfw boot.

Panther

3d_export

$18

Panther

...panther

3dexport

3dmodel

turbosquid

$25

panther

...turbosquid

royalty free 3d model panther for download as c4d on turbosquid: 3d models for games, architecture, videos. (1689584)

turbosquid

$10

panther

...turbosquid

royalty free 3d model panther for download as stl on turbosquid: 3d models for games, architecture, videos. (1477377)

turbosquid

$5

Panthers

...urbosquid

royalty free 3d model panthers for download as fbx on turbosquid: 3d models for games, architecture, videos. (1619034)

turbosquid

$25

Panther

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Panther

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

panther

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Panther

...d model panther for download as 3ds, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1318855)

turbosquid

$4

Panther

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

panther

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Blade

3d_export

$20

cossack blades

...

3dexport

cossack blades. the set contains 10 blades with a scabbard. each object (blade + scabbard) has a texture of 2048x2048.

3d_export

free

Blade Katarina

...blade katarina

3dexport

blade

turbosquid

free

Blades

...urbosquid

royalty free 3d model blades for download as blend on turbosquid: 3d models for games, architecture, videos. (1544896)

turbosquid

$40

Blade

...royalty free 3d model blade for download as max, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1222665)

turbosquid

$35

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

E

3ddd

$1

WALL-E

...wall-e

3ddd

wall-e , робот

wall-e

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw- it have 3d model of passenger e-rickshaw

3d_ocean

$12

Wall E

...wall e

3docean

character robot wall e

its a 3d model of wall e….

turbosquid

$68

Model-E Droids 2-E Q-E Star Wars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$45

Model-E Droids 2-E Q-E Star Wars3d model

....3ds .c4d .obj .vue - model-e droids 2-e q-e star wars 3d model, royalty free license available, instant download after purchase.

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw design for passenger it have all mechanical component

design_connected

$7

Cone E

...cone e

designconnected

bonaldo cone e computer generated 3d model. designed by pasini, ennio.

3ddd

$1

Wall-E NEW

...wall-e new

3ddd

wall-e , робот

wall-e

design_connected

$29

Extrasoft E

...extrasoft e

designconnected

living divani extrasoft e computer generated 3d model. designed by lissoni, piero.

3ddd

$1

E-Turn

... скамейка

современная скамейка фирмы kundalini.

модель e-turn.

дизайнер brodie neil.

размеры: h 42 cm l 185 cm w 54 cm