Thingiverse

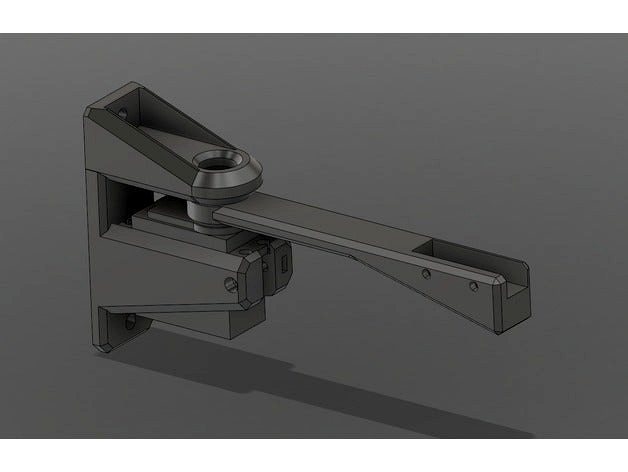

Servo-deployed Nozzle Wiper for 3030mm Extrusion -*UPDATE* by LumberjackEngineering

by Thingiverse

Last crawled date: 4 years, 6 months ago

This is a servo-deployed nozzle wiping system designed to mount on 3030 Aluminum Extrusion. I developed this for the Hypercube Evolution that I built. I use the Precision Piezo Orion sensor, which is absolutely awesome, but requires a somewhat clean nozzle.

This allows me to automate the cleaning of the nozzle at the start of the probing cycle.

I updated/finalized this design on 4/15/19 - the updated design uses a bearing above the servo to provide a stiffer/more reliable nozzle wipe. Additionally, you no longer need to remove the bottom of the servo to install it into the mount. It seems to work pretty well, so I've removed the "Work in Progress" tag.

NOTE #1: I use this with a hardened steel E3D nozzle, so I have no concerns using a brass brush as the wiping material. If you're using a standard brass nozzle, you might want to consider using a nylon brush (or a piece of silicone) to avoid wear.

Things you'll need to buy:

3x M3x10mm screws (2 to mount the servo to the mount, 1 to secure the arm to the servo)

1x M3x20mm to clamp the servo at the front of the mount.

2x M3x6mm screws (to clamp the brass brush in place. Could use just about any screw length here, M3x6mm just looks the nicest)

5x square M3 nuts (https://www.amazon.com/100pcs-Stainless-Steel-Square-Nuts/dp/B018JPZNS6/ref=sr_1_3?ie=UTF8&qid=1517527748&sr=8-3&keywords=square+m3+nut)

MG995 Servo: (https://www.amazon.com/gp/product/B01N4QD32E/ref=oh_aui_detailpage_o01_s02?ie=UTF8&psc=1)

1x 608 bearing

Brass Brush

(https://www.amazon.com/gp/product/B06XWFM1HJ/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1)

NOTE: I cut the head off of the brush right before it starts the curve of the handle.

Additionally, I used a small piece of 0.008" shim stock on one side of the brush to act as a "wiper" to help catch large pieces before they hit the brush. We'll see how well this works in practice once I get the machine up and running.

This allows me to automate the cleaning of the nozzle at the start of the probing cycle.

I updated/finalized this design on 4/15/19 - the updated design uses a bearing above the servo to provide a stiffer/more reliable nozzle wipe. Additionally, you no longer need to remove the bottom of the servo to install it into the mount. It seems to work pretty well, so I've removed the "Work in Progress" tag.

NOTE #1: I use this with a hardened steel E3D nozzle, so I have no concerns using a brass brush as the wiping material. If you're using a standard brass nozzle, you might want to consider using a nylon brush (or a piece of silicone) to avoid wear.

Things you'll need to buy:

3x M3x10mm screws (2 to mount the servo to the mount, 1 to secure the arm to the servo)

1x M3x20mm to clamp the servo at the front of the mount.

2x M3x6mm screws (to clamp the brass brush in place. Could use just about any screw length here, M3x6mm just looks the nicest)

5x square M3 nuts (https://www.amazon.com/100pcs-Stainless-Steel-Square-Nuts/dp/B018JPZNS6/ref=sr_1_3?ie=UTF8&qid=1517527748&sr=8-3&keywords=square+m3+nut)

MG995 Servo: (https://www.amazon.com/gp/product/B01N4QD32E/ref=oh_aui_detailpage_o01_s02?ie=UTF8&psc=1)

1x 608 bearing

Brass Brush

(https://www.amazon.com/gp/product/B06XWFM1HJ/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1)

NOTE: I cut the head off of the brush right before it starts the curve of the handle.

Additionally, I used a small piece of 0.008" shim stock on one side of the brush to act as a "wiper" to help catch large pieces before they hit the brush. We'll see how well this works in practice once I get the machine up and running.