Thingiverse

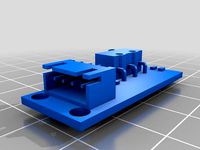

Sapphire Pro - Optical Z Endstop Conversion by petrzmax

by Thingiverse

Last crawled date: 3 years, 3 months ago

If You enjoyed this project and You want to say "Thank You" please consider supporting me by sending a tip on thingiverse or my PayPal here.

I had some problems with homing Z Axis. After a few prints my perfectly leveled bed was homing in different position and ideal first layer was wasted. It was difficult to have exactly the same first layer every time. My glass for printing was almost ideally flat, so I don't need to use Bltouch or some similar probe. Also while using Z offset and positive Z offset value Z axis has not much space - Z endstop will be squished etc.

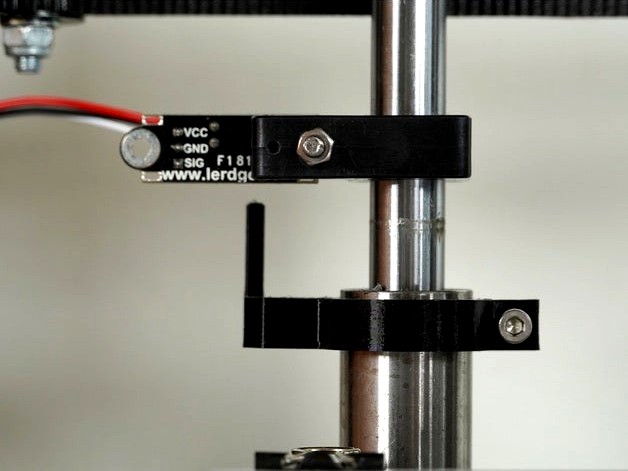

The way to go is using optical endstop. I have used this one:

https://bit.ly/3aiVJ4E

I have drilled 3 mm hole in original endstop holder and screwed endstop using 3 mm screw and 3D printed washer (You can use standard washer). Cables that came with endstop will fit in original endstop socket, but You will need to switch wires in the socket - probably signal wire with Vcc wire. I'm not sure at the moment, I will write it here when I will be looking in to the printer again. Just keep it in mind. It will not break Your endstop or printer, it will just be not working and the green light will be glowing all the time. While it's connected properly it lights up only when endstop is triggered.

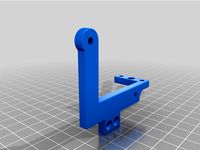

I have also designed part which will trigger new Endstop. Print it with PETG if You want to be able to put it on without taking Z rods out.

Also You will need to invert Z endstop logic in marlin.

Change:

#define Z_MIN_ENDSTOP_INVERTING

From true to false

You need to have also disabled Z min software endstop in order to use huge positive Z offset. Just comment out this line in config:

#define MIN_SOFTWARE_ENDSTOP_Z

Using optical Endstop will allow You to use large, positive Z offset.

This means that while homing Your nozzle will be at safe distance from the bed.

Sometimes some plastic may be sticked to Your nozzle which means collision with the bed and probably distracted homing.

Example Gcode for Z offset.

M206 Z1.2

This code will make Your bed go closer to the nozzle by 1.2 mm than Z endstop 0 point.

After this modification I'm always having exactly the same first layer.

I had a lot 3D printers with standard Z endstops, BLtouche's, inductive Z endstops and none of these gave me so perfect homing. I do really recommend it - You will be stunned with the results!

You can find my Marlin setup here:

https://github.com/petrzmax/Marlin

I had some problems with homing Z Axis. After a few prints my perfectly leveled bed was homing in different position and ideal first layer was wasted. It was difficult to have exactly the same first layer every time. My glass for printing was almost ideally flat, so I don't need to use Bltouch or some similar probe. Also while using Z offset and positive Z offset value Z axis has not much space - Z endstop will be squished etc.

The way to go is using optical endstop. I have used this one:

https://bit.ly/3aiVJ4E

I have drilled 3 mm hole in original endstop holder and screwed endstop using 3 mm screw and 3D printed washer (You can use standard washer). Cables that came with endstop will fit in original endstop socket, but You will need to switch wires in the socket - probably signal wire with Vcc wire. I'm not sure at the moment, I will write it here when I will be looking in to the printer again. Just keep it in mind. It will not break Your endstop or printer, it will just be not working and the green light will be glowing all the time. While it's connected properly it lights up only when endstop is triggered.

I have also designed part which will trigger new Endstop. Print it with PETG if You want to be able to put it on without taking Z rods out.

Also You will need to invert Z endstop logic in marlin.

Change:

#define Z_MIN_ENDSTOP_INVERTING

From true to false

You need to have also disabled Z min software endstop in order to use huge positive Z offset. Just comment out this line in config:

#define MIN_SOFTWARE_ENDSTOP_Z

Using optical Endstop will allow You to use large, positive Z offset.

This means that while homing Your nozzle will be at safe distance from the bed.

Sometimes some plastic may be sticked to Your nozzle which means collision with the bed and probably distracted homing.

Example Gcode for Z offset.

M206 Z1.2

This code will make Your bed go closer to the nozzle by 1.2 mm than Z endstop 0 point.

After this modification I'm always having exactly the same first layer.

I had a lot 3D printers with standard Z endstops, BLtouche's, inductive Z endstops and none of these gave me so perfect homing. I do really recommend it - You will be stunned with the results!

You can find my Marlin setup here:

https://github.com/petrzmax/Marlin

Similar models

thingiverse

free

Adjustable Z endstop Prusa I3 by Volkvanmyn25

...iverse

screw adjustable z endstop trigger to make fine tuning of the z home position. you need an optical endstop for this part.

thingiverse

free

Bastard bltouch adapter by trickius

...eft +right [of the nozzle]"

"#define y_probe_offset_from_extruder -18 // y offset: -front +behind [the nozzle]"

thingiverse

free

Alfawise BLTouch mount by abdesmok

...define y_probe_offset_from_extruder -5 // y offset: -front +behind [the nozzle]

z offset is approximately -1.5 mm (mine is -1.42)

thingiverse

free

Anet A6 BLTouch/3DTouch mount (front) by thvranken

...isplay or with command m851) and saved to the eeprom (using the display or with command m500), in my case, this was around -2 mm.

thingiverse

free

BLTouch Wanhao Duplicator i3 Mount by mibzzer15

...t setup correctly: http://web.archive.org/web/20170319023213/http://media.wix.com/ugd/f5a1c8_20aa9a75b70d46d3849140fb4d6b6e31.pdf

thingiverse

free

BLTouch Wanhao Duplicator i3 Mount V2.1 by mibzzer15

...t setup correctly: http://web.archive.org/web/20170319023213/http://media.wix.com/ugd/f5a1c8_20aa9a75b70d46d3849140fb4d6b6e31.pdf

thingiverse

free

3D/BL touch mount for Anet A6 by ithinuel

...ly 3 grid points on a linear bed levelling.

i am printing on a borosilicate glass bed, i don't know if more point are needed.

thingiverse

free

Anycubic i3 Mega BLtouch Mount by ajl959

... axis to allow the nozzle to dip just below the bed during regular homing before the z offset would work (end stops override it).

thingiverse

free

BlTouch Mount for CR10S by Skydesigne

... in this guide.

help

uncomment//g20/g21 inch mode support#define inch_mode_support

to avoid errors with serial-printing-software.

thingiverse

free

JGAurora A5 bltouch mount by heindaddel

...ft_probe_bed_position 11

define right_probe_bed_position 300

define front_probe_bed_position 0

define back_probe_bed_position 270

Petrzmax

thingiverse

free

M4 Nut Knob - ANET A6 by petrzmax

...se or my paypal here.

m4 nut knob - anet a6

designed for use with this custom x axis: https://www.thingiverse.com/thing:2106854

thingiverse

free

Orange Pi Plus 2 Case by petrzmax

...nge pi plus 2 case. you will need four m3x20 screws to fix it. they should easily thread into plastic. it's a tight fit case.

thingiverse

free

Z17 Housing parts for DIY Power Supply by petrzmax

...tip on thingiverse or my paypal here.

z17 housing parts for diy power supply

video: https://www.youtube.com/watch?v=kjklw6qgomi

thingiverse

free

Z Rod Top Stabilizer - ANET A6 by petrzmax

...part fixes the rods, so the printer is more stable. (especially rods) it can be used with bearings, but it's not recommended.

thingiverse

free

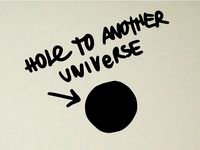

Hole To Another Universe from Life is Strange by petrzmax

...e. i have used double-sided tape to stick it to the wall. it's tricky to put it straight but after all the result is great ;)

thingiverse

free

VW Golf 4 Subwoofer Fit-Box Holder by petrzmax

... and screw it in as on the pictures and it will hold fit-box very well. there is no need for making holes in metal car chassis :)

thingiverse

free

Longer Top Spool Holder Beam - ANET A6 by petrzmax

...h lcd board cover: https://www.thingiverse.com/thing:2170152

and this top spool holder: https://www.thingiverse.com/thing:2009565

thingiverse

free

Velbon QB-6RL Quick Release Plate by petrzmax

...on the photos)

but don't worry! uploaded model is straight, so you can print it and made a few low cost quick release plates!

thingiverse

free

Black Powder Gun Barrel Rod Centerer by petrzmax

...the barrel surface. so this simple part is for centering the rod while cleaning the barrel :)

diameter of my pushing rod is 7 mm.

thingiverse

free

Uberti Remington 1858 Wolf Spring Adapter by petrzmax

...my case the spring was too far away from the hammer. so this part will set the spring a bit higher, and it will work just fine :)

Endstop

thingiverse

free

Endstop-holder for endstop v1.2 by albiuz

...endstop-holder for endstop v1.2 by albiuz

thingiverse

endstop-holder designed for mech endstop v1.2

thingiverse

free

Endstop by 3dboxpro

...endstop by 3dboxpro

thingiverse

endstop

thingiverse

free

Endstop by 1sPiRe

...endstop by 1spire

thingiverse

endstop model for conceptions

thingiverse

free

Endstop holder for Opto or Mechanical endstops by LulzBot

... endstops by lulzbot

thingiverse

these are the standard 1.0 prusa endstops with an added mounting hole for mechanical endstops.

thingiverse

free

Endstop Holder by onurhamdiuzun

...endstop holder by onurhamdiuzun

thingiverse

endstop holder for makerbot endstop and other endstops

thingiverse

free

Endstop Cover

...endstop cover

thingiverse

cover for endstop boards for makerbot design.

thingiverse

free

Endstop Mount for optical Endstops by Whitehawk2000

...whitehawk2000

thingiverse

use two 20mm m3 screws and nuts to screw the endstop onto the mount and just clip it onto the 8mm rod.

thingiverse

free

C-beam endstop mount for Makerbot type endstops

...c-beam endstop mount for makerbot type endstops

thingiverse

c-beam endstop mount for makerbot type endstop boards.

thingiverse

free

Endstop Mount for MakerBot Mecanical Endstop. by nka

...v-slots carriage.

endstop is screw with m3 (8mm) tapped hole and the endstop hold on the extrusion using a m5 (8mm) and t-nuts.

thingiverse

free

ENDSTOP 10mm by desert500

...endstop 10mm by desert500

thingiverse

endstop

Optical

design_connected

$9

Optic

...optic

designconnected

alessi optic computer generated 3d model. designed by colombo, joe.

3ddd

$1

обои OPTIC

...обои optic

3ddd

в архиве текстуры и фото обоев из коллекции optic.

archive3d

free

Optics 3D Model

...optics 3d model

archive3d

optics

optics - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$49

optical eyewear

...id

royalty free 3d model optical eyewear for download as max on turbosquid: 3d models for games, architecture, videos. (1592243)

3d_ocean

$5

optical mouses

...al mouses

3docean

3d models computer electronics mouse

optical mouses 3d models. realistic mouse model. custom and unique design.

turbosquid

$10

Optic cross

...yalty free 3d model optic cross for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1683403)

turbosquid

$7

OPTIC Mirror

... free 3d model optic mirror for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1223927)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$8

Mouse optical

...3d model mouse optical for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1504476)

turbosquid

free

Optical puzzle

... optical puzzle for download as max, ige, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1405925)

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

Sapphire

turbosquid

$30

Sapphire

...alty free 3d model sapphire for download as obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1304434)

turbosquid

$9

Sapphire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

turbosquid

$35

Sapphire ring

...quid

royalty free 3d model sapphire ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1320838)

turbosquid

$22

Ring with sapphires

...royalty free 3d model ring with sapphires for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1375607)

turbosquid

$20

sapphire ring

...quid

royalty free 3d model sapphire ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1306560)

turbosquid

$3

Zora Sapphire

... free 3d model zora sapphire for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1613795)

turbosquid

$50

sapphire ring

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Sapphire Lode

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Sapphire Gem

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

3ddd

$1

Aviation PRO

... aviation

http://www.oligo.de/en/products/system-luminaires/prod/st-aviation-pro-1.html