Thingiverse

Rostock Max drop in Spool Scale by Turpinator

by Thingiverse

Last crawled date: 3 years ago

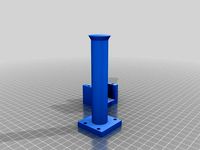

Dec 29, 2016 -- Printed parts, everything on the spool holder end went as it should, however... I realized this design isnt the greatest as depending on where the spool sits on the spindle, it can show different weights. To get around this... Hmm... I dont know. Itd have to be a different design. If anyone has any thoughts, let me know.

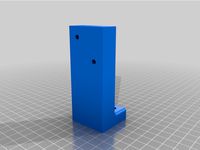

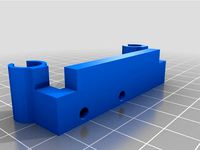

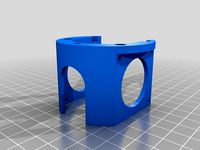

Dec 16, 2016 -- Time for an update. Printed the parts today, and assembled, except im missing screws and one of the holes on the big piece was in the wrong spot. Whoops. So dont print as is. It wont work correctly. A few days ago I started figuring out the screen. I can write text to it, but havent actually made any modifications to smokinpuppy's code yet. However, I have some plans for the code, so it will most likely function a bit differently.I also started designing a face plate tonight (in yellow) to house the screen and buttons. Updated to current solidworks files, but still not complete. The faceplate is just floating there, not mounted, The buttons are again, floating. Theres no actual button to activate the button/switch yet. Also no mounting for the arduino or hx711 bridge. Also render config is not my exact, the uprights for the spindle mount is rotated 180º, so it sticks forward, rather than back like pictured. Also ive got the EZStruder, not the EZRStruder. Close enough.

Dec 11, 2016 -- Finalized design a bit more, printed one piece, then started another, only to have my hotend start jamming (its been doing it for the past 2 months). After getting tired of it, i completely tore it apart... Come to find my bowden tube wasnt going all the way into the heat brake. Need to pick up some new ferrules from my shop before i can reassemble, and hopefully, get rid of this jamming problem.

Complete WIP, Just figured id post it now to have some ambition to actually finish it.

Supplies:

Arduino Uno (or clone)

5kg weight sensor beam thing (see remixed from or exact one)

Amplifier for the weight sensor (again, see remixed from)

A screen. I was going to use the one used in the others, but i realized the one i ordered didnt come with the I2C bridge thingy, so i ordered a 1$ one from china...

However, i ordered this: https://www.amazon.com/gp/product/B01HHOETIA, and plan to try and make it work. It will fit my Printer better too, as I plan to put the screen right in the front flat part on the Rostock Max. The others wouldnt fit with my extruder mounted there.

2 M5-10mm (approx) screws

2 M4-10mm (approx) screws

2 Self Tapping M3 screws, 6mm long or so. After disassembling plenty of computers, i have lots of spare screws from those, i think they are self tapping m3 or similar. Or maybe they are 2.9mm self tapping. idk.

Dec 16, 2016 -- Time for an update. Printed the parts today, and assembled, except im missing screws and one of the holes on the big piece was in the wrong spot. Whoops. So dont print as is. It wont work correctly. A few days ago I started figuring out the screen. I can write text to it, but havent actually made any modifications to smokinpuppy's code yet. However, I have some plans for the code, so it will most likely function a bit differently.I also started designing a face plate tonight (in yellow) to house the screen and buttons. Updated to current solidworks files, but still not complete. The faceplate is just floating there, not mounted, The buttons are again, floating. Theres no actual button to activate the button/switch yet. Also no mounting for the arduino or hx711 bridge. Also render config is not my exact, the uprights for the spindle mount is rotated 180º, so it sticks forward, rather than back like pictured. Also ive got the EZStruder, not the EZRStruder. Close enough.

Dec 11, 2016 -- Finalized design a bit more, printed one piece, then started another, only to have my hotend start jamming (its been doing it for the past 2 months). After getting tired of it, i completely tore it apart... Come to find my bowden tube wasnt going all the way into the heat brake. Need to pick up some new ferrules from my shop before i can reassemble, and hopefully, get rid of this jamming problem.

Complete WIP, Just figured id post it now to have some ambition to actually finish it.

Supplies:

Arduino Uno (or clone)

5kg weight sensor beam thing (see remixed from or exact one)

Amplifier for the weight sensor (again, see remixed from)

A screen. I was going to use the one used in the others, but i realized the one i ordered didnt come with the I2C bridge thingy, so i ordered a 1$ one from china...

However, i ordered this: https://www.amazon.com/gp/product/B01HHOETIA, and plan to try and make it work. It will fit my Printer better too, as I plan to put the screen right in the front flat part on the Rostock Max. The others wouldnt fit with my extruder mounted there.

2 M5-10mm (approx) screws

2 M4-10mm (approx) screws

2 Self Tapping M3 screws, 6mm long or so. After disassembling plenty of computers, i have lots of spare screws from those, i think they are self tapping m3 or similar. Or maybe they are 2.9mm self tapping. idk.

Similar models

thingiverse

free

Rostock Max Dial Indicator Mount by Turpinator

...ure still using the peek hotend on your v2, youll need to find some self tapping screws that are the correct size. #4s, i think.

thingiverse

free

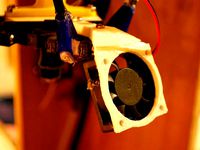

Hot end fan mount Geeetech Rostock mini G2 by Wirecase

...9;s from the rostock build kit.

to attach the fan duct you will need 2 additional m3 x 8mm or 10mm screws also from the build kit

thingiverse

free

Makerbot2 Spindle for 30 CM Spool. by ShaneC

...ter spool holes. this also works with the original makerbot spools as well, and it does not require pinching to get the spool on.

thingiverse

free

Parametrized mounting bracket for power brick by josefadamcik

...your own in fusion 360. everything can be changed including the size of screw.

print without supports rotated so it lies on side.

thingiverse

free

30A Relay Module mount by stevohen

...ne (big 30a relay) so i designed one myself.

uses 4x self tapping m3 screw holes for the module and one m3 screw hole to mount it

thingiverse

free

Spool unravel protector by TobyCWood

...3/8" all thread rods and it's diameter fits the hole for the prototype supply spools. this should also fit esun spools/

thingiverse

free

CR-6 Left Side Screen Mount and End Cap Cover by cghildreth

... and m5x8mm cap screws for the extrusion end-cap cover.

obviously, you'll have to re-route the screen cable to the left side.

grabcad

free

M3x10 Screw Self-Tapping Tribulor Button Head

...m3x10 screw self-tapping tribulor button head

grabcad

m3x10 screw self-tapping tri-bulor button head

thingiverse

free

Rostock Max Spool Rod & Clip by Av8rRC

...lip by av8rrc

thingiverse

i was asked to upload a spool rod for the original size of the rostock max spool mount.

so here it is.

thingiverse

free

RPi Camera mount for Rostock Max by jvince

...st start them loose, insert into the channel then turn 90 degrees and tighten (pulling out on frame to hold them in the channel).

Turpinator

thingiverse

free

Turpin FTC Robotics Designs 2017-2018 by pjbentley1199

...turpin ftc robotics designs 2017-2018 by pjbentley1199

thingiverse

turpin ftc robotics designs 2017-2018

thingiverse

free

Tippmann Alpha Black Rail by Turpinator

... alpha black barrel shroud.

print, open up your shroud, place this in, and close it back up. simple as that.

nothing super fancy

thingiverse

free

TacSol X-Ring TSS Wrench by Turpinator

..., use the feed lips on an empty magazine to get a bit more leverage.

may also work with the pac-lite, axiom, ascent22, and aeris.

thingiverse

free

Polaris Fuel Tank Wrench by Turpinator

...e, smaller od). the original size didnt fit on my friends 2015 assault. it fit my rush and friend's switchback fine though.

thingiverse

free

CNC Clamp remix 1/4" hole by Turpinator

...d some clearance on the side of the clamp near the workpiece, so you can put the clamp on at an angle, for tight to reach places.

thingiverse

free

HE280 Silicone Mold by Turpinator

...s centered in the mold, without making going to a multiple piece mold and stuff. but then again... ive already got 2+core as is.

thingiverse

free

Spool Storage Bin by Turpinator

...ngs...

card height = 1.5"

card width = 2.5"

card overlap = 5mm

offset = 0.5mm (this is the clearance between everything

thingiverse

free

---- in a box! 'costume' by Turpinator

... see image for how much i bent mine and feel free to compare size.

hopefully thats everything, let me know if i missed something.

thingiverse

free

Rostock Max Dual HE280 by Turpinator

...ogress. any and all comments appreciated, this probably wont go any further, but it was a fun couple hours spent playing around.

thingiverse

free

Valve Stem Puller by Turpinator

...rinter's accuracy), and give it a nice, gentle pull. gentle! remember, its plastic and may break. one more time... gentle!

Rostock

thingiverse

free

Endstop for Rostock by Raz0neR

...endstop for rostock by raz0ner

thingiverse

endstop for rostock.

thingiverse

free

Rostock Cooling by nobicore

...rostock cooling by nobicore

thingiverse

rostock cooling

thingiverse

free

ROSTOCK PARTS by OC3D

...rostock parts by oc3d

thingiverse

parts for our modified rostock extruder assembly

thingiverse

free

Rostock squirrel fan by MarioPanic

...rostock squirrel fan by mariopanic

thingiverse

rostock squirrel fan

thingiverse

free

FC Hansa Rostock by ron86

...fc hansa rostock by ron86

thingiverse

fc hans rostock logo

thingiverse

free

rostock mini carriage by cjol

...rostock mini carriage by cjol

thingiverse

carriage for my rostock mini project

thingiverse

free

Rostock and Rostock Mini Dual Extruder Mount by westonshakespear

...ht.

sorry about the pictures, my filament jammed for part of the print and i am waiting for a new part to print a better version.

thingiverse

free

Rostock mini clip by Scott_Chen

...rostock mini clip by scott_chen

thingiverse

rostock mini clip for printer base glass

thingiverse

free

Rostock Board holder by drewan

...rostock board holder by drewan

thingiverse

this is a clip for using a rostock board as a print surface.

thingiverse

free

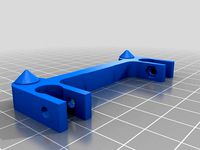

Rostock Fan Bracket by ImprisonedByTime

...rostock fan bracket by imprisonedbytime

thingiverse

this bracket is for a 40mm fan to attach to the rostock 3d printer

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Drop

3ddd

$1

Писсуар Drop

...писсуар drop

3ddd

писсуар , drop

писсуар drop

3d_ocean

$1

Water Drop

...g drops fresh liquid rain refresh splash water water drop

3ds max 2010, 3ds max 2013 & obj model of water drop. vray 2.30.01

3ddd

$1

Drop, Faber

... , faber , вытяжка

вытяжка drop, компания faber

turbosquid

$5

Drop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

cartoon blood drop - water drop - medicine drop

...od drop - water drop - medicine drop

3dexport

texture size:small size number of texture:3 texture format: png 1 texture= 1 model

3d_export

free

Nose Drops

...nose drops

3dexport

nose drops)

3ddd

$1

Mirror Drops

...mirror drops

3ddd

mirror drops 530х410 max2011

3ddd

$1

Зеркало Drops

... drops

зеркало drops 53x41

фабрика : kare design

артикул : 74419

материал : glass, aluminium

3ddd

$1

Acid Drop

... curiousa&curiousa

curiousa&curiousa;

acid drophttp://www.curiousa.co.uk/acid-drops

design_connected

$11

Drop Top

...drop top

designconnected

plumen drop top computer generated 3d model.

Scale

turbosquid

$20

Weight scale or Bathroom Scale

...ght scale or bathroom scale for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1664576)

turbosquid

$19

Scale

...e

turbosquid

royalty free 3d model scale for download as fbx on turbosquid: 3d models for games, architecture, videos. (1411722)

turbosquid

$5

Scales

...s

turbosquid

royalty free 3d model scales for download as ma on turbosquid: 3d models for games, architecture, videos. (1393439)

turbosquid

$40

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$17

Scales

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

of scales

...s have a flat point of support. the samples are rendered in the standard cinema 4d renderer. enjoy your use and creative success.

3d_export

$5

scale knob

...scale knob

3dexport

scale knob

3d_export

$20

cartoon weight scale or bathroom scale

...cartoon weight scale or bathroom scale

3dexport

texture size:512px number of texture:1 texture format: png