Thingiverse

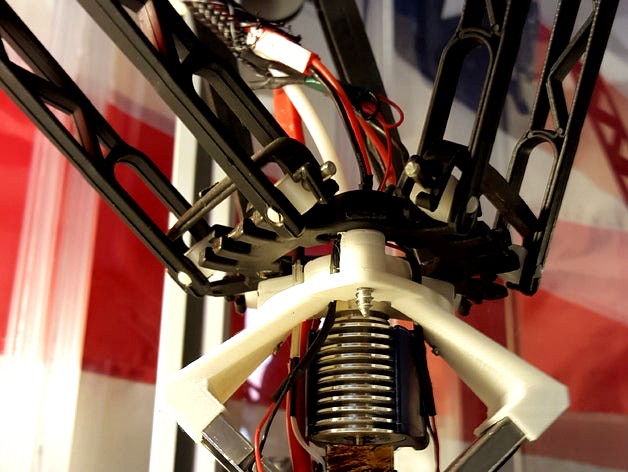

Rostock Max (Delta) - E3D v6 Mount and Layer Fan by Herrminator117

by Thingiverse

Last crawled date: 3 years ago

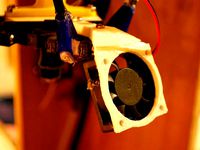

Two things prompted me to make yet another v6 mount and layer fan:

1) The lack of a compact efficient layer fan for delta printers. Which I needed since I have an enclosure on my RMv2

2) My old bulky layer fan was absolutely abismal. It would get caught on prints and wreck hours of prints, and and didnt even cool all that well.

I pulled inspiration from the Atom 2.0 Delta printer, google it! Quite fancy delta printer!

This layer fan is the second attempt, my first design had issues with the air stream being too far from the nozzle. Which meant that the PLA would just look like poop.

These are the fans the holder is designed around:http://www.mpja.com/5VDC-Mini-CPU-Fan/productinfo/32166%20FN/

NOTE:

Too get an effective layer fan I had to pull in the air stream very close to the nozzle to get the results I wanted. On the first few layers when the fan turns on, it will lower the temps maybe 3 degrees. It shouldnt be any more and it doesnt cause any jamming. As you get farther from the build plate the temps normal out. I have 60 hours of testing and printing with this setup (w/ long 15 hour prints) You must make sure the fans are seated correctly in the holders.

ASSEMBLY INSTRUCTIONS:

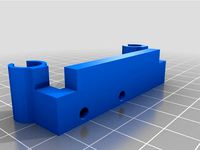

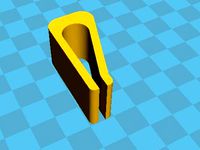

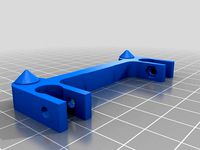

The collar and ring for mounting the v6 are pretty standard and straight forward. The notches are to keep your wires close and through the effector.

Steps:

1) Flip effector - smooth side facing bed

2) Put all wiring through effector hole before mounting

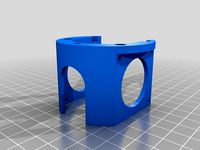

3) Seat fans in holder - NEED to be fully seated. Use vice grip to push fan in to holder. The fans are metal, dont need to worry about being gentle

4) Place ring and collar mount on v6 - Collar opening facing toward z arm (backwards)

5) Hook up all wiring if you havent already done so.

6) Re-calibrate bed level with new nozzle height

7) In your slicer set min fan speed to 35% and max to 100%

1) The lack of a compact efficient layer fan for delta printers. Which I needed since I have an enclosure on my RMv2

2) My old bulky layer fan was absolutely abismal. It would get caught on prints and wreck hours of prints, and and didnt even cool all that well.

I pulled inspiration from the Atom 2.0 Delta printer, google it! Quite fancy delta printer!

This layer fan is the second attempt, my first design had issues with the air stream being too far from the nozzle. Which meant that the PLA would just look like poop.

These are the fans the holder is designed around:http://www.mpja.com/5VDC-Mini-CPU-Fan/productinfo/32166%20FN/

NOTE:

Too get an effective layer fan I had to pull in the air stream very close to the nozzle to get the results I wanted. On the first few layers when the fan turns on, it will lower the temps maybe 3 degrees. It shouldnt be any more and it doesnt cause any jamming. As you get farther from the build plate the temps normal out. I have 60 hours of testing and printing with this setup (w/ long 15 hour prints) You must make sure the fans are seated correctly in the holders.

ASSEMBLY INSTRUCTIONS:

The collar and ring for mounting the v6 are pretty standard and straight forward. The notches are to keep your wires close and through the effector.

Steps:

1) Flip effector - smooth side facing bed

2) Put all wiring through effector hole before mounting

3) Seat fans in holder - NEED to be fully seated. Use vice grip to push fan in to holder. The fans are metal, dont need to worry about being gentle

4) Place ring and collar mount on v6 - Collar opening facing toward z arm (backwards)

5) Hook up all wiring if you havent already done so.

6) Re-calibrate bed level with new nozzle height

7) In your slicer set min fan speed to 35% and max to 100%

Similar models

thingiverse

free

Delta Effector for E3D V6 by Osechi

...effector offset : 25mm

i use the following parts,

・lj12a3-4-z-bx

・e3d v6 hotend

・3010 fans

・3010 blower fan

・m3 screws & nuts

thingiverse

free

40mm to 30mm E3D V6 Fan Mount by spencercga

...e it was originally mounted.

i printed with a raft but i had trouble getting the raft off that is why it seems wavy near the fan.

thingiverse

free

Kossel Pro Delta E3D V6 End Effector Version 8 by calviniba

...nd print super slow (30mm/s) to be able to print the overhangs properly with no support.

dimensions:

arm width: 41mm

radius: 30mm

thingiverse

free

Air cooler for Delta printer by ken1sand

...nects as a fan to the system.

good luck with your project.

the system have for me made warp free prints with all tested plastics.

thingiverse

free

Orca 0.43 x-carriage fan mount by Aggresive

...w out of the nozzle is good, i've printed this again and needed a lot less support for it to print, and there was no curling.

thingiverse

free

Monoprice Mini Delta Effector / Mount by mfink70

... e3d v6 to keep it from sliding in the mount. this will locate the bottom of the e3d v6 heatsink with the bottom of the effector.

thingiverse

free

Autolevel mount for V6 delta printers by citruspers

...vel probe.

open source

as always the original design file (fusion360) is included, so feel free to improve it (or learn from it)!

thingiverse

free

XYZ Davinci E3D V6 40mm Cooling Fan Shroud by njmerola

...o make the fan functional, i needed to modify the configuration.h file. once i find the instructions i used, i will add the link.

thingiverse

free

K40 Air Assist Radial Fan by Aleckz

...le which is exchangeable, the outer diameter is 10mm if you want to use another nozzle.

support is only needed for the main part.

thingiverse

free

Kossel Mini Delta Effector For E3D V6 With Dual Fan Mount by cristiprefac

...mount, so you can use auto bed leveling with it (see the pics).

you'll need a bunch of m3 screws and nuts to put it together.

Rostock

thingiverse

free

Endstop for Rostock by Raz0neR

...endstop for rostock by raz0ner

thingiverse

endstop for rostock.

thingiverse

free

Rostock Cooling by nobicore

...rostock cooling by nobicore

thingiverse

rostock cooling

thingiverse

free

ROSTOCK PARTS by OC3D

...rostock parts by oc3d

thingiverse

parts for our modified rostock extruder assembly

thingiverse

free

Rostock squirrel fan by MarioPanic

...rostock squirrel fan by mariopanic

thingiverse

rostock squirrel fan

thingiverse

free

FC Hansa Rostock by ron86

...fc hansa rostock by ron86

thingiverse

fc hans rostock logo

thingiverse

free

rostock mini carriage by cjol

...rostock mini carriage by cjol

thingiverse

carriage for my rostock mini project

thingiverse

free

Rostock and Rostock Mini Dual Extruder Mount by westonshakespear

...ht.

sorry about the pictures, my filament jammed for part of the print and i am waiting for a new part to print a better version.

thingiverse

free

Rostock mini clip by Scott_Chen

...rostock mini clip by scott_chen

thingiverse

rostock mini clip for printer base glass

thingiverse

free

Rostock Board holder by drewan

...rostock board holder by drewan

thingiverse

this is a clip for using a rostock board as a print surface.

thingiverse

free

Rostock Fan Bracket by ImprisonedByTime

...rostock fan bracket by imprisonedbytime

thingiverse

this bracket is for a 40mm fan to attach to the rostock 3d printer

Delta

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Layer

design_connected

$9

Layer

...layer

designconnected

gallotti & radice layer tables computer generated 3d model. designed by luca nichetto.

3ddd

$1

Calligaris LAYERS

...calligaris layers

3ddd

calligaris , layers

стол фабрики calligaris модель layers

3ddd

$1

Eglo Layer

...eglo layer

3ddd

eglo , layer

люстра eglo layer (89593) h=1100 l=655

3d_export

$5

pipe layer

...pipe layer

3dexport

3d_export

$25

mandala layer

... modelled in cinema 4d r23 hope you like it! also check out my other models, just click on my username to see a complete gallery.

turbosquid

$29

cloth layers

... 3d model cloth layers for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1441919)

turbosquid

$29

Layer desk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

layered traffic

...layered traffic

3dexport

simple rendering of the scene file

turbosquid

$400

testis with covering layers

...ee 3d model testis with covering layers for download as blend on turbosquid: 3d models for games, architecture, videos. (1431659)

turbosquid

$210

Thoracic wall layers

...alty free 3d model thoracic wall layers for download as blend on turbosquid: 3d models for games, architecture, videos. (1674521)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)