Thingiverse

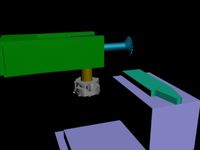

Root 3 CNC X Gantry Panels (Z Panels) by Menneset

by Thingiverse

Last crawled date: 3 years ago

A set of printable X carriage (Z) panels for the Root3CNC by sailorpete.

For more details on the Root CNC project, look here.

Updated 8/1/17 - Upper_Front.stl and Z_Carriage.123dx, see Comments.

Final Assessment: After using the machine with the printed panels for a couple of weeks, I have concluded that they are just not stiff enough to do the job. I had to dial down both the speed and depth of cut. They work, and will get your machine running reliably, but it can easily be better. So, my suggestion is to use these to get your machine running long enough to cut some wooden panels, then replace them. - Thanks.

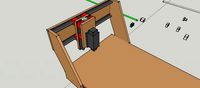

This model is based on the dual wood brace version of the X carriage with the universal panel option. I removed some unnecessary holes and clipped a bit off of the top of the panel to create my version of the front panel. You can if you prefer, print two back panel sets to get the original universal panel set.

I split both the front and back panels into two parts. The bottom half for both panels is identical, you will need to print one Z_Upper_Front, one Z_Upper_Back, and two Z_Lower. Or, print two Z_Upper_Back and omit the Z_Upper_Front. You will likely not need to print the Z_Bonding_Plate

To assemble you will need four smooth 3mm rods 60mm to 80mm long. The rods should fit snugly in the two holes found on the mating edge of each panel piece. Taping the rods into place with a small hammer may help. If you have to do more than just tap them, then they are too tight--forcing them will crack the plastic. It may be necessary to clear out the holes with a 3mm (or 1/8 inch) drill bit. I salvaged my 3mm rods from old CDROM and DVD drives.

As you assemble the remainder on the CNC build, components will be bolted into place which will serve to hold the two halves of the panel securely together. At this time I have not assembled the front panel (I am still waiting on parts to arrive.) The intention is that the linear rails will secure the two halves of the panel. I have also provided a Z_Bonding_Plate model that may be used to strengthen the front panel. Again, I don't think that will be necessary.

One final note regarding the bonding plate only... when I model a screw hole with a nut trap that will be printed in an inverted position such as this piece has, I include a very thin layer across the screw hole at the top of the nut trap. This causes the slicer to treat the top of the nut trap as a bridge rather than an overhang.

For more details on the Root CNC project, look here.

Updated 8/1/17 - Upper_Front.stl and Z_Carriage.123dx, see Comments.

Final Assessment: After using the machine with the printed panels for a couple of weeks, I have concluded that they are just not stiff enough to do the job. I had to dial down both the speed and depth of cut. They work, and will get your machine running reliably, but it can easily be better. So, my suggestion is to use these to get your machine running long enough to cut some wooden panels, then replace them. - Thanks.

This model is based on the dual wood brace version of the X carriage with the universal panel option. I removed some unnecessary holes and clipped a bit off of the top of the panel to create my version of the front panel. You can if you prefer, print two back panel sets to get the original universal panel set.

I split both the front and back panels into two parts. The bottom half for both panels is identical, you will need to print one Z_Upper_Front, one Z_Upper_Back, and two Z_Lower. Or, print two Z_Upper_Back and omit the Z_Upper_Front. You will likely not need to print the Z_Bonding_Plate

To assemble you will need four smooth 3mm rods 60mm to 80mm long. The rods should fit snugly in the two holes found on the mating edge of each panel piece. Taping the rods into place with a small hammer may help. If you have to do more than just tap them, then they are too tight--forcing them will crack the plastic. It may be necessary to clear out the holes with a 3mm (or 1/8 inch) drill bit. I salvaged my 3mm rods from old CDROM and DVD drives.

As you assemble the remainder on the CNC build, components will be bolted into place which will serve to hold the two halves of the panel securely together. At this time I have not assembled the front panel (I am still waiting on parts to arrive.) The intention is that the linear rails will secure the two halves of the panel. I have also provided a Z_Bonding_Plate model that may be used to strengthen the front panel. Again, I don't think that will be necessary.

One final note regarding the bonding plate only... when I model a screw hole with a nut trap that will be printed in an inverted position such as this piece has, I include a very thin layer across the screw hole at the top of the nut trap. This causes the slicer to treat the top of the nut trap as a bridge rather than an overhang.

Similar models

thingiverse

free

Easier to Print Simonious' Supa-Flat X-Carriage by Ember

...w your slicer to generate any kind of bridging to print the hole on top of the larger nut trap, resulting in additional clean-up.

thingiverse

free

DVD laser carriage plotter parts by NilsR

...progress will be shared here. if you're building a similar project, you can use these parts as a base,...

thingiverse

free

Nut trap size test by Torby

...n, i'd give them credit.

oh. it came from github uploaded by stemer114 https://gist.github.com/stemer114/324c382a528d10b43759

thingiverse

free

Dremel CNC - Long Bed Printer Carriage by ConnorM2009

...co poly or abs may be better. it is still work in progress as need to work on limit switch bracketry and a bracket for a bl touch

thingiverse

free

MPCNC Corner Span Supports by Droneme

... .25in. dowel for alignment. after the threads are started you can pull the dowel out.

update-added a nut trap for 25mm conduit.

thingiverse

free

Topeak Quicktrack adapter for Stromer ST1X Racktime rack by pmeyer

...nd a nut below. the brace keeps the adapter from sliding off.

the quicktrack bag should then slide on and clip to the front bar.

thingiverse

free

Eclips3D modified A9,A10,A11,A12 Y axis rod holders by Av8er

... change to the rear holders is that i enlarged the rod hole to mach the front. if you use them you may not need to use any shims.

thingiverse

free

Bushing holder for 20mm hole-separation by misan

...the holder and the holder has nut-traps for m3 that with 12mm m3 screws will allow the part to be securely fixed to the carriage.

thingiverse

free

Rear Axle For 3mm threaded rod by jsloat31

...ors. i secured the wheels with the 3mm nuts that are used for the build. i did use the printed wheel lock nuts for added support.

thingiverse

free

ANET A8 Power Switch Box by MrWoo

...ay also want to resize the motor plate (the part that slides under the motor for stability) to fit your own personal installation

Menneset

thingiverse

free

DaVinci Lid Brace by Menneset

...ci lid brace by menneset

thingiverse

a simple, easy to make and use brace that will hold the lid of the davinci 3d printer open.

thingiverse

free

5mm LED clip by Menneset

...lds a 5mm led close to a surface. not the prettiest thing ever, but it is designed to be used for indirect light or backlighting.

thingiverse

free

Maze Box Redux keys by Menneset

...the maze box redux gift boxes.

the red one is maze 1, the easy one. perhaps i didn't fully think through the color choices...

thingiverse

free

Root 3 CNC NEMA 23 Spacer with Tab by Menneset

...oot 3 cnc that has an extra tab for adding a threaded rod cross piece to serve as a stiffener for the entire x carriage assembly.

thingiverse

free

Mega/Ramps Fan Mount by Menneset

...it has mounting holes for both 60mm fans and for 40mm fans. typically you will print two, but one alone could work in some cases.

thingiverse

free

Arduino Uno Model by Menneset

...be.

the dimensions came from this image by matthew beckler. thank you mr. beckler. another good source is, (as always,) adafruit.

thingiverse

free

T-Rex Tape Dispenser Revisited by Menneset

...ome on your desk and actually dispense a full roll of tape. it is especially awesome when printed with glow-in-the-dark filament!

thingiverse

free

Dremel Foot 45 degree hold by Menneset

...t; i am thinking that the head piece could have been bigger, i may come back and revisit that after i have used them for a while.

thingiverse

free

D&D Meeples Smaller Party by Menneset

...ee. basically i just used meshmixer to cut his tray of meeples into fourths and named them a,b,c,d. hope this helps someone else.

thingiverse

free

Light Ring for 65mm CNC Spindle by Menneset

...er you normally do should be just fine. i used e3000 to glue the led ring to the clamp, but again, use whatever you have on hand.

Gantry

turbosquid

$349

Gantry crane

...alty free 3d model gantry crane for download as ige and sldas on turbosquid: 3d models for games, architecture, videos. (1476278)

3d_export

free

firestone advertising gantry

...rs premises and<br>these advertisement gantries, were very popular in the 30-70's at grand prix races advertising tyres

turbosquid

$30

Derelict Launch Gantry

...alty free 3d model derelict launch gantry for download as fbx on turbosquid: 3d models for games, architecture, videos. (1669952)

turbosquid

$129

Gantry Crane RTG

...e 3d model gantry crane rtg for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1491933)

turbosquid

$120

Gantry stacker Assembly

...try stacker assembly for download as sldas, fbx, 3ds, and ige on turbosquid: 3d models for games, architecture, videos. (1648516)

turbosquid

$19

Train Signals Gantry

...l train signals gantry for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1462242)

turbosquid

$5

STS Gantry Crane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$160

Bulk carrier with gantry crane

...carrier with gantry crane for download as lwo, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1285258)

3d_export

$50

RMG Gantry Crane 3D Model

...t hoist rail rubber tyre tire rtg eot beam portal heigh tonne shipyard port

rmg gantry crane 3d model 5starsmodels 42860 3dexport

3d_export

$29

gantry crane

...istic model that will enhance the detail and realism of any of your rendering projects.<br>file formats: max, obj, fbx, 3ds

Root

3d_export

$5

root

...root

3dexport

a root from the tree

archive3d

free

Roots 3D Model

...ation ornament

roots of ginseng n010313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

yucca root

...yucca root

3dexport

3d_export

$5

lotus root

...lotus root

3dexport

3d_export

$5

turmeric root

...turmeric root

3dexport

3ddd

$1

CHAIR ROOT by Customform

...chair root by customform

3ddd

customform

chair root by customform.texture included.

turbosquid

$35

Turmeric Root

...oyalty free 3d model turmeric root for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1588571)

turbosquid

$17

Root on Stand

...yalty free 3d model root on stand for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1215521)

turbosquid

$2

Root Plant

...yalty free 3d model root plant for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1608270)

turbosquid

$49

Root Lamp

...lty free 3d model root lamp for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1253803)

Cnc

3d_export

$35

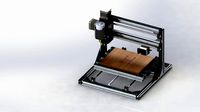

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Panels

3d_export

$15

panel

...panel

3dexport

panel

archibase_planet

free

Panel

...panel

archibase planet

panel

panel - 3d model for interior 3d visualization.

3d_export

$5

panel

...panel

3dexport

panel with cones

3ddd

$1

Panels

...panels

3ddd

панель

panels

3d_export

$5

panel

...panel 3dexport panels grapes with...

archibase_planet

free

Panel

...panel

archibase planet

panel wainscot dado

play panel n050707 - 3d model for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

lining panel facing material

panel 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

lining panel facing material

panel 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

keyboard patchboard finger-board

security panel - 3d model for interior 3d visualization.

turbosquid

$10

Panel

...l

turbosquid

royalty free 3d model panel for download as stl on turbosquid: 3d models for games, architecture, videos. (1387163)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

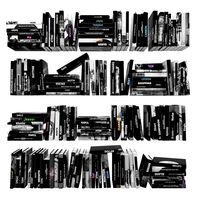

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder