Thingiverse

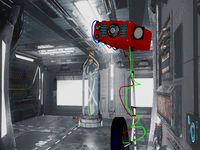

Robot Power Supply by NirDobovizki

by Thingiverse

Last crawled date: 2 years, 12 months ago

Without a doubt this is the most useful robot I designed so far.

This is basically an old 12v wall-wart I found in my drawer, an adjustable buck convertor and a volt/amper meter - together they become a very usable power supply for my crazy electronic projects.

This adjustable power supply has 2 banana terminals (one +, one -), 4 connectors for jumper wires (2 +, 2 -) an ampermeter and a voltmeter.

Read the instruction below carefully, assembling this is a bit tricky - the know is very hard to connect after the buck converter in already in it's place.

Designed with SketchUp, fixed with Microsoft 3D Builder, sliced with Cura and printed in PLA on my Robo3D R1+

Parts:

Some kind of power supply with a 5.5mm plug

A 5.5mm socket (from AliExpress "5pcs/lot High Quality Socket Female Panel Mount Connector 2.1mmx5.5mm Plug Adapter 2 Terminal types for DC Power Supply Jack")

A DC/DC buck convertor, the only model that will fit is the one in the picture (from AliExpress "1pc Small LM2596 power supply module DC/DC BUCK 3A adjustable buck module regulator ultra LM2596S 24V switch 12V 5V 3V Newest")

Amper/Volt meter (from AliExpress "1pcs Professional DC 100V 10A Voltmeter Ammeter Blue + Red LED Amp Dual Digital Volt Meter Gauge")

A power switch (from AliExpress "Free shipping Hot 5pcs AC125V 10A 250V 6A 2 Pin ON/OFF I/O SPST Snap in Mini Boat Rocker Switch")

Red/black banana plugs (from AliExpress "Electrical Supplies 4PCS / 2 Pairs Speaker Amplifier Terminal Binding Post Banana Plug Socket Female Connector")

Two short Dupont female-female jumper wires

Some electrical wires

Printing/Assembly:

First print knob1 (no support, 100% infill), just as the print is finished while it is still hot squeeze the flat piece in the center with a pair of tweezers to make it thinner

Now print knob2, back and the body with high infill (no support)

Make sure Knob 1 and knob 2 fit together, connect and disconnect them a few times.

Print the head and arms with low infill, no supports

Cut the two jumper wires in the middle so you have 4 wires with a female connector on one side.

insert the 5.5mm jack into the hole in the right arm

Solder the thin red wire from the amper meter + another wire to the buck converter IN+

Solder the thick black wire from the amper meter into the buck OUT-

Solder two more wires, one to the buck's IN- and one to the OUT+

Press the smaller knob 2 firmly into the buck's potentiometer, it should fit like a screw driver into the potentiometer screw.

Carefully place the buck between the 4 columns inside the body so that the knob part goes into the round hole

Carefully slide the back part into the slots in the 4 columns, the little ledge goes in the lower end, use hot glue to hold everything in place

Now, carefully (again) connect the outer part of the knob

Soldering time, make sure you solder everything on the correct side of the body so things fit into their holes

Solder the free wire from IN+ to the switch, then from the switch other terminal to the 5.5mm jack +

Solder the wire from the IN- to the 5.5mm jack

Solder the wire from OUT+ and the Amper meter thick red wire nd two of the dupont jumpers to the red banana

Solder the last thick wire from the amper meter and the other two dupont jumpers to the black banana

The amper meter thin black wire should be left unconnected

Now push all the component so they snap into their holes

Push the 4 DuPont connectors into the square hole between the two bananas, make sure the positive connectors are closer to the red banana and the negative to the black one

Use some glue in the right shoulder so the arm doesn't come out when you disconnect the power cord

Those were some long instructions, if you got this far leave a comment

This is basically an old 12v wall-wart I found in my drawer, an adjustable buck convertor and a volt/amper meter - together they become a very usable power supply for my crazy electronic projects.

This adjustable power supply has 2 banana terminals (one +, one -), 4 connectors for jumper wires (2 +, 2 -) an ampermeter and a voltmeter.

Read the instruction below carefully, assembling this is a bit tricky - the know is very hard to connect after the buck converter in already in it's place.

Designed with SketchUp, fixed with Microsoft 3D Builder, sliced with Cura and printed in PLA on my Robo3D R1+

Parts:

Some kind of power supply with a 5.5mm plug

A 5.5mm socket (from AliExpress "5pcs/lot High Quality Socket Female Panel Mount Connector 2.1mmx5.5mm Plug Adapter 2 Terminal types for DC Power Supply Jack")

A DC/DC buck convertor, the only model that will fit is the one in the picture (from AliExpress "1pc Small LM2596 power supply module DC/DC BUCK 3A adjustable buck module regulator ultra LM2596S 24V switch 12V 5V 3V Newest")

Amper/Volt meter (from AliExpress "1pcs Professional DC 100V 10A Voltmeter Ammeter Blue + Red LED Amp Dual Digital Volt Meter Gauge")

A power switch (from AliExpress "Free shipping Hot 5pcs AC125V 10A 250V 6A 2 Pin ON/OFF I/O SPST Snap in Mini Boat Rocker Switch")

Red/black banana plugs (from AliExpress "Electrical Supplies 4PCS / 2 Pairs Speaker Amplifier Terminal Binding Post Banana Plug Socket Female Connector")

Two short Dupont female-female jumper wires

Some electrical wires

Printing/Assembly:

First print knob1 (no support, 100% infill), just as the print is finished while it is still hot squeeze the flat piece in the center with a pair of tweezers to make it thinner

Now print knob2, back and the body with high infill (no support)

Make sure Knob 1 and knob 2 fit together, connect and disconnect them a few times.

Print the head and arms with low infill, no supports

Cut the two jumper wires in the middle so you have 4 wires with a female connector on one side.

insert the 5.5mm jack into the hole in the right arm

Solder the thin red wire from the amper meter + another wire to the buck converter IN+

Solder the thick black wire from the amper meter into the buck OUT-

Solder two more wires, one to the buck's IN- and one to the OUT+

Press the smaller knob 2 firmly into the buck's potentiometer, it should fit like a screw driver into the potentiometer screw.

Carefully place the buck between the 4 columns inside the body so that the knob part goes into the round hole

Carefully slide the back part into the slots in the 4 columns, the little ledge goes in the lower end, use hot glue to hold everything in place

Now, carefully (again) connect the outer part of the knob

Soldering time, make sure you solder everything on the correct side of the body so things fit into their holes

Solder the free wire from IN+ to the switch, then from the switch other terminal to the 5.5mm jack +

Solder the wire from the IN- to the 5.5mm jack

Solder the wire from OUT+ and the Amper meter thick red wire nd two of the dupont jumpers to the red banana

Solder the last thick wire from the amper meter and the other two dupont jumpers to the black banana

The amper meter thin black wire should be left unconnected

Now push all the component so they snap into their holes

Push the 4 DuPont connectors into the square hole between the two bananas, make sure the positive connectors are closer to the red banana and the negative to the black one

Use some glue in the right shoulder so the arm doesn't come out when you disconnect the power cord

Those were some long instructions, if you got this far leave a comment

Similar models

thingiverse

free

Enclosure for the DPS3005 by Mawkes

...switch") as can be seen on the picture.

the box has a small tilt for qol.

all the items needed are available via aliexpress.

thingiverse

free

12V power supply attachment by vandenmar

...b

iec320 c14 inlet module 10a 250v

12v dot light rocker switch 170228

second model is for an additional digital volt/amper meter.

thingiverse

free

Versatile Power Supply Cover/Enclosure

... the power supply into the case (the wires will be squeezed into the remaining area).

secure with m3 screws on the back and side.

grabcad

free

2 Position, Screw-Down Terminal Block to Female DC Power Adapter.

...wer-applications

amazon source:

https://www.amazon.com/gp/product/b01fhym61e/ref=ppx_yo_dt_b_search_asin_title?ie=utf8&psc=1

thingiverse

free

WZ3605E Buck boost power supply case by kiril_nedev

...

hp/dell charge connector

standart 5.5mm dc connector

and two 6mm holes for the output terminals.

i may add later a pd usb type-c

grabcad

free

DC Power Supply Panel Mount Jack, 2.1mm x 5.5mm

...wer supply jack panel mount connector 5.5mm x 2.1mm. model has separable nut. typically found on ebay, etc (where mine are from).

grabcad

free

2-way Banana Plug Jack

...2-way banana plug jack

grabcad

used as speaker terminals or bench power supply dc output terminals

thingiverse

free

DC-DC enclosure

...3a step down power supply module voltage buck converter adjustable"

example:https://www.aliexpress.com/item/32826540392.html

thingiverse

free

Case for RD DPS5005 DC-DC step down module (laboratory mini power supply) by Egorich

...l4a57bw

4) banana plugs couple terminal: https://www.amazon.com/highrock-terminal-binding-amplifier-copper/dp/b00d6aicr4

5) wires

thingiverse

free

Fume extractor by NirDobovizki

...ingiverse.com/thing:193647

designed with sketchup, fixed with microsoft 3d builder, sliced with cura and printed on a robo 3d r1+

Nirdobovizki

thingiverse

free

Dragon Box by NirDobovizki

...dragon box by nirdobovizki

thingiverse

my oldest son is into dungeons and dragons, so i made him a box to store his dice set.

thingiverse

free

Fish by NirDobovizki

...asy to print, it can be scaled up or down to just about any size and it looks very fishy.

i hope someone here will find it useful

thingiverse

free

Knob by NirDobovizki

...er infill percentage you want because the important parts are all walls.

designed with autodesk fusion 360, printed on robo3d r1+

thingiverse

free

Code Monkey by NirDobovizki

...res some post processing work with a knife to get right, if i have the time i'll redo the lower part of the head to fix this.

thingiverse

free

Lion Box by NirDobovizki

...and printed on my robo 3d r1+, if you print this model please upload a "make" with a photo i really enjoy seeing those.

thingiverse

free

Tracktor robot with place for electrnics by NirDobovizki

...f the parts don't need any infill, print 4 wheels and 1 each of the other stl files (i recommend high infill for the wheels).

thingiverse

free

Fume extractor by NirDobovizki

...ingiverse.com/thing:193647

designed with sketchup, fixed with microsoft 3d builder, sliced with cura and printed on a robo 3d r1+

thingiverse

free

Simple cabinet door handle by NirDobovizki

...ions for the parts above it.

design with onshape, cleaned with microsoft 3d builder, sliced with cura and printed on a robo3d r1+

thingiverse

free

ESP 01 Connector by NirDobovizki

...in your own designs.

designed with sketchup, stl cleaned with microsoft 3d builder, sliced with cura and printed on my robo3d r1+

thingiverse

free

Durable Fully Printable Customizable Spring by NirDobovizki

...akes it work.

i tested it in abs and petg and it worked really well (petg seems to be more durable), didn't try with pla yet.

Supply

3d_export

$5

black supply

...black supply

3dexport

black supply size: 57.9 x 29.2 x 34 sm

3d_export

free

office supplies

...office supplies

3dexport

turbosquid

$75

Supply Helicopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

Supply Ship

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Power Supply

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

school supplies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

3d_ocean

$15

Office Supplies Pack

...e dispenser eraser markers office paper pencils pens scissors stapler supplies tape tools work

pack of different office supplies.

3d_export

$18

dance supplies-workshop

...dance supplies-workshop

3dexport

dance supplies-workshop<br>3ds max 2015

3ddd

$1

Art Supplies

...art supplies

3ddd

мольберт , краски

318 793 poly count

Robot

3d_ocean

$20

Robot

...robot

3docean

character metal robot robot robotic white

robot model for 3dsmax 2009 and greater

3d_ocean

$45

Robot

...robot

3docean

fighing machine robot

a fighting robot from the scrapyard.

3d_ocean

$18

Robot

...robot

3docean

machin robot science fiction

high poly robot.

3d_export

$7

Robot

...robot

3dexport

robot

3d_export

$5

robot

...robot

3dexport

robot

3d_export

free

Robot

...robot

3dexport

robot

turbosquid

$10

Robot/ Alien Robot

...

royalty free 3d model robot/ alien robot for download as max on turbosquid: 3d models for games, architecture, videos. (1442828)

3d_export

$5

robot

...robot

3dexport

robot in blender

3ddd

$1

robot

...robot

3ddd

робот

robot

3ddd

$1

Robot

...robot

3ddd

робот

robot

Power

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx