Thingiverse

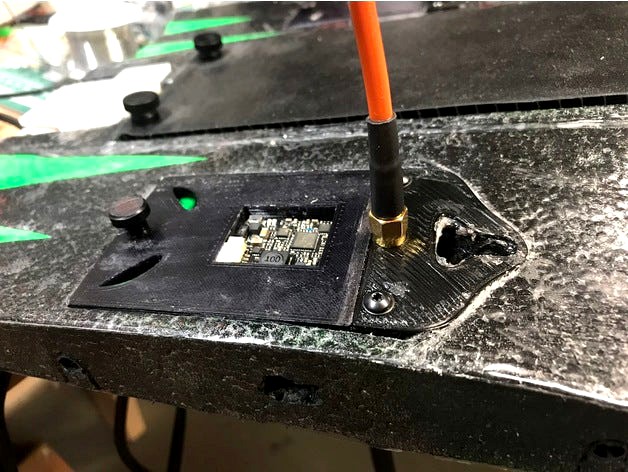

Ritewing Mini Drak TBS Unify Pro HV/RMRC 1.3ghz VTX Hatch & Duct by zanthor

by Thingiverse

Last crawled date: 3 years ago

UPDATED!

There was a design flaw with the original version of this... the leading edge caught the wind, and it worked it's way free... I ended up EJECTING my VTX/Antenna doing 85MPH... 285ft above the ground in a dive... needless to say I'm building a new drak.

This new revision is designed to be printed with a TPU hinge that is glued to the airframe and a rigid filament hatch that does the job of keeping things in place. With the leading edge glued in place there should be no problems with this design, I'll be testing it soon and will keep a close eye on it for wear and tear. (In my prototype I'll also be tethering the VTX to the airframe so if it comes loose it won't be an epic failure.)

UPDATED

I stuffed my TBS Unify Pro HV into one of the hatches on my Mini Drak and it was fine when it was 50F out... but at 75F I had it overheat and nearly lost my plane because of it. So I fixed the issue.

The hatch is printed out of a solid filament, and then once installed you heat the front end with a heat gun to allow the duct cover to form to the planes contours. Once it sets, use a hot wire to melt out the appropriate amount of foam to allow the duct to work.

Open to the top with a duct to run air under, this should solve the overheating issues. I ran this static on the bench at 200mw without overheating for 10 minutes...

Edit: Added a hatch without a VTX mount but still the front tongue for a naca duct intake with rear exits. This was simply because I wanted symmetry on my plane hatches!

Edit: Added a hatch for the RMRC 1.3ghz vtx uncased with a 20x20 heatsync attached!

There was a design flaw with the original version of this... the leading edge caught the wind, and it worked it's way free... I ended up EJECTING my VTX/Antenna doing 85MPH... 285ft above the ground in a dive... needless to say I'm building a new drak.

This new revision is designed to be printed with a TPU hinge that is glued to the airframe and a rigid filament hatch that does the job of keeping things in place. With the leading edge glued in place there should be no problems with this design, I'll be testing it soon and will keep a close eye on it for wear and tear. (In my prototype I'll also be tethering the VTX to the airframe so if it comes loose it won't be an epic failure.)

UPDATED

I stuffed my TBS Unify Pro HV into one of the hatches on my Mini Drak and it was fine when it was 50F out... but at 75F I had it overheat and nearly lost my plane because of it. So I fixed the issue.

The hatch is printed out of a solid filament, and then once installed you heat the front end with a heat gun to allow the duct cover to form to the planes contours. Once it sets, use a hot wire to melt out the appropriate amount of foam to allow the duct to work.

Open to the top with a duct to run air under, this should solve the overheating issues. I ran this static on the bench at 200mw without overheating for 10 minutes...

Edit: Added a hatch without a VTX mount but still the front tongue for a naca duct intake with rear exits. This was simply because I wanted symmetry on my plane hatches!

Edit: Added a hatch for the RMRC 1.3ghz vtx uncased with a 20x20 heatsync attached!

Similar models

thingiverse

free

TBS Unify Pro HV FPV VTX case by raar

...tbs unify pro hv fpv vtx case by raar

thingiverse

just a simple tbs unify pro hv fpv vtx case ;-)

thingiverse

free

TBS Source One Unify Pro HV Race Mount by Phoks

...unify pro hv race mount by phoks

thingiverse

just my design of a vtx mount for the unify pro hv race on the tbs source one quad.

thingiverse

free

TBS Unify Pro HV Mount by Koosie101

...help with heat, so the heat sink is designed to stick out the opening to the outside of the aircraft. i used a 23x23mm heat sink.

thingiverse

free

TBS Sourceone VTX unify pro hv + GPS BN880 mount by derbodesign

... gps bn880 mount by derbodesign

thingiverse

support pour tbs source one v3, avec le vtx de chez tbs unify pro hv et le gps bn880

thingiverse

free

Rotorama H5 Unify VTX Antenna mount by AdamHelbing

...rotorama h5 unify vtx antenna mount by adamhelbing

thingiverse

made it for tbs unify hv but will work with unify pro, too.

thingiverse

free

DQuad Obsession VTX Mount by Colorado_CJ

... is a vtx mount for the dquad obsession. i designed it to fit the tbs unify pro race hv vtx, though it might fit other vtx's

thingiverse

free

Ranger 1600 / 2000 VTX Mount by FPV_Sekta

...ranger 1600 / 2000.

designed for mounting tbs unify pro32 hv, but may fit any other vtx with dimensions not larger than 27*50 mm

thingiverse

free

TBS Unify Pro HV Race stack mount by Awacs

...www.thingiverse.com/thing:1569752

this one is for the tbs unify pro hv race.

you'll need a flexible material like tpu for it.

thingiverse

free

TBS Unify Pro32 HV Mount for Emax Buzz by 3dphdrx

... red (red jst plug)

7v-26v

gnd

green

black (red jst plug)

gnd

vout

yellow

yellow

video

tx6

white

white

rx1

thingiverse

free

TBS Unify HV Race + Kiss mini OSD holder by Kerle

...e + kiss mini osd holder by kerle

thingiverse

hello guys,

this is my selvemade holder for the unify and the flydunino mini osd.

3Ghz

3dfindit

free

AXION HF RELAY 3GHZ

...axion hf relay 3ghz

3dfind.it

catalog: te connectivity

3dfindit

free

AXICOM HF RELAY 3GHZ SHIELDED

...axicom hf relay 3ghz shielded

3dfind.it

catalog: te connectivity

thingiverse

free

IBCrazy 1.3GHz BlueBeam Ultra Antenna Case by Klattrup

...antenna case by klattrup

thingiverse

protective case for these antennas: http://www.getfpv.com/ibcrazy-1-3ghz-blubeam-ultra.html

thingiverse

free

FPV Ground station insert for Harbor Freight case by Shakeyjake

...dock power modulehttps://www.facebook.com/pcbs_for_fpv-603354826782830/ true dhttps://www.getfpv.com/furious-true-d-diversity-receiver-module-5-8ghz-system-v3-firmware-3-9.html matek 1.3 vrxhttps://www.racedayquads.com/products/matek-vrx-1g3-v2-1-2-1-3ghz-video-receiver?variant=31954972541041&gclid=cjwkcaiai_d_brapeiwasslbj53hiycfu2fniimcpkiufe7flaboctqtvqwsyrompprhaaxqp8nzaxocrfkqavd_bwe led lightshttps://www.racedayquads.com/products/matek-vrx-1g3-v2-1-2-1-3ghzvideo-receiver?variant=31954972541041&gclid=cjwkcaiai_d_brapeiwasslbj53hiycfu2fniimcpkiufe7flaboctqtvqwsyrompprhaaxqp8nzaxocrfkqavd_bwe cooling fan...

thingiverse

free

1.3GHz VTX Mount by StuntDouble

...ith friction. it is highly recommended to attach a heat sink to the exposed part of the vtx when using this mount (see pictures).

thingiverse

free

Yet another sax reed

...quite a lot faster (about 15 secs on a 3ghz machine) i also had issues with the cited design...

thingiverse

free

1.3 / 5.8 FPV station by bilou02130

...une antenne 5.8 : https://www.banggood.com/realacc-rhcp-super-mini-axii-stubby-5_8ghz-1_6dbi-antenna-for-tx-rx-fatshark-goggles-p-1221877.html?rmmds=category un recepteur 1.3ghz : https://www.readymaderc.com/products/details/rmrc-900mhz-1-3ghzreceiver-1258-with-rmrc-comtech-tuner une antenne 1.3 :...

blendswap

free

Engines Room VB GI Test Scene

...this thing renders in 30mins on a core quad 3ghz at 1080p. quality is not extra-high , gi noise...

grabcad

free

Ybox idea

...it is using an arm cpu (tegra 5 at 3ghz it would be able to run the same os...

cg_trader

free

Ybox idea

...it is using an arm cpu (tegra 5 at 3ghz it would be able to run the same os...

Zanthor

thingiverse

free

RC Plane Bungee Launch Hook by zanthor

...r

thingiverse

glue this to the bottom of your aircraft for use with bungee launch systems. need it bigger? scale the model :d.

thingiverse

free

rx5808-pro-diversity Case by zanthor

...that tupor designed, specifically designed for v1.0 rev 4. there are multiple arduino pro mini pinouts so you may need to tweak.

thingiverse

free

BLTouch Mount for Flexion E3D by zanthor

...d work with pretty much anything.

offsets are roughly as below:

x_probe_offset_from_extruder -25

y_probe_offset_from_extruder -29

thingiverse

free

Mini Drak Skid by zanthor

...es more organic, added glue swales in the bottom of it... ok, so there's not a lot to compare with such a simple part.

enjoy!

thingiverse

free

Taz5 BLTouch Mount by zanthor

...ide of your extruder to anchor this. i ran the bolt through the original nut and then captured the bltouch mount with a 2nd nut.

thingiverse

free

Transmitter Kickstand by zanthor

...protects my tbs crossfire when folded or kicked out.

vertical carbons are 120mm

top horizontal is 95mm

bottom horizontal is 85mm

thingiverse

free

Ram Air Scoop by zanthor

...p of the coro so you don't leave ugly edges behind. i printed out of taulman 910 nylon and used goop to stick them in place.

thingiverse

free

Ritewing Mini Drak LED Clamshell by zanthor

... so... in the end i settled on putting these pulsing led's under a clamshell that serves as a diffuser in front of the motor.

thingiverse

free

Taranis Antenna Hack Adapter by zanthor

... place...

remove the stock antenna, insert a bulkhead rp-sma connector in this print, and secure to the top with welder adhesive.

thingiverse

free

RX5808 Pro Diversity Bracket by zanthor

...have a printer, i have these for sale on my site (http://www.twistedquads.com/rx5808-pro-diversity-mounting-bracket_p_2602.html).

Ritewing

thingiverse

free

Ritewing SD/battery holder

...ritewing sd/battery holder

thingiverse

ritewing sd/battery holder

thingiverse

free

Ritewing HardCore24 FPV Cam Mounts by IcarusFPV

...ritewing hardcore24 fpv cam mounts by icarusfpv

thingiverse

fpv cam mounts for the ritewing hardcore44

thingiverse

free

Ritewing mini Drak camera nose

...ritewing mini drak camera nose

thingiverse

camera nose for mini drak from ritewing. for foxeer legend2 and any fpv camera

thingiverse

free

Ritewing Hardcore38 FPV Cam Mount by IcarusFPV

...ritewing hardcore38 fpv cam mount by icarusfpv

thingiverse

fpv cam mount for the ritewing hardcore 38

thingiverse

free

Ritewing Zcon motor mount for Ritewing D3542 motor by npmullins

......

untested so that why its marked as a work in progress. if you print it please provide so feedback on how well it fits, cheers

thingiverse

free

Ritewing Drak Parts

...ritewing drak parts

thingiverse

various parts i used on my big drak build

thingiverse

free

Ritewing Recon Vtx Vent for DJI by bjogro

...ritewing recon vtx vent for dji by bjogro

thingiverse

vents ritewing recon /zcon to cool a dji airtunit

thingiverse

free

Ritewing HC Screw by Guytranspo

... made the head a little larger than the stock screw, so it is easier to handle.

i print them with 100% infill for added strength.

thingiverse

free

Ritewing Nano Drak Servo Locating Jig

...ritewing nano drak servo locating jig

thingiverse

easy and fast servo locating jig for ritewing nano drak

thingiverse

free

Ritewing Motormount Badass 28xx Motor by bjogro

...ritewing motormount badass 28xx motor by bjogro

thingiverse

ritewing motormount for a badass 28xx motor.

i have it on my recon

Rmrc

thingiverse

free

RMRC recruit nose weight

...rmrc recruit nose weight

thingiverse

nose weight for the rmrc recruit v2 wing

adjust infill to achieve desired weight

thingiverse

free

RMRC Recruit Battery Tray by GWC71

...rmrc recruit battery tray by gwc71

thingiverse

battery tray for the rmrc recruit because i broke mine.

thingiverse

free

RMRC Hellbender antenna mount by porknick

...rmrc hellbender antenna mount by porknick

thingiverse

rmrc hellbender antenna mount. tbs pigtail style mount.

thingiverse

free

RMRC Anaconda connection board by robinbw

...inbw

thingiverse

intended for the rmrc anaconda. this connection board makes attaching the main wings to the fuselage less messy

thingiverse

free

RMRC-VTx-mount by Oxcart

...-off specifically for the ready made rc (rmrc) cricket video transmitter.

http://www.rcgroups.com/forums/showthread.php?t=2733031

thingiverse

free

RMRC Strix Screech antenna mount by porknick

...rmrc strix screech antenna mount by porknick

thingiverse

rmrc strix screech antenna holder and immortal t holder.

thingiverse

free

MFD crossbow mini - 1.3GHz Optimized 8dBi Patch RMRC by Vladimir_G

...mfd crossbow mini - 1.3ghz optimized 8dbi patch rmrc by vladimir_g

thingiverse

rmrc

thingiverse

free

samsung gear 360 mount for rmrc valorem by frankegold

...60 mount for rmrc valorem by frankegold

thingiverse

remixed this samsung 360 case to mount to the top of my rmrc valorem. enjoy!

thingiverse

free

RMRC GOBY 180 GoPro mount 30 degrees by steeves

...rmrc goby 180 gopro mount 30 degrees by steeves

thingiverse

gopro mount for rmrc goby 180.

30 degrees

thingiverse

free

AR Wing / RMRC Recruit Battery Tray by micaheli

...mrc recruit battery tray by micaheli

thingiverse

rmrc recruit / ar wing battery tray. stronger/better than original wooden one.

Drak

turbosquid

free

drak

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Ritewing Drak Parts

...ritewing drak parts

thingiverse

various parts i used on my big drak build

thingiverse

free

Drak esc scoop

...ingiverse

just adjusted the size of the original design in order to make it applicable to the component bay of the ritewing drak

thingiverse

free

Drak the Barbarian by NinjaMMA1

...n by ninjamma1

thingiverse

drak the barbarian is a gladiator in the arena. if you want to see more gladiators, please follow me.

thingiverse

free

mini drak esc clamp by clevis41

...mini drak esc clamp by clevis41

thingiverse

clamps for mini drak esc

thingiverse

free

Mini Drak wing tips by scottyh72

...mini drak wing tips by scottyh72

thingiverse

wing tip protectors for the ritewing mini drak.

thingiverse

free

Drak Saddle scoop

...drak saddle scoop

thingiverse

part one of a compartment scoop

thingiverse

free

Nano Drak wingtips

...nano drak wingtips

thingiverse

scaled version of the winglets by norcot.

thingiverse

free

Drak scoop cover latch

...drak scoop cover latch

thingiverse

thingiverse

free

FC mount for Mini Drak by curlypaul

...size flight controllers for mini drak

just a simple mount that tilts fc up 3.5°, which is what i measured the mini-drak bay to be

Hv

3ddd

$1

Tobias Grau BILL HV + LED

...tobias grau bill hv + led

3ddd

tobias grau

tobias grau bill hv + led

3ddd

$1

Мясорубка MOULINEX ME 6061 HV 8

...ка moulinex me 6061 hv 8

3ddd

мясорубка , moulinex

"moulinex" прослужит долго)

cg_studio

$129

Republic P-47D Thunderbolt - HV-A - Lt.Col. F.S.Gabreski3d model

...public p-47d thunderbolt - hv-a - lt.col. f.s.gabreski 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Hudson Valley Lighting Mansfield Transitional Foyer Light HV-1315

...5

материал: polished nickel

d=15" / 38 cm

url:http://www.hudsonvalleylighting.com/productdetails.aspx?item=1315-pn

3ddd

$1

Occhio, Sento, faro singolo

...occhio, sento, faro singolo 3ddd occhio http://www.occhio.de/en/products/occhio-system/sento/ceiling-lamps/faro-singolo/hv ...

3dfindit

free

HV

...hv

3dfind.it

catalog: festo

3dfindit

free

HV

...hv

3dfind.it

catalog: festo

thingiverse

free

hv pylon by Syzguru11

...hv pylon by syzguru11

thingiverse

hv pylon

3dfindit

free

HV Series

...hv series

3dfind.it

catalog: wain electrical

thingiverse

free

HV transformer housing by zomtronic

...hv transformer housing by zomtronic

thingiverse

hv transformer housing with cover

Unify

3ddd

$1

Душевой Смеситель

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3ddd

$1

Зеркало в санузел

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3ddd

$1

Набор гостиничной мебели

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3ddd

$1

Сушка для тарелок

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3ddd

free

энергосберегающий контроллер "SALTO"

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3d_export

$15

PKP Pecheneg

...ary improvements to the new model.<br>model format: fbx<br>texture format: png<br>texture resolution: 2048x2048

3d_export

$79

Female Muscular System

...ss what version your 3d program is. preview images are rendered in keyshot formats are: 3ds max maya lightwave3d cinema4d 3ds obj

3d_export

$15

Masculine Female

...ss what version your 3d program is. preview images are rendered in keyshot formats are: 3ds max maya lightwave3d cinema4d 3ds obj

3ddd

$1

Диван "БОСТОН"

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

3ddd

$1

Стол на опоре Spartak-light с табуретами

...я сэмплов в материалах можно воспользоваться скриптомhttp://lextorlex.blogspot.com/2013/12/a-global-samples-script.html

Vtx

turbosquid

$1

FPV VTX Antenna

...e 3d model fpv vtx antenna for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1230317)

humster3d

$75

3D model of Toyota 86 GT VTX 2013

...tailed 3d model of toyota 86 gt vtx 2013 in various file formats. all our 3d models were created maximally close to the original.

thingiverse

free

Gnarlyfpv - Primo VTX adapter - Triangle VTX by Gnarlyfpv

...angle vtx by gnarlyfpv

thingiverse

tiny lightweight vtx adapter for the gnarlyfpv primo.

supports most triangle style vtx units.

thingiverse

free

FLOSS2 VTX MOUNT

...floss2 vtx mount

thingiverse

antenna vtx mount floss2

thingiverse

free

Drone vtx offset vtx stack mount by drvonhoss

... offset vtx stack mount by drvonhoss

thingiverse

offset vtx mount so the antenna clears the outer standoff on some drones/quads.

thingiverse

free

Vtx mount by kerst

...vtx mount by kerst

thingiverse

just a vtx mount for spceone 220

thingiverse

free

nano VTX mount 20x20

...nano vtx mount 20x20

thingiverse

for 20x20 stacks and mounts, nano vtx holder like eachine vtx nano or tbs nano vtx.

thingiverse

free

A01 VTX Mount

...ections/camera-vtx/products/a01-25-200mw-5-8g-vtx

and first of all it was design for a primo from gnarly fpv but fit on all tw fc

thingiverse

free

vtx sheath by mabadajo

...vtx sheath by mabadajo

thingiverse

this is to help hold the vtx mast more steady in a crash.

thingiverse

free

SWH210 vtx holder by Dubeswings

...swh210 vtx holder by dubeswings

thingiverse

vtx holder for swh210. fits rctimer micro 200mw vtx

Hatch

3d_export

$5

hatch

...hatch

3dexport

hatch canalizatton 3d model in formats fbx, obj, blend + materials.

turbosquid

$29

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Hatch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Roof Hatch

...bosquid

royalty free 3d model roof hatch for download as obj on turbosquid: 3d models for games, architecture, videos. (1689690)

turbosquid

$29

Metal Hatch

...

royalty free 3d model metal hatch for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1365087)

turbosquid

$28

Floor Hatch

...ty free 3d model wall hatch for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1669707)

Tbs

turbosquid

$69

TB Vaccine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

TB Bacteria

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

TB Lamp

...tb lamp

3ddd

море

настольный светильник. похожа с моделью zonca.

turbosquid

free

GUN TBS 01C

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$58

1992 Ferrari 348 TB 3D Model

...1992 ferrari white red tb 348 car rim tire glass material chrome mirror parts

1992 ferrari 348 tb 3d model cafeout 35209 3dexport

3d_ocean

$49

Roland TB-303 (including chip)

...you like acid music, you must know it. full model including chips! - original dimension - original chip - hi res textures and ...

3d_export

$12

tb office building

...s a office building design that made by 3dsmax 2012 and vray 3.2. containing max file, fbx file (with full material and texture).

3d_export

$99

Ferrari 348 tb 1989 to 1995 3D Model

... 1994 1995 1990 1991 1992 italy supercar interior ferrari ferari 348 tb

ferrari 348 tb 1989 to 1995 3d model squir 81175 3dexport

turbosquid

$15

Renault TB Armored Train (low poly)

...model renault tb armored train (low poly) for download as obj on turbosquid: 3d models for games, architecture, videos. (1165536)

cg_studio

$99

Ferrari 348 tb 1989 -19953d model

...s .c4d .fbx .lwo .max .obj - ferrari 348 tb 1989 -1995 3d model, royalty free license available, instant download after purchase.

Duct

turbosquid

$19

Duct Set

...d

royalty free 3d model duct set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1145038)

turbosquid

$10

Duct Tape

...id

royalty free 3d model duct tape for download as ma and ma on turbosquid: 3d models for games, architecture, videos. (1580351)

turbosquid

free

Duct Tape

...

free 3d model duct tape for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1486518)

3d_ocean

$7

Air-duct

... ventilation

high quality industrial air duct ventilation model. created in cinema 4d but comes in various other formats as well.

turbosquid

$20

Air ducts

...lty free 3d model air ducts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262476)

3d_export

$10

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

turbosquid

$2

Duct Tape

...e 3d model duct tape for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1473972)

turbosquid

free

Duct Tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Duct tape

...polys. includes: cinema 4d project. model in 3 formats (obj, fbx, 3ds). 6 .tga texture maps (albedo, ambient occlusion, diffus...

turbosquid

$40

Ventilation Duct PACK

...tion duct pack for download as ma, obj, fbx, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1287068)

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)