Thingiverse

Rhombot by 3dexplorer

by Thingiverse

Last crawled date: 3 years ago

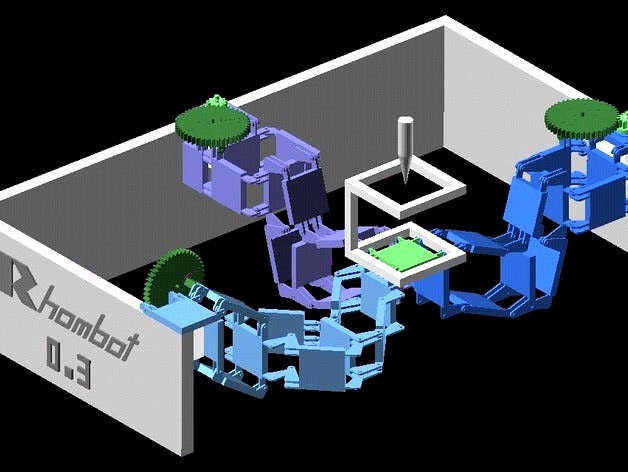

Rhombot 0.3 alpha

See an animation of it on YouTube: http://www.youtube.com/watch?v=zSeg-Th1tRw

The Rhombot is a printable XYZ stage based on 3 chains of rhombus shapes. It is currently just an early alpha version. It's a rough sketch of the idea. See one of the two .MOV videos for how it is intended to work.

The Rhombot can be used with Makerbot motors, electronics, and extruders. All parts can be built in a Makerbot, or in itself. The Rhombot has no rods, belts, pulleys, nuts, threads, screws (other than the screws on the motor), sarrus hinges, moving towers, or moving motors.

That last point is important. The XYZ motors and extruder motor are all fixed. The X motor does NOT move a carriage carying the Y motor. The Z motor does NOT raise a platform carrying the extruder motor. Instead, all 4 motors can be permanently mounted. This means it will work with motors that are arbitrarily large and heavy. That should help when we start printing motors, since the early ones are likely to be large and heavy.

The green build platform has a Z coordinate that is the sine of the rotation angle of the NEMA17 stepper motor under the light blue panel. X is the sine of the dark blue arm's motor, and Y is the sine of the purple arm's motor. To use this to print, it would be necessary to modify Skeinforge to take the extra sine into account.

The build volume is large enough to print all its own parts. The animation even shows it building 4 of its own parts, as well as building a cube large enough to hold any of its own parts. The build volume actually extends beyond this cube, but is an odd shape. The cube in the video is the largest cube that fits within the build volume, oriented that way.

This has now been printed on a ZCorporation ZPrinter 650. It glues powder together to give an object similar to sandstone. This means the pieces are extremely rigid, but break easily. The printed Rhombot has hinges that move smoothly, with almost no slop at all in the direction of the hinge, nor orthogonal to it. The smooth movement is surprising, since the surface feels like sandpaper.

If you hold two panels that should stay parallel and try to twist one, it seems to allow almost no twisting at all. The small amount of twisting that it does allow seems to be from some of the hinge pins that are too thin. The hinge pins are wooden toothpicks, and don't have uniform diameter. They will soon be replaced with segments of 2.4 mm diameter aluminum rod.

The next step is to build this in plastic. It will be far stronger, but it may start having problems with panels bending and twisting. That's the big question. There are also several design changes that should make it into the next version.

See an animation of it on YouTube: http://www.youtube.com/watch?v=zSeg-Th1tRw

The Rhombot is a printable XYZ stage based on 3 chains of rhombus shapes. It is currently just an early alpha version. It's a rough sketch of the idea. See one of the two .MOV videos for how it is intended to work.

The Rhombot can be used with Makerbot motors, electronics, and extruders. All parts can be built in a Makerbot, or in itself. The Rhombot has no rods, belts, pulleys, nuts, threads, screws (other than the screws on the motor), sarrus hinges, moving towers, or moving motors.

That last point is important. The XYZ motors and extruder motor are all fixed. The X motor does NOT move a carriage carying the Y motor. The Z motor does NOT raise a platform carrying the extruder motor. Instead, all 4 motors can be permanently mounted. This means it will work with motors that are arbitrarily large and heavy. That should help when we start printing motors, since the early ones are likely to be large and heavy.

The green build platform has a Z coordinate that is the sine of the rotation angle of the NEMA17 stepper motor under the light blue panel. X is the sine of the dark blue arm's motor, and Y is the sine of the purple arm's motor. To use this to print, it would be necessary to modify Skeinforge to take the extra sine into account.

The build volume is large enough to print all its own parts. The animation even shows it building 4 of its own parts, as well as building a cube large enough to hold any of its own parts. The build volume actually extends beyond this cube, but is an odd shape. The cube in the video is the largest cube that fits within the build volume, oriented that way.

This has now been printed on a ZCorporation ZPrinter 650. It glues powder together to give an object similar to sandstone. This means the pieces are extremely rigid, but break easily. The printed Rhombot has hinges that move smoothly, with almost no slop at all in the direction of the hinge, nor orthogonal to it. The smooth movement is surprising, since the surface feels like sandpaper.

If you hold two panels that should stay parallel and try to twist one, it seems to allow almost no twisting at all. The small amount of twisting that it does allow seems to be from some of the hinge pins that are too thin. The hinge pins are wooden toothpicks, and don't have uniform diameter. They will soon be replaced with segments of 2.4 mm diameter aluminum rod.

The next step is to build this in plastic. It will be far stronger, but it may start having problems with panels bending and twisting. That's the big question. There are also several design changes that should make it into the next version.

Similar models

thingiverse

free

Parametric nesting fidget cube by Aahz

...k.

ears on top hinges are weakest part, be carefull with it at the beginning.

bottom hinges are the hardest part to start moving.

thingiverse

free

box by Onodera_chan

...her nicely and has a quality design that is sturdy and efficient.

https://www.thingiverse.com/thing:2690013 (link to puzzle cube)

grabcad

free

Motor Blower Assembly

...f all are present in the folder. blower motors are able to move large volumes of air since they use fan cages in enclosed spaces.

thingiverse

free

MBot Cube by mbot3d

...d printer based on makerbot's replicator. thanks for makerbot's open source project.

get more on mbot cube www.mbot3d.com

thingiverse

free

Negasphere by hoeken

... taken out of the inside. should be easy to print with a makerbot machine. i\'m looking forward to trying in a few minutes.

3dwarehouse

free

Awesome twisted building.

...d building.

3dwarehouse

this is an oddly shaped building that has its own helicopter and is twisted. #helicopter #shape #twisted

thingiverse

free

Winding key - Prusa extruder indicator by slawek

...arm, so i don't recommend to print with pla because the tip of the part slides into the motor where it could deform and melt.

thingiverse

free

MakerBot extruder hose holder

...er, but i image it should fit the any makerbot extruder.

attach the small end to the swivel and push the hose into the other end.

thingiverse

free

Extruder motor strain relief bracket by Pointedstick

...round. tested with a greg's hinged accessible extruder, but it'll probably fit any extruder design with an exposed motor.

3dwarehouse

free

Twist and Turn

...twist and turn

3dwarehouse

large cube twisted #cube #large #turn #twist

3Dexplorer

thingiverse

free

Public Domain Numbers by 3dexplorer

...l 43 parts, two parts connect if they have the same number printed on them. it's quite a jigsaw puzzle without the numbers.

thingiverse

free

Public Domain Involute Parameterized Gears by 3dexplorer

... of missing features. perhaps someone could build on this to create a public domain gear script with all the bells and whistles.

thingiverse

free

Public Domain Involute Parameterized Gears: Optimized for Speed by zkarcher

...for speed by zkarcher thingiverse this is remix of @3dexplorer#39;s excellent involute parameterized gears. this code is optimized for...

thingiverse

free

OpenScad Rack & Pinion generator by racatack

...on as separate features in v1.1) many thanks to 3dexplorer for the original work and to quisam2342 for his/her...

thingiverse

free

Public Domain Involute Parameterized Gears: Powered Up by TrinaryLogic

...update to the public domain involute gears library by @3dexplorer with optimisations by @zkarcher. this library provides a module...