Thingiverse

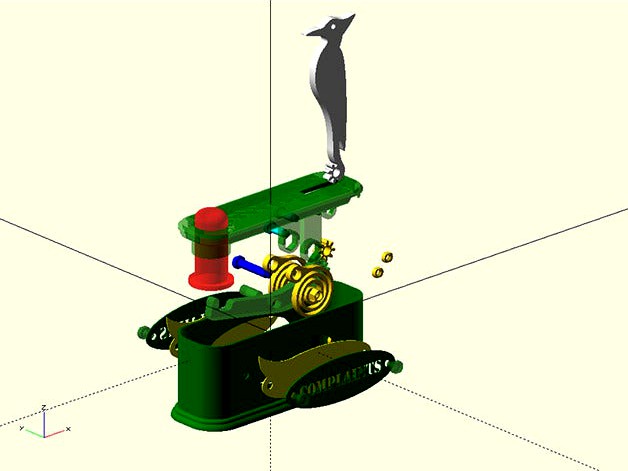

Remix of Complaint Button by GeoDave

by Thingiverse

Last crawled date: 3 years ago

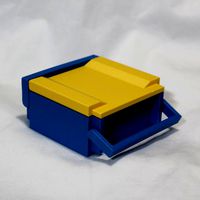

I really liked this design, but the tolerances were a little tight for my printer. I started to just redo the axles & pins, but then got a little carried away and changed all but the button. I changed the 8mm axles to be an 8mm bolt with 6mm threads on the end. By doing this, I did have to cut an access slot for the hole where the woodpecker gear connects. This is not noticeable when the top is attached to the bottom. Since I had to change the top, I decided to round the corners as well & they are customizable in the openscad script. I used a radius of 20mm for the corners, but up to 28mm should work. Do not use less than 2mm for the radius as I did not allow for sharp corners in the code. I generally had a tolerance of .4mm for axles, holes & threaded parts.

The threaded parts I used a non-standard threading for better printing at .2mm layer height, by changing the thread pitch from 1.0 to 1.25 & Thread_Angle = 40. To modify any of the openscad files that use the threading, you will need to download the threads.scad file from http://dkprojects.net/openscad-threads/

There are 2 versions of the base, one with cutouts for the sign(Base_Mod_WithCutouts_Rev5.stl) I am using & one without cutouts(Base_Mod_Rev5.stl).

You should be able to print 1 each of the parts, except print 2 each of the Complaints_Blank.stl & Complaints_Text.stl.

The AxleShort_WithNut_Rev5.stl are 2 axles with nuts to connect to the woodpecker gear & small gear.

The AxleLong_WithNut_Rev7.stl goes in middle of the springs. I print 2 of these for longer printing per layer, but you only need 1 of these.

The PinLong_WithNut_Rev7.stl goes at the end of the spring connection.

The ComplaintScrews_WithNuts_Rev3.stl are the screws & nuts to connect the Complaint Text.

Follow the directions from the original design: https://www.thingiverse.com/thing:2882432 for installing this.

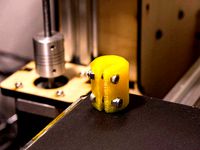

The STL files I generated worked for me with any sanding, but think I do need to sand the top and bottom of the woodpecker gear for smoother movement.

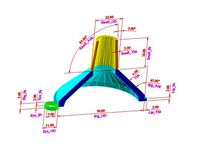

I used .2mm layer height for all prints except for the Top & Base I used variable layer height with the Slic3r Prusa Edition 1.40.0-beta. This saves probably 30 minutes on each of those prints.

For the top I used these layer ranges

//Top Variable Slicing Layers

//0 - 2.35 .2

//2.35 - 6.75 .3

//6.75 - 26.15 .2

//26.15 - 40.95 .3

//40.95 - 58.35 .2

If you use the base without the cutouts, you could use .3mm for all the layers

//Base Variable layer slicing

//0 - 24.75 .3

//24.75 - 62.55 .2

//62.55 - 77.95 .3

The openscad file for the Spring_Left_Mod_Rev2.scad is also used to generate the Right spring. It is just mirrored about one of the axis.

I would like to change the text a little better, but that works for now.

If I missed something let me know.

The threaded parts I used a non-standard threading for better printing at .2mm layer height, by changing the thread pitch from 1.0 to 1.25 & Thread_Angle = 40. To modify any of the openscad files that use the threading, you will need to download the threads.scad file from http://dkprojects.net/openscad-threads/

There are 2 versions of the base, one with cutouts for the sign(Base_Mod_WithCutouts_Rev5.stl) I am using & one without cutouts(Base_Mod_Rev5.stl).

You should be able to print 1 each of the parts, except print 2 each of the Complaints_Blank.stl & Complaints_Text.stl.

The AxleShort_WithNut_Rev5.stl are 2 axles with nuts to connect to the woodpecker gear & small gear.

The AxleLong_WithNut_Rev7.stl goes in middle of the springs. I print 2 of these for longer printing per layer, but you only need 1 of these.

The PinLong_WithNut_Rev7.stl goes at the end of the spring connection.

The ComplaintScrews_WithNuts_Rev3.stl are the screws & nuts to connect the Complaint Text.

Follow the directions from the original design: https://www.thingiverse.com/thing:2882432 for installing this.

The STL files I generated worked for me with any sanding, but think I do need to sand the top and bottom of the woodpecker gear for smoother movement.

I used .2mm layer height for all prints except for the Top & Base I used variable layer height with the Slic3r Prusa Edition 1.40.0-beta. This saves probably 30 minutes on each of those prints.

For the top I used these layer ranges

//Top Variable Slicing Layers

//0 - 2.35 .2

//2.35 - 6.75 .3

//6.75 - 26.15 .2

//26.15 - 40.95 .3

//40.95 - 58.35 .2

If you use the base without the cutouts, you could use .3mm for all the layers

//Base Variable layer slicing

//0 - 24.75 .3

//24.75 - 62.55 .2

//62.55 - 77.95 .3

The openscad file for the Spring_Left_Mod_Rev2.scad is also used to generate the Right spring. It is just mirrored about one of the axis.

I would like to change the text a little better, but that works for now.

If I missed something let me know.

Similar models

thingiverse

free

Hummingbird Remix by GeoDave

...

there is an openscad file for each part i changed in case you want to modify this further. if i left something out, let me know.

thingiverse

free

Remix of Trammel of Archimedes by GeoDave

...les & stl files and photos. print 1 each of the stl files. i printed at 20% infill, but minimum infill should be sufficient.

thingiverse

free

Remix of Dual Mode Spring Motor Rolling Chassis by GeoDave

...r further info & assembly instructions of this see the original design of this part: http://www.thingiverse.com/thing:2025760

thingiverse

free

Remix of i3v Lead Screw Nut Plate by GeoDave

...ere are openscad files for this nut plate & coupler if you want to adjust any of the variables. it is commented fairly well.

thingiverse

free

YA Spool Cone by Gythral

...heights that are smaller than the bearing, as i discovered that openscad needs new variables so that conditions can change values

thingiverse

free

i3v anti z wobble and backlash mount Remix for easier printing & variable configurations by GeoDave

...ted the height of the tmount connection so it is a slip fit. i had to file the previous version down a little to get it to fit.

thingiverse

free

Complaint Button - Woodpecker Artwork by TimTimTimTimTim

... double-sided tape should work just fine as well!)

brilliant model, lots of fun to print & assemble!

[more photos to follow].

thingiverse

free

A Very Customizable Funnel by GeoDave

...gs in the openscad script.

i changed the hook_xx variable names to a more appropriate eye_xx names after a friend mentioned this.

thingiverse

free

Parametric Upgrade of HicWic Universal Tool Mount And Holder for MPCNC by GeoDave

...sample stl files, a us emt mount, an ie emt mount & a 49mm tool mount.

for the test prints, i changed the following variables

thingiverse

free

2mm Motor To Lego Axle by Adr1an64

... a lego axle. can be used for any lego project to connect a motor to a wheel.

i added a f3d file if a size adjustment is required

Geodave

thingiverse

free

Shower Caddy accessory holder by GeoDave

... upside down on out shower caddy. i did this a few months back, but changed the design recently to make it stay in place better.

thingiverse

free

Wood Bracket with Wire Clip by GeoDave

...be either at 0 or 90 degrees to wood bracket. i included the openscad & dxf files if you want to adjust this to other sizes.

thingiverse

free

Gimbal Spinner by GeoDave

...elow 24mm for the inside width clearance distance or below 54mm for the gimbal distance. i will take a look at fixing that soon.

thingiverse

free

Spinning Top with Thumbwheel by GeoDave

... works.

https://youtu.be/fpaissfvmqm

here is the openscad source file for the thumbwheelhttps://www.thingiverse.com/thing:2407027

thingiverse

free

Parametric Shaft Coupler by GeoDave

... - m3x14mm bolts & locknuts for the 5mm to 5mm that is shown printed in yellow petg.

you can also open this in the customizer

thingiverse

free

Thumbwheel for a Jack Screw by GeoDave

...ese parts, i realized this might make a good spinning top. here is a link to that top. https://www.thingiverse.com/thing:2407034

thingiverse

free

Remix of Meade Autostar holder for LXD75/LX90 mount by GeoDave

... added 1mm extra around the holes.

i used 2 - m3x16mm screws with locknuts & printed at 40% infill with esun silver pla pro.

thingiverse

free

Parametric Tapered Spacer by GeoDave

... the larger diameter against the wheels & they did not roll at all. the 2nd & 3rd photo should show what i mean by this.

thingiverse

free

A Very Customizable Funnel by GeoDave

...gs in the openscad script.

i changed the hook_xx variable names to a more appropriate eye_xx names after a friend mentioned this.

thingiverse

free

Parametric Honeycomb containers by GeoDave

...file to varie the size of them based on 8 variables. since making this, i have made a number of containers for various purposes.

Complaint

3d_export

free

Smart and Luxurious Apartment in Bangalore

...bhk luxurious flats for sale at sarjapur, a vaastu complaint flat for sale at kankapura bangalore. feel free to...

3d_export

$80

brachiosaur forever - 8k

...is always available should you have any question or complaint ...

3d_export

$70

stegosaur forever - 8k

...is always available should you have any question or complaint stegosaur brachiosaur brachiosaurus t t rex rex trex trex...

3d_export

$70

Triceratops Tribute - 8K

...is always available should you have any question or complaint triceratops stegosaur brachiosaur brachiosaurus rex rex trex trex trex...

3d_export

$60

Carnotaur Forever - 8K

...is always available should you have any question or complaint carno carnotaur carnotaurus stegosaur t rex rex trex trex...

3d_export

$70

raptor forever - 8k

...is always available should you have any question or complaint ...

3d_export

$50

Suchomimus Tenerensis - 8K animated

...is always available should you have any question or complaint<br>spinosaur spinosaurus suchomimus suchomim rex rex trex trex trex dinosaur...

3d_export

$50

Mosasaurus Rex - 8K animated

...is always available should you have any question or complaint<br>[video=https://www.youtu.be/zztqjjxihey]<br>mosasaur mosasaurus rex rex trex trex trex dinosaur animal reptile...

3d_export

$100

the t rex - 8k

...is always available should you have any question or complaint<br>t rex rex trex trex trex dinosaur animal creature monster...

3d_export

$100

t rex forever - 8k

...is always available should you have any question or complaint<br>t rex rex trex trex trex dinosaur animal creature monster...

Button

archibase_planet

free

Buttons

...buttons

archibase planet

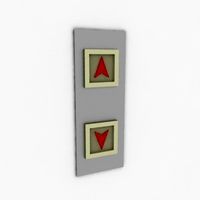

lift elevator call buttons

elevator call buttons - 3d model for interior 3d visualization.

3ddd

$1

Button

... button , john reeves

набор мебели button от дизайнера john reeves

3d_export

$5

Button

...button

3dexport

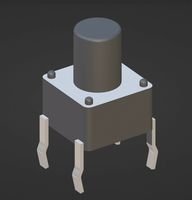

smd button<br>verts 2.180<br>faces 3.848

turbosquid

$4

Button

...

turbosquid

royalty free 3d model button for download as fbx on turbosquid: 3d models for games, architecture, videos. (1297941)

turbosquid

$1

Button

...

turbosquid

royalty free 3d model button for download as fbx on turbosquid: 3d models for games, architecture, videos. (1392935)

turbosquid

$9

buttons

...id

royalty free 3d model buttons for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1404875)

turbosquid

$6

button

...uid

royalty free 3d model button for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1669204)

turbosquid

$5

Button

...uid

royalty free 3d model button for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1710868)

turbosquid

$3

Button

...quid

royalty free 3d model button for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1510524)

turbosquid

$3

Button

...quid

royalty free 3d model button for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1509961)

Remix

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

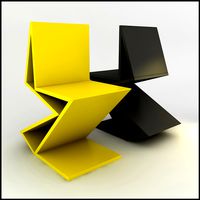

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...grey/grey, dusty green/dusty green, nature/oak, natural white/oak upholstery options remix 183/black, remix 133/grey, remix 643/dusty red leather options black...

3ddd

$1

Barovier&Toso 7190-7195

...7190-7195 3ddd barovier&toso потолочнай люстра фабрики barovier&toso;, коллекция manhattan remix артикул 7190-7195. размеры в inches: 39"...

3d_export

$5

3D Locking Handle Weatherproof Storage Box Container

...handle weatherproof storage box container 3dexport new, improved and remixd! no screws required. print-in-place. weatherproof. parametric. 2 parts. easy...

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...cell phone mobile cellular super lcd touchscreen touch screen remix amber gold .max .obj .mb .lwo .fbx .c4d .3ds...