Thingiverse

ReliaBuild 3D - 20 tooth Pulley Option by JP1

by Thingiverse

Last crawled date: 3 years, 3 months ago

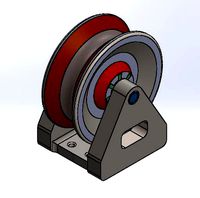

These brackets are the official ReliaBuild 3D printer brackets for using 20 tooth pulleys. They will work with the RB3 and RBB3. They will also work with the Rigidbot Standard and Big printers if they are using the upgraded bed carriage. In general these will work on a 0.75" or 19 mm square rail with rounded edges.

Assembly hardware needed for a pair of brackets:

4 x MF115ZZ flanged bearings

4 x 9.5mm x 5mm x 3mm Nylon spacers

2 x GT2 5mm bore 14mm tall 16 tooth pulley for a 6mm belt (3 or 4 mm set screws)

2 x 5x25 mm 4mm socket head bolts and nuts

Use the same M4x8 bolts (qty 8) used to mount the original brackets

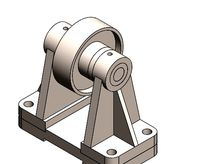

These are designed for using two MF115ZZ flanged bearings in each X and Y bracket set with a 5x11x4mm size and opposite of a GT2 5mm bore 16mm tall 20 tooth pulley for a 7mm belt. Since the idler bearing with the belt wrapped around it has the same diameter as the 20 tooth pulley with a belt around it the brackets can be centered in relation to the pulleys. The same bracket set will work for the X and Y directions. There is however a top and a bottom bracket piece with the slot for the nut intended to be facing down for easy tightening.

A 9.5mm x 5mm x 3mm spacer goes on either side of the bearing set between the brackets. A printable version is included here.

Two 5x25 mm 4mm socket head bolts with M5 nuts are needed for assembly of the two bracket sets. The assembled brackets mount to the rails with M4x8 bolts.

The belt clips on the bed carriage and the extruder carriage need to be moved over towards the new belt location. A drill guide to mark the holes is included. The small pegs go in the original holes and the through holes mark the new location to align the belt clip. Use a 1/8" drill to make teh through holes in the bed and extruder carriages.

DXFs of a modified carriage for a Single and a Dual extruder are included for those that want to have one cut from 1/8" thick flat aluminum plate.

Adjust the height of the pulleys such that the belt clip barely clears under the carriage.

If you have an RB2 or ReliaBuild 3D board in your machine change the number of steps in the firmware for the X and Y directions to 80.3309814

If you are using an original Rigidbot board the Y value will be half of this.

There is a belt tightening key to help push the bearings in and tighten the belts.

Use thermally calibrated filament for best fit results. I use this clip method.https://www.thingiverse.com/thing:1037301

Assembly hardware needed for a pair of brackets:

4 x MF115ZZ flanged bearings

4 x 9.5mm x 5mm x 3mm Nylon spacers

2 x GT2 5mm bore 14mm tall 16 tooth pulley for a 6mm belt (3 or 4 mm set screws)

2 x 5x25 mm 4mm socket head bolts and nuts

Use the same M4x8 bolts (qty 8) used to mount the original brackets

These are designed for using two MF115ZZ flanged bearings in each X and Y bracket set with a 5x11x4mm size and opposite of a GT2 5mm bore 16mm tall 20 tooth pulley for a 7mm belt. Since the idler bearing with the belt wrapped around it has the same diameter as the 20 tooth pulley with a belt around it the brackets can be centered in relation to the pulleys. The same bracket set will work for the X and Y directions. There is however a top and a bottom bracket piece with the slot for the nut intended to be facing down for easy tightening.

A 9.5mm x 5mm x 3mm spacer goes on either side of the bearing set between the brackets. A printable version is included here.

Two 5x25 mm 4mm socket head bolts with M5 nuts are needed for assembly of the two bracket sets. The assembled brackets mount to the rails with M4x8 bolts.

The belt clips on the bed carriage and the extruder carriage need to be moved over towards the new belt location. A drill guide to mark the holes is included. The small pegs go in the original holes and the through holes mark the new location to align the belt clip. Use a 1/8" drill to make teh through holes in the bed and extruder carriages.

DXFs of a modified carriage for a Single and a Dual extruder are included for those that want to have one cut from 1/8" thick flat aluminum plate.

Adjust the height of the pulleys such that the belt clip barely clears under the carriage.

If you have an RB2 or ReliaBuild 3D board in your machine change the number of steps in the firmware for the X and Y directions to 80.3309814

If you are using an original Rigidbot board the Y value will be half of this.

There is a belt tightening key to help push the bearings in and tighten the belts.

Use thermally calibrated filament for best fit results. I use this clip method.https://www.thingiverse.com/thing:1037301

Similar models

thingiverse

free

ReliaBuild 3D - 16 tooth Pulley Option by JP1

... belts.

use thermally calibrated filament for best fit results. i use this clip method.https://www.thingiverse.com/thing:1037301

thingiverse

free

3DRAG/K8200 GT2 X BELT by popeye

...nt right, with hole for endstop m3x50 bolt

left pulley support (needed: 2 x 625 bearings, 1 x m5x30 rod, 1 x gt2 pulley 20 tooth)

thingiverse

free

Toothed belt spacer by 3DBobCZ

...4 washers to accurately set the toothed belt with the gt2 pulley and the pulley on other side. i used two washers for each bolt.

thingiverse

free

ANET A8 X Axis Belt Tensioner for GT2 20 Tooth Metal Pulley by Mr_Dabrudda

...ooth metal pulley by mr_dabrudda

thingiverse

this is a remix which fits a gt2 20 tooth metal pulley instead of the two bearings.

thingiverse

free

Anet A8 Y-Axis Belt Tensioner for GT2 20 Tooth Metal Pulley by Mr_Dabrudda

...ulley with ball bearings bought from ebay on my y-axis.

how to counter-sink a hex nut into a 3d printhttps://youtu.be/qx_bx5um4yg

3dwarehouse

free

GT2 20T PULLEY, 5mm BORE

...ulley, 5mm bore

3dwarehouse

20 tooth pulley for gt2 belts, 5mm bore. dimensions taken from actual item as used on my 3d printer.

grabcad

free

GT2 10mm 20 tooth Pulley

...gt2 10mm 20 tooth pulley

grabcad

gt2 10mm 20 tooth pulley with set screw hole

thingiverse

free

Alumunium profile 3030 Carriage slider by squadzone

...h

4 bolts 8mm length 70mm

2 bolts 8mm length 45mm

2 bolts 6mm length 40mm

2 bolts 6mm length 55mm

6 lock nuts 8mm

4 lock nuts 6mm

grabcad

free

GT2 Pulleys, 80 tooth, 20 tooth, idlers 6 & 9 mm wide

...ers 6 & 9 mm wide

grabcad

gt2 pulleys, 80 tooth and 20 tooth. 20 tooth idlers for 6 & 9 mm wide belts. drawn in freecad.

thingiverse

free

Laser engraver 12mm rod LM12UU 12mm Linear Ball Bearing, new items. by ezsolt74

... and the gt2 20 tooth pulley was designed for.

the bearings in the pulley 625zz, the front holder 624zz.

40x40mm aluminium frame.

Reliabuild

thingiverse

free

Reliabuild Extruder Illuminator (with LED COB Light Strip)

...intensity, led cob light strip to illuminate the reliabuild rbb3 extruder nozzle during printing, without glaring into your eyes.

thingiverse

free

ReliaBuild 3D Printed Parts Collection by JP1

...s it is highly recommended that you use calibrated filament using the system found here: http://www.thingiverse.com/thing:1037301

thingiverse

free

ReliaBuild 3D - 16 tooth Pulley Option by JP1

... belts.

use thermally calibrated filament for best fit results. i use this clip method.https://www.thingiverse.com/thing:1037301

thingiverse

free

ReliaBuild 3D Extruder Carriage Mounted Limit Switch System by JP1

...s it is highly recommended that you use calibrated filament using the system found here: http://www.thingiverse.com/thing:1037301

thingiverse

free

RBB3-XL Name Plate by JP1

...this is a special configuration name plate for the reliabuild 3d big xl printer. this is the 12x16x14" configuration,...

thingiverse

free

ReliaBuild 3D Tilted LCD case - Rounded edges by JP1

...s it is highly recommended that you use calibrated filament using the system found here: http://www.thingiverse.com/thing:1037301

thingiverse

free

Acrylic Enclosure's Printed Pieces

...printed pieces thingiverse this is an upgrade to our reliabuild printer line which will enclose your open-frame printer! not...

thingiverse

free

RBB3 Heated Bed Cable Strain Relief

...reduce flexing of the wires entering the bed connector. reliabuild provides a great clip to help secure the cable...

thingiverse

free

Filament Dry-Box to RigidBot/Realibuild Single or Dual Extruder Bracket by MediaXtudio

...feed dry filament from a dry-box directly to a ridigbot/reliabuild extruder by means of a pneumatic push-to-connect pc4-m10 fitting...

Jp1

turbosquid

$18

jp1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Mod of JP1's Death Star Turret for Lego by ICanMakingThings

...nclude a destroyed turret conversion. it opens up all sorts of options. find it here... http://www.thingiverse.com/make:178576

thingiverse

free

RBB3-XL Name Plate by JP1

...our own front plates this name plate replaces the reliabuild 3d name plate found here: https://www.thingiverse.com/thing:2096308

thingiverse

free

BUTToN GEAR FOREVER by JP1

...

https://www.thingiverse.com/thing:1037301https://www.thingiverse.com/thing:2502677

a good part cooling fan helps as well.

enjoy!

thingiverse

free

Ammo clip loader Pin by JP1

....

the stl file is cura scaled and oriented for printing. note the printing instructions to get a strong accurately printed part.

thingiverse

free

BUTToN GEAR by JP1

...and a button installed on a boot.

for further details see the original style post here: http://www.thingiverse.com/thing:1117591

thingiverse

free

Spool Hub - 56mm to 8mm by JP1

...include the source file with object units in mm and scene units in inches. the cs file is cura scaled and oriented for printing.

thingiverse

free

ID Badge Holder by JP1

... is extra security to keep the two parts together when strapped to your arm.

the parts are cura scaled and oriented for printing.

thingiverse

free

Can Handle - High Resolution by JP1

...ted in pla but i would not leave it in a hot car when using that material.

the stl file is cura scaled and oriented for printing.

thingiverse

free

Spool Hub 54mm x 8mm with tapered shims by JP1

...ated filament for best results using the clip system found here:http://www.thingiverse.com/thing:1037301

print two of these hubs.

Tooth

3d_export

$10

tooth

...tooth

3dexport

tooth 3d model

archibase_planet

free

Tooth

...tooth

archibase planet

tooth

tooth n260111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$4

tooth paste

...tooth paste

3docean

amouth brushing teeth helty teeth tooth tooth paste

3d model tooth paste

turbosquid

$29

Tooth

...h

turbosquid

royalty free 3d model tooth for download as max on turbosquid: 3d models for games, architecture, videos. (1533290)

turbosquid

$29

Tooth

...h

turbosquid

royalty free 3d model tooth for download as max on turbosquid: 3d models for games, architecture, videos. (1529951)

turbosquid

$26

Tooth

...h

turbosquid

royalty free 3d model tooth for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486108)

turbosquid

$13

Tooth

...ty free 3d model tooth for download as dae, obj, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1611126)

archibase_planet

free

Tooth brush

...tooth brush

archibase planet

tooth-brush sanitary ware

tooth brush - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$40

Tooth Paste and Tooth Brush Models

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Tooth 3D Model

... 3d model

archive3d

tooth

tooth n260111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Pulley

3d_export

$1

pulley

...pulley

3dexport

3d_export

$30

Pulley export

...pulley export

3dexport

pulley export design render 3d modelling

3d_export

free

Pulley

...ort

this is a pulley<br>formats: ".3ds", ".fbx", ".obj", ".stl", "blend"

3d_export

$6

roller pulley

...r pulley

3dexport

this is the roller pulley 3d model its used for 3d printers and some other uses for toys and usefull things .

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$29

pulley wheel

...d model pulley wheel for download as obj, wrl, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1319384)

turbosquid

free

Pulley.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

design and assembly of pulley

...design and assembly of pulley

3dexport

design and assembly of pulley 3d model which is used for drive and driven

3d_export

$10

Pulley 3D Model

...y sewing sewingmachine c4d fbx metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107270 3dexport

3d_export

$10

Pulley 3D Model

...trial machine c4d fbx cinema4d metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107271 3dexport

20

3d_export

$15

rocks 20

...rocks 20

3dexport

rocks 3d model 20

3ddd

$1

DECOR MEDIEVO 20*20 MIX

...ллекция: bolonia

фабрика: mainzu

страна: испания

размер: 20x20 см

ссылка:http://www.mainzu.com/bolonia.php#prettyphoto

3d_export

$6

tap-20

...tap-20

3dexport

3ddd

$1

Bed 20

...bed 20

3ddd

постельное белье

bed 20. i hope you like it

software : 3dsmax + md + vray 2.4

turbosquid

$40

20 Shields

...turbosquid

royalty free 3d model 20 shields for download as on turbosquid: 3d models for games, architecture, videos. (1305068)

3d_export

$5

houseberg home 20

...houseberg home 20

3dexport

houseberg home 20

turbosquid

$96

J-20

...20

turbosquid

royalty free 3d model j-20 for download as max on turbosquid: 3d models for games, architecture, videos. (1658873)

turbosquid

$10

Decor 20

...urbosquid

royalty free 3d model decor 20 for download as stl on turbosquid: 3d models for games, architecture, videos. (1677149)

turbosquid

$10

building 20

...osquid

royalty free 3d model building 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1362227)

turbosquid

$6

Bedcloth 20

...osquid

royalty free 3d model bedcloth 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1522681)

Option

3ddd

$1

Фритюр SG14S with Options

...фритюр sg14s with options

3ddd

фритюр

проф. фритюр sg14s with options

3d_ocean

$15

trophy options

...e material property props trophy winner

-trophy options -low polys -obj, fbx,blender, 3ds. -zip : 5.7 mb - include gold material.

turbosquid

$2

keyboard 3 options

...oyalty free 3d model keyboard 3 options for download as blend on turbosquid: 3d models for games, architecture, videos. (1711408)

design_connected

$18

Swivel Chairs with Footrest Option

...swivel chairs with footrest option

designconnected

swivel chairs with footrest option computer generated 3d model.

design_connected

$16

Swivel Armchairs with Footrest Option

...swivel armchairs with footrest option

designconnected

swivel armchairs with footrest option computer generated 3d model.

3d_export

$19

1955 sideboard 3 options

...1955 sideboard 3 options

3dexport

turbosquid

$29

Office Chair with Multi Options

... 3d model office chair with multi options for download as max on turbosquid: 3d models for games, architecture, videos. (1380794)

turbosquid

$25

claddagh ring two options

...y free 3d model claddagh ring two options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1673087)

turbosquid

$20

PADDY PLANE OPTION 12

...yalty free 3d model paddy plane option 12 for download as max on turbosquid: 3d models for games, architecture, videos. (1696286)

turbosquid

$18

pendant sun three options

...free 3d model pendant sun three options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1555386)