GrabCAD

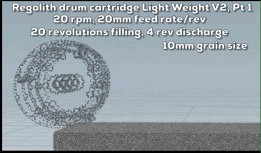

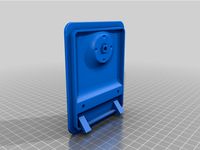

Regolith Drum Cartridge Light Weight V2

by GrabCAD

Last crawled date: 1 year, 10 months ago

This version is a design comparison to show what is possible.

The Stamped version is made from stamped magnesium side plates. 200lb load on Shearing face of Teeth yields a 1.7 Safety Factor. Mass is dropped below 3kg for the Drums. This design could also be adapted for Additive manufacturing.

This design is for a cartridge based 3 component drum system.

Details:

OD: 450mm

Overall Width: 359mm

Cutting Width: 119.5mm

Cutting Edges: 3

Cut depth: aprox. 11mm

Mass:

Stamped Magnesium 2.847kg(.949kg/Cartridge)

Capacity: (note includes 30mm allowance for central drive shaft) See Images for estimated volumes

Internal Volume(theoretical maximum, 3 Cartridges): 42 liters(14L/cartridge)

Max individual Cartridge Fill Ratio: 99% (scoop at horizontal upside)

Minimum Individual Cartridge Fill Ratio: 76% (scoop at bottom)

Combined overall Fill ratio: 90% (combined 3 scoops at 120degree offsets(99%, 94%, 76%)

Estimated actual Fill Ratio: 80-85%(5-10% less than Theoretical)

Materials:

Side Plates: Machined T6 Magnesium

Drum Shell: T6 Magnesium

Scoop Head: T6 Magnesium

Teeth: Carbide, Cast Ceramic or Hardened Steel, Machined or Cast, Riveted to Shell(Al Rivets)

Construction:

Sides and Shell: Welded

Scoop and Shell: Welded

Scoop and Teeth: Riveted

Design Features:

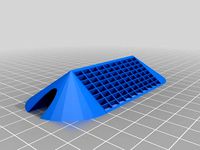

Cartridge design:

a) allows for quick swap out in the event of damage or obstruction.

b) Reduces chance of total loss of function of a unified drum assembly due to damage or obstruction

c) simplifies construction while maximizing material properties

Welded Construction:

Removes need for internal structures to maximize storage and minimize potential build up and blockages

Offset design:

self regulating depth of cut

Single cutting edges:

Increase available shearing force

Radiused cutting edge:

Reduce Digging in, uses a shearing action to remove material rather than an breaking digging action reducing chance of grabbing.

Manufacture:

Minimum component count(6)

Manufacture methods are common and well known

Simple and quick assembly of components

Additional Notes;

Oversize scoop and tunnel vs cutting depth reduce chance of Blockage or jamming approximately 3 times larger than designed depth of cut.

The Stamped version is made from stamped magnesium side plates. 200lb load on Shearing face of Teeth yields a 1.7 Safety Factor. Mass is dropped below 3kg for the Drums. This design could also be adapted for Additive manufacturing.

This design is for a cartridge based 3 component drum system.

Details:

OD: 450mm

Overall Width: 359mm

Cutting Width: 119.5mm

Cutting Edges: 3

Cut depth: aprox. 11mm

Mass:

Stamped Magnesium 2.847kg(.949kg/Cartridge)

Capacity: (note includes 30mm allowance for central drive shaft) See Images for estimated volumes

Internal Volume(theoretical maximum, 3 Cartridges): 42 liters(14L/cartridge)

Max individual Cartridge Fill Ratio: 99% (scoop at horizontal upside)

Minimum Individual Cartridge Fill Ratio: 76% (scoop at bottom)

Combined overall Fill ratio: 90% (combined 3 scoops at 120degree offsets(99%, 94%, 76%)

Estimated actual Fill Ratio: 80-85%(5-10% less than Theoretical)

Materials:

Side Plates: Machined T6 Magnesium

Drum Shell: T6 Magnesium

Scoop Head: T6 Magnesium

Teeth: Carbide, Cast Ceramic or Hardened Steel, Machined or Cast, Riveted to Shell(Al Rivets)

Construction:

Sides and Shell: Welded

Scoop and Shell: Welded

Scoop and Teeth: Riveted

Design Features:

Cartridge design:

a) allows for quick swap out in the event of damage or obstruction.

b) Reduces chance of total loss of function of a unified drum assembly due to damage or obstruction

c) simplifies construction while maximizing material properties

Welded Construction:

Removes need for internal structures to maximize storage and minimize potential build up and blockages

Offset design:

self regulating depth of cut

Single cutting edges:

Increase available shearing force

Radiused cutting edge:

Reduce Digging in, uses a shearing action to remove material rather than an breaking digging action reducing chance of grabbing.

Manufacture:

Minimum component count(6)

Manufacture methods are common and well known

Simple and quick assembly of components

Additional Notes;

Oversize scoop and tunnel vs cutting depth reduce chance of Blockage or jamming approximately 3 times larger than designed depth of cut.

Similar models

grabcad

free

Ultralightweight High capacity Drum

...times larger than designed depth of cut, which is similar you what the current rassor system has found most...

grabcad

free

RASSOR Scroll Drum

... reducing chance of grabbing.

manufacture:

manufacture methods are common and well known

simple and quick assembly of components

grabcad

free

RV - RASSOR Digging Drum

...n, total assembly weight of only 3.83kg

3 - cost effective assembly, easy to manifacture and maintain

4 - high fill ration 72.4%

grabcad

free

RASSOR Bucket Drum V3

...ance). the final weight of my design was arrived at using aluminum side walls, titanium cutting edges and magnesium alloy ramps.*

grabcad

free

NASA Bucket Drum Double-Helix

...ed: 30,2 l

fill ratio: ~75 %

material: magnesium alloy

manufacturing: 3d-printing

further description is attached as a pdf-file.

grabcad

free

NASA RASSOR "Chum Bucket"

... be cnc milled. these parts can then be welded together to create one solid part.

4. the design meets all dimension requirements.

grabcad

free

Mrida Patra

...loading and unloading of regolith. construction of drum is similar to existing drum with aluminium sheet metal panels assembled...

grabcad

free

NASA RASSOR Spiral Drum

...erial: ti 6al 4v

mass: 2.6 kg

drum length: 348mm

drum diameter: 450mm

engaged scoop width: 172mm

max captured regolith: 33 liters

grabcad

free

Side Winder Excavation Drum

...vertical excavation forces and instead combines with axial forces similar to those a screw would exert to excavate, leading...

grabcad

free

RASSOR_DRUM_THE_GUIDE

...m at maximum engagement. total drum mass: 4.82 kg, greatest diameter: 365mm, length: 346mm. estimated regolith capture is 17.7 l.

Regolith

3d_sky

free

Ikea regolith

...ikea regolith

3dsky

ikea

floor lamp, curvedhttp://www.ikea.com/ru/ru/catalog/products/50103406/

thingiverse

free

Customizable struts for regolith-shielded dugout houses by drxenocide

...golith.

*edit (2014jun01) added support for model making and sheet building. because if i win, makerbot will want to print one.

thingiverse

free

HP V1910-24G Tabletop Stand by Regolith

...006a) switch on my desk and be able to organize patch cables below. foot uses the mounting locations for rack ears. requires two.

thingiverse

free

Replacement knob for Harbor Freight ladder by Regolith

...nob for the folding hinge. printed this in pla and it's held up fine. maybe abs or petg if you want it to be super bombproof.

thingiverse

free

Headrest Maglite Mount by Regolith

...10mm rods). the clip installs by twisting onto the headrest rods, and the maglite adds a rigid connection between the two mounts.

thingiverse

free

Mars complex: Regolith construction by smichel

...cal factories wii extract oxygen and chlorates from the abundant minerals to fuel the trip back and forth between earth and mars.

3d_sky

free

Ikea01

...ikea01 3dsky regolith lamp from ikea...

3d_sky

$8

IKEA / REGOLIT

...ikea / regolit 3dsky lampshade ikea regolith regolit shade diameter: 45...

thingiverse

free

Tekonsha P3 Mount (Toyota Tacoma Gen1) by Regolith

...l using an earlier revision (this version has the mounting screws moved outboard to hold the hoop a little tighter to the panel).

thingiverse

free

Mars Research Station Two by xmbrst

...habs are printed in black in the photos.) 3d-printed regolith structures -- to provide better radiation and structural protection,...

Cartridge

turbosquid

$10

cartridge

...osquid

royalty free 3d model cartridge for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357854)

3d_export

$10

cartridge filter

...cartridge filter

3dexport

cartridge filter

turbosquid

$1

cartridge

...e 3d model cartridge for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1265144)

turbosquid

$25

Cartridge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$9

cartridge ce285a

...cartridge ce285a

3dexport

high detailed printer cartridge 3d model.

3d_export

$10

80000 air volume cartridge filter inclined cartridge filter

...000 air volume cartridge filter inclined cartridge filter

3dexport

80000 air volume cartridge filter (inclined cartridge filter)

3d_export

$10

mineral cartridge

...ive soothing & sweet taste to the pure drinking water. the mineral cartridge can be used as substitute of post carbon filter.

turbosquid

$25

5.45x39 Cartridge

... 3d model 5.45x39 cartridge for download as max, 3ds, and obj on turbosquid: 3d models for games, architecture, videos. (1516718)

turbosquid

$25

7.62x39 Cartridge

... 3d model 7.62x39 cartridge for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1303044)

turbosquid

$25

303 Cartridge

...free 3d model 303 cartridge for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1303030)

Drum

3d_export

$5

drums

...drums

3dexport

drums

3d_ocean

$20

Drums

...iled model of drums. charleston,bass drum, tamtam drums, cymbal,etc. available in .blend, .obj, and .lwo format. ready for render

archibase_planet

free

Drum

...hibase planet

drum musical instrument tambour drum kit

drum taiko n091115 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$9

Drum

...drum

designconnected

brent comber drum computer generated 3d model. designed by comber, brent.

turbosquid

$4

Drum 7 Drum 12

... model drum 7 drum 12 for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1641795)

3d_export

$15

Conga Drum

...conga drum

3dexport

conga drums

3d_export

$10

electro drums

...electro drums

3dexport

electro drums

3d_export

$5

electric drums

...electric drums

3dexport

electric drums

turbosquid

$1

Drum

...turbosquid

royalty free 3d model drum for download as blend on turbosquid: 3d models for games, architecture, videos. (1480093)

turbosquid

$1

Drums

...s

turbosquid

royalty free 3d model drums for download as max on turbosquid: 3d models for games, architecture, videos. (1240112)

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

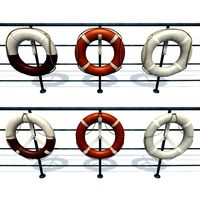

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Weight

archibase_planet

free

Weight

...weight

archibase planet

weight

weight n030907 - 3d model for interior 3d visualization.

3ddd

$1

Weighted

...weighted

3ddd

weighted

высота (см)165ширина (см)75

archibase_planet

free

Weight

...weight

archibase planet

weight dumb-bell dumbbell

weight 24 kg n290313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

weight

...weight

3dexport

archibase_planet

free

Weight

...weight

archibase planet

gym sport equipments

sport`s weight n010907- 3d model for interior 3d visualization.

turbosquid

$14

Weight

...uid

royalty free 3d model weight for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1197215)

turbosquid

$19

Weight

...alty free 3d model weight for download as , stl, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1684982)

turbosquid

$4

Weights

...yalty free 3d model weights for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1494762)

turbosquid

$6

weights

... free 3d model weights for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1261435)

turbosquid

$3

weight

...free 3d model weight for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1558127)

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...