Thingiverse

RC Tank adaptor plate for Geared Motors by Oger

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a set of adaptor plates to use a pair of 37 mm geared DC motors for the RC Tank published by Staind.

Parts needed:

2 x geared motor 12 Vhttps://www.ebay.de/itm/DE-Lager-DC-Motor-12V-300-RPM-6mm-Hoch-Drehmoment-Speed-Reduzieren-Getriebemotor/361664472611?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649

2x brushed ESC (or suitable dual tank ESC for brushed motors)

left and right adaptor plate

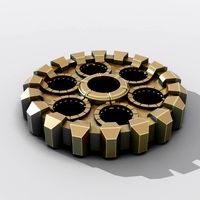

2 x drive gear with 18 teeth

12 x screw M3x8 with flat head

2 x screw M4x60 (replaces the M4x50 screw holding the track drive wheel, gives a third fixture point for the adaptor plate)

6 x M4 nut

6 x washer M4

Assembly:

Print the adaptor plates and two 18 teeth drive gears. The drive gears come in 4 different versions. Each has a different size of the hole for the motor axle. The gear is supposed to sit very tight on the motor axle, use the one which gives the best fit for your 3D printer. Gear_18T_0025mm means, that the hole in the drive gear is 0,025 mm larger than the axle.

Drill the adaptor plates with a 3 mm drill bit for the M3x8 screws and with a 4 mm drill bit for the M4 screws attaching the plates to the tank chassis.

Use the M3x8 screws to attach the motors to the plates first and then push the drive gears onto the motor axles. A drop of super glue can't hurt.

Solder the wires onto the motors, make sure the wires are flat against the end of the motor housing. You don't want the wires to add more length to the motors, it is a tight fit.

Insert the adaptor plates with the motors attached into the tank and use the two original M4 screws which held the stock motor and gear assembly in place. Replace the M4x50 screw inside of the track drive wheel with an M4x60 screw and fasten the plates down with M4 nuts and washers.

Note:

The 300 RPM geared motors @ 3S are quite slow but very powerful for crawling, climbing or earth/snow work with a dozer blade. I think 500 RPM might be a better tradeoff between speed and power. I already ordered some motors with 500 RPM from China, we'll see how these work.

https://www.ebay.de/itm/DC12V-500RPM-Mikro-Mini-Motor-Getriebe-Speed-Reduzieren-Drehmoment-

Parts needed:

2 x geared motor 12 Vhttps://www.ebay.de/itm/DE-Lager-DC-Motor-12V-300-RPM-6mm-Hoch-Drehmoment-Speed-Reduzieren-Getriebemotor/361664472611?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649

2x brushed ESC (or suitable dual tank ESC for brushed motors)

left and right adaptor plate

2 x drive gear with 18 teeth

12 x screw M3x8 with flat head

2 x screw M4x60 (replaces the M4x50 screw holding the track drive wheel, gives a third fixture point for the adaptor plate)

6 x M4 nut

6 x washer M4

Assembly:

Print the adaptor plates and two 18 teeth drive gears. The drive gears come in 4 different versions. Each has a different size of the hole for the motor axle. The gear is supposed to sit very tight on the motor axle, use the one which gives the best fit for your 3D printer. Gear_18T_0025mm means, that the hole in the drive gear is 0,025 mm larger than the axle.

Drill the adaptor plates with a 3 mm drill bit for the M3x8 screws and with a 4 mm drill bit for the M4 screws attaching the plates to the tank chassis.

Use the M3x8 screws to attach the motors to the plates first and then push the drive gears onto the motor axles. A drop of super glue can't hurt.

Solder the wires onto the motors, make sure the wires are flat against the end of the motor housing. You don't want the wires to add more length to the motors, it is a tight fit.

Insert the adaptor plates with the motors attached into the tank and use the two original M4 screws which held the stock motor and gear assembly in place. Replace the M4x50 screw inside of the track drive wheel with an M4x60 screw and fasten the plates down with M4 nuts and washers.

Note:

The 300 RPM geared motors @ 3S are quite slow but very powerful for crawling, climbing or earth/snow work with a dozer blade. I think 500 RPM might be a better tradeoff between speed and power. I already ordered some motors with 500 RPM from China, we'll see how these work.

https://www.ebay.de/itm/DC12V-500RPM-Mikro-Mini-Motor-Getriebe-Speed-Reduzieren-Drehmoment-

Similar models

thingiverse

free

Fastmike Heng Long Worm Gear Drive by fastmike75

...e, dec 2017: added a new mount plate and bearing button for the leopard 2a6 tank base # 3889 to be uses with the long axle setup.

grabcad

free

Bench Type Pillar Drilling Machine

...

pillar drill main dimensions : 500 x 922 x 2050 mm

weight (approximately) : 350 kg

motor : 0,75 kw double speed 500-1500 rev/min

thingiverse

free

TLR22 22T SCT Standup ESC plate by DirtRCRacer

...he spacer on the waterfall screw that attaches to the motor plate. a longer screw for the rear may be needed, but not neccessary.

thingiverse

free

Trunk Hook for BMW E90

...90

thingiverse

can be installed in preexisting holes, no drilling necessary.

parts:

2 x m4x10 screws

1 x m4x50 screw

3 x m4 nuts

thingiverse

free

D5SGA 'Floating' ESC Mount & Template for Mid Motor by ALPHAQGTI

...ws

use the m3x8 screws to attach the platform to the fan bracket.

use the m3x10 screws to attach the fan bracket to the bulkhead.

thingiverse

free

Brushless Motor for OPEN RC Trial truck with timing belt by DasSchaf

.... if you managed to build the openrc this is self explanatory.

benefits: no noise at all anymore. no melt down of the first gear.

grabcad

free

Advanced Differential Gear

...example, many differentials in motor vehicles provide a gearing reduction by having fewer teeth on the pinion than the ring gear.

thingiverse

free

Yokomo YD2SX3 esc wiring stealth mount by defMondo

... the surface of the printer and the only supports will be under the beveled screw holes and the hump lined up with the out drive.

grabcad

free

bevel gear motor reducer

...rs, the function of this reduction motor is to decrease the input speed from 2955 rpm to an output transmission speed of 314 rpm.

grabcad

free

Claw

...claw

grabcad

motor driven claw. using a drive gear and worm geared motor at 25 rpm.

Oger

turbosquid

$19

OGER

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$600

oger model a.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Delgado Oger (Fighter)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$100

Battle Orc 3D Model

...battle orc 3d model 3dexport cave troll orc ogre oger trolls orcs fantasy character monster creature beast dungeon club...

3dbaza

$3

Mini Oger Lustre Loft4You Chandelier (109883)

...t;br>xform: no<br>box trick: no<br>model parts: 24<br>render: v-ray<br>formats: 3ds max 2014, obj, fbx

thingiverse

free

Wheels with groove and colored insert by Oger

...r track drive wheel (insert is the same as for track_wheel_v1)

2017-07-24: added files and pictures for track_wheel with insert.

thingiverse

free

shrek by jackson_894

...shrek by jackson_894 thingiverse oger are like onions get out of my...

thingiverse

free

Improved Track Drive Wheel for RC Tank by Oger

...ot tested this drive wheel with a fast setup. right now i am using a very slow high torque setup with geared motors for crawling.

thingiverse

free

Make of RC Tank with 500 rpm geared motor by rchobby

...a (chains blocked). i use the original gears from oger ...

thingiverse

free

tank tracks with easy to make rubber pads by Oger

... piece of rubber of the appropriate length. no measuring or thinking needed. :-)

i will add the version for 3 mm rubber shortly.

Adaptor

turbosquid

$15

Adaptor-2

...alty free 3d model adaptor-2model for download as dwg and ige on turbosquid: 3d models for games, architecture, videos. (1710809)

turbosquid

free

Adaptor plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Male DFP adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Female VGA Adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Male VGA Adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

Memory stick adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

male union tee adaptor

...ame is male union tee adaptor , it is used in home and industrial area . if you want to get yhis parts blue print buy it from me

turbosquid

$20

Male M1 Digital Adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Male M1 Digital & Analog Adaptor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Samsung Travel Adapter 3D Model

...samsung travel adapter 3d model 3dexport charger white travel adaptor battery charging device samsung travel adapter 3d model g.lex...

Rc

3ddd

$1

RC Helicopter

...rc helicopter

3ddd

вертолет

mini rc helicopter

93.329 polys

3d_export

$7

rc helicopter model

...rc helicopter model

3dexport

rc helicopter model

3d_ocean

$25

RC F1

...rc f1

3docean

auto car control f1 formula race rc remote speed

remote control f1 car

turbosquid

$10

rc plane

...lane

turbosquid

free 3d model rc plane for download as blend on turbosquid: 3d models for games, architecture, videos. (1295828)

turbosquid

$100

RC Helicopter

...free 3d model rc helicopter for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298511)

turbosquid

$59

Drone with RC

...3d model drone with rc for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1363601)

turbosquid

$75

RC buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

RC Plane001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

RC Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Rc airplane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Tank

archibase_planet

free

Tank

...ibase planet

tank tank-wagon tank-truck tank-car

tank train small n110113 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_ocean

$49

Tank

...tank

3docean

kv-1s tank

tank kv-1s

archibase_planet

free

Tank

...tank

archibase planet

tank medium tank

tank wmcvun n070712 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Tank

...k

archibase planet

tank light tank bt-2 high-speed tank

tank bt-2 n200814 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

tanks

...tanks

3dexport

tanks

3d_export

free

tank

...tank

3dexport

tank

archibase_planet

free

Tank

...tank

archibase planet

tank heavy tank

tank abrams l n090511 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Tank

...tank

archibase planet

tank medium tank

tank m60 n070712 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Tank

...tank

archibase planet

tank medium tank

tank female n070712 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

tank

...tank

3dexport

tank lowpoly

Geared

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

Motors

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

plate

...plate

3dexport

plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate kitchen ware

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plates

...plates

archibase planet

plate plates and dishes crockery

plates 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plate

...plate

archibase planet

dinner-plate plate kitchen ware

plate n070808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$6

plate

...plate

3dexport

design of plate

3d_export

$5

plate

...plate

3dexport

plate lowpoly

archibase_planet

free

Plates

...plates

archibase planet

plate dish kitchen-ware

plate - 3d model for interior 3d visualization.

3ddd

$1

Plates

...plates

3ddd

полка , тарелка

african plates

archibase_planet

free

Plate

...plate

archibase planet

plate kitchen ware

plate - 3d model (*.gsm+*.3ds) for interior 3d visualization.