Thingiverse

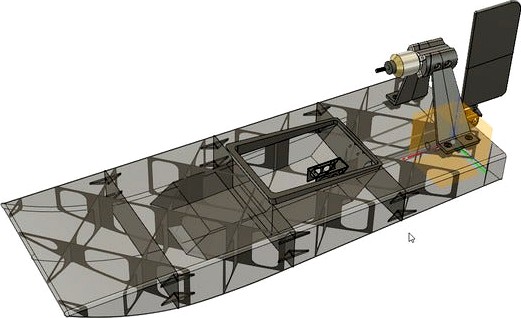

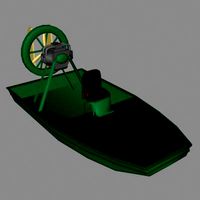

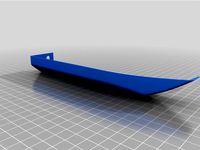

RC Airboat Swamp Buggy by AeroFredcom

by Thingiverse

Last crawled date: 3 years ago

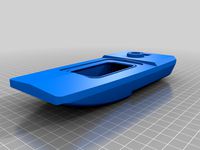

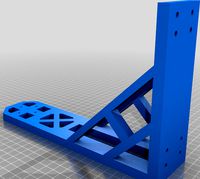

This is a fully printable airboat or swamp buggy or swamp boat with adjustable motor angle.

For those interested I will also be selling printed kits on my website: https://aerofred.com after I finish testing, taking photos and filming it.

Build Thread:

https://www.rcgroups.com/forums/showthread.php?3104321-AeroFred-Swamp-Buggy

In page 3 there is a wooden hull that can be cut with a cnc router, the dxf files are there to download.

Hull length: 700mm

Hull Width: 240mm

Print weight: Aprox. 850g

Motor: 3536 3542 1100kv outrunner

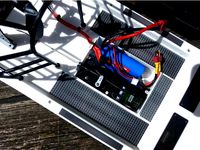

Battery: 3d2200mA/h

Propeller: 9X7

Servo: Mini Servo, HS81 type

Included are the STL files and also .factory files for Simplify3D and Gcodes for a cr10/cr10 mini with direct drive.

Also included the hull unsplit in two versions, one is single wall to be used if you want to print with 3 or 4 perimeters, you will have to split it to fit your printer, the idea is to split in the least number of parts possible. The other one is a double skin hull with a keel, this should be printed with only one perimeter and the double skin should be enough to keep the hull watertight, it has a filet in the transition from the back flat panel to help to seal.

These unsplit hulls have not been print tested.

Can also be printed on a prusa i3 mk2/3, its just a mater of opening the factory files and rearranging the objects, they will all fit.

Print specs are commented in the gcode files.

You will need:

4mm carbon fibre tube for the rudder post

6 M6 nylon screws

4 M4 nylon screws

The motor can be a 3536 out runner with a 3s 2200 battery

The servo can be a mini size (HS-81) type

A rubber balloon to seal the hull battery opening, it will be cut in half and stretched around the hull rim.

The motor wires hole can be sealed wit a bit of silicone sealant, just a blob.

This project will use about 850g of filament, I tested it with PLA but PET-G or ABS can also be used.

Printing info:

The hull is printed with 2 perimeters and no infill

The motor mount and pod are printed with 3 perimeters and 20-30% of infill

The remaining parts can be printed with 2 perimeters and 10% of infill

Each one of the hull sections should have 3 bottom layers to create compartments

The Hull1 (the front) should also have 4-5 top layers to close well.

Make sure the hull is watertight

You can always use CA and kicker to close small gaps in the joins and several coats of clear acrylic paint or epoxy to seal the hull.

Only the hull perimeters number is critical because of the inner structure distance to the skin, the rest you can print however you like.

Nozzle is 0.4mm

Extrusion width 0.42mm

Layer height 0.24mm

More detailed info can be found commented at the top of the gcode files.

Please post your makes and pictures, if you make videos please post the link in the comments

Video by Bob Neitzke

https://www.youtube.com/watch?v=XZZk5Bv0qcY

Upadate Log

30.7.2018 Added unsplit hulls redone the gcodes

For those interested I will also be selling printed kits on my website: https://aerofred.com after I finish testing, taking photos and filming it.

Build Thread:

https://www.rcgroups.com/forums/showthread.php?3104321-AeroFred-Swamp-Buggy

In page 3 there is a wooden hull that can be cut with a cnc router, the dxf files are there to download.

Hull length: 700mm

Hull Width: 240mm

Print weight: Aprox. 850g

Motor: 3536 3542 1100kv outrunner

Battery: 3d2200mA/h

Propeller: 9X7

Servo: Mini Servo, HS81 type

Included are the STL files and also .factory files for Simplify3D and Gcodes for a cr10/cr10 mini with direct drive.

Also included the hull unsplit in two versions, one is single wall to be used if you want to print with 3 or 4 perimeters, you will have to split it to fit your printer, the idea is to split in the least number of parts possible. The other one is a double skin hull with a keel, this should be printed with only one perimeter and the double skin should be enough to keep the hull watertight, it has a filet in the transition from the back flat panel to help to seal.

These unsplit hulls have not been print tested.

Can also be printed on a prusa i3 mk2/3, its just a mater of opening the factory files and rearranging the objects, they will all fit.

Print specs are commented in the gcode files.

You will need:

4mm carbon fibre tube for the rudder post

6 M6 nylon screws

4 M4 nylon screws

The motor can be a 3536 out runner with a 3s 2200 battery

The servo can be a mini size (HS-81) type

A rubber balloon to seal the hull battery opening, it will be cut in half and stretched around the hull rim.

The motor wires hole can be sealed wit a bit of silicone sealant, just a blob.

This project will use about 850g of filament, I tested it with PLA but PET-G or ABS can also be used.

Printing info:

The hull is printed with 2 perimeters and no infill

The motor mount and pod are printed with 3 perimeters and 20-30% of infill

The remaining parts can be printed with 2 perimeters and 10% of infill

Each one of the hull sections should have 3 bottom layers to create compartments

The Hull1 (the front) should also have 4-5 top layers to close well.

Make sure the hull is watertight

You can always use CA and kicker to close small gaps in the joins and several coats of clear acrylic paint or epoxy to seal the hull.

Only the hull perimeters number is critical because of the inner structure distance to the skin, the rest you can print however you like.

Nozzle is 0.4mm

Extrusion width 0.42mm

Layer height 0.24mm

More detailed info can be found commented at the top of the gcode files.

Please post your makes and pictures, if you make videos please post the link in the comments

Video by Bob Neitzke

https://www.youtube.com/watch?v=XZZk5Bv0qcY

Upadate Log

30.7.2018 Added unsplit hulls redone the gcodes

Similar models

thingiverse

free

RC Airboat for water, ice and snow

...tery

by a velcro tape attached by a hot glue. it is better to mount the electronics

on the walls in case some water gets through.

thingiverse

free

Fin for Dumas Swamp Buggy / Airboat

.... i think there is a lot of room for improvement but if you need a fin here it is. feel free to do what you want with the file.

3dwarehouse

free

RC Airboat swamp style garvey

... swamp style garvey

3dwarehouse

rc airboat model about 19' long and 9' wide for 1100kv motor and 2250mah 3s lipo battery

thingiverse

free

Gartt airboat servo tray by Jmzwiers

... stay dry when some water enters the servo bay. also much more space for the battery and easy access and changing of the battery.

thingiverse

free

YAY - FPV Racing Flying Wing

...suitable for selected motor servo sg-90 or any other similar battery about 1500 mah 3-4s 1p (weight 150 g.)...

thingiverse

free

RC Airboat Remix by birdofplay

...ot; to assist with alignment designed in.

hull settings per original

motor mount settings with added infill percentage and layers

3dwarehouse

free

Two Story Swamp Buggy

...two story swamp buggy

3dwarehouse

model of our 468 powered swamp buggy with motorized second level

thingiverse

free

Small boxes for dividing double side storage box compartments by andrealmeidadomingues

... cr10 printer (300x300x400) as well as the cr10 simplify3d settings for each sol file.

fell free to ask anything you have doubts.

thingiverse

free

Box fits square box 175*175*43mm by andrealmeidadomingues

... cr10 printer (300x300x400) as well as the cr10 simplify3d settings for each sol file.

fell free to ask anything you have doubts.

thingiverse

free

Intex 1.5 to 1.5 inch hose coupling by mike99ca

...size. just print and install.

update:

uploaded new files with proper inside diameter of 41.5mm and changed seal thickness to 3mm.

Aerofredcom

thingiverse

free

Heatbed Spatula by AeroFredcom

...d from the first layer residues.

i prefer the hard edged version, its quicker to print and the scraping edge seams to be better.

thingiverse

free

Bede BD-5J by AeroFredcom

... and the fuselage pieces you can make it 80vm to 1meter span on a prusa i3mk2 printer.

this plane seems interesting, it may fly.

thingiverse

free

Tabletop FM Radio by AeroFredcom

... do this would be with a summing circuit, not big deal:

here:http://www.rane.com/note109.html

its the stereo to mono summing box.

thingiverse

free

Folgertech FT-5 X Carriage adapter for Prusa i3 MK2 Extruder by AeroFredcom

...ess to one or just print them on your ft5 and see what comes out.

print in abs 40% or so of infil and 2 or 3 perimeters and tops.

thingiverse

free

Logitech c270 Prusa i3 MK2 camera mount Follow Y/Z by AeroFredcom

... here.

added: camera_holder.stl 35mm lomger than the original one

added: y_holder.stl is tighter to the printbed aluminium frame

thingiverse

free

RC Flying Wing - The Klingberg Wing by AeroFredcom

...comments, this will help me to improve the design.

video thanks to mikael christensen:https://www.youtube.com/watch?v=sqqavzxcaus

thingiverse

free

CR-10 or Mini to Prusa i3 conversion kit by AeroFredcom

...a bed probe this is better than the other version.

added a new larger main board box, new lcd box type with adjustable view angle

Airboat

turbosquid

$10

AIRBOAT.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$99

Airboat 3D Model

...verglades louisiana engine motor fan fishing recreational alligator bayou propeller

airboat 3d model dzejsi.models 72673 3dexport

cg_studio

$99

Airboat3d model

...odel

cgstudio

.3ds .fbx .lwo .lxo .max .obj - airboat 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Electric Boat

...transport of the future. my model is a rubber airboat in the bow part of which there are 3...

thingiverse

free

Airboat meeple by willssweetescape

...airboat meeple by willssweetescape

thingiverse

this is a simple airboat meeple i designed for a fellow game designer.

thingiverse

free

Airboat

...te control : 2 - 3ch

brushless motor 1806

esc 10a-25a

li-polymer 2-3s

9 grams servo

20mm x 2mm o-ring x 1.

14mm x 2mm o-ring x 2.

thingiverse

free

Airboat skid plates by josiaht04

...airboat skid plates by josiaht04

thingiverse

skid plates for airboat for added protection

thingiverse

free

Extended Rudder for Airboat by Renngarage

...ization fins are not in the intention of an airboat but - hey - if it works - on the water at least.

https://youtu.be/ut9wtrccw7y

thingiverse

free

Airboat motor mount by Aaron370150

...airboat motor mount by aaron370150

thingiverse

thingiverse

free

Airboat rudder by dlacko

...using plywood, meccano and standard rc parts (9g servo, brushless motor + esc, lipo battery, turnigy 9x transmitter and receiver)

Swamp

3d_export

free

swamp

...swamp

3dexport

swamp

3d_export

$5

The Russia Swamp

...the russia swamp

3dexport

the russian swamp is a real hell. this is clearly shown in this model

turbosquid

$10

Swamp Monster

...quid

royalty free 3d model swamp monster for download as ztl on turbosquid: 3d models for games, architecture, videos. (1193942)

turbosquid

$3

swamp wolf

...squid

royalty free 3d model swamp wolf for download as blend on turbosquid: 3d models for games, architecture, videos. (1639879)

turbosquid

$1

Hovel swamp

...royalty free 3d model hovel swamp for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1532373)

turbosquid

$499

Murky Swamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

swamp plant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

swamp plant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

swamp monster

...swamp monster

3dexport

low polygonal game-ready model monster

3d_export

$10

swamp fairy house

...swamp fairy house

3dexport

Buggy

3d_ocean

$45

High Quality Buggy Buggy

...high quality buggy buggy

3docean

buggy car race rally sport car vehicle

car model, like buggy buggy style

3d_export

$5

buggy chassi

...buggy chassi

3dexport

chassis of a simple ride buggy.

3ddd

$1

Buggy

...buggy

3ddd

коляска

без модификаторов

turbosquid

$89

buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$49

Buggy Concept

... poly massive outdoor robust vehicle

just a model of are own buggy concept vehicle. maybe you can make a beautiful renders of it!

3d_export

$15

Buggy 3D Model

...buggy 3d model

3dexport

buggy bug car offroad sport risko

buggy 3d model risko 73925 3dexport

Rc

3ddd

$1

RC Helicopter

...rc helicopter

3ddd

вертолет

mini rc helicopter

93.329 polys

3d_export

$7

rc helicopter model

...rc helicopter model

3dexport

rc helicopter model

3d_ocean

$25

RC F1

...rc f1

3docean

auto car control f1 formula race rc remote speed

remote control f1 car

turbosquid

$10

rc plane

...lane

turbosquid

free 3d model rc plane for download as blend on turbosquid: 3d models for games, architecture, videos. (1295828)

turbosquid

$100

RC Helicopter

...free 3d model rc helicopter for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298511)

turbosquid

$59

Drone with RC

...3d model drone with rc for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1363601)

turbosquid

$75

RC buggy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

RC Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Rc airplane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

RC-Car

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.