Thingiverse

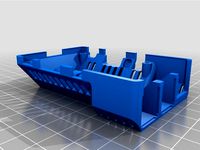

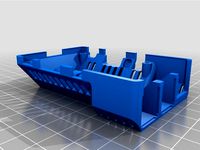

Raspberry Pi Mini Desktop Vertical Case with 40mm Fan

by Thingiverse

Last crawled date: 4 years, 3 months ago

EDIT: October 28 2019 - I made an iteration of this case that is optimized for shorter print time, fewer screws and nuts, and to show off the Pi board more when used with clear acrylic panels instead of wood. All that at the expense of a fair amount of strength.

Link to new version here --> https://www.thingiverse.com/thing:3942831

I made a (not very good) video detailing some aspects about this thing.

https://youtu.be/nZuMiytBGjc

This is a case for the Raspberry Pi 3 or Raspberry Pi 4.

They hold the Pi vertically on its side. Power and HDMI cords plug into the Pi through the bottom between the uprights. The fan is at the top and can be oriented to blow in either direction (up or down).

There are two variants.

The taller variant has holes for cable routing and an option strain relief and/or cosmetic cover for the cord holes if you choose not to use them.

The shorter version is cuter, but requires some 90 degree adapters (or special cables with 90 degree ends) as it sit too short for most cable connectors to fit under.

It is quite sturdy and features pressed in captive nuts for all structural screw locations.

All exterior screws are countersunk for a clean look.

There is 27mm of headroom above the processor for a large heatsink.

There is 10mm of headroom below the board for heatsinks on components on the bottom of the board.

The fan blows across both sides of the board.

There is room next to the fan under the lid for cable management without excess cable length blocking airflow through the cavity around the Pi.

There is a recessed divot to ease access to the SD card.

The parts are designed to print flat on their face (get your first layer game on) and require no infill, require almost no support (only around the recessed divot for the SD card access). There is a part ( SDdivotSUPPORTtest.stl ) so you can tune your support settings for this part before endeavoring to print the whole side.

There are two faces of the finished case which in the pictures are made from wood. These are intended to minimize print time and to give the maker the opportunity to customize their case. The slots that hold these sides are .25" (~6.5mm) and the inserts are intended to be 75mm x 86mm.

There are 9mm x 2mm recesses in the bottom for silicon foot pads. These are the foot pads I use for all of my designs. -->https://www.amazon.com/gp/product/B07QW58TZH/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

There are more pics of the shorty version here --> https://imgur.com/a/UoAlEnf

There are more pics of the tall version here --> https://imgur.com/a/RjQQ7zu

NECESSARY HARDWARE

16x m3x8mm countersunk screws

16x m3 nuts (for 5.5mm wrench - 2.5mm thick).

4x m3x16mm screws for fan

4x m2x6mm screws to mount Pi to structure

2 m3x6mm screws for optional strain relief and/or blank plate on tall version

If you would like to customize the strain relief for your particular cables, they are simple a 22mm radius quadrant, for an 8mm thick hole. I made mine 21.5mm radius with a 5 degree draft angle on the sides to ease installation.

I originally designed these to not use nuts, I can upload files designed for the screws to self-tap into the printed parts on request, but there are so many file already I decided to only upload the nut version. I found that upon repeated assembly and disassembly during the iteration process that the threads tend to pull out - thus the redesign to use nuts.

The total print time on my Ender 3, sliced in Cura, with 5 walls and no infill, at .2mm layer height, at 50mm/s (Cura default print speeds) is about 10 hours. Maybe an hour less for the shorty version.

If you wish to mount the fan so that it blows upwards (drawing hot air out of the cavity) screw the mount screws in from the bottom. The fan will be held captive by the lid. Or use countersunk screws.

Mounting the fan so it blows down from the top, standard m3 cap head screws can be used.

10/24/2019 - Uploaded FACEshimADJUSTED which is the same as face shim, just slightly taller (2mm) and slightly narrower (.5mm) for a better fit.

Link to new version here --> https://www.thingiverse.com/thing:3942831

I made a (not very good) video detailing some aspects about this thing.

https://youtu.be/nZuMiytBGjc

This is a case for the Raspberry Pi 3 or Raspberry Pi 4.

They hold the Pi vertically on its side. Power and HDMI cords plug into the Pi through the bottom between the uprights. The fan is at the top and can be oriented to blow in either direction (up or down).

There are two variants.

The taller variant has holes for cable routing and an option strain relief and/or cosmetic cover for the cord holes if you choose not to use them.

The shorter version is cuter, but requires some 90 degree adapters (or special cables with 90 degree ends) as it sit too short for most cable connectors to fit under.

It is quite sturdy and features pressed in captive nuts for all structural screw locations.

All exterior screws are countersunk for a clean look.

There is 27mm of headroom above the processor for a large heatsink.

There is 10mm of headroom below the board for heatsinks on components on the bottom of the board.

The fan blows across both sides of the board.

There is room next to the fan under the lid for cable management without excess cable length blocking airflow through the cavity around the Pi.

There is a recessed divot to ease access to the SD card.

The parts are designed to print flat on their face (get your first layer game on) and require no infill, require almost no support (only around the recessed divot for the SD card access). There is a part ( SDdivotSUPPORTtest.stl ) so you can tune your support settings for this part before endeavoring to print the whole side.

There are two faces of the finished case which in the pictures are made from wood. These are intended to minimize print time and to give the maker the opportunity to customize their case. The slots that hold these sides are .25" (~6.5mm) and the inserts are intended to be 75mm x 86mm.

There are 9mm x 2mm recesses in the bottom for silicon foot pads. These are the foot pads I use for all of my designs. -->https://www.amazon.com/gp/product/B07QW58TZH/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

There are more pics of the shorty version here --> https://imgur.com/a/UoAlEnf

There are more pics of the tall version here --> https://imgur.com/a/RjQQ7zu

NECESSARY HARDWARE

16x m3x8mm countersunk screws

16x m3 nuts (for 5.5mm wrench - 2.5mm thick).

4x m3x16mm screws for fan

4x m2x6mm screws to mount Pi to structure

2 m3x6mm screws for optional strain relief and/or blank plate on tall version

If you would like to customize the strain relief for your particular cables, they are simple a 22mm radius quadrant, for an 8mm thick hole. I made mine 21.5mm radius with a 5 degree draft angle on the sides to ease installation.

I originally designed these to not use nuts, I can upload files designed for the screws to self-tap into the printed parts on request, but there are so many file already I decided to only upload the nut version. I found that upon repeated assembly and disassembly during the iteration process that the threads tend to pull out - thus the redesign to use nuts.

The total print time on my Ender 3, sliced in Cura, with 5 walls and no infill, at .2mm layer height, at 50mm/s (Cura default print speeds) is about 10 hours. Maybe an hour less for the shorty version.

If you wish to mount the fan so that it blows upwards (drawing hot air out of the cavity) screw the mount screws in from the bottom. The fan will be held captive by the lid. Or use countersunk screws.

Mounting the fan so it blows down from the top, standard m3 cap head screws can be used.

10/24/2019 - Uploaded FACEshimADJUSTED which is the same as face shim, just slightly taller (2mm) and slightly narrower (.5mm) for a better fit.

Similar models

thingiverse

free

Vertical Case for Raspberry Pi 4 with Ice Tower Cooler

...ttps://imgur.com/a/xnnljwp

pics of the first prototype and disassembly (reverse process of assembly) https://imgur.com/a/fuhbiuq

thingiverse

free

"The Wind Tunnel" Raspberry Pi Cluster Case v1 by johtib

...witch.

slide in the trays. they should snap in.

connect the network cables, sata adaters cables, and the fan hub's usb cable.

thingiverse

free

Duet 3 support (with Raspberry Pi) by cad405

...cools down both the pi and the bottom part of the duet. in my case i have a noctua nf12x25 cooling this setup (overkill, i know).

thingiverse

free

Raspberry Pi 4 B Case With Fan Cross Blow by Coolkid171717

...s across the board instead of blowing down on top of the board.

it will take a bit of super glue to attach the parts for the fan.

thingiverse

free

Raspberry Pi A+ Case | simple by TueftelTyp

...h 30mm fan

top2 = with air passage

top3 = without any cuts

as always i would be happy to see your print as a make to get feedback

thingiverse

free

Raspberry Pi Case by edsped

...se

basic raspberry pi case. requires (4) m3 x 8 socket head cap screws. top and bottoms are 2mm thick, sides are 1.5mm thick.

thingiverse

free

Raspberry Pi 3 A+ Case (remix from tvarok)

...ll just go back to the screws instead(screw holes hidden from top). the nut recess is completely removed for the 2mm screw holes.

thingiverse

free

Raspberry PI 2 Case by Davideraffo

...tted to 8) with 4 m2 nut (for the raspberry board)

i hope you like it!

if you have any problem with the printing, please write me

thingiverse

free

Raspberry Pi Model B (B+/2/3) Case for 40mm Low Profile Fan

...countersink machine screws. the raspberry pi board itself is attached by use of standard m2.5x6 machine screws and m2.5 hex nuts.

thingiverse

free

Ender 3 OctoPi Case (with GeekPi Cooling Fan clearance) by DrakonKlaw

...:4568590) to be place on the v-slots of the ender 3.

this is meant for an octopi.

image bypass: https://imgur.com/gallery/dm03ydo

Raspberry

3d_export

free

raspberry

...raspberry

3dexport

3d model of a raspberry. i tried to make it realistic.

turbosquid

$27

Raspberries

...y free 3d model raspberries for download as max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1354176)

turbosquid

$14

Raspberries

...y free 3d model raspberries for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1364663)

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$99

Raspberry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

raspberries

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Raspberries 3D Model

...raspberries 3d model archive3d raspberries raspberry raspberries n300911 - 3d model (*.3ds) for interior 3d...

3d_export

$5

raspberry fruit

...raspberry fruit

3dexport

3d_export

$5

raspberry

...y different sizes. their color ranges from light burgundy to pink. there are formats: obj, 3ds, blend, dae, fbx, mtl.<br>:)

evermotion

$12

raspberries 23 am130

...evermotion raspberries 23 am130 evermotion key 23 food fruit raspberry fruits am130 raspberries highly detailed 3d model of raspberries...

40Mm

turbosquid

$10

40MM Bullet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

40mm Vickers-Terni

... free 3d model 40mm vickers-terni for download as lwo and obj on turbosquid: 3d models for games, architecture, videos. (1260063)

turbosquid

$3

40mm grenade M9XX

...y free 3d model 40mm grenade m9xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408150)

turbosquid

$3

40mm grenade M3XX

...y free 3d model 40mm grenade m3xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408145)

turbosquid

$3

40mm grenade M1XX

...y free 3d model 40mm grenade m1xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408144)

turbosquid

$8

40mm Smith & Wesson

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free 40mm grenade M433

...e 3d model free 40mm grenade m433 for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1404768)

turbosquid

$98

40mm 6G30 grenade launcher

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Famas G2 M203 40mm.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

40mm Bofors TNT-11606

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Desktop

3d_export

$5

desktop

...desktop

3dexport

full desktop

3d_export

$15

Desktop

...desktop

3dexport

desktop, monitor, system unit, backlit keyboard.

3d_export

$5

desktop

...desktop

3dexport

desktop with shelving. very convenient and practical find.

turbosquid

$5

Desktop

...turbosquid

royalty free 3d model desktop for download as jpg on turbosquid: 3d models for games, architecture, videos. (1329464)

turbosquid

$1

Desktop

...turbosquid

royalty free 3d model desktop for download as fbx on turbosquid: 3d models for games, architecture, videos. (1661325)

3d_export

$10

110x60 desktop

...110x60 desktop

3dexport

110x60 desktop

turbosquid

$20

Desktop

...lty free 3d model desktop for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1624648)

turbosquid

$20

Desktop

...oyalty free 3d model desktop for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1309418)

turbosquid

$15

Desktop

...yalty free 3d model desktop for download as 3ds, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1445073)

3d_export

$5

desktop

...desktop

3dexport

a desk will fit into the room

Pi

design_connected

$11

Pi

...pi

designconnected

ligne roset pi chairs computer generated 3d model. designed by thibault desombre.

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$18

pied

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люста emme pi light

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

бра классическое emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

design_connected

$16

Pi-Air

...pi-air

designconnected

living divani pi-air lounge chairs computer generated 3d model. designed by harry & camila.

3d_ocean

$15

Manneken Pis

...picting a naked little boy urinating into a fountain’s basin. (wikipedia) the model was sculpted in blender 2.70a rendered wit...

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люстра классическая фирма: emme pi light

артикул: 3595/5/cot/12/wh

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Vertical

3ddd

$1

Vertical curtain

...vertical curtain

3ddd

роллеты

vertical curtain

modern curtain

design_connected

$11

Mr.Tubes Vertical

...mr.tubes vertical

designconnected

tonone mr.tubes vertical computer generated 3d model.

3ddd

free

Vertical gardening

... фитомодуль , фитостена

vertical gardening

2000x1000x165

vizpark

$5

Einstein Vertical

...tical is a set of 3d brick textures for modern buildings, including mulit-textures and 4k tileable textures with material layers.

turbosquid

$5

brazier vertical

... free 3d model brazier vertical for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1647570)

turbosquid

$18

Vertical blinds

...ee 3d model vertical blinds for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1604868)

3d_export

$40

vertical stirling engine

...vertical stirling engine

3dexport

vertical stirling engine

turbosquid

$6

vertical fence

...d model vertical fence for download as c4d, 3ds, dxf, and obj on turbosquid: 3d models for games, architecture, videos. (1571631)

turbosquid

$50

Vertical Garden

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

vertical flag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.