Thingiverse

Rapid Moisture Removal Prototype by Ductsoup

by Thingiverse

Last crawled date: 4 years, 2 months ago

First off, this is just documenting one of my infamous cocktail napkin ideas (that totally bypassed the cocktail napkin stage). Full disclosure, I don't have the slightest idea what I'm doing but, it seems a harmless enough venture.

My PLA stock was getting completely out of hand and half the time spools don't come with a resealable bag leading to moisture issues. My bad. So, I grabbed a couple $7 bins from Lowes, picked up some silica gel desiccant from Amazon and printed a couple Desiccant Box with Slotted Snap-on Lid things by micromet.

http://www.thingiverse.com/thing:531437http://www.amazon.com/Gallon-Orange-Indicating-Desiccant-Replacement/dp/B00BXJ52GO

Definitely neater. Over the last couple days the humidity inside the bins has been slowly decreasing and the beads are changing color at about the pace I expected. Some of these spools have been stored in less than ideal conditions for at least a year so there's probably a fair amount of latent moisture. Over time this setup seems really good but, I've rarely been accused of being a patient person.

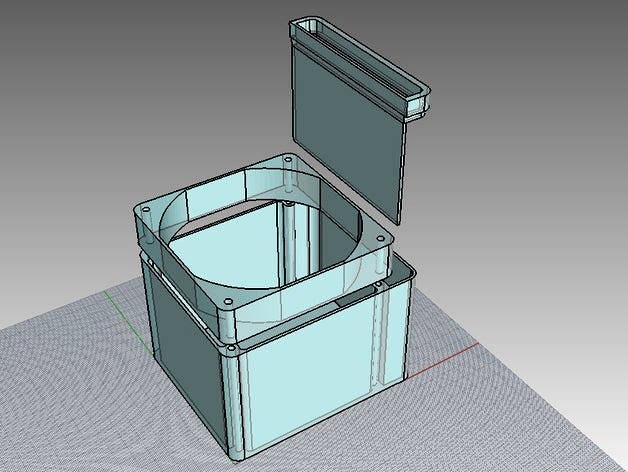

Guessing more air flow over and around the desiccant beads might speed things up. I found a 12VDC 120mm 64 CFM cooling fan (I've also rarely been accused of being subtle) in my salvaged parts box, applied some WAG (Wild A** Guess) engineering for the air flow and dimensions and quick modeled this thing to try out the idea.

http://www.newegg.com/Product/Product.aspx?Item=N82E16835200048

The goal is to change and recharge the media every couple hours until the moisture level is exactly where you want it. I prefer things that don't have a single single purpose. This is massive overkill for PLA storage, I'm actually thinking about a better solution for drying nylon..

http://taulman3d.com/drying-materials.htmlhttp://richrap.blogspot.co.uk/2013/04/3d-printing-with-nylon-618-filament-in.html

2016-05-22 update

First, I normally print with PLA and forgot to remember that ABS is bad for shapes like this with my setup. Got some nasty lifts and gaps in the bin, the rest printed fine. Fortunately I don't need it waterproof, just bead proof so some white electrical tape fixed up the bin just fine. Second, the screws to mount the fan should be M4 or 8-32. I had both handy, but not the right length. More tape was indicated. Eh, it's rapid prototype/proof of concept ... fix the rest in the mix. In the time it took me to type this the internal humidity dropped 3%, looks promising.

2016-05-23 update

Well, that certainly seems to work as intended. Compare the image of the fresh media to the stuff that's been in the storage bin with the fan on for 24 hours. Opted to do a control tonight without the fan to check if the party responsible for the good result was the increased air flow or the extra volume of media.

2016-05-26 update

Definitely the air flow. Two days without the fan and the beads look almost like new.

My PLA stock was getting completely out of hand and half the time spools don't come with a resealable bag leading to moisture issues. My bad. So, I grabbed a couple $7 bins from Lowes, picked up some silica gel desiccant from Amazon and printed a couple Desiccant Box with Slotted Snap-on Lid things by micromet.

http://www.thingiverse.com/thing:531437http://www.amazon.com/Gallon-Orange-Indicating-Desiccant-Replacement/dp/B00BXJ52GO

Definitely neater. Over the last couple days the humidity inside the bins has been slowly decreasing and the beads are changing color at about the pace I expected. Some of these spools have been stored in less than ideal conditions for at least a year so there's probably a fair amount of latent moisture. Over time this setup seems really good but, I've rarely been accused of being a patient person.

Guessing more air flow over and around the desiccant beads might speed things up. I found a 12VDC 120mm 64 CFM cooling fan (I've also rarely been accused of being subtle) in my salvaged parts box, applied some WAG (Wild A** Guess) engineering for the air flow and dimensions and quick modeled this thing to try out the idea.

http://www.newegg.com/Product/Product.aspx?Item=N82E16835200048

The goal is to change and recharge the media every couple hours until the moisture level is exactly where you want it. I prefer things that don't have a single single purpose. This is massive overkill for PLA storage, I'm actually thinking about a better solution for drying nylon..

http://taulman3d.com/drying-materials.htmlhttp://richrap.blogspot.co.uk/2013/04/3d-printing-with-nylon-618-filament-in.html

2016-05-22 update

First, I normally print with PLA and forgot to remember that ABS is bad for shapes like this with my setup. Got some nasty lifts and gaps in the bin, the rest printed fine. Fortunately I don't need it waterproof, just bead proof so some white electrical tape fixed up the bin just fine. Second, the screws to mount the fan should be M4 or 8-32. I had both handy, but not the right length. More tape was indicated. Eh, it's rapid prototype/proof of concept ... fix the rest in the mix. In the time it took me to type this the internal humidity dropped 3%, looks promising.

2016-05-23 update

Well, that certainly seems to work as intended. Compare the image of the fresh media to the stuff that's been in the storage bin with the fan on for 24 hours. Opted to do a control tonight without the fan to check if the party responsible for the good result was the increased air flow or the extra volume of media.

2016-05-26 update

Definitely the air flow. Two days without the fan and the beads look almost like new.