GrabCAD

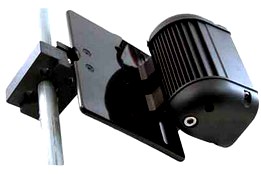

Rail Mount for LED Emitter Bars and Vehicle Mount Halogen and HID Lights (Bar Clamp)

by GrabCAD

Last crawled date: 1 year, 11 months ago

https://www.larsonelectronics.com/product/1833/rail-mount-for-led-emitter-bars-and-vehicle-mount-halogen-and-hid-lights-bar-clamp

Heavy duty clamping system for rail mount, bar clamp mounts, pipe mounts and other tube stock applications. This bar clamp mount is designed specifically to mount LED emitter light bars, halogen and HID off road lights and High Intensity Discharge vehicle mount lights to vehicles, heavy equipment, ATVs and boats.

Heavy duty clamping system that enables owners of vehicles, heavy equipment and boats to mount lights or other equipment to square or round tubes, bars, pipes or rails. The adjustable clamping system cinches to size around rails of different diameters and can handle payloads to 40+ pounds under extreme vibration.

The mounting plate on this light mount bracket was designed to mount all types of indoor and outdoor lighting including our explosion proof lights for hazardous location light applications, LED light emitter bars and Infrared emitters.

The bar clamp mount is made from Delrin II (acetal copolymer) and is available in white and black. Delrin is designed to be an alternative to metal, and is strong, durable and cannot be damaged by water and UV rays. Thus Delrin is an ideal material for boating applications and is popular in the petrochemical space, due to its chemical and heat resistance. This rail or tube mount adjusts to fit bars, rails, racks, etc. with square or tubular dimensions ranging from 3/8 inch to 1.25 inches in diameter. There are 2 sets of interlocking brackets which are cinched around the square or round tube, using the imbedded pair of 1/4-20 stainless steel, socket head bolts.

A mounting plate attaches to the clamps, creating a mounting surface for just about anything. Existing mounting holes include the mounting pattern for the Larson Electronics LED emitter bars, LED spreader light bars, High Intensity Discharge (HID) equipment lights, HID boat lights and LED spotlight bars and all manner of off road and vehicle lights that are mounted with a simple stud (bolt) mount. Most auxiliary lighting on vehicles boats and heavy equipment is mounted with a 3/8 inch bolt at the base of the light. This mount can accommodate this mounting option.

NOTE ON MOUNTING HOLES: The top mounting plate ships with pre-drilled holes that are designed for accepting the bolt patterns for Radioray and Stryker remote control spotlights. These spotlights went under a design revision in 2020. Older Radioray mounting holes are NOT the same as newer Radioray mounting holes. Older Stryker mounting holes are NOT the same as newer Stryker mounting holes. Please choose correct mounting option at time of ordering to ensure fitment with your spotlight.

- Old Radioray. This is compatible with Pre-2020 Radioray series GL-2XXX, GL-5XXX, GL-7XXX, and GL-9XXX series spotlights.

- New Radioray GT. This is compatible with Post-2020 Radioray GT series GL-2XXXGT, GL-7XXXGT, and GL-9XXXGT series spotlights. The mounting holes of the GT Series of Radioray spotlights (Post-2020) are NOT compatible with previous generation (Pre-2020) models.

- Old Stryker. This is compatible with Pre-2020 Stryker series GL-3XXX series spotlights.

- New Stryker ST. This is compatible with Post-2020 Stryker ST series GL-3XXXST series spotlights. The mounting holes of the ST Series of Stryker spotlights (Post-2020) are NOT compatible with previous generation (Pre-2020) models.

A 3.8 inch hole in the center accommodates post mount lights (like the HID off road lights, 24 volt equipment lights, 12 volt flood lights, Vision-X HID lights and Duralux HID equipment lights and the Larson Electronics permanent mount lights).

The design of the bar clamp enables the operator to position it on horizontally or vertically situated poles, rails, etc. 2 sets of mounting holes offer the operator the ability to mount the mounting plate on the top or the side of the brackets. Thus this bracket system can be mounted on horizontal or vertical rails, bars or tubes. This was in response to customer`s demand for mounting solutions for vertical rails on pumping trucks, etc.

This clamping system is effective on heavy equipment, boats, ATVs, trucks, toy haulers, etc.

More on Delrin (acetal copolymer)

Acetal copolymers have an excellent balance of properties and processing characteristics.

Melt temperature of 450 °F with little effect on part strength

UV-resistant grades

high tensile and flexural strength, fatigue resistance, and hardness.

Lubricity is excellent.

Moisture absorption resistant.

Good electrical properties, combined with high mechanical strength and a UL electrical rating of 100 °C, qualify these materials for electrical applications requiring long-term stability.

Acetal copolymers have excellent resistance to chemicals and solvents. This makes them ideal for mounting explosion proof lights in tanks, vessels and paint booths.

Most organic reagents tested have no effect, nor do mineral oil, motor oil, or brake fluids. Resistance to strong alkalis is exceptionally good; specimens immersed in boiling 50% sodium hydroxide solution and other strong bases for many months show no property changes.

Strength of acetal copolymer is only slightly reduced after aging for one year in air at 240 °F. Impact strength holds constant for the first six months, and falls off about one-third during the next six-month period. Aging in air at 180 °F for two years has little or no effect on properties, and immersion for one year in 180 °F water leaves most properties virtually unchanged. Samples tested in boiling water retain nearly original tensile strength after nine months.

Heavy duty clamping system for rail mount, bar clamp mounts, pipe mounts and other tube stock applications. This bar clamp mount is designed specifically to mount LED emitter light bars, halogen and HID off road lights and High Intensity Discharge vehicle mount lights to vehicles, heavy equipment, ATVs and boats.

Heavy duty clamping system that enables owners of vehicles, heavy equipment and boats to mount lights or other equipment to square or round tubes, bars, pipes or rails. The adjustable clamping system cinches to size around rails of different diameters and can handle payloads to 40+ pounds under extreme vibration.

The mounting plate on this light mount bracket was designed to mount all types of indoor and outdoor lighting including our explosion proof lights for hazardous location light applications, LED light emitter bars and Infrared emitters.

The bar clamp mount is made from Delrin II (acetal copolymer) and is available in white and black. Delrin is designed to be an alternative to metal, and is strong, durable and cannot be damaged by water and UV rays. Thus Delrin is an ideal material for boating applications and is popular in the petrochemical space, due to its chemical and heat resistance. This rail or tube mount adjusts to fit bars, rails, racks, etc. with square or tubular dimensions ranging from 3/8 inch to 1.25 inches in diameter. There are 2 sets of interlocking brackets which are cinched around the square or round tube, using the imbedded pair of 1/4-20 stainless steel, socket head bolts.

A mounting plate attaches to the clamps, creating a mounting surface for just about anything. Existing mounting holes include the mounting pattern for the Larson Electronics LED emitter bars, LED spreader light bars, High Intensity Discharge (HID) equipment lights, HID boat lights and LED spotlight bars and all manner of off road and vehicle lights that are mounted with a simple stud (bolt) mount. Most auxiliary lighting on vehicles boats and heavy equipment is mounted with a 3/8 inch bolt at the base of the light. This mount can accommodate this mounting option.

NOTE ON MOUNTING HOLES: The top mounting plate ships with pre-drilled holes that are designed for accepting the bolt patterns for Radioray and Stryker remote control spotlights. These spotlights went under a design revision in 2020. Older Radioray mounting holes are NOT the same as newer Radioray mounting holes. Older Stryker mounting holes are NOT the same as newer Stryker mounting holes. Please choose correct mounting option at time of ordering to ensure fitment with your spotlight.

- Old Radioray. This is compatible with Pre-2020 Radioray series GL-2XXX, GL-5XXX, GL-7XXX, and GL-9XXX series spotlights.

- New Radioray GT. This is compatible with Post-2020 Radioray GT series GL-2XXXGT, GL-7XXXGT, and GL-9XXXGT series spotlights. The mounting holes of the GT Series of Radioray spotlights (Post-2020) are NOT compatible with previous generation (Pre-2020) models.

- Old Stryker. This is compatible with Pre-2020 Stryker series GL-3XXX series spotlights.

- New Stryker ST. This is compatible with Post-2020 Stryker ST series GL-3XXXST series spotlights. The mounting holes of the ST Series of Stryker spotlights (Post-2020) are NOT compatible with previous generation (Pre-2020) models.

A 3.8 inch hole in the center accommodates post mount lights (like the HID off road lights, 24 volt equipment lights, 12 volt flood lights, Vision-X HID lights and Duralux HID equipment lights and the Larson Electronics permanent mount lights).

The design of the bar clamp enables the operator to position it on horizontally or vertically situated poles, rails, etc. 2 sets of mounting holes offer the operator the ability to mount the mounting plate on the top or the side of the brackets. Thus this bracket system can be mounted on horizontal or vertical rails, bars or tubes. This was in response to customer`s demand for mounting solutions for vertical rails on pumping trucks, etc.

This clamping system is effective on heavy equipment, boats, ATVs, trucks, toy haulers, etc.

More on Delrin (acetal copolymer)

Acetal copolymers have an excellent balance of properties and processing characteristics.

Melt temperature of 450 °F with little effect on part strength

UV-resistant grades

high tensile and flexural strength, fatigue resistance, and hardness.

Lubricity is excellent.

Moisture absorption resistant.

Good electrical properties, combined with high mechanical strength and a UL electrical rating of 100 °C, qualify these materials for electrical applications requiring long-term stability.

Acetal copolymers have excellent resistance to chemicals and solvents. This makes them ideal for mounting explosion proof lights in tanks, vessels and paint booths.

Most organic reagents tested have no effect, nor do mineral oil, motor oil, or brake fluids. Resistance to strong alkalis is exceptionally good; specimens immersed in boiling 50% sodium hydroxide solution and other strong bases for many months show no property changes.

Strength of acetal copolymer is only slightly reduced after aging for one year in air at 240 °F. Impact strength holds constant for the first six months, and falls off about one-third during the next six-month period. Aging in air at 180 °F for two years has little or no effect on properties, and immersion for one year in 180 °F water leaves most properties virtually unchanged. Samples tested in boiling water retain nearly original tensile strength after nine months.

Similar models

grabcad

free

Bar Clamp Mount for Permanent Mount and Magnetic Mount Spotlights - BC-1 - 7/8" - 1.75" Diameter

...ill stay firmly affixed during use.

this clamping system is effective on heavy equipment, boats, atvs, trucks, toy haulers, etc.

grabcad

free

Bar Clamp for Permanent or Magnetic mounting of Lights and other Devices - 3/8" - 1.25"

...t 7900, golight 7950, golight 5167 and golight 5149. available in black anodized finish with black shoe for black golight models.

grabcad

free

20204 Wired Joystick Remote LED Spotlight - 6, 6-Watt High Power LEDs - 900' Beam - White

...amps, making it ideal for vehicles, boats, atvs, and similar sources of 12 volt direct current. on this particular...

grabcad

free

Protective Steel Light Cage for Golight Spotlights - 1/8" CNC Machined - Powder Coated - Predrilled

...an affect the light. this light cage is predrilled with holes to work with both golight stryker units and golight radioray units.

3d_sky

free

Led Spotlight GL-SP30

...led spotlight gl-sp30

3dsky

spotlight

led spotlight gl-sp30

grabcad

free

High Intensity Bar Clamp Mounted LED Light - 10 Watt LED - 12-32V DC - 650 Foot Spot Beam

...led spotlight is well suited for atvs, utvs, 4-wheelers, golf carts, and any other application with a post to mount the light to.

thingiverse

free

2020 Series Extruder Mounting Clamp

... in case like me it needs some clearance.

prints with no support. print the main base on it's side for strength.

thank you!

grabcad

free

LED Light Emitter - 160 LEDs - 480 Watts - 40 X 4 Array - IP68 - Extreme Environment

...ars come standard with amp connectors instead of the deutsch connector commonly found on various larson electronics led emitters.

grabcad

free

Small Gear

...small gear

grabcad

material : pom acetal copolymer

grabcad

free

Ultraviolet LED Light Emitter - 160 3-Watt LEDs - 9-42V - 2350'L X 450'W Beam - 400NM

...ars come standard with amp connectors instead of the deutsch connector commonly found on various larson electronics led emitters.

Hid

turbosquid

$20

Spaceship HID

...free 3d model spaceship hid for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1227809)

turbosquid

$3

HID ABYS

...alty free 3d model hid abys for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1466368)

3ddd

$1

синтезатор nord lead 2x

...синтезатор nord lead 2x 3ddd синтезатор http://market.yandex.ru/model.xml?hid91248&modelid;=6908140&clid;=502 ...

3ddd

$1

sennheiser hd 215

...3ddd наушники , sennheiser hd 215 , sennheiser мониторные наушникиhttp://market.yandex.ru/model.xml?hid90555&modelid;=658733&clid;=502 ...

3ddd

$1

звуковая карта tascam us-122mkii

...tascam us-122mkii 3ddd звуковая карта , внешняя , tascam http://market.yandex.ru/model.xml?hid91027&modelid;=6122964&clid;=502 ...

3ddd

free

midi клавиатура m-audio axiom air 32

...клавиатура m-audio axiom air 32 3ddd midi , клавиатура http://market.yandex.ru/model.xml?hid91248&modelid;=9326509&clid;=502 ...

3ddd

$1

колонки KRK RP6-G2

...колонки krk rp6-g2 3ddd колонки , krk http://market.yandex.ru/model.xml?modelid=6032760&hid=90548&show-uid;=075686013962197959&track;=mdlttl ...

3ddd

$1

объектив Canon EF 50mm f-1.2L USM

...3ddd объектив , canon объектив canon ef 50mm f-1.2l usmhttp://market.yandex.ru/model.xml?modelid=988322&hid=90613 ...

3ddd

free

Valente Lacrima 1100 белая gelcoat Мебельная раковина

...3ddd valente lacrima , полотенце , зеркало , ковер раковинаhttps://market.yandex.ru/product/10661501?hid91614&show-uid;=083274414401457823 смесительhttp://sant74.ru/smesiteli/1604-smesitel-hansgrohe-logis-71130000.html + полотенце, шкаф и коврик...

3ddd

$1

Набор детской мебели PALI PRESTIGE

...pali , prestige в набор входят: 1. кроватка pali prestigehttp://market.yandex.ru/product/6176082?hidamp;show-uid;=173123414305211352 2. пеленальный комод pali prestigehttp://weskids.ru/product/komod_pali_prestige_belyy_seryy?utm_source=yamarket&utm;_medium=cpc&utm;_campaign=export&utm;_content=pelenalnyy_komod 3.бельевой комод pali prestigehttp://www.kriblekrable.ru/detskaja-mebel/pali/tumba_prestige/?utm_source=yandex.market&utm;_medium=cpc&utm;_term=222621&_openstat=bwfya2v0lnlhbmrlec5ydtvqkdc10lvrjnc10llqvtc5inc60l7qvnc-0lqgugfsasbqcmvzdglnzttyeu1infctyvjnqknzcmg3vzbhedhrow ...

Emitter

turbosquid

free

Beam Emitter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Laser Fence Emitter

...royalty free 3d model laser fence emitter for download as fbx on turbosquid: 3d models for games, architecture, videos. (1681085)

turbosquid

$25

BLAME! Gravitational beam emitter

...el blame! gravitational beam emitter for download as and dae on turbosquid: 3d models for games, architecture, videos. (1536111)

3d_ocean

$20

Swarm O Bees

...swarm o bees 3docean bee emitter – create a swarm of bees! easy to use...

3d_export

$19

Gas ceramic heater 216 XLA 3D Model

...heaters brooder 216 xla ceramic burner gas infrared radiator emitter sbm v-ray gas ceramic heater 216 xla 3d model...

3d_export

$80

Wild Raccoon

...rig controls the main body and the body hair emitter objects. includes morpher modifier with basic actions: blink, breath,...

3d_export

$5

sci-fi lab table - low poly - pbr - game ready

...eevee render engine.<br>this 3d model has metallic texture and emitter texture.<br>all blender file, textures are also attached with this.<br>environment...

thingiverse

free

oxygen emitter

...oxygen emitter

thingiverse

oxygen emitter for hydroponic deep water culture or aquarium

thingiverse

free

Holo Emitter by LukeSkypilot

...holo emitter by lukeskypilot

thingiverse

star wars - holo emitter

thingiverse

free

Mobile Emitter by MorganCoLLC

...mobile emitter by morgancollc

thingiverse

i was bored so i made the mobile emitter from voyager.

Halogen

turbosquid

$29

Halogen Torchiere

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Halogen projector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Halogen Bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Halogen Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Halogen Light

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Halogen Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Halogen lamp 3D Model

...halogen lamp 3d model

3dexport

halogen lamp

halogen lamp 3d model cukier 58695 3dexport

turbosquid

$15

Halogen light

...alogen light for download as max, max, 3ds, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1707623)

3d_ocean

$14

H4 Halogen Bulb

...gen bulb. the package contains the .max scene(max 2011) with lights and walls for render. and .3ds explot file with h4 bulb only.

3d_ocean

$15

Halogen Stand Work Light

.... great model for industrial scens or construction area visualizations. i attached only model, without render setup. (renders ...

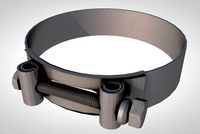

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

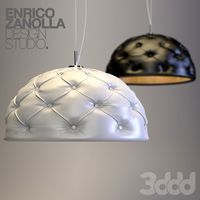

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Rail

3d_ocean

$5

rails

...rails

3docean

old rails rails sleepers

old rails

archibase_planet

free

Rail

...chibase planet

rail railing handrail guard-rail

rail forged fence n310814 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

handrail railing guard-rail

rail n220914 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

railing hand-rail banisters

rail n130309 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

railing hand-rail banisters

rail n270510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...

archibase planet

railing handrail fence guard-rail

railing n140314 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing

railing- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing enclosure barrier

light railing - 3d model for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

metal railing

rail n280608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing kitchen ware

railing 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Led

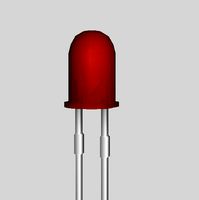

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bar

archibase_planet

free

Bar

...bar

archibase planet

bar bar rack

bar 2 - 3d model for interior 3d visualization.

archibase_planet

free

Bars

...bars

archibase planet

horizontal bar parallel bars

parallel bars - 3d model for interior 3d visualization.

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

Bars

archibase_planet

free

Bar

...bar

archibase planet

bar bar rack

bar 2 - 3d model for interior 3d visualization.

archibase_planet

free

Bars

...bars

archibase planet

horizontal bar parallel bars

parallel bars - 3d model for interior 3d visualization.

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

Vehicle

3d_export

$30

Vehicle display

...vehicle display

3dexport

vehicle display consists of podium and vehicle cover no vehicle there is a veiled vehicle silhouette

turbosquid

$41

vehicle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

vehicle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$40

Heavy vehicles

...el this model is created with 3ds max 2009 and content .max (3ds max), size: 7,65 mb this model can be used in any scene. enjoy !

3d_export

$6

Trailer Transporter Consignment Vehicle Turnover Vehicle

...trailer transporter consignment vehicle turnover vehicle

3dexport

trailer transporter consignment vehicle turnover vehicle

archive3d

free

Vehicle 3D Model

... sports and recreational vehicle n250714 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$50

Vehicle 3D Model

...vehicle 3d model

3dexport

vehicle

vehicle 3d model fred-13 21262 3dexport

3d_export

$15

special vehicles

...special vehicles

3dexport

3d_export

$10

utility vehicle

...utility vehicle

3dexport

turbosquid

$9

Vehicles pack

...bosquid

royalty free 3d model vehicles pack for download as on turbosquid: 3d models for games, architecture, videos. (1635451)

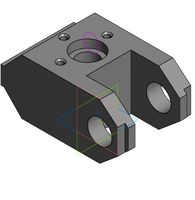

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Lights

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...