Thingiverse

Proteus Plus PW51

by Thingiverse

Last crawled date: 4 years, 2 months ago

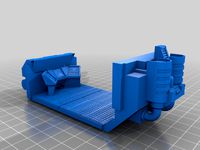

This is a 1.8 m span version of the Proteus wing, with flaps, using the PW51 airfoil and designed to print in a 200 x 200 x200 mm build volume.

Following Peter Wick's advice, the flaps and elevons are bottom hinged.

This version is designed to be an improvement on the 1.65 m span version (which uses the MH45 airfoil) shown in this video:https://www.youtube.com/watch?v=2Ngxi2U_f7g

It has now flown successfully, exhibits excellent efficiency, and handles well (video coming).

It uses two swept 1x10x715 mm carbon fiber half - spars and a rear 5 mm OD x 500 mm long tube spar (the same as the Proteus).

For transport, the design allows the outer halves of the wing to be slid off the spar after disconnecting the elevon clevises. Be sure to use a strong cross-hatch glass reinforced tape 2.5 cm wide for joining the wing sections, e.g.:https://www.aliexpress.com/item/33040897587.html?spm=a2g0o.productlist.0.0.11566b91frQ3BL&algo_pvid=30557374-9691-486b-9e65-163e8c47de83&algo_expid=30557374-9691-486b-9e65-163e8c47de83-14&btsid=d6647c72-a085-42a8-9fb5-d9c117668db3&ws_ab_test=searchweb0_0,searchweb201602_3,searchweb201603_55

otherwise the gears in the elevon servos could be stripped if the outer half of the wing comes loose during a crash or bad landing.

Printing instructions are similar to the original Proteus: https://www.thingiverse.com/thing:2086413

Note: the hatch is designed to be printed on its side.

The spar joiner is printed in PLA+ at 240 C with no fan, 5 perimeters and 65% infill.

Zip ties are used to reduce the risk of it splitting and a section of 1x10x120 mm strip is used to connect the spar joiner with the fuselage.

The flap and elevon are each comprised of 2 pieces that need to be glued together with a 2 mm OD carbon fiber rod and CA glue, after a little sanding of the mating ends.

I have included Simplify3D factory files. Note that the starting scripts might need adjustment as I use Marlin's Unified Bed Levelling system (G29 etc) and volumetric extrusion mode.

The temperature is set to 240 C, suitable for PLA+.

A rear tube spar 500 mm long is used close to the CoG to increase the wing stiffness.

The reason thin 1x10mm strip is used for the spars is so they flex rather than ripping the fuselage apart in a crash/hard landing.

I highly recommend printing the nose using a (semi-) flexible filament.

All up flying weight: 960 g

Wing area: 30.4 dm^2 , 3.27 sq ft

Wing loading: 31 g/dm^2

Printed Parts weights and approximate print times:

Nose: 43 g, 7 hours

Rear fuse: 96 g, 10.5 hours

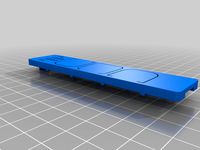

Spar joiner: 18 g, 1.5 hours

Hatch: 17 g, 2 hours

Fin: 21 g each, 6.5 hours for 2

Root wing: 81 g each, 6 hours each

Mid wing 0: 63 g each, 10 hours for 2

Mid wing 1: 45 g each, 7 hours for 2

Tip wing: 37 g each, 5.5 hours for 2

Flaps: 56 g for 2, 6 hours for 2

Elevons: 47 g for 2, 6 hours for 2

Total weight printed parts: 770 g

Total print time (approx): 74 hours

Vitamins:

The 1x10 mm CF strip can be found here: https://www.aliexpress.com/item/32720654666.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The 5 mm OD tube spar can be found here:https://www.aliexpress.com/item/32242824992.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The 2 mm and 3 mm joiner dowels can be found here:https://www.aliexpress.com/item/32573564619.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The dowels for joining the nose to the rear fuselage should be cut to 13 mm from 2 mm rod.

The dowels for joining the wing sections should be cut to 35 mm from 3 mm rod

The dowels for joining the flap and elevon sections should be cut to 55 mm from 2 mm rod.

The hinges should be cut to 14 x 27 mm from 0.3 mm hinging film, e.g. :https://hobbyking.com/en_us/ca-hinge-sheet-180mmx140mmx0-3mm.html

I don't bother gluing the hinging sheet into the wing or elevon. I just insert the hinges then apply a single layer of Blenderm hinging tape on the bottom surface only, to seal the join.

Servos (4 needed):https://hobbyking.com/en_us/hxt900-micro-servo-1-6kg-0-12sec-9g.html

2x 30 cm long servo extension leads for elevon servos.

Elevon linkage : 70 mm (horn to horn, including clevises)

Flap linkage : 65 mm (horn to horn, including clevises)

Following Peter Wick's advice, the flaps and elevons are bottom hinged.

This version is designed to be an improvement on the 1.65 m span version (which uses the MH45 airfoil) shown in this video:https://www.youtube.com/watch?v=2Ngxi2U_f7g

It has now flown successfully, exhibits excellent efficiency, and handles well (video coming).

It uses two swept 1x10x715 mm carbon fiber half - spars and a rear 5 mm OD x 500 mm long tube spar (the same as the Proteus).

For transport, the design allows the outer halves of the wing to be slid off the spar after disconnecting the elevon clevises. Be sure to use a strong cross-hatch glass reinforced tape 2.5 cm wide for joining the wing sections, e.g.:https://www.aliexpress.com/item/33040897587.html?spm=a2g0o.productlist.0.0.11566b91frQ3BL&algo_pvid=30557374-9691-486b-9e65-163e8c47de83&algo_expid=30557374-9691-486b-9e65-163e8c47de83-14&btsid=d6647c72-a085-42a8-9fb5-d9c117668db3&ws_ab_test=searchweb0_0,searchweb201602_3,searchweb201603_55

otherwise the gears in the elevon servos could be stripped if the outer half of the wing comes loose during a crash or bad landing.

Printing instructions are similar to the original Proteus: https://www.thingiverse.com/thing:2086413

Note: the hatch is designed to be printed on its side.

The spar joiner is printed in PLA+ at 240 C with no fan, 5 perimeters and 65% infill.

Zip ties are used to reduce the risk of it splitting and a section of 1x10x120 mm strip is used to connect the spar joiner with the fuselage.

The flap and elevon are each comprised of 2 pieces that need to be glued together with a 2 mm OD carbon fiber rod and CA glue, after a little sanding of the mating ends.

I have included Simplify3D factory files. Note that the starting scripts might need adjustment as I use Marlin's Unified Bed Levelling system (G29 etc) and volumetric extrusion mode.

The temperature is set to 240 C, suitable for PLA+.

A rear tube spar 500 mm long is used close to the CoG to increase the wing stiffness.

The reason thin 1x10mm strip is used for the spars is so they flex rather than ripping the fuselage apart in a crash/hard landing.

I highly recommend printing the nose using a (semi-) flexible filament.

All up flying weight: 960 g

Wing area: 30.4 dm^2 , 3.27 sq ft

Wing loading: 31 g/dm^2

Printed Parts weights and approximate print times:

Nose: 43 g, 7 hours

Rear fuse: 96 g, 10.5 hours

Spar joiner: 18 g, 1.5 hours

Hatch: 17 g, 2 hours

Fin: 21 g each, 6.5 hours for 2

Root wing: 81 g each, 6 hours each

Mid wing 0: 63 g each, 10 hours for 2

Mid wing 1: 45 g each, 7 hours for 2

Tip wing: 37 g each, 5.5 hours for 2

Flaps: 56 g for 2, 6 hours for 2

Elevons: 47 g for 2, 6 hours for 2

Total weight printed parts: 770 g

Total print time (approx): 74 hours

Vitamins:

The 1x10 mm CF strip can be found here: https://www.aliexpress.com/item/32720654666.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The 5 mm OD tube spar can be found here:https://www.aliexpress.com/item/32242824992.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The 2 mm and 3 mm joiner dowels can be found here:https://www.aliexpress.com/item/32573564619.html?spm=a2g0s.9042311.0.0.27424c4dea5VT9

The dowels for joining the nose to the rear fuselage should be cut to 13 mm from 2 mm rod.

The dowels for joining the wing sections should be cut to 35 mm from 3 mm rod

The dowels for joining the flap and elevon sections should be cut to 55 mm from 2 mm rod.

The hinges should be cut to 14 x 27 mm from 0.3 mm hinging film, e.g. :https://hobbyking.com/en_us/ca-hinge-sheet-180mmx140mmx0-3mm.html

I don't bother gluing the hinging sheet into the wing or elevon. I just insert the hinges then apply a single layer of Blenderm hinging tape on the bottom surface only, to seal the join.

Servos (4 needed):https://hobbyking.com/en_us/hxt900-micro-servo-1-6kg-0-12sec-9g.html

2x 30 cm long servo extension leads for elevon servos.

Elevon linkage : 70 mm (horn to horn, including clevises)

Flap linkage : 65 mm (horn to horn, including clevises)

Similar models

thingiverse

free

nadav zrihan by nadavz

...0s.9042311.0.0.27424c4dnxx4j8

slip ring - https://www.aliexpress.com/item/4001171413716.html?spm=a2g0s.9042311.0.0.59014c4dmidnoe

thingiverse

free

Brushless 48mm cover + bracket original = joeynovak by pek

...?spm=a2g0s.9042311.0.0.27424c4dlz1gvb

7-gearhttps://www.aliexpress.com/item/33031516913.html?spm=a2g0s.9042311.0.0.27424c4dsll0v1

thingiverse

free

KP3S BMG E3DV6 extruder mod by ehitaja_fpv

...af19b7xaof8q

nema17 17hs4023 extruder motor https://www.aliexpress.com/item/32998564515.html?spm=a2g0s.9042311.0.0.27424c4da1ai8m

thingiverse

free

Curtain Control System

...2311.0.0.3bb14c4djb8a7m

dc-dc (12v to 5v) : https://www.aliexpress.com/item/32742116421.html?spm=a2g0s.9042311.0.0.27424c4doqjuwk

thingiverse

free

Servo - Linkage Clevises by spu

...e clevises by spu

thingiverse

this is designed for hooking up a servo with a controller horn, using only 1.5mm cfk or steel rod.

thingiverse

free

Flux Dispenser Adapt3r by h3nkGer

...l?spm=a2g0s.9042311.0.0.27424c4dk2putr

into:https://www.aliexpress.com/item/32860544361.html?spm=a2g0s.9042311.0.0.27424c4dyuiryi

thingiverse

free

Clock Case by AlanMagalhaes

...spm=a2g0s.9042311.0.0.5e6db90azbcs2j

clock:

https://www.aliexpress.com/item/33024660919.html?spm=a2g0s.9042311.0.0.5e6db90azbcs2j

thingiverse

free

PANASONIC BATTERY

...2g0s.9042311.0.0.27424c4d6unh2a

power meter:https://www.aliexpress.com/item/33003319718.html?spm=a2g0s.9042311.0.0.27424c4d6unh2a

thingiverse

free

Rc Plane Servo Horn by GerardFernandes

...rc plane servo horn by gerardfernandes

thingiverse

a very basic servo horn for elevon, ailerons or rudder.

thingiverse

free

Dart XL - Rear Bay Electronics Shelf

...dart xl - rear bay electronics shelf

thingiverse

print with the legs sticking up.

zip-tie to the wing spar for hinge

Proteus

3d_export

$199

Proteus 3D Model

...proteus 3d model

3dexport

sci-fi spaceship warship cruiser destroyer

proteus 3d model psicore 4922 3dexport

turbosquid

$25

Proteus PEC 2025

...d

royalty free 3d model proteus pec 2025 for download as c4d on turbosquid: 3d models for games, architecture, videos. (1275757)

thingiverse

free

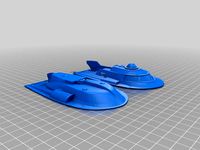

Proteus Proxy Detailed

...proteus proxy detailed

thingiverse

this is a version of the proteus proxy with a detailed interior.

unity_asset_store

$36

PROTEUS Frigate

...te your workflow with the proteus frigate asset from cgpitbull. find this & other space options on the unity asset store.

3dcadbrowser

free

Proteus

...software.this 3d object can be downloaded in .max, .obj, .3ds, .fbx, .dxf, .lwo, .stl, .wrl, .ma, .dae, .x and .asc file formats.

unity_asset_store

$7

Proteus Mech Robot

...r workflow with the proteus mech robot asset from polyanarchy. find this & other robots options on the unity asset store.

thingiverse

free

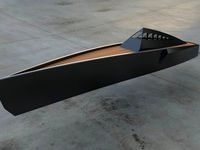

Proteus Concept Boat by omega

...is is my grabcad entry for the

makerbot replicator 2 desktop 3d printer challenge

http://grabcad.com/library/proteus-boat-concept

thingiverse

free

Proteus with Fuse Rear Motor mount by MADRobotNO

...tor cables.

this is 200 version of proteus: https://www.thingiverse.com/thing:2086413

2 last parts er designet for gopro session.

thingiverse

free

Proteus (halved) by guydebored

...e made a few changes on this version. the rear fins should be better conected now and you won't need rafts or support.

enjoy!

thingiverse

free

VFL Bochum 1848 - Proteus Key Holder by MacNite

...e

i made this quick mod of the proteus key holder by proteanman for my grand-father-in-law.

i hope, it may help someone as well.

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

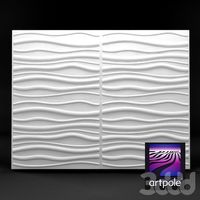

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus