Thingiverse

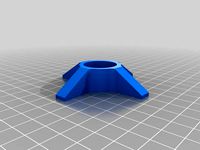

Printing Testpart for RepRap Machines by Patrick

by Thingiverse

Last crawled date: 3 years ago

I published this on the RepRap buliders blob http://builders.reprap.org/ some days before and was asked to publish it here also.. so here is my post from the Builders blog...

nspired by a paper from Kruth et al. (2005, Benchmarking of different SLS/SLM processes as rapid manufacturing techniques) I also designed a benchmark model for the RepRap. It looks quite random but by printing it you can check whether your RepRap prints geometrically correct. I included the following features:

-vertical holes for M3, M4, M8 screws

-vertical hexagons suitable for M3, M4 M8 nuts

-horizontal teardrops M3, M4 M8 and hexagons for suitable nuts

-sharp edges with angles of 15, 30 and 45 deg

-thin walls 0.5mm, 1,0mm, 1.5mm and 2mm horizontally and vertically

-stair effect at sloped walls with angles of 15, 30, 45, 60 and 80 deg

-round corners, radius 4mm to 16mm

-gear teeth with 2mm wide teeth

-in addition to this, you can also check perpendicularity and parallelism of your printed objects, which were the general intentions of designing a benchmark.

You can download both the STL and the AoI file from SourceForge

/mendel/mechanics/test-parts

Printing it took about two hours, so why not watching a fancy movie while your RepRap prints its benchmark.

The very first version included a complete horizontal hexagon for M8 nuts, but apparently this made the object to big in height, so I just cut it off, leaving just a small offset ;)

The gear teeth were not built as expected but as a round corner with a bubbled rim. I am also missing the 0.5mm thin walls. The 1.5mm walls consist of only two parallel strings and are not solid, there is a small gap between them in both directions.

nspired by a paper from Kruth et al. (2005, Benchmarking of different SLS/SLM processes as rapid manufacturing techniques) I also designed a benchmark model for the RepRap. It looks quite random but by printing it you can check whether your RepRap prints geometrically correct. I included the following features:

-vertical holes for M3, M4, M8 screws

-vertical hexagons suitable for M3, M4 M8 nuts

-horizontal teardrops M3, M4 M8 and hexagons for suitable nuts

-sharp edges with angles of 15, 30 and 45 deg

-thin walls 0.5mm, 1,0mm, 1.5mm and 2mm horizontally and vertically

-stair effect at sloped walls with angles of 15, 30, 45, 60 and 80 deg

-round corners, radius 4mm to 16mm

-gear teeth with 2mm wide teeth

-in addition to this, you can also check perpendicularity and parallelism of your printed objects, which were the general intentions of designing a benchmark.

You can download both the STL and the AoI file from SourceForge

/mendel/mechanics/test-parts

Printing it took about two hours, so why not watching a fancy movie while your RepRap prints its benchmark.

The very first version included a complete horizontal hexagon for M8 nuts, but apparently this made the object to big in height, so I just cut it off, leaving just a small offset ;)

The gear teeth were not built as expected but as a round corner with a bubbled rim. I am also missing the 0.5mm thin walls. The 1.5mm walls consist of only two parallel strings and are not solid, there is a small gap between them in both directions.

Similar models

grabcad

free

Helical Gear

...helical gear

grabcad

45 teeth

module 2mm

20 deg helix angle

thingiverse

free

Thin Square Nut M3, M4, M5, M6, M8, M10

... m6, m8, m10

thingiverse

hey,

maybe someone need it :-)

metric m3, m4, m5, m6, m8, m10

please tell me the results after printing

thingiverse

free

Roomba Barrier Caddy 45 Deg by BikerNerd

...it it. i want to block off a corner of the room securely. so i made this caddy.

it sits securely in a corner or against the wall.

grabcad

free

HEXAGONAL NUT

...hexagonal nut

grabcad

standard hexagonal nut size

m3, m4, m5, m6, m8, m10, m12, m16, m20, m24

grabcad

free

Hex Nut M2 M3 M4 M5 M6 M8 M10

...hex nut m2 m3 m4 m5 m6 m8 m10

grabcad

hex nut m2 m3 m4 m5 m6 m8 m10

thingiverse

free

Hypercube xy ideer 8mm rod (m4) by muratxxf

...hypercube xy ideer 8mm rod (m4) by muratxxf

thingiverse

0.25mm 0.5mm nozzle my best print settings desings is m4 nut+m3 nut.

thingiverse

free

allen key 2mm and 1.5mm handle

...so handle is the solution. when i finish 2.5mm 3mm i will publish them. i printed the handle vertically to provide smooth shape.

grabcad

free

M3 Hex Nut

...m3 hex nut

grabcad

m3x1.8mm; m3x2.4mm; m3x2.7mm (fix-m3 nylon) - 0.5mm pitch hexagonal nut

thingiverse

free

Screw Knob (for Hexagon head bolts) by Steven29

...ink for drawings:https://1drv.ms/u/s!aty3bg3ygnjymahpi5nzt9vnnyvrba?e=xf5ngu

please report the result if you have printed it out.

thingiverse

free

Flow test cube by Elektrolenin

...inter

vertical rounded walls

horizontal surfaces with all types of wall connections

corners of all types

tiny horizontal surfaces

Testpart

thingiverse

free

Testparts 2 by bonsen

...testparts 2 by bonsen

thingiverse

testparts 2

thingiverse

free

Quick Testpart by Chri

...quick testpart by chri

thingiverse

quick testpart for printer calibration

thingiverse

free

Test Parts by bonsen

...test parts by bonsen thingiverse testpart ...

thingiverse

free

P47 Thunderbolt, WingR1 testpart - retract version by stephencz

...ing files for your printer, userguide...):http://3dlabprint.comhttp://www.facebook.com/3dlabprintfacehttps://youtu.be/dzk9az0yhfm

thingiverse

free

Text font test by LPHconus

...by lphconus thingiverse fin: testikappale erikorkuisien fonttien testaamiseen eng: testpart for the test correct size of...

thingiverse

free

Printing Standard Test Part for 3D Printers by ferret7

...by ferret7 thingiverse this is copied from "thing:9681" printing testpart for reprap machines by patrick http://www.thingiverse.com/thing:968 we as a...

thingiverse

free

Schubkarrengriff, wheelbarrow handle by Renngarage

...wheelbarrow has 30mm in diameter. i made a small testpart of it, so you can scale it up or...

thingiverse

free

Volkswagen Window Crank Handle

...most models of volkswagen company! there is also a testpart in here that you can print and test whether...

thingiverse

free

Oozing / Retraction Test Part by DM4DS

...everywhere and so i decided to make a small testpart to find my settings. now i am happy ....

Patrick

3ddd

$1

Patrick

...patrick

3ddd

патрик , статуэтка

игрушка-статуэтка patrick из мультсериала спанч боб.

turbosquid

$60

patrick

...turbosquid

royalty free 3d model patrick for download as ztl on turbosquid: 3d models for games, architecture, videos. (1682952)

turbosquid

$20

Patrick

...id

royalty free 3d model patrick for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1637550)

3d_export

$5

patrick star

...patrick star

3dexport

patrick star mit textur

3ddd

$1

кровать Patrick

...кровать patrick

3ddd

cattelan , patrick

сделана по каталогу

turbosquid

$35

Patrick

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Patrick

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Patrick

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

patrick essamambo

...patrick essamambo

3dexport

hello everyone. the character patrick will look good in your cartoons

turbosquid

$20

patrick star

...squid

royalty free 3d model patrick star for download as obj on turbosquid: 3d models for games, architecture, videos. (1472931)

Reprap

turbosquid

$1

Go Pro Balance Hand Wand Reprap

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Reprap keychain by AndreasD

...reprap keychain by andreasd

thingiverse

a simple reprap logo keychain for the reprap lovers like me!

thingiverse

free

REPRAP CHASSIS by leonk

...reprap chassis by leonk

thingiverse

reprap chassis

thingiverse

free

COUPLER RepRap by leonk

...coupler reprap by leonk

thingiverse

coupler reprap

thingiverse

free

RepRap Switch by n3opl4n

...reprap switch by n3opl4n

thingiverse

switch for reprap prusa i2.

p-space hackerspace logo.

thingiverse

free

Reprap pendulum by mr_seeker

...ap pendulum by mr_seeker

thingiverse

its a pendulum in the shape of the reprap logo. it has a 1mm hole for putting a wire in it.

thingiverse

free

RepRap Ornament by redskinsjbs

...reprap ornament by redskinsjbs

thingiverse

i tried to make a teardrop shape ornament for the holiday season in honor of reprap

thingiverse

free

Spool holder reprap by mdnm

...spool holder reprap by mdnm

thingiverse

this is spool holder for reprap.

thingiverse

free

RepRap logo keyring by mrjohnc

...reprap logo keyring by mrjohnc

thingiverse

reprap logo keyring

thingiverse

free

REPRAP LEON K by leonk

...reprap leon k by leonk

thingiverse

reprap leon k

Machines

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

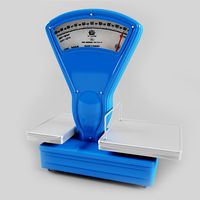

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Printing

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints