Thingiverse

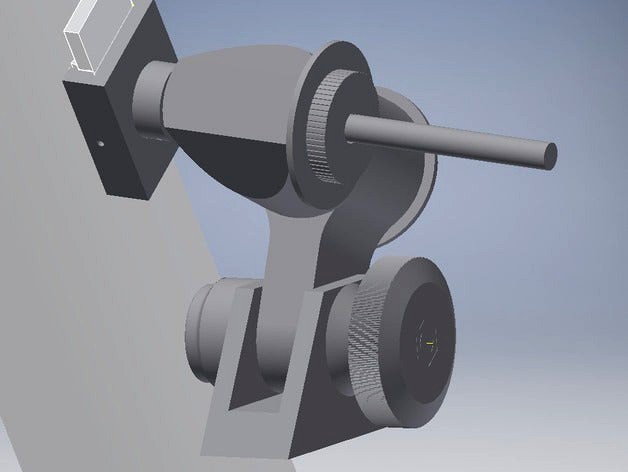

Printable Equitorial mount by crucial97

by Thingiverse

Last crawled date: 3 years ago

UPDATE 11/12/17: I have a new (bigger) version printed and being constructed at the moment, so keep an eye out for the models once it's done.

A printable equatorial mount for a telescope with a dovetail. I plan on using 1/2" threaded rods, 1/2" x 9/8" x 5/16" bearings, and 1/2" nuts to hold everything together.

I have it designed to use two steppers (I will test if NEMA 17s will work, otherwise high torque NEMA 23s) and they will be belt driving the RA and Dec axis of the mount. This doesn't include a way to attach to a tripod or anything, so bust out the hotglue and drills.

I honestly have no idea if this will work or how many pounds it will hold, most likely variable on plastic (I'm using colorfabb ngen - clear personally).

UPDATE 10-14-16:

-Designed a 'belt'box to decrease the arcseconds traveled. ~211 arcsec per 1 step to ~4 arcsec per 1 step (1:42.25 ratio). I'll be using GT2 3mm timing belt from openbuildspartstore.com.

-I also redesigned the polar knob to make it faster to print (I do recommend a cloth or something to tighten it since it is a little hard to grab, I'll redesign that later). Pictures soon!

-Quick redesing of the declination drive cover, I don't know why I put bearings there since it shouldn't be freely spinnging. put a hole for a 1/2" nut instead, I recommend epoxying the nut into place (as straight as physically possible). Might want to clamp some scrap metal or plastic on the nut and flat end of the drive cover to make sure it is flat.

UPDATE 11/15/16

-Finally put it all together: http://imgur.com/a/sjWkY

-I'll be updating these models soon, once I get some time to fix them.

-Scrapped the bottom knob tightener thing, I bought a cheap 1/2 threaded knob off of amazon and put some locktite red on it.

-Redesigned the axis drives (again) decided on a 15 and 100 tooth pulley setup (15:100:15:100) which gives 1:44.4 gear ratio. Ill mess with programming later.

A printable equatorial mount for a telescope with a dovetail. I plan on using 1/2" threaded rods, 1/2" x 9/8" x 5/16" bearings, and 1/2" nuts to hold everything together.

I have it designed to use two steppers (I will test if NEMA 17s will work, otherwise high torque NEMA 23s) and they will be belt driving the RA and Dec axis of the mount. This doesn't include a way to attach to a tripod or anything, so bust out the hotglue and drills.

I honestly have no idea if this will work or how many pounds it will hold, most likely variable on plastic (I'm using colorfabb ngen - clear personally).

UPDATE 10-14-16:

-Designed a 'belt'box to decrease the arcseconds traveled. ~211 arcsec per 1 step to ~4 arcsec per 1 step (1:42.25 ratio). I'll be using GT2 3mm timing belt from openbuildspartstore.com.

-I also redesigned the polar knob to make it faster to print (I do recommend a cloth or something to tighten it since it is a little hard to grab, I'll redesign that later). Pictures soon!

-Quick redesing of the declination drive cover, I don't know why I put bearings there since it shouldn't be freely spinnging. put a hole for a 1/2" nut instead, I recommend epoxying the nut into place (as straight as physically possible). Might want to clamp some scrap metal or plastic on the nut and flat end of the drive cover to make sure it is flat.

UPDATE 11/15/16

-Finally put it all together: http://imgur.com/a/sjWkY

-I'll be updating these models soon, once I get some time to fix them.

-Scrapped the bottom knob tightener thing, I bought a cheap 1/2 threaded knob off of amazon and put some locktite red on it.

-Redesigned the axis drives (again) decided on a 15 and 100 tooth pulley setup (15:100:15:100) which gives 1:44.4 gear ratio. Ill mess with programming later.

Similar models

thingiverse

free

Nema 17 Direct Belt Drive by MatGyver85

... 1-m8 nut, 1-608zz bearing, and 4- m3x16mm bolts. enjoy.

p.s. i adjusted the gap size to be tighter on belt to prevent slippage

thingiverse

free

Marshall Bison Fidget Spinner by wingnut2k

...a v2 which uses (3) 1/2" ball bearings instead of the 5/16" nuts.

i'll update this with a picture when i print one.

thingiverse

free

Bogen 3028 Tripod Head Adjustment Knob by fbourke

...t is a standard 5/16" unc with a 1/2" head size.

i haven't actually printed this, but i'll update here if i do.

thingiverse

free

Spool holder by RickSanchez137

..."-20

updates

04/22/15 centering nuts have an updated smaller diameter to fit more spools and legs updated for more support

thingiverse

free

CR-10 X-Axis Realigned Tensioner by jneilliii

...ion of assembly can be seen here

updates:

07/6/2017: added knob that is flipped to have the outer part larger, idea from phiippe.

thingiverse

free

Knob for 1/4" Nut by Makify1

...allows a bolt or threaded rod to pass through the knob. you'll probably want to use a 1/4" washer with the knob as well.

thingiverse

free

Yet another belt tensioner by kwg08

...his stuff (for non profit uses only.)

if we meet some day, and you think this stuff is worth it, you can buy me a beer in return.

thingiverse

free

Sapphire Plus Belt Tensioner by wildvortex

...designed it.

i have included my fusion file. please don't mind my work flow. i know it could be better but it is what it is.

thingiverse

free

Promega CoreXY Belt Tensioner by supinemonkey

...loosen the four top screws as normal and hand tension with the knob. tighten the top screws when the tension feels nice and snug.

thingiverse

free

CR-10 X Axis Belt Tensioner by bglover

... cap screws

2 x m4 lock nuts

2 x m4 flat washers

1 x m4 nut

check back often. i will be uploading my y axis belt tensioner soon.

Crucial97

thingiverse

free

Pen case by crucial97

...o you will either need to edit those out or remove them after printing. other than that it is 6.25in high, 2in wide, and 1in long

thingiverse

free

Kraken Quad Fan Mount by crucial97

...sent me my print and it fits on the kraken if you screw the side plug in all the way. i have no idea how well it works yet though

thingiverse

free

Equitorial Mount Mk2 by crucial97

...et a lightweight conduit that fits into a similar bushing

i will be making an assembly guide soon possibly a video, we'll see

Equitorial

thingiverse

free

Equitorial Mount Mk2 by crucial97

...et a lightweight conduit that fits into a similar bushing

i will be making an assembly guide soon possibly a video, we'll see

thingiverse

free

Camera mount for Celestron CG-5 by teravolt

...by teravolt thingiverse astrophotography camera adaptor for celestron cg-5 equitorial goto...

thingiverse

free

EQ6 Cable Tidy Mk6

...management cable holder. the onlt point on a german equitorial mount that doesn't physically move is the declination axis,...

thingiverse

free

Equatorial Sundial (N 51°) by SLUB_Makerspace

...thingiverse this is a lasercutter template to make an equitorial sundial. because it needs a fixed angle to work...

thingiverse

free

Equatorial mount for DSLR (for 15mm pipe and 32mm bearings) by CrispyDragon

...crispydragon thingiverse this is a remix for the excellent equitorial camera mount design by simonrob.https://www.thingiverse.com/thing:4365068 as i couldn't get...

Printable

turbosquid

$5

printable giraffe

...uid

royalty free 3d model printable giraffe for download as on turbosquid: 3d models for games, architecture, videos. (1504825)

turbosquid

$49

Longhorn Printable

...

royalty free 3d model longhorn printable for download as stl on turbosquid: 3d models for games, architecture, videos. (1712930)

3d_export

$2

printable audi car

...printable audi car

3dexport

printable audi car

turbosquid

$40

Fox printable

...lty free 3d model fox printable for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1507558)

turbosquid

$23

Printable Statue

...ty free 3d model printable statue for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1415137)

turbosquid

$3

Ear Printable

...yalty free 3d model ear printable for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1671689)

turbosquid

$1

heart printable

...y free 3d model heart printable for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1209566)

turbosquid

$1

Printable Hook

...

royalty free 3d model 3d printable hook for download as stl on turbosquid: 3d models for games, architecture, videos. (1413683)

turbosquid

$30

Printable support

... model 3d printable support for download as max, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1689342)

turbosquid

$24

Printable Dolphin

...el printable dolphin for download as , dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1602353)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)