Thingiverse

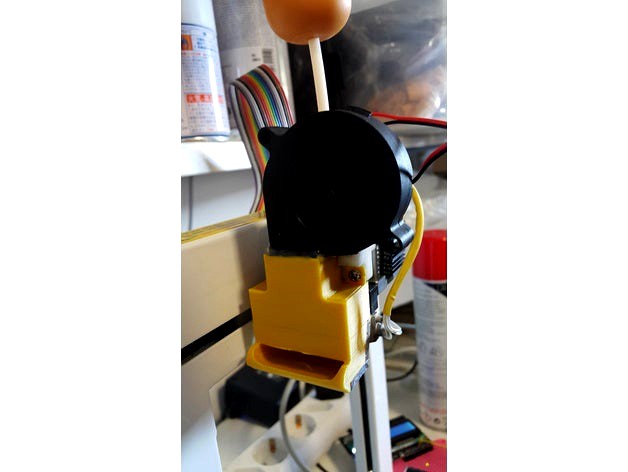

PP3D UP Plus extruder cooling duct for hot printing (ABS, PETG, PC..) by BogdanKecman

by Thingiverse

Last crawled date: 3 years ago

The stock PP3DP "wind barrier" for UP Plus, UP Plus2 and some similar printers (Afinia etc.) is ok for PLA but for ABS the air passing trough "closed flap" makes ABS prints warp. There's a nice upgrade PP3DP Up Plus redesigned wind barrier by PrintMo that I have bin using for years and that works like a charm for ABS. Now if you want to move away from ABS and go bit hotter and print PETG, PC, Nylon.. (all possible since we do have an all metal hotend here!) the small axial fan that cools the cold end of the extruder (the throat) is not enough and for too hot or very long prints you can have jams in the throat, underextrusion etc. This is why I redesigned the piece from cratch for a radial fan. Radial fan can push more air at higher speed then regular axial fan, they are easy to get (~5$ on ebay delivered) and they do not produce much more noise then the provided fan. You can even get some "super strong" ones that can push huge amount of air that you can slow down with 7809 or 7805 to get the quiet and still have huge amount of air going trough...

I intentionally didn't add any mounting arms for the fan mount as I prefer to just use hot glue (hotsnot, hotmelt glue, whatever you call it) to link the duct and the fan. This way the hot glue seals the hole between duct and fan and provides some vibration dampening. It's still easy to remove fan from duct if need arises.

The exit hole of the duct is projecting air at 30°-45° upwards so it does not interfere with the print.

This part will not help you print with PLA or any other material that require part cooling! For that use the original pp3dp design and open the door to cool the part.

and of course, sources are available on onshape

UPDATE 2018-09-23: Uploaded V2, this one is little more sturdy

increased height where blower is attached

added a place to screw blower in (so you don't have to glue it in)

increased the thickness of the pads with screwholes (after a year of operation the vibration of the blower broke the original ones, I decided to make the pads thicker now but this now requires a new screws, original screws were 2.9mm dia 6.5mm long, new ones that fit perfect are 2.9mm dia 8mm long)

I intentionally didn't add any mounting arms for the fan mount as I prefer to just use hot glue (hotsnot, hotmelt glue, whatever you call it) to link the duct and the fan. This way the hot glue seals the hole between duct and fan and provides some vibration dampening. It's still easy to remove fan from duct if need arises.

The exit hole of the duct is projecting air at 30°-45° upwards so it does not interfere with the print.

This part will not help you print with PLA or any other material that require part cooling! For that use the original pp3dp design and open the door to cool the part.

and of course, sources are available on onshape

UPDATE 2018-09-23: Uploaded V2, this one is little more sturdy

increased height where blower is attached

added a place to screw blower in (so you don't have to glue it in)

increased the thickness of the pads with screwholes (after a year of operation the vibration of the blower broke the original ones, I decided to make the pads thicker now but this now requires a new screws, original screws were 2.9mm dia 6.5mm long, new ones that fit perfect are 2.9mm dia 8mm long)

Similar models

thingiverse

free

RepRapPro Ormerod dual fan duct by jstck

...s design.

while this was designed for the ormerod, it might fit other reprappro printers that have the same hotend cooling block.

thingiverse

free

Radial Fang Axial 50mm Fan by Rickbhs

...o use a much quieter 50mm for the hotend cooling and a 5015 radial blower for part cooling

is has also a sensor mounting for sn04

thingiverse

free

PP3DP UP Plus 2 PLA printing kit by BogdanKecman

...w instead of only one v1 did allowing for much nicer prints but the tip requires support to print (turn on only support from bed)

thingiverse

free

JGAurora A5 Hot'n Cold duct and Tube mount by CarstenD

...ans. you can use any part cooling duct of your liking - the duct i prefere is this one: https://www.thingiverse.com/thing:2788702

thingiverse

free

Circular fan-duct for blower for my custom carriage by lukie80

...om exit holes are made larger to compensate for the loss of pressure in the duct.

added a throat nozzle to reduce throat cooling.

thingiverse

free

Fan adapter for Rostock Max v2 to use BD5015 radial fan by Hichi

....

i print abs at 18% fan speed to avoid shrinkage, while still having good layer adhesion.

pla at about 70%, thats with 3 fans.

thingiverse

free

JGAurora A5 Part Cooling Duct- and Tube Mount by CarstenD

...ct (not recommented) or any other of your liking. i prefer the one shown in the images: https://www.thingiverse.com/thing:2788702

thingiverse

free

fan 25/25 duct for hexagon hotend on i3 rework by BrookwayCreations

...weight on your extruder.

mount the fan with m3 screws or like i did you can glue it with some foam rubber to minimise vibrations.

thingiverse

free

Dual fan duct for 5015 radial fans (Tevo Tarantula) by EldeTabernas

...d up 60ºc this print should last long in pla. i'm planing to print it in petg for an extra ensurance, i'll post pictures.

thingiverse

free

Axial Cooling Fan for 3D PRINTING by fkirita

... adapter and glue to the fan. the adapter can be customized for your application.

this is it all, enjoy your new 3d printing fan.

Pp3D

thingiverse

free

Robot Wars Logo by PP3D

...robot wars logo by pp3d

thingiverse

a 3d printable model of the robot wars logo for the new series.

thingiverse

free

Huawei Mate 10 Lite (worker case) by Printareprototipare3d

...by printareprototipare3d thingiverse worker case with 4 bolts. regards pp3d ...

thingiverse

free

Mavic Pro Strobon Mount With Transparent Front by paramanch36

...the gap apart to slip over... i have a pp3d up mini printer and as show it works... have...

thingiverse

free

Weather Station Bracket by alistardean

...a new one and printing it with the up! pp3d that's turning up tomorrow. designed for a 21mm tube...

Bogdankecman

thingiverse

free

LCD mounting mask by BogdanKecman

...lcd mounting mask by bogdankecman

thingiverse

mounting mask for 2x16char lcd

thingiverse

free

Battery pack by BogdanKecman

...k that allows you to have the 4batteries in a tight formation and then to extend that as a stick with as many more 4batteries ...

thingiverse

free

Holder for NEMA23 type stepper motor by BogdanKecman

...holder for nema23 type stepper motor by bogdankecman

thingiverse

holder for nema23 type stepper motor

thingiverse

free

RJ45 Lock by BogdanKecman

...ot meant to prevent anyone from unplugging cables but actually just locks cables properly so they don't pop out on themselves

thingiverse

free

Y pulley for MENDEL by BogdanKecman

...lley for mendel. it replaces one of the drive-pulley_3off pulleys and features a rim so your belt don't slip from the pulley.

thingiverse

free

NEMA17/23 SCRIPT by BogdanKecman

...or nema23 motors in your design's, the simple openscad fully parametric script that will generate you nema17 or nema23 object

thingiverse

free

Probe holder for your oscilloscope by BogdanKecman

... probe holder. parameters to the module are

number of probes to hold (4 probes by default)

height of the holder (20mm by default)

thingiverse

free

V-Block with 3 center holes by BogdanKecman

...kecman

thingiverse

just added center holes to thing://611746

(converted to solidworks so step and sdlprt files available also)

thingiverse

free

gopro handlebar mount by BogdanKecman

...d= 22, th= 3.2, gap= 1.5, screw_d= 3, screw_head_d= 6.2,

screw_nut_d= 6.01, screw_shoulder_th=4.5, screw_reversed=false

);

thingiverse

free

Flexy Shaft holder for MENDEL by BogdanKecman

...e the einhell flexy shaft but dremel one should work too - the inner dia of the hole is 21mm). it can hold a marker or a pen too.

Duct

turbosquid

$19

Duct Set

...d

royalty free 3d model duct set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1145038)

turbosquid

$10

Duct Tape

...id

royalty free 3d model duct tape for download as ma and ma on turbosquid: 3d models for games, architecture, videos. (1580351)

turbosquid

free

Duct Tape

...

free 3d model duct tape for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1486518)

3d_ocean

$7

Air-duct

... ventilation

high quality industrial air duct ventilation model. created in cinema 4d but comes in various other formats as well.

turbosquid

$20

Air ducts

...lty free 3d model air ducts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262476)

3d_export

$10

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

turbosquid

$2

Duct Tape

...e 3d model duct tape for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1473972)

turbosquid

free

Duct Tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Duct tape

...polys. includes: cinema 4d project. model in 3 formats (obj, fbx, 3ds). 6 .tga texture maps (albedo, ambient occlusion, diffus...

turbosquid

$40

Ventilation Duct PACK

...tion duct pack for download as ma, obj, fbx, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1287068)

Petg

turbosquid

$9

Chandra rugs T-PETG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

Makita lawn mower motor cover

...makita lawn mower motor cover for print . plastic petg carbon or...

3d_export

$5

snorkel connector snorkel bracket snorkel holder

...free to comment or cantact me via dm. pla, petg and abs should be fine for printing although i...

3d_export

$8

mounting of a front wing of the bicycle for a fork rockshox

...20 mm. 3d printing settings plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16...

3d_export

$15

E30 tweeter pods speaker mounts

...plastic, interlayer adhesion is poor, i want to try petg ...

3d_export

free

danish lunch

...made in thindercad and printed on ender3 max,<br>i used petg filament and have painted with vajjejo model paint.<br>this is...

3d_export

$21

stock adapter grand power stribog

...from cyma zhukov and install stock on new adapter. petg settings 0,10 - 0,15, infill 100%, supports everywhere, brim....

3d_export

$7

shimano xt-slx brake level piston guide right top

...with printed parts: i recommend: plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16....

3d_export

$7

shimano xt-slx brake level piston guide left top

...with printed parts: i recommend: plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16....

3d_export

$29

cup holder b m w e90-91-92-93

...cup holder b m w e90-91-92-93 3dexport printed with petglt;br>infil 20-40%<br>speed: 50mm/s<br>i make this design for people who don't...

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

Pc

archibase_planet

free

PC

...pc

archibase planet

pc case pc tower pc equipment system unit

pc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

Pc

...pc

3dexport

pc

archibase_planet

free

PC

...pc

archibase planet

notebook pc computer equipment

pc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

PC

...pc

archibase planet

system unit pc equipment

pc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

PC

...pc

archibase planet

pc equipment cabinet system unit

pc 70 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

pc

...pc

3dexport

computer

archibase_planet

free

PC

...pc

archibase planet

cabinet chassis system unit

pc case n241107 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$3

PC

...id

royalty free 3d model pc for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1159175)

turbosquid

$7

lap top ,pc portable, PC

...ty free 3d model lap top ,pc portable, pc for download as c4d on turbosquid: 3d models for games, architecture, videos. (1352084)

turbosquid

$100

PC

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Abs

3ddd

free

Preciosa AB

...preciosa ab

3ddd

preciosa

lustra preciosa ab s 12 svetilnikami

turbosquid

$8

abe oodworld

...squid

royalty free 3d model abe oodworld for download as obj on turbosquid: 3d models for games, architecture, videos. (1607965)

3ddd

$1

Ab King Pro

...ab king pro

3ddd

тренажер

тренажер ab king pro.

3d_export

$19

Upper ab machine

...upper ab machine

3dexport

3d_ocean

$16

AB King 3D Model

...ab king 3d model

3docean

3d ab king athletic model trainer

highly detailed ab king model file formats: .max, obj, fbx.

3ddd

$1

Ecosmart AB Series

...ab series

3ddd

камин

ecosmart ab series.

polys: 327 574

price: $565.00http://www.ecosmartfire.com/

био-спиртовые камины

turbosquid

$15

House ABS V106

...ree 3d model house abs v106 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1216161)

turbosquid

$11

Fabiela Pillow AB

...odel fabiela pillow ab for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1574015)

turbosquid

$70

AB Sun Parakeets

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

AB American Goldfinch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cooling

turbosquid

free

Cool Inc. Cool Box

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

cool penguin

...cool penguin

3dexport

cool penguin

turbosquid

$1

cooling

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$26

cooling tower

...ers.<br>model with full detail in real size. all nodes and bolted connections are built. it was designed for nuclear power.

3ddd

$1

Mantra Cool

...14 версиях и obj-файл, а также материал для включенного и для выключенного светильника. turbosmooth/meshsmooth при необходимости.

3d_export

$5

cool electric guitar

...cool electric guitar

3dexport

cool electric guitar

turbosquid

$5

Cooling glass

...quid

royalty free 3d model cooling glass for download as obj on turbosquid: 3d models for games, architecture, videos. (1193829)

turbosquid

$30

CPU Cooling

...royalty free 3d model cpu cooling for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1386263)

turbosquid

$5

Cool CLoud

...

royalty free 3d model cool cloud for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1572300)

3d_export

$5

table cooling fan

...table cooling fan

3dexport

table cooling fan made of black plastic. individual small size cooling fan for office desk.

Printing

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints