Thingiverse

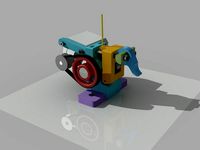

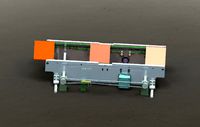

PowerFlower Belted Extruder

by Thingiverse

Last crawled date: 4 years, 2 months ago

Introduction

This is a remix of my PowerFlower Geared Extruder but designed for a 220mm (110T) GT2 6mm belt. You can use the same body as the geared version and simply replace the gears with pulleys.

The belted version is quieter and doesn't suffer from degredation (for gears printed in PLA as opposed to a more suitable material such as Nylon) but has no additional advantages.

You can find the Fusion 360 source at http://a360.co/2W1MYH2 and http://a360.co/3aI4nbD

Details

The pulleys are 100T and 20T respectively (providing a ratio of 5:1). You cannot use a 16T pulley as the distance between the axles has been precicely calculated and is not adjustable.

As with the geared version the PowerFlower is a Bowden extruder designed for 1.75mm filament and an 8mm Hobbed Shaft. In the makefile I have generated and included the main and rear bodies for shafts with common effective diameters. Measure and print the correct parts or change the parameters in the F3D file. The other parts do not change!

x-body-175-60 - For 1.75 filament with 6.0mm shaft ED.

x-body-175-65 - For 1.75 filament with 6.5mm shaft ED.

x-body-175-70 - For 1.75 filament with 7.0mm shaft ED.

x-body-175-75 - For 1.75 filament with 7.5mm shaft ED.

The design is semi-modular. There are two additional M3 holes in the front body of the extruder which will allow you to mount whatever you want e.g. a filament cleaner.

Components

1x M8 Hobbed Shaft (I'm using the E3D Hobb Goblin)

1x NEMA17 Stepper Motor

3x 608ZZ Bearings

1x PC4 M5 Pneumatic Coupling (2x if you want a Bowden inlet)

1x GT2 20T Pulley

1x GT2 6mm 220mm (110T) Belt

1x M8 Self Locking Nut

1x M8 Washer

2x M8 Standard Nuts

3x M3x25mm for the rear body and idler

4x M3x10mm (or 8mm) for the stepper.

1x M3x12mm for the Tensioner.

2x M3 Flat Washers for the Tensioner.

Final Points

I recommend printing the large pulley with 50% infill as unlike the geared version it will be under slight tension from the belt.

If upgrading from the geared version adjust your E steps/mm as the ratio changes to 5:1.

This is a remix of my PowerFlower Geared Extruder but designed for a 220mm (110T) GT2 6mm belt. You can use the same body as the geared version and simply replace the gears with pulleys.

The belted version is quieter and doesn't suffer from degredation (for gears printed in PLA as opposed to a more suitable material such as Nylon) but has no additional advantages.

You can find the Fusion 360 source at http://a360.co/2W1MYH2 and http://a360.co/3aI4nbD

Details

The pulleys are 100T and 20T respectively (providing a ratio of 5:1). You cannot use a 16T pulley as the distance between the axles has been precicely calculated and is not adjustable.

As with the geared version the PowerFlower is a Bowden extruder designed for 1.75mm filament and an 8mm Hobbed Shaft. In the makefile I have generated and included the main and rear bodies for shafts with common effective diameters. Measure and print the correct parts or change the parameters in the F3D file. The other parts do not change!

x-body-175-60 - For 1.75 filament with 6.0mm shaft ED.

x-body-175-65 - For 1.75 filament with 6.5mm shaft ED.

x-body-175-70 - For 1.75 filament with 7.0mm shaft ED.

x-body-175-75 - For 1.75 filament with 7.5mm shaft ED.

The design is semi-modular. There are two additional M3 holes in the front body of the extruder which will allow you to mount whatever you want e.g. a filament cleaner.

Components

1x M8 Hobbed Shaft (I'm using the E3D Hobb Goblin)

1x NEMA17 Stepper Motor

3x 608ZZ Bearings

1x PC4 M5 Pneumatic Coupling (2x if you want a Bowden inlet)

1x GT2 20T Pulley

1x GT2 6mm 220mm (110T) Belt

1x M8 Self Locking Nut

1x M8 Washer

2x M8 Standard Nuts

3x M3x25mm for the rear body and idler

4x M3x10mm (or 8mm) for the stepper.

1x M3x12mm for the Tensioner.

2x M3 Flat Washers for the Tensioner.

Final Points

I recommend printing the large pulley with 50% infill as unlike the geared version it will be under slight tension from the belt.

If upgrading from the geared version adjust your E steps/mm as the ratio changes to 5:1.

Similar models

thingiverse

free

PowerFlower Belted Extruder

...from the belt.

if upgrading from the geared version you will need to adjust your e steps/mm as the ratio changes from 4:1 to 5:1.

thingiverse

free

PowerFlower Geared Extruder by Emphacy

...0mm/s

e jerk: 5.0

e accelleration: 1000mm/s

i will be releasing a mount for a filament cleaner and gear guard in the near future.

thingiverse

free

Belted extruder by Drasko

...ned m8 hobbed bolt

2x m8 locking nuts

the top part, which enables mounting is available here geeetech z-axes top and bottom mount

thingiverse

free

Compact Belt Drive Extruder by loco

...) 608 bearing

(1x) 688 bearing

(1x) 8x18mm smooth rod or threaded rod

(2x) m4x50

(2x) m4x20

(1x) m3x30

(3x) m3x10

(4x) m4 hex nut

thingiverse

free

double Hobbed bolt bowden extruder :) by yoyoek1

...2x 608

4x 688

m8 thread 2x ~30mm

m8 nuts

~ 100mm ptfe tube 4/2 (for 1.75 filament, for 3mm filament no need)

2x m3 x ~30 and nut

thingiverse

free

NEMA17 Universal Belted 2:1 Reduction Drive by mildw4ve

...rews

2x m3x25 socket hex screws

4x m3x25 or longer socket hex screws for mounting the top plate and anything that might be on it.

thingiverse

free

Voron Belted Extruder (Extra Tension) by Maglin

...nyloc nuts

2x springs (0.5" long, 0.18" od 0.024" wire) mcmaster carr p/n: 9657k267

1x gt2 closed loop belt 188mm

thingiverse

free

UM reduced extruder for 3.0mm filament by EazyBreezy

... bearing 3x10x4

2x - 625 bearings 5x16x5

5x - m3 nuts

5x - m3x30 screws

1x - m3x12 screw

1x - little spring to the clamp filament

thingiverse

free

Nema 17 belted reduction gear by D14

...earance for bolt and bearing to sit tighter. so, you need to adjust them.

links:

gt2-80t http://www.thingiverse.com/thing:1812138

thingiverse

free

Yet Bondtech Bowden Extruder - Geared with Belt

... be printed in the orientation they are in when loading the files.

designed to be printed with 0.2mm layer or a division here of.

Powerflower

thingiverse

free

PowerFlower Geared Extruder - Nema17 90 Connector

...ket for connecting the powerflower to a nema17 mounting position. works quite well for my heavily modified monoprice select mini.

thingiverse

free

PowerFlower Geared Extruder by Emphacy

...0mm/s

e jerk: 5.0

e accelleration: 1000mm/s

i will be releasing a mount for a filament cleaner and gear guard in the near future.

thingiverse

free

PowerFlower Belted Extruder

...from the belt.

if upgrading from the geared version you will need to adjust your e steps/mm as the ratio changes from 4:1 to 5:1.

3dwarehouse

free

1934 Douglas Z1 Powerflow

...1934 douglas z1 powerflow

3dwarehouse

744cc side valve flat twin #british_motorcycle #douglas

3dwarehouse

free

1934 Douglas Z1 Powerflow & Sidecar

...1934 douglas z1 powerflow & sidecar

3dwarehouse

744cc flat twin side valve #british_motorcycle #douglas #combination

Belted

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

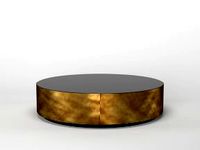

design_connected

$11

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.