Thingiverse

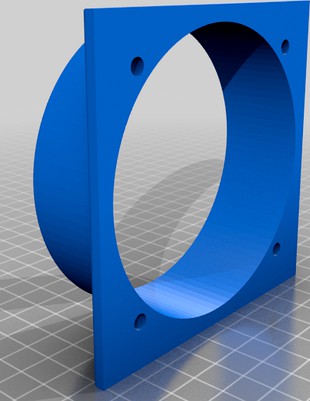

Portable laser/printer exhaust vent - for use under garage door by SteveW25561

by Thingiverse

Last crawled date: 3 years, 3 months ago

I have my Snapmaker A350 (3d printer/laser cutter/CNC) set up in my garage which serves as a workshop and gym. I wanted to make an exhaust for my Snapmaker A350 laser module and enclosure that didn't require me to cut a 4"+ hole in my wall.

I designed this flattened exhaust that can be attached to standard 4" ventilation ducting and then it can be placed under my garage door. I calculated the area of a 4" circle and made it into a 1 1/2" x 12" rectangle so it would not obstruct airflow appreciably. This made for an exhaust that can be placed under my garage door, with 2x4's laid flat to both fill the full width of the garage door (and to prevent the garage door from crushing the plastic you just printed!). I also made a screen for it so bugs or rodents don't decide to climb up the duct into my printer enclosure!

For the Snapmaker A350 enclosure I made an adapter to fit 4" ventilation ducting to the existing fan output, then I added an inline ventilation fan.

I then cut 2x4's to fill the rest of the width, painted them black to blend better, then closed the garage door onto the setup - I did have to be quick to pull the release cable on the garage door so it wouldn't reverse back up after it sensed the 1 1/2" obstruction on the floor, and it seals up nicely.

Hooking all of this up worked perfectly: no more burnt odor inside the garage, and this is all removable when not doing a laser project!

This large model needed the full size bed of the Snapmaker A350 - and honestly was a pain to print (multiple failed prints which was time consuming and wasted lots of filament due to size -- likely a leveling problem over the big build plate, but it worked after several tries).

It's built into 2 main parts with a lip for easier alignment. I tried doing a full one piece print but it used a ton of support material and it was impossible to remove. I'm totally a noob with Fusion 360 but it seems to have worked out well.

For the bug screen, I didn't know how to make a mesh so I made a frame and a solid rectangle. In Simplify3D I printed the frame as a full 20% infilled solid, and set a different printing profile for the solid rectangle specifying no top or bottom layers and a 25% rectilinear infill. These 2 pieces were aligned overlapping each other and then printed as a single piece.

I used PETG (in case of summer heat blasting the garage door, but it might not be needed). To assemble, I used Gorilla Super Glue.

Although it may not be needed I also taped up the assembly with 2" wide Gorilla tape running along the back edge, folded over the top, to ensure it wouldn't leak much air and not fall apart if dropped (I wasn't sure how well PETG would stay glued).

Fan I used: a nice DC controlled ventilation exhaust fan - it's quiet and moves a lot of air) https://www.amazon.ca/gp/product/B07JB292JC/ref=ppx_yo_dt_b_asin_title_o00_s01?ie=UTF8&psc=1

Ducting: https://www.amazon.ca/gp/product/B071LHCFZ8/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

I designed this flattened exhaust that can be attached to standard 4" ventilation ducting and then it can be placed under my garage door. I calculated the area of a 4" circle and made it into a 1 1/2" x 12" rectangle so it would not obstruct airflow appreciably. This made for an exhaust that can be placed under my garage door, with 2x4's laid flat to both fill the full width of the garage door (and to prevent the garage door from crushing the plastic you just printed!). I also made a screen for it so bugs or rodents don't decide to climb up the duct into my printer enclosure!

For the Snapmaker A350 enclosure I made an adapter to fit 4" ventilation ducting to the existing fan output, then I added an inline ventilation fan.

I then cut 2x4's to fill the rest of the width, painted them black to blend better, then closed the garage door onto the setup - I did have to be quick to pull the release cable on the garage door so it wouldn't reverse back up after it sensed the 1 1/2" obstruction on the floor, and it seals up nicely.

Hooking all of this up worked perfectly: no more burnt odor inside the garage, and this is all removable when not doing a laser project!

This large model needed the full size bed of the Snapmaker A350 - and honestly was a pain to print (multiple failed prints which was time consuming and wasted lots of filament due to size -- likely a leveling problem over the big build plate, but it worked after several tries).

It's built into 2 main parts with a lip for easier alignment. I tried doing a full one piece print but it used a ton of support material and it was impossible to remove. I'm totally a noob with Fusion 360 but it seems to have worked out well.

For the bug screen, I didn't know how to make a mesh so I made a frame and a solid rectangle. In Simplify3D I printed the frame as a full 20% infilled solid, and set a different printing profile for the solid rectangle specifying no top or bottom layers and a 25% rectilinear infill. These 2 pieces were aligned overlapping each other and then printed as a single piece.

I used PETG (in case of summer heat blasting the garage door, but it might not be needed). To assemble, I used Gorilla Super Glue.

Although it may not be needed I also taped up the assembly with 2" wide Gorilla tape running along the back edge, folded over the top, to ensure it wouldn't leak much air and not fall apart if dropped (I wasn't sure how well PETG would stay glued).

Fan I used: a nice DC controlled ventilation exhaust fan - it's quiet and moves a lot of air) https://www.amazon.ca/gp/product/B07JB292JC/ref=ppx_yo_dt_b_asin_title_o00_s01?ie=UTF8&psc=1

Ducting: https://www.amazon.ca/gp/product/B071LHCFZ8/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Similar models

thingiverse

free

Snapmaker 2 enclosure 4" fan outlet by SteveW25561

...05_s01?ie=utf8&psc=1

ducting:https://www.amazon.ca/gp/product/b071lhcfz8/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=utf8&psc=1

thingiverse

free

Snapmaker Enclosure Exhaust Filter Adapter by cpverne

...u6

i also purchased some 4" thumb screw clamps, but zip-ties would work as well.https://www.amazon.com/gp/product/b07pds9hg3

thingiverse

free

Snapmaker enclosure to vacuum adapter by rgprints

...y not be a standard size, so you may have to modify the design. i used freecad and the fcstd files are included for that purpose.

thingiverse

free

Exhaust elbow for Snapmaker 2.0 enclosure by Northbr00k

...uld imagine most of you have your printers on a desk like mine and attaching a flexible duct for the exhaust fan was a bit tight.

thingiverse

free

Exhaust Duct Adapter and Filter by MandaSim21

...er size to a filter you like.

https://smile.amazon.com/gp/product/b07hmrz4lj/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=utf8&psc=1

thingiverse

free

Enclosure Ventilation / Extractor by alvoeiro

...;duct_left" need "touching buildplate" support.

i can provide a fusion 360 file to anyone who wants to do a remix.

thingiverse

free

Snapmaker 2.0 Corner Block by PliskinAJ

...hese blocks to square out the enclosure. there are 2 ø1/8" holes on each side of the block to aid in bolting items to them.

thingiverse

free

DIY Printer Enclosure Box by rustyskysports

... diameter hole. eliminates open area where air can suck through. idea is to have inlet air come from the front of the enclosure.d

thingiverse

free

Flexible Duct Fan Connections by frostryche

... cover to that instead to prevent excess heat loss in the winter.

both parts can be printed in any resolution without supports.

3dwarehouse

free

Ventilator Project, Exhaust fan Enclosure

...ventilator project, exhaust fan enclosure

3dwarehouse

ventilator project, exhaust fan enclosure

Exhaust

turbosquid

$2

Exhaust

...id

royalty free 3d model exhaust for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1603373)

turbosquid

$1

Exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

exhaust manifold

...exhaust manifold

3dexport

this is a 3d design of an exhaust manifold used in automobile.

archive3d

free

Exhauster 3D Model

... air exhauster hoover

exhauster n101015 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$13

Exhaust 3D Model

...exhaust 3d model

3dexport

exhaust smoke engine motor bike car detail detailed

exhaust 3d model cesar_vonc 12007 3dexport

turbosquid

free

car exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Exhaust system

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

MSX EXHAUSTS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Vent

archibase_planet

free

Vent

...vent

archibase planet

aeration venting home equipment

diffuser vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent atlantica - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent half frame - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood kitchen equipment

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

damper diffuser air gate

vent grate n100807 - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Vent

...nt

turbosquid

royalty free 3d model vent for download as fbx on turbosquid: 3d models for games, architecture, videos. (1143454)

turbosquid

$2

Vent

...nt

turbosquid

royalty free 3d model vent for download as obj on turbosquid: 3d models for games, architecture, videos. (1323956)

Portable

3d_ocean

$4

Portable Shelves

...portable shelves

3docean

drawer furniture portable shelves wheel

portable shelves with wheels

3d_export

$5

portable generator

...portable generator

3dexport

3d model portable generator. videogames.

3d_export

$16

Portable Radio

...portable radio

3dexport

turbosquid

$30

Portable Generator

...

royalty free 3d model portable generator for download as obj on turbosquid: 3d models for games, architecture, videos. (1579389)

turbosquid

$5

Portable Radio

...uid

royalty free 3d model portable radio for download as fbx on turbosquid: 3d models for games, architecture, videos. (1402570)

turbosquid

$3

Portable Keyboard

...royalty free 3d model portable keyboard for download as blend on turbosquid: 3d models for games, architecture, videos. (1281917)

turbosquid

$49

Portable Office

...3d model portable office for download as max and unitypackage on turbosquid: 3d models for games, architecture, videos. (1470540)

turbosquid

$15

PORTABLE LIGHTS

...lty free 3d model portable lights for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1679464)

3d_ocean

$12

Portable Sofa

...r table 2. minimalis sofa 3. sofa and mini sofa (can for foot) 4. mini sofa and table tertured with v-ray, and no material needed

turbosquid

$11

Safe portable

...free 3d model safe portable for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410826)

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Garage

3d_export

free

garage

...garage

3dexport

garage

3d_export

$10

garage

...garage

3dexport

garage with colored gates

3d_export

$5

garage

...garage

3dexport

old rusty garage with graffiti

archibase_planet

free

Garage

...arage

archibase planet

construction building garage

multistoried garage n011009 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Garage

...arage

archibase planet

garage carport awning

garage carport n040915 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$9

garage

...garage

3dexport

low poly garage included texture. object: 1 faces: 315 vertices:459

turbosquid

free

Garage

...garage

turbosquid

free 3d model garage for download as skp on turbosquid: 3d models for games, architecture, videos. (1606634)

turbosquid

$39

Garage

...

turbosquid

royalty free 3d model garage for download as fbx on turbosquid: 3d models for games, architecture, videos. (1687250)

turbosquid

$3

Garage

...

turbosquid

royalty free 3d model garage for download as fbx on turbosquid: 3d models for games, architecture, videos. (1705014)

turbosquid

$3

Garage

...

turbosquid

royalty free 3d model garage for download as fbx on turbosquid: 3d models for games, architecture, videos. (1711138)

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Door

3d_export

$5

door handle of doors

...door handle of doors

3dexport

door handle of doors

3d_ocean

$4

Door

...3docean

architecture door gate gothic door old style door

door, 3d door, gothic door, architecture, old style door, gate, 3d gate

3d_ocean

$10

Door

...door

3docean

design door doors home house indoor interior opening doors

door design

archibase_planet

free

Door

...r

archibase planet

door sliding door interior door rail door

door n250515 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 900 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 600 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 800 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 800 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 700 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 600 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Use

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...character from the game "among us". it can be use as a toy or...

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us 3dexport turbosmooth modifier can be use to increase mesh resolution if...

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation