Thingiverse

Plastic Monstrosity -- The 3D Printed CNC for 4x8' Plywood by spiffcow

by Thingiverse

Last crawled date: 3 years ago

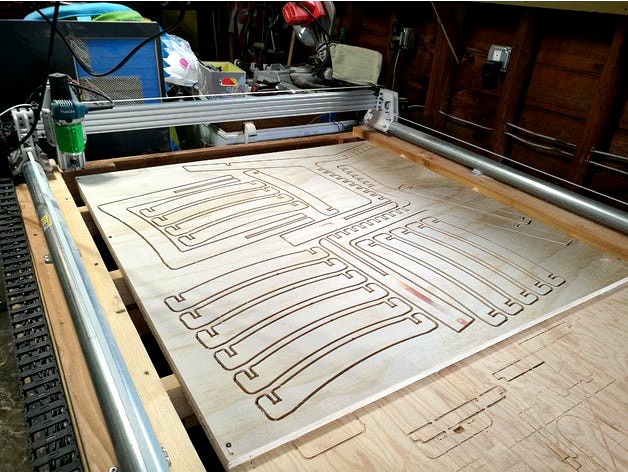

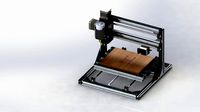

This is my massive CNC capable of cutting a full 4x8 sheet of plywood with room to spare! This is optimized specifically for cutting plywood, and I believe this is probably the least expensive way to build a CNC capable of accurately cutting plywood in a reasonable amount of time. There are other designs out there, but I've yet to see another one that maintains performance and accuracy while keeping the overall price below $1000 for a 4x8' cutting area. I really enjoyed designing and building this, and I hope it can help lower the barrier of entry for makers looking to build the kind of things you see on OpenDesk or WikiHouse.

Bill of Materials

Thanks to kaoskido for helping me organize this! If you see anything missing, please let me know!

Amazon apparently doesn't want to let me use their affiliate program to link to items, so I'm going to start selling hardware kits in the near future, which should reduce the cost compared to buying all these individually.

Hardware

3x 1KG PETG filament: ~$57

1x 1500mm OpenBuilds C Beam linear rail: ~$40

1x 250mm OpenBuilds C Beam linear rail: ~8

1x OpenBuilds Anti-Backlash leadscrew nut: ~$11

1x 20 pack 625ZZ bearings: $7

1x 20 pack 608ZZ bearnings: ~$10

2x 8 pack polycarbonate mini V wheel kits: ~$60

1x 5 pack 20 tooth GT2 pulleys with 6.35mm bore: ~$10

2x 100 pack 12mm M5 screws: $30

1x 50 pack 25mm M5 screws: ~$11

1x 50 pack 30mm M5 screws: ~$11

2x 10 pack 75mm M5 screws: ~$15

5x 25 pack 5mm sliding T nuts: ~$40

1x 50 pack thin M5 nuts: ~$5

1x 100 pack M5 lock nut: ~$9

1x [50 pack 1.5" long 5/16" bolts]https://www.amazon.com/gp/product/B01MTU6TL0/ref=as_li_qf_asin_il_tl?ie=UTF8&tag=spiffcow-20&creative=9325&linkCode=as2&creativeASIN=B01MTU6TL0&linkId=7fa1210ccd086d92cf7b8477c7755251): ~$10

1x 10 pack 3.5" long 5/16" bolts: ~$6

2x 10 pack 5/16" lock nuts: ~$7

2x 5m run of GT2 belt, 10mm width: ~$27 (note: the 10mm width is very important)

2x 2" conduit from Home Depot (10 ft): ~$42

1x 1/4" up cut router bit: ~$19

1x 300mm 4 start 8mm lead screw: ~$10

Hardware total: ~$430

Electronics

3x 269 oz. in. NEMA23 stepper motor: ~$78

1x 78 oz. in. NEMA17 stepper motor: ~$16

1x MKS SBase controller: ~$60

1x 100 ft 4 conductor 22AWG stranded wire: ~$29

1x 360W 24V power supply: ~$18

1x JST connector set: ~$16

Electronics total: ~$217

Spindle (choose 1)

Makita Compact Router: ~$100

DeWalt DWP611 Router: ~$100

Overall cost

~$750 + the cost of building a table (roughly $100 or so), assuming you don't already have any of the parts.

Change Log

Update 2018-04-19

Added improved short axis carriage plates.

Update 2018-04-14

Added a dust shoe. It mounts to the rear of the C Beam.

Update 2018-04-04

Added a print list and bill of materials!

Also, stay tuned for a dust collector attachment (hopefully in the next couple weeks :)

Update 2018-01-13

Added an 80mm spindle Z axis piece.

Update 2017-12-03

I fixed the print orientation for the gantry parts and the endcap. Remember to enable supports on the gantry.

Update 2017-12-01

If you're having trouble with slight variations in plywood height, I have created a simple Z probe that you can use in conjunction with bed height autocorrection (I'm using Smoothieware, so I have it do the height probing and correction in the firmware).https://www.thingiverse.com/thing:2685926

Sorry for the lack of updates. I still don't have a BoM ready, much less a build guide. I've had a lot of other projects going on, and this is all just a hobby for me at the moment, so the amount of time I can allot for it is pretty minimal. Maybe I'll try to sell kits or something in the future -- if you'd be interested in such a thing, let me know.

Update 2017-11-04

Added guardPlate.stl. Reduce the belt bearings on the short axis to 2 per side (4 total) and place the guardPlate.stl piece along with a 1mm spacer. This prevents the belt from twisting.

Also added a picture of a full chair from OpenDesk cut in a single session. I'm marking the build complete, but will add more documentation in the future.

Update 2017-09-20

I added the following:

Makita compact router mount Z axis (makita.stl)

DWP-611 mount Z axis (dwp611.stl) - untested

pieces optimized for 60.3mm OD conduit (50NB)

Update 2017-08-21

Added components for the short axis belt for use with motors that have a shorter shaft. The belts are closer to the motor, but the new end supports take up an additional 30mm on the short axis.

Bill of Materials

Thanks to kaoskido for helping me organize this! If you see anything missing, please let me know!

Amazon apparently doesn't want to let me use their affiliate program to link to items, so I'm going to start selling hardware kits in the near future, which should reduce the cost compared to buying all these individually.

Hardware

3x 1KG PETG filament: ~$57

1x 1500mm OpenBuilds C Beam linear rail: ~$40

1x 250mm OpenBuilds C Beam linear rail: ~8

1x OpenBuilds Anti-Backlash leadscrew nut: ~$11

1x 20 pack 625ZZ bearings: $7

1x 20 pack 608ZZ bearnings: ~$10

2x 8 pack polycarbonate mini V wheel kits: ~$60

1x 5 pack 20 tooth GT2 pulleys with 6.35mm bore: ~$10

2x 100 pack 12mm M5 screws: $30

1x 50 pack 25mm M5 screws: ~$11

1x 50 pack 30mm M5 screws: ~$11

2x 10 pack 75mm M5 screws: ~$15

5x 25 pack 5mm sliding T nuts: ~$40

1x 50 pack thin M5 nuts: ~$5

1x 100 pack M5 lock nut: ~$9

1x [50 pack 1.5" long 5/16" bolts]https://www.amazon.com/gp/product/B01MTU6TL0/ref=as_li_qf_asin_il_tl?ie=UTF8&tag=spiffcow-20&creative=9325&linkCode=as2&creativeASIN=B01MTU6TL0&linkId=7fa1210ccd086d92cf7b8477c7755251): ~$10

1x 10 pack 3.5" long 5/16" bolts: ~$6

2x 10 pack 5/16" lock nuts: ~$7

2x 5m run of GT2 belt, 10mm width: ~$27 (note: the 10mm width is very important)

2x 2" conduit from Home Depot (10 ft): ~$42

1x 1/4" up cut router bit: ~$19

1x 300mm 4 start 8mm lead screw: ~$10

Hardware total: ~$430

Electronics

3x 269 oz. in. NEMA23 stepper motor: ~$78

1x 78 oz. in. NEMA17 stepper motor: ~$16

1x MKS SBase controller: ~$60

1x 100 ft 4 conductor 22AWG stranded wire: ~$29

1x 360W 24V power supply: ~$18

1x JST connector set: ~$16

Electronics total: ~$217

Spindle (choose 1)

Makita Compact Router: ~$100

DeWalt DWP611 Router: ~$100

Overall cost

~$750 + the cost of building a table (roughly $100 or so), assuming you don't already have any of the parts.

Change Log

Update 2018-04-19

Added improved short axis carriage plates.

Update 2018-04-14

Added a dust shoe. It mounts to the rear of the C Beam.

Update 2018-04-04

Added a print list and bill of materials!

Also, stay tuned for a dust collector attachment (hopefully in the next couple weeks :)

Update 2018-01-13

Added an 80mm spindle Z axis piece.

Update 2017-12-03

I fixed the print orientation for the gantry parts and the endcap. Remember to enable supports on the gantry.

Update 2017-12-01

If you're having trouble with slight variations in plywood height, I have created a simple Z probe that you can use in conjunction with bed height autocorrection (I'm using Smoothieware, so I have it do the height probing and correction in the firmware).https://www.thingiverse.com/thing:2685926

Sorry for the lack of updates. I still don't have a BoM ready, much less a build guide. I've had a lot of other projects going on, and this is all just a hobby for me at the moment, so the amount of time I can allot for it is pretty minimal. Maybe I'll try to sell kits or something in the future -- if you'd be interested in such a thing, let me know.

Update 2017-11-04

Added guardPlate.stl. Reduce the belt bearings on the short axis to 2 per side (4 total) and place the guardPlate.stl piece along with a 1mm spacer. This prevents the belt from twisting.

Also added a picture of a full chair from OpenDesk cut in a single session. I'm marking the build complete, but will add more documentation in the future.

Update 2017-09-20

I added the following:

Makita compact router mount Z axis (makita.stl)

DWP-611 mount Z axis (dwp611.stl) - untested

pieces optimized for 60.3mm OD conduit (50NB)

Update 2017-08-21

Added components for the short axis belt for use with motors that have a shorter shaft. The belts are closer to the motor, but the new end supports take up an additional 30mm on the short axis.

Similar models

thingiverse

free

Anet A8 Z Axis End Stop Adjuster by FredGenius

...a knob to make adjusting easier.

you will need:

2x m3x18mm screws

2x m3 nuts

2x m3x25mm screws

1x m5x40mm hex bolt

1x m5 half nut

thingiverse

free

Ender 2 x-axis y-axis belt tensioner by Gladjolt

...nut

1x m4 20mm~

1x m4 locknut

updated model:

-optimized model for better fitting with belt/buildplate

-no support needed anymore

thingiverse

free

CR-10 V2 V3 Z-axis timing belt tensioner by sorteds

...op of the printer i used these holders from fattyguyriley

https://www.thingiverse.com/thing:3504265

thank you for this design :)

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount 2.0 by SaberShip

...ler pulley for 6mm wide gt2 belt

1x m5 x30 bolt

1x m5 nylon lock insert nut (regular m5 nut may work)

2x m3 x10 screws

2x m3 nuts

thingiverse

free

Nema17 belt-shaped mount by zakamik

...saintflint extruder

mounts on 20x series profile.

bom:

2x 20m5 t-nut

2x m5x8 bolt

1x m5x16 bolt

1x m5 nut

2x m5 washer (optional)

thingiverse

free

TEVO Tarantula - X belt tensioner

...ensioning

2x m4 10/12mm screws

2x m4 t-nuts

1x m4 20-30mm screw (nut head preferred, but it can be a bit grinded)

1x m4 lock nut

thingiverse

free

Z-axis optical endstop 16 mm

...z-axis optical endstop 16 mm

thingiverse

z-axis optical endstop 16 mm

print in pla

1x pen spring used

2x m3

2x m5

thingiverse

free

2020 adjustable Feet by ceerzet

...ew

1x m4 nut

1x m4 x 12mm washer

2x m5 x 8mm screw

2x m5 hammer nut

1x stick-on floor protector 20mm (like ikea "fixa")

thingiverse

free

Voron Belted Extruder (Extra Tension) by Maglin

...nyloc nuts

2x springs (0.5" long, 0.18" od 0.024" wire) mcmaster carr p/n: 9657k267

1x gt2 closed loop belt 188mm

thingiverse

free

Openbuilds OX CNC router Belt Tensioner Remix by hilleke

...nsioner remix by hilleke

thingiverse

added slots for cables through the profile

and

short version for 2mm belt for shorter screw

Spiffcow

thingiverse

free

Parametric Stepper Bracket by spiffcow

... can choose how far away from the extrusion you want to mount your stepper motor so that it's flush with the leadscrew mount.

thingiverse

free

Giant Sorry game piece piggy bank by spiffcow

...son was obsessed with sorry, so i surprised him with a giant sorry game piece on his birthday. i also made a piggy bank version.

thingiverse

free

Portable Work Table by spiffcow

...2x bottomtop.step and 4x side.step.

and if you don't have a 4x4' or larger cnc, please consider my plastic monstrosity ;)

thingiverse

free

Parameterized Delta Effector by spiffcow

...s printed in place. for the other one, just detach it and turn it around, then attach it to the effector collar with an m3 bolt.

thingiverse

free

CNC Z Probe (Customizable) by spiffcow

...ll. the default settings work for a makita compact router with a 1/4" endmill, but you can edit the settings in customizer.

thingiverse

free

Bottom Frame Corners for Modified C-Bot by spiffcow

...metric v-slot corner bracket if you need to make any changes.

these should print without supports, but add them if you need them.

thingiverse

free

Span Support Generator for MPCNC rails by spiffcow

...mv.

the customizer view renders the the image a bit oddly. don't worry, the weird top and bottom tabs won't be printed.

thingiverse

free

Customizable Delta Push Rod by spiffcow

...re or wherever you can find them cheapest)

i used docpayce's effector and carriages: http://www.thingiverse.com/thing:1584513

thingiverse

free

Parametric V-Slot/T-Slot Power Supply Mount by spiffcow

...ses 10mm m3 bolts to attach to the common hobby power supplies, but you could easily change this up to mount an atx power supply.

thingiverse

free

Gigantic Bastard CNC by spiffcow

...s for the round tubes and the belts.

side.dxf

this is the wooden panel that joins the mpcnc sliders to the root 2.1 short axis.

Monstrosity

thingiverse

free

Stitched Monstrosity

... monstrosity

thingiverse

a stitched monstrosity.

you can support me on https://www.patreon.com/schlossbauer if you like my work.

thingiverse

free

Monstrosity hand by Dantego

...and or like a decorative object.

she can be print in once print. but you can slice it with a software like netfabb / meshimixer.

thingiverse

free

yodapus AKA a monstrosity

...yodapus aka a monstrosity

thingiverse

i have created a monster... just because i was bored...

thingiverse

free

Five Headed Monstrosity by ASLLEXICON

...https://brave.com/tod573

visit my website: https://starlabs3d.com

my youtube: https://www.youtube.com/c/toddolsen

see video below

thingiverse

free

RPI plus 12V Cooling Monstrosity

...mean-looking cooling tower for the raspberry pi 3b+, primed for overclocking, and ready for raw data, or just running octo-print.

thingiverse

free

Gloomhaven Jaws of the Lion: Rat Monstrosity by VirtuallyJason

...ttps://patreon.com/virtuallyjason. if you appreciate my work and have a few dollars to spare each month, please consider joining!

thingiverse

free

Angler Fish Monstrosity - Tabletop Miniature by M3DM

...ts here! i also offer a learn to 3d model package for aspiring 3d sculptors.

no errors in meshmixer, so it should be good to go!

thingiverse

free

Vase Monstrosity by barty3d

... out the assembly modeling and if i like that i will go ahead and buy. renders are in bryce 3d (green glass) and keyshot (wood).

thingiverse

free

Vase Monstrosity by barty3d

... out the assembly modeling and if i like that i will go ahead and buy. renders are in bryce 3d (green glass) and keyshot (wood).

thingiverse

free

Blood Monstrosity / Gloomhaven / Jaws of the Lion by Sevyd

...bjohnson06https://www.thingiverse.com/thing:3151039

base was made by ezowens found here:https://www.thingiverse.com/thing:2797144

4X8

turbosquid

$6

Platform Corner 4x8 V2

...odel platform_corner_4x8_v2 for download as lwo, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1514203)

turbosquid

$6

Platform Corner 4x8 V1

...odel platform_corner_4x8_v1 for download as lwo, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1513587)

thingiverse

free

4x8 Flat by Techvvolf

...4x8 flat by techvvolf

thingiverse

a 4x8 flat (studio flat)

3dcadbrowser

free

Jinker Truck 4x8

...software.this 3d object can be downloaded in .max, .obj, .3ds, .fbx, .dxf, .lwo, .stl, .wrl, .ma, .dae, .x and .asc file formats.

thingiverse

free

4x8 bubble mailer boxes by jrdnhsnbrg

...n a stock ender 3 bed. you may need to increase the bed size in cura/your slicer to 225x225 in order for it to fit but it will.

thingiverse

free

4x8 plywood by kungfudabu

...98'

when i print them, i scale it down big enough to fit in my hand. i use them to create a small scale design of structures.

thingiverse

free

VEX 5x5 Plate/LEGO 4x8 Plate VEX-LEGO converter by Honmeg287

...287

thingiverse

a mix of a vex 5x5 plate and a lego 4x8 plate. use this to combine models/robots using both vex and lego pieces.

thingiverse

free

OpenForge Dungeon Stone 4x8 Tile - No Gap

...en the two 4x4 tiles, resulting in non-continuous printing of the base layers. this version has the two 4x4 tiles fused together.

thingiverse

free

Lego Plates 4x8 for Train Ramps by clockwork58

...al size so it emulates two plates together (6.4mm) so that you have a level train crossing in just one piece to make life easier.

thingiverse

free

LowRider CNC -Full Sheet 4x8 CNC Router XZ Plate STL File by Arrowcreek316

...hematic for the drawing. all credits goes to vicious1.

sorry about the previous one. this is my first time uploading a .stl file.

Plywood

3ddd

free

plywood chair

...plywood chair

3ddd

plywood chair , plywood

plywood chair

turbosquid

$10

Plywood

...yalty free 3d model plywood for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1432356)

3d_ocean

$19

Watch plywood

...watch plywood

3docean

clock horologe plywood timekeeper timepiece timer watch wood

watch plywood + vray

3d_ocean

$2

Old Plywood

...old plywood

3docean

cracked fracture green old paint painted plywood wood

the texture of old painted plywood.

3d_ocean

$7

Plywood Chair

...ood chair

3docean

chair female screw kitchen plywood screw seat stuhl tiled floor tiles wood wooden chir

a chair made of plywood.

3ddd

$1

Стол Eames Plywood

... круглый , кофейный

стол eames plywood

d: 860mm

h: 400mm

turbosquid

$29

Plywood Stool

...free 3d model plywood stool for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410610)

turbosquid

$29

Plywood Chair

...free 3d model plywood chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410607)

turbosquid

$10

Plywood Armchair

...e 3d model plywood armchair for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678524)

turbosquid

free

Plywood Bench

...l plywood bench for download as blend, fbx, obj, dae, and png on turbosquid: 3d models for games, architecture, videos. (1587899)

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Plastic

archibase_planet

free

Plastic

...plastic

archibase planet

moulding friezes moldings border pilaster

deco plastic dw - 3d model for interior 3d visualization.

turbosquid

$1

Plastics

...

royalty free 3d model plastics for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1581776)

archibase_planet

free

Plastic

...lastic

archibase planet

moulding friezes moldings border pilaster decor

deco plastic rz - 3d model for interior 3d visualization.

3ddd

$1

Plastic Playground

... kids , toy , child

plastic playground

3d_export

$5

plastic lid

...plastic lid

3dexport

plastic lid

3d_export

$5

plastic clothespin

...plastic clothespin

3dexport

plastic clothespin

turbosquid

$39

Plastics

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Plastic Packaging

...ging plastic

intended for blender, cycles: plastic packaging to place your product in. subdivision modifier has not been applied.

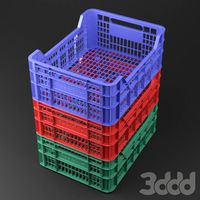

3ddd

$1

plastic box

... ящик

model of plastic box for fruits in 3 levels of detail. highpoly - 23,6k, midpoly - 7,3k and lowpoly - 2,6k polygons.

3d_ocean

$12

Plastic Chair

...furniture plastic chair side chair

3d model of plastic chair. 3ds and obj multi format files included. scanline renderer version.

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints