Thingiverse

Planer Blade Sharpening Jig by scottmi

by Thingiverse

Last crawled date: 3 years, 3 months ago

!!! UPDATED: Version 1 uses 10-32 bolts. Version 2 uses 1/4-20 bolts !!!

Planer Blade Sharpening Jig for 2 blades at 40 degree bevel / edge. Printed parts are the base and shoe. Requires 5 bolts, washers, and wingnuts. Heads of bolts are seated in the base of the shoe, and run up through the base to washer and wingnut at the top. Light finger tight should do it. Specifically designed for Delta 22-547 blades, but will serve for any number of blades requiring a 40 degree top bevel angle. Length 9.69" (246 mm), width 1.77" (45 mm), width of blade tip to blade tip: 1.7" (43.26 mm), height with blades (not including bolts) 1 1/16" (~27 mm).

Can sharpen with sandpaper laid on flat surface plate (such as granite or plate glass), a large stone (such as a Norton IM-313), or smaller hone "floated" over the edges (try inverting the jig). Easy does it!

Version 1 Bolts: 10-32 thread, 1 1/4" long, 5/16" head width, 1/8" head height.

Version 2 Bolts: 1/4-20 thread, 1/14" long, 7/16" head width, 5/32" head height

Norton IM-313: https://www.nortonabrasives.com/en-us/norton-im313-multi-oilstone-sharpening-system

Notes for use: Overtightening wingnuts can impart a bend in the jig. Take care to seat blades flat in the base, edges even against the back corner of their pocket. When tightening the wingnuts, bring them to just a very gentle snug. Place the jig with blades on your sharpening surface. Ease the wingnuts and ensure both blades are evenly flat on your surface, and jig body settled down with no rocking or bend detected. Snug wingnuts just to touch washers all around, check all is seated and flat, snug only a teeny bit more (blades will not fall out) evenly and checking all is flat. If a bend occures, loosen nuts and snug again a little less. This procedure worked for me with some very ugly old used blades.

Planer Blade Sharpening Jig for 2 blades at 40 degree bevel / edge. Printed parts are the base and shoe. Requires 5 bolts, washers, and wingnuts. Heads of bolts are seated in the base of the shoe, and run up through the base to washer and wingnut at the top. Light finger tight should do it. Specifically designed for Delta 22-547 blades, but will serve for any number of blades requiring a 40 degree top bevel angle. Length 9.69" (246 mm), width 1.77" (45 mm), width of blade tip to blade tip: 1.7" (43.26 mm), height with blades (not including bolts) 1 1/16" (~27 mm).

Can sharpen with sandpaper laid on flat surface plate (such as granite or plate glass), a large stone (such as a Norton IM-313), or smaller hone "floated" over the edges (try inverting the jig). Easy does it!

Version 1 Bolts: 10-32 thread, 1 1/4" long, 5/16" head width, 1/8" head height.

Version 2 Bolts: 1/4-20 thread, 1/14" long, 7/16" head width, 5/32" head height

Norton IM-313: https://www.nortonabrasives.com/en-us/norton-im313-multi-oilstone-sharpening-system

Notes for use: Overtightening wingnuts can impart a bend in the jig. Take care to seat blades flat in the base, edges even against the back corner of their pocket. When tightening the wingnuts, bring them to just a very gentle snug. Place the jig with blades on your sharpening surface. Ease the wingnuts and ensure both blades are evenly flat on your surface, and jig body settled down with no rocking or bend detected. Snug wingnuts just to touch washers all around, check all is seated and flat, snug only a teeny bit more (blades will not fall out) evenly and checking all is flat. If a bend occures, loosen nuts and snug again a little less. This procedure worked for me with some very ugly old used blades.

Similar models

3dwarehouse

free

5-16 nuts, bolts, washer, low-poly

...5/16' hex bolt, carriage bolt, nut and insert nut, washer, wingnut #carriage_bolt #hex_bolt #insert_nut #nut #washer #wingnut

thingiverse

free

spokeshave sharpening jig by chatzi88

...ening jig by chatzi88

thingiverse

4 x m3 screws

4 x wingnuts

4 x washers

1 x 1 1/4in washer for the top for magnetic angel gauge

thingiverse

free

Wing / Nut Holder for a 1/4" bolt with a 7/16" Head or for a Nut with 7/16" flat to flat by psehorne

... to flat by psehorne

thingiverse

wing nut for a 1/4" bolt with a 7/16" head or for a nut with 7/16" flat to flat.

3dwarehouse

free

Sharpening jig

...g described in youtube video http://www.youtube.com/watch?v=esrlkrcy5y4 for sharpening jointer and planer knives #jig #sharpening

3dwarehouse

free

Mower Blade Sharpening Jig

...arehouse

this is a bench top jig in which mower blades can be held in place to accurately sharpen an edge using a bench grinder.

grabcad

free

Filament Bearing Roller

...t base 1

bolt base 2 (carriage bolt insert)

20mm washer

5mm washer

wingnut (epoxy 5/16 nut inside)

see image for assembly order.

thingiverse

free

Makita Power Planer Blade Sharpener - 1900B by MaxPower1977

.... load the blade in the slot and run a sharpening stone across the top of it.

link to how to use it:https://youtu.be/crxellnxk74

3dwarehouse

free

sharpen blades

...sharpen blades

3dwarehouse

easy jig for sharpening mower blades

thingiverse

free

Hand Tightening Knob for 5/16" Bolts by GarageBot

...htening knob for 5/16" bolts by garagebot

thingiverse

this knob for hand tightening 5/16" hex head bolts used in jigs.

3dwarehouse

free

Blade Setting Jig

...blade setting jig

3dwarehouse

set depth of planer blades

Scottmi

thingiverse

free

Covid Tree Ornament 2020 by scottmi

...covid tree ornament 2020 by scottmi

thingiverse

because, 2020

a somber comemmorative for a year dominated by the pandemic.

thingiverse

free

Caulk Squeezer by scottmi

...any material you like. for this print, i used petg at .20 layer resolution, 2 perimeters, 20% grid infill. same settings for pla.

thingiverse

free

Box for Hubless Fly Reel by scottmi

... fly reel! here is a box to keep it in when not streamside.

assembled size in mm: 111 x 111 x 69

can see the reel pictured, here.

thingiverse

free

Biscuit Joiner Insert **With Text** by scottmi

... no metal-to-metal contact. snug up the collar capscrew and blade stays still and secure when moving/storing/shelving the joiner.

thingiverse

free

Protective case for Icom IC-M25 by scottmi

...does not fit the charger.

change scale measurements in slicer for different size radios.

close fit for minimal 'rattle.'

thingiverse

free

Folding Worktable Foot by scottmi

...int time is ~4 hours per foot).

other material to consider would be petg.. but the tpe is magnificent.

the table is stable again!

thingiverse

free

Zebco Reel Storage Box (Model 606) by scottmi

...other zebco / other brand reels. pdf drawing with dimensions included with the files. optional 'zebco logo' lid included.

thingiverse

free

Hub Style Wing Nut 3/8 - 16 UNC Wingnut by scottmi

... is one for 3/8 - 16 unc thread. base is .75" diamerter, overall hight is 1.02 inches, "wingspan" is 1.52 inches.

thingiverse

free

Try Square Version 2 by scottmi

...out of the freezer one at a time, press with tumb all the way through, flush to table surface. now as tight and square as can be!

thingiverse

free

Vintage Fishing Rod Butt Caps by scottmi

...mm diameter end).

if you rod is a different size, might be able to use x,y,z scale adjustments in your slicer for a perfect fit.

Planer

turbosquid

$20

Wood Planer Machine

... wood planer machine for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1436545)

3d_export

$5

wood planer

...ght cut on the biggest face of your board. i have made this object as a beginner, if there is any problem, i am here to fix that.

turbosquid

$13

Giano and Planer Crystalart by Cattelan Italia Dining Table

...rystalart by cattelan italia dining table for download as max on turbosquid: 3d models for games, architecture, videos. (1509691)

3d_export

$14

hand held planer

...br textures. fbx obj pbr textures with 5 different colour variants packed grayscale textures, occlusion, roughness & metallic

3d_export

$15

dewalt planer thicknesser clean

...r>please contact me in case of any questions or difficulties, i will help you) contact us, i will make you a 3d model to order

3d_export

$10

cold planers pm200 - 22 m hq

...;multiple formats c4d, dae, fbx, 3ds, obj, sbs etc<br>substance file included<br>low poly<br>high quality model

3d_export

$149

pm 622 cold-planer - asphalt removal

... in this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

3d_export

$5

V-Manor from Skyrim

...roof is scaly.<br>nearby there is a recreation area, a planer and a cleaver, a firewood...

sketchfab

$10

planer

...planer

sketchfab

planer - buy royalty free 3d model by sergeykuchmin (@sergeykuchmin) [ba2ac2e]

sketchfab

$149

Cold Planer

...r

sketchfab

quality 3d model of cold planer.

detailed for close-up renders. - cold planer - buy royalty free 3d model by 3dhorse

Sharpening

turbosquid

$5

Sharpener

...

turbosquid

royalty free 3d model sharpener for download as on turbosquid: 3d models for games, architecture, videos. (1603397)

3d_export

$5

sharpener

...r is made in the compass 3d program, the rendering is made in the keyshot program. the model is saved in the stl, fbd, stl format

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Jig

turbosquid

$25

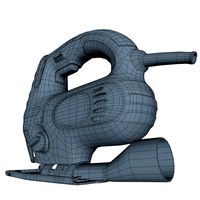

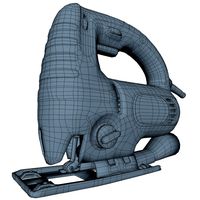

jig-saw_mid_SM

...uid

royalty free 3d model jig-saw_mid_sm for download as obj on turbosquid: 3d models for games, architecture, videos. (1244761)

turbosquid

$20

jig-saw_low

...osquid

royalty free 3d model jig-saw_low for download as obj on turbosquid: 3d models for games, architecture, videos. (1244760)

turbosquid

$10

jig-saw_hi

...bosquid

royalty free 3d model jig-saw_hi for download as obj on turbosquid: 3d models for games, architecture, videos. (1244757)

turbosquid

$7

Jig Armchair

...squid

royalty free 3d model jig armchair for download as max on turbosquid: 3d models for games, architecture, videos. (1648936)

turbosquid

$5

Jig Tail

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Blade

3d_export

$20

cossack blades

...

3dexport

cossack blades. the set contains 10 blades with a scabbard. each object (blade + scabbard) has a texture of 2048x2048.

3d_export

free

Blade Katarina

...blade katarina

3dexport

blade

turbosquid

free

Blades

...urbosquid

royalty free 3d model blades for download as blend on turbosquid: 3d models for games, architecture, videos. (1544896)

turbosquid

$40

Blade

...royalty free 3d model blade for download as max, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1222665)

turbosquid

$35

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

blade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.