Thingiverse

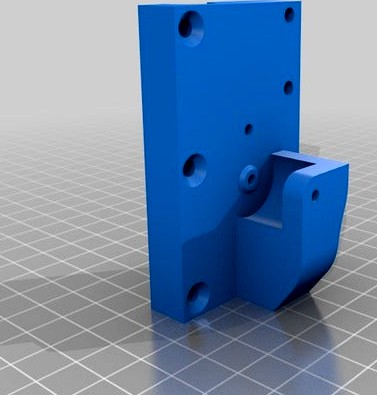

Piper 2 Bearing-less Short Gantries (PTFE Sliders) - 8mm, 10mm, and 12mm rods versions by Zinoberrot

by Thingiverse

Last crawled date: 4 years, 4 months ago

This is a bearing-less version of the Piper 2's gantries, using common 2 or 3mm OD PTFE (Teflon) tubes as sliders.

The problem with steel linear rods is that they are very heavy and the problem with using any other kind of rod is that the linear bearings will chew soft metals/composites like gum. The concept behind this design is simple; it reduces the number of required parts to build the printer and also allows the use of light guiding rods (aluminum, carbon fiber, etc.). Therefore, these are necessary for achieving high printing speeds and for the reduction of vibration artifacts (ringing). It also improves the clearances between the rod and the screws and, last but not least, it will be completely silent.

My first attempt integrated the tubes as part of the gantry and that failed because different printers behave differently, so something calibrated to perfectly fit my parts was not usable by everyone. Therefore, I separated the bushings from the gantry, so that they can be individually printed/calibrated/replaced without having to print the whole part again. As the bushings are a separate part from the gantry and can be easily generated via the included OpenSCAD file, these bushings can be used with any (<4mm) PTFE tubing and for any rod diameter (up to a theoretical maximum of 14mm with 2mm OD PTFE but these will be too close to the screw holes in the Y gantry). I also included adapters to use 8mm and 12mm rods with the 12mm versions of the gantries if you want to mix & match different rod sizes (not recommended but it will probably work fine).

The only part required are small pieces of PTFE tubing (15 mm long each). Simply insert the tubing into the openings and assemble the gantries. The rod should have a snug fit but will slide like there is nothing but air holding it. If the grip is too tight, use the included OpenSCAD file and increase the tolerance a little bit (e.g. use 3.2mm instead of 3mm). I strongly recommend printing one bushing first and check how it fits, then print the rest.

You can also use the included OpenSCAD file to create such bearings for the stock gantries (or for anything else, actually). Just be careful with the distances - you cannot use 3-4mm OD tubing for a 15mm LM8UU-size bearing!

Regarding reliability, the PTFE tubing will most likely outlive the user, let alone the printer. I'm using it on high speed machinery that is much faster than any printer and never had one fail in my life. I also use similar solutions along with aluminum rods on most of my printers in order to reliably print at high speeds.

The X and Y gantry versions that I uploaded are a bit shorter than the originals, increasing travel by about 40mm across the X axis and 18mm across the Y axis (compared to the 12mm version). My version of the X gantry is smaller and a bit more complicated, and in no way superior to the default one, I just had to redesign it for my filament intake Y splitter to fit and I am uploading it because it increases the print surface significantly. All of my uploaded parts are based on the 12mm original version, so they require GT2 10mm belts/pulleys/idlers.

I also uploaded the extremely simple BL Touch adapter that I made for the Piper 2. It simply requires a significantly longer X gantry screw and is secured with two extra nuts behind/beside the hotend. Its height can be simply adjusted via the two mounting nuts.

Edit: I added a Y-Slider version with 5mm holes for the idlers/gears because 10mm tall parts with 3mm bore are notoriously hard to find. You will need M5×25mm screws for these, the holes are not going all the way through the part, they are meant to tap directly onto the plastic (or they would be getting uncomfortably close to the rod).

The problem with steel linear rods is that they are very heavy and the problem with using any other kind of rod is that the linear bearings will chew soft metals/composites like gum. The concept behind this design is simple; it reduces the number of required parts to build the printer and also allows the use of light guiding rods (aluminum, carbon fiber, etc.). Therefore, these are necessary for achieving high printing speeds and for the reduction of vibration artifacts (ringing). It also improves the clearances between the rod and the screws and, last but not least, it will be completely silent.

My first attempt integrated the tubes as part of the gantry and that failed because different printers behave differently, so something calibrated to perfectly fit my parts was not usable by everyone. Therefore, I separated the bushings from the gantry, so that they can be individually printed/calibrated/replaced without having to print the whole part again. As the bushings are a separate part from the gantry and can be easily generated via the included OpenSCAD file, these bushings can be used with any (<4mm) PTFE tubing and for any rod diameter (up to a theoretical maximum of 14mm with 2mm OD PTFE but these will be too close to the screw holes in the Y gantry). I also included adapters to use 8mm and 12mm rods with the 12mm versions of the gantries if you want to mix & match different rod sizes (not recommended but it will probably work fine).

The only part required are small pieces of PTFE tubing (15 mm long each). Simply insert the tubing into the openings and assemble the gantries. The rod should have a snug fit but will slide like there is nothing but air holding it. If the grip is too tight, use the included OpenSCAD file and increase the tolerance a little bit (e.g. use 3.2mm instead of 3mm). I strongly recommend printing one bushing first and check how it fits, then print the rest.

You can also use the included OpenSCAD file to create such bearings for the stock gantries (or for anything else, actually). Just be careful with the distances - you cannot use 3-4mm OD tubing for a 15mm LM8UU-size bearing!

Regarding reliability, the PTFE tubing will most likely outlive the user, let alone the printer. I'm using it on high speed machinery that is much faster than any printer and never had one fail in my life. I also use similar solutions along with aluminum rods on most of my printers in order to reliably print at high speeds.

The X and Y gantry versions that I uploaded are a bit shorter than the originals, increasing travel by about 40mm across the X axis and 18mm across the Y axis (compared to the 12mm version). My version of the X gantry is smaller and a bit more complicated, and in no way superior to the default one, I just had to redesign it for my filament intake Y splitter to fit and I am uploading it because it increases the print surface significantly. All of my uploaded parts are based on the 12mm original version, so they require GT2 10mm belts/pulleys/idlers.

I also uploaded the extremely simple BL Touch adapter that I made for the Piper 2. It simply requires a significantly longer X gantry screw and is secured with two extra nuts behind/beside the hotend. Its height can be simply adjusted via the two mounting nuts.

Edit: I added a Y-Slider version with 5mm holes for the idlers/gears because 10mm tall parts with 3mm bore are notoriously hard to find. You will need M5×25mm screws for these, the holes are not going all the way through the part, they are meant to tap directly onto the plastic (or they would be getting uncomfortably close to the rod).