Thingiverse

Penstruder Full color ABS, PLS printing head project by Virtuabotix

by Thingiverse

Last crawled date: 2 years, 12 months ago

Update Designs for the printable Marker have been successfully printed and are now being fine tuned while I come up with the most economical way of cutting custom felt tips the marker thing can be found at this link http://www.thingiverse.com/thing:5592 .

This project was inspired by this thing: http://www.thingiverse.com/thing:5570

Which truly proved the concept behind this hopefully soon to be reality full color printer head for any plastic extruder.

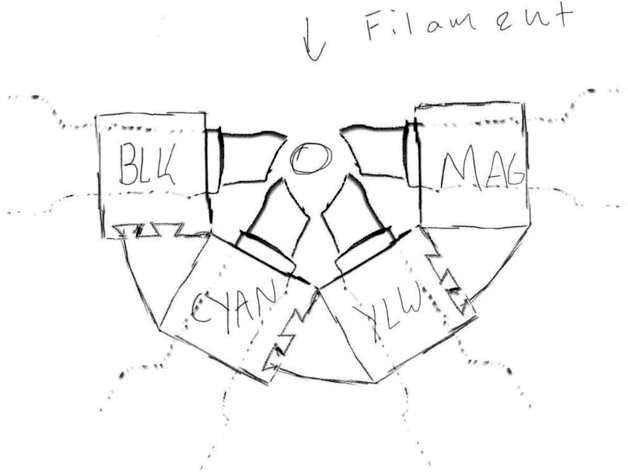

For the moment this is just concept art, but I wanted to share it while all the wheels are still turning. I have several other concepts, but these two are the most refined so far. I will be heading out to get an idea of the most economical way to move forward in just a moment.

So here is the concept, I will be designing nib heads for either a Four Headed, or a Five Headed coloring mechanism. Right now, I am leaning heavily towards four heads, because it will eliminate some nib proximity issues, and give more room for the drive system I will be designing shortly. (Also the only real reason for a fifth head is either to make one particular color darker, I.E. Black, or to introduce metallic ink which I have never superheated so I don't even know if that is such a good an idea ^-^).

Any ways what I will be doing is either purchasing empty markers, or printing my own marker heads out and designing them around some cheap nib supplier. Then I will either design ink cartridges, or indicator lines on the markers themselves (along with a port that allows for easy ink refills). After that all you have to do is use a cheap ink cartridge refilling kit and lode each cartridge up with Black, Magenta, Yellow, and Cyan ink (standard ink jet ink should be readily available and work).

After I have designed the parts mentioned above I will proceed with the design of the drive system. At the moment I plan to design it around micro servos, the goal of the drive system will be to convert as much of the 180 degrees of motion a servo produces into very fine nib pressure control. Once calibrated it should be possible to produce at least 1049760000 colors if you use a servo with at least control to the nearest 1 degree.

After the drive system is complete I plan on designing an Arduino board that stores the calibration data interfaces with the Makerbot Motherboard (takes g-code commands) and interfaces directly with a computer via USB for calibration, initial versions, and for those who just want to change the color for an entire print, or change colors dynamically as the print proceeds.

------------------------ The Way Forward -------------------------------

So to summarize:

Step one: Design 3D Printable nib head that allows attachment of drive system.

in progress

Step Two: Design printable marker suited for "Penstruder", design in progress see this thing http://www.thingiverse.com/thing:5592

Step three: Design and build drive system that allows 180 degrees to be converted into very precise nib pressure accurate to 1 degree.

Step Four: Design board to control drive system.

Step Five: Design GUI for computer control.

Step Six: Patch Makerbot Motherboard for full integration.

Step Seven: Celebrate Great Success!

This is a huge project, and I will need as much help as I can get. Just think of the awesomeness if we all come together on this though.

I am still waiting for my Thing-O-Matic to arrive, but I will be designing parts in the meantime.

This project was inspired by this thing: http://www.thingiverse.com/thing:5570

Which truly proved the concept behind this hopefully soon to be reality full color printer head for any plastic extruder.

For the moment this is just concept art, but I wanted to share it while all the wheels are still turning. I have several other concepts, but these two are the most refined so far. I will be heading out to get an idea of the most economical way to move forward in just a moment.

So here is the concept, I will be designing nib heads for either a Four Headed, or a Five Headed coloring mechanism. Right now, I am leaning heavily towards four heads, because it will eliminate some nib proximity issues, and give more room for the drive system I will be designing shortly. (Also the only real reason for a fifth head is either to make one particular color darker, I.E. Black, or to introduce metallic ink which I have never superheated so I don't even know if that is such a good an idea ^-^).

Any ways what I will be doing is either purchasing empty markers, or printing my own marker heads out and designing them around some cheap nib supplier. Then I will either design ink cartridges, or indicator lines on the markers themselves (along with a port that allows for easy ink refills). After that all you have to do is use a cheap ink cartridge refilling kit and lode each cartridge up with Black, Magenta, Yellow, and Cyan ink (standard ink jet ink should be readily available and work).

After I have designed the parts mentioned above I will proceed with the design of the drive system. At the moment I plan to design it around micro servos, the goal of the drive system will be to convert as much of the 180 degrees of motion a servo produces into very fine nib pressure control. Once calibrated it should be possible to produce at least 1049760000 colors if you use a servo with at least control to the nearest 1 degree.

After the drive system is complete I plan on designing an Arduino board that stores the calibration data interfaces with the Makerbot Motherboard (takes g-code commands) and interfaces directly with a computer via USB for calibration, initial versions, and for those who just want to change the color for an entire print, or change colors dynamically as the print proceeds.

------------------------ The Way Forward -------------------------------

So to summarize:

Step one: Design 3D Printable nib head that allows attachment of drive system.

in progress

Step Two: Design printable marker suited for "Penstruder", design in progress see this thing http://www.thingiverse.com/thing:5592

Step three: Design and build drive system that allows 180 degrees to be converted into very precise nib pressure accurate to 1 degree.

Step Four: Design board to control drive system.

Step Five: Design GUI for computer control.

Step Six: Patch Makerbot Motherboard for full integration.

Step Seven: Celebrate Great Success!

This is a huge project, and I will need as much help as I can get. Just think of the awesomeness if we all come together on this though.

I am still waiting for my Thing-O-Matic to arrive, but I will be designing parts in the meantime.

Similar models

grabcad

free

Refillable Marker

...te:the tip of the marker is a placeholder and an actual tip is made of paper and sand. also note that dimensions are not to scale

thingiverse

free

Compact Filament Colorizer by mrm64

...nter

drinking straw or ptfe tube

if you use a 3mm diameter filament, use a thick straw/tube

silicone spray (contains no solvents)

thingiverse

free

Printable Marker for "Penstruder" by Virtuabotix

...tep 2: prepare and print marker.

step 3: cut and install custom nib.

step 4: perform and publish function tests using inkjet ink.

thingiverse

free

Cubic Filament Colorizer by mrm64

...cubic filament colorizer by mrm64

thingiverse

requirements

polyurethane foam sponge

refill ink for permanent marker

thingiverse

free

Pelikan cartridge holder - portacartuccia by fabi71

...pelikan cartridge holder - portacartuccia by fabi71

thingiverse

container for refilled ink cartridges

3dwarehouse

free

Ink jet color cartridge

...warehouse

this is a color cartridge for an hp deskjet5 5150 printer. #cartridge #color #ink #jet #paper #picture #print #printer

thingiverse

free

Ink cartridge recycle box by qbi2

...r ink cartridges.

this is the result. a box with a recycle symbol and a ink cartridge symbol.

hope you like, print and use it ;-)

thingiverse

free

Printer Refill Nozzle by oneil

...r refill nozzle by oneil

thingiverse

used for the new style of refilling bubble jet ink cartridges. requires the refill syringe.

thingiverse

free

ink cartridge container

...itable for all designs.

there is a smal container for one cartridge(no photo), the other two are made for three cartridges(tp/6).

thingiverse

free

Ink Nib 2 by visheshmardolkar1983

...ink nib 2 by visheshmardolkar1983

thingiverse

ink nib, ink tip,

Virtuabotix

thingiverse

free

Virtuabotix Servo Housing Joint by Virtuabotix

...t is printed on its side for best strength.

this part is designed to work with this thing: http://www.thingiverse.com/thing:20217

thingiverse

free

Virtuabotix Microservo Housing by Virtuabotix

... should work with any microservo you fancy.

we have lots of other parts based on this design that i look forward to posting soon.

thingiverse

free

3D Printable Virtuabotix.com Logo by Virtuabotix

...ng electronics. it was a pretty fun thing to print, and is a great way to say you support the team at https://www.virtuabotix.com

thingiverse

free

Mirror Image Case for Versalinoâ„¢ V1S0B by Virtuabotix

...s my first crack at designing a case that is composed of a single piece that is printed twice to get a symmetrical pcb enclosure.

thingiverse

free

Rover Motor Shaft to Wheel Connector by Virtuabotix

...tion was simple a 3d printed shaft that matched the inside of my hobby tire, and had a hole down the center for the motor itself.

thingiverse

free

doubleback buckle for webbing by Virtuabotix

...chine, and materials as to whether or not they have the same performance. so use this for climbing applications at your own risk.

thingiverse

free

Make your own robotics Loadboard/Shield! by Virtuabotix

...of development time.

simply drop it into your favorite design program and start taking advantage of the versalinoâ„¢ bus system.

thingiverse

free

Bareduino - Arduino Compatible Breadboard Microcontroller by Virtuabotix

...ed/?p=407!

pickup the kit at http://www.amazon.com/gp/product/b007ax97ze

or build it yourself with our parts list and schematics.

thingiverse

free

Printable Marker for "Penstruder" by Virtuabotix

...tep 2: prepare and print marker.

step 3: cut and install custom nib.

step 4: perform and publish function tests using inkjet ink.

thingiverse

free

Versalino Rove 2 Wheel Drive Laser Cut Rover Platform 1.0.8 by Virtuabotix

... wheels. the whole body can be laser cut if you have access to a laser cutter, or you can pick up the kit from virtuabotix.com .

Pls

3d_export

$50

pls concrete module

...pls concrete module

3dexport

pls concrete module<br>pls with concrete mobile mixer module m5

3ddd

$1

Potocco Diva / PL

...potocco diva / pl

3ddd

potocco

итальянское кресло potocco diva/pl

790х770х630

turbosquid

$30

PL 01Plant09

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

PL-14

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

DELUXE 50 PL

...deluxe 50 pl

3ddd

leucos deluxe , archirivolto

люстра leucos deluxe 50 pl, italy

3ddd

$1

Vintage / Poison PL 60

...vintage / poison pl 60

3ddd

poison

vintage poison pl 60

3ddd

free

камин kratki pl zuzia a t

...камин kratki pl zuzia a t

3ddd

камин , kratki pl

камин kratki pl zuzia a t

turbosquid

$25

Platin PL 73

...rbosquid

royalty free 3d model platin pl 73 for download as on turbosquid: 3d models for games, architecture, videos. (1382455)

turbosquid

$25

Platin PL 72

...rbosquid

royalty free 3d model platin pl 72 for download as on turbosquid: 3d models for games, architecture, videos. (1382454)

turbosquid

$25

Platin PL 71

...rbosquid

royalty free 3d model platin pl 71 for download as on turbosquid: 3d models for games, architecture, videos. (1382451)

Abs

3ddd

free

Preciosa AB

...preciosa ab

3ddd

preciosa

lustra preciosa ab s 12 svetilnikami

turbosquid

$8

abe oodworld

...squid

royalty free 3d model abe oodworld for download as obj on turbosquid: 3d models for games, architecture, videos. (1607965)

3ddd

$1

Ab King Pro

...ab king pro

3ddd

тренажер

тренажер ab king pro.

3d_export

$19

Upper ab machine

...upper ab machine

3dexport

3d_ocean

$16

AB King 3D Model

...ab king 3d model

3docean

3d ab king athletic model trainer

highly detailed ab king model file formats: .max, obj, fbx.

3ddd

$1

Ecosmart AB Series

...ab series

3ddd

камин

ecosmart ab series.

polys: 327 574

price: $565.00http://www.ecosmartfire.com/

био-спиртовые камины

turbosquid

$15

House ABS V106

...ree 3d model house abs v106 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1216161)

turbosquid

$11

Fabiela Pillow AB

...odel fabiela pillow ab for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1574015)

turbosquid

$70

AB Sun Parakeets

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

AB American Goldfinch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Full

3ddd

$1

Full Mobili

...ull mobili , шкаф

группа шкафов, серия мебели "классика" фабрики «full mobili»

turbosquid

$80

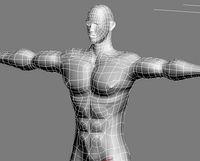

full man body+full facials

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Full Mobili

...сика , стол

стол круглый офисный серия мебели "классика" фабрики «full mobili»

3ddd

$1

FULL MOBILI

... стол

cтол офисный серии мебели "классика" итальянской компании full mobili

design_connected

$16

Full Circle

...full circle

designconnected

atmosphere full circle computer generated 3d model.

3d_export

$5

full office

...full office

3dexport

this is full office cgi model created with maya -detailed -textured -uv mapped

design_connected

$16

Full Moon

...full moon

designconnected

roche bobois full moon computer generated 3d model. designed by ragot, cedric.

turbosquid

$100

FULL KITCHEN

...squid

royalty free 3d model full kitchen for download as skp on turbosquid: 3d models for games, architecture, videos. (1345817)

turbosquid

$15

Full Bedroomset

...id

royalty free 3d model full bedroomset for download as max on turbosquid: 3d models for games, architecture, videos. (1540649)

3d_export

$10

full human body

...full human body

3dexport

it is a full human sculpt

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

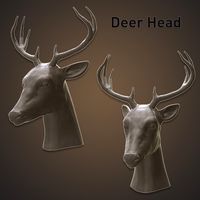

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear

Color

design_connected

$11

Colors

...colors

designconnected

zanotta colors lounge chairs computer generated 3d model. designed by ilkka suppanen.

3ddd

$1

pillows colors

...pillows colors

3ddd

pillows colors , подушка

pillows colors

3ddd

free

color dress

...3ddd

color dress , манекен , одежда

color dress

3ddd

$1

светильники Colors

... massive , бельгия

светильники massive серия colors, очень веселые

3d_export

$30

color chameleon

...color chameleon

3dexport

color chameleon

3ddd

$1

color vase

...color vase

3ddd

color vase

3d_ocean

$2

color pen

...3d model of color pen. model is based on edge loop topology. all materials are included. model is render ready and ready for use.

3ddd

$1

Color Parquet

...color parquet

3ddd

паркет

color parquet

3ddd

free

color console

...color console

3ddd

консоль

color console

3d_export

$5

Technum Color

...technum color

3dexport

technum color led от imperiumloft https://imperiumloft.ru/dizajn-loft/technum-color-led.html

Project

3d_export

$7

project

...project

3dexport

project

3d_export

$20

Project

...project

3dexport

design_connected

$16

Project Chair

...project chair

designconnected

rex kralj project chair computer generated 3d model. designed by žitnik, marjan.

3ddd

$1

lectric Project

...настроены. сетка очень плотная.

доступно только для группы "profi"

про группу "profi" можно прочитать в чаво

3d_ocean

$19

Soon project

...kup. made in 3ds max 2013 1- 3dsmax with vray render included material and light 2- obj file 3- fbx file hope you like it plea...

turbosquid

$49

Joint | Project

...squid

royalty free 3d model joint | project for download as on turbosquid: 3d models for games, architecture, videos. (1297983)

turbosquid

$11

house project

...bosquid

royalty free 3d model house project for download as on turbosquid: 3d models for games, architecture, videos. (1672482)

turbosquid

$450

University project

...

royalty free 3d model university project for download as rvt on turbosquid: 3d models for games, architecture, videos. (1463354)

turbosquid

$30

smart projecter

...lty free 3d model smart projecter for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1236214)

3d_export

$5

project drawing

...project drawing

3dexport

project drawing and 3d model<br>format jpg sldprt dwg<br>by 3d make

Printing

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints