Thingiverse

Parkside X20V Team LED 10W Floodlight / Work Light by jaaanik

by Thingiverse

Last crawled date: 3 years, 1 month ago

Sorry for the incomplete description, but Thingiverse still sucks. Playing with this shitty interface and service is a waste of time.

I present the floodlight for the Parkside X20V Team battery from the LIDL store.

The lamps can be used, for example, to illuminate the working space, to illuminate rooms and campsites without access to the mains power supply.

I recommend using this inexpensive lamp, which is available in various variants and has a built-in DC converter, so you can power it directly from the X20V battery:https://www.aliexpress.com/item/32827528992.html

Standard 2Ah battery allows you to use the lamp for about 4-5 hours.

WARNING! X20V batteries have no built-in over-discharge protection, so check the battery voltage and do not discharge below 15V.

This is my project of useful gadgets and portable wireless devices for Parkside X20V batteries. There are:

Mounting brackets for the charger

Battery mounting bracket (shelf and wall mount)

Floodlight / Work Light - LED 10W

Audio amplifier TPA3116 Wuzhi - maximum output power RMS 2x20W/4R, 2x24W/8R

Power supply DPS3005 (max 19.5V/5.1A) - available on Cults3D.com only

Soldering station KSGER T12 OLED - available on Cults3D.com only

STEP files are available so you can modify them to suit your needs.

If you like this project and appreciate my work, you can support me through PayPal.

You need:

10W LED floodlight

2 pieces M3x12 mm screw

2 pieces M3 nut

2 pieces M3 washer

2 pieces long 6.3 mm connectors

The photos should explain everything.

Cut the connectors as shown in the photos and solder the wire connections. Cut the lamp cable to the correct length and strip it.

Push the wires through the holes in the 3D print. Solder the ends of the wire and solder the connectors to the wires.

Put the connectors in place and secure them with CA glue. Screw the lamp holder onto the 3D printed part.

The third photo shows the recommended orientation of the elements when printing.

Walls thickness 1.6 mm (4 shells). Layer height 0.2 mm. Infill 25-30%.

I present the floodlight for the Parkside X20V Team battery from the LIDL store.

The lamps can be used, for example, to illuminate the working space, to illuminate rooms and campsites without access to the mains power supply.

I recommend using this inexpensive lamp, which is available in various variants and has a built-in DC converter, so you can power it directly from the X20V battery:https://www.aliexpress.com/item/32827528992.html

Standard 2Ah battery allows you to use the lamp for about 4-5 hours.

WARNING! X20V batteries have no built-in over-discharge protection, so check the battery voltage and do not discharge below 15V.

This is my project of useful gadgets and portable wireless devices for Parkside X20V batteries. There are:

Mounting brackets for the charger

Battery mounting bracket (shelf and wall mount)

Floodlight / Work Light - LED 10W

Audio amplifier TPA3116 Wuzhi - maximum output power RMS 2x20W/4R, 2x24W/8R

Power supply DPS3005 (max 19.5V/5.1A) - available on Cults3D.com only

Soldering station KSGER T12 OLED - available on Cults3D.com only

STEP files are available so you can modify them to suit your needs.

If you like this project and appreciate my work, you can support me through PayPal.

You need:

10W LED floodlight

2 pieces M3x12 mm screw

2 pieces M3 nut

2 pieces M3 washer

2 pieces long 6.3 mm connectors

The photos should explain everything.

Cut the connectors as shown in the photos and solder the wire connections. Cut the lamp cable to the correct length and strip it.

Push the wires through the holes in the 3D print. Solder the ends of the wire and solder the connectors to the wires.

Put the connectors in place and secure them with CA glue. Screw the lamp holder onto the 3D printed part.

The third photo shows the recommended orientation of the elements when printing.

Walls thickness 1.6 mm (4 shells). Layer height 0.2 mm. Infill 25-30%.

Similar models

thingiverse

free

Parkside X20V Team Wuzhi TPA3116 Portable 2x20W Bluetooth 5.0 Audio Amplifier for Speakers by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Parkside X20V Team Shelf / Wall Battery Holder by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Parkside X20V Team Charger Wall Mount by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

grabcad

free

Adapter Parkside X20V battery to Dedra tools

...adapter parkside x20v battery to dedra tools

grabcad

adapter parkside x20v battery to dedra tools

thingiverse

free

ATX Power supply quick lab connector REMIXED by AlexandreGomes

... in some cases , the holes for the leds must be increased with a drill . do not need much , just enough to hold the led in place.

thingiverse

free

Fake AA AAA battery for using a power supply design in openscad by sigoestudiando

... screws and 2 nuts,

the stl files are designed for m3 for the bottom, and m2 for the top.

simply solder each wire to their nut.

thingiverse

free

Teal 9V, 10W power LED cover by toymulders

...ta scheet to make sure you attach the wires the the wright side)

test the light

does it work?

then you are ready to start flying

thingiverse

free

Illuminated clock by bretthalliday

...v 30 cm led

you will also need some wire, a soldering iron, two small wood screws, sticky tape

12 mm drill

8 mm drill

3 mm drill

thingiverse

free

Extruder LED Strip Holder for Wanhao Duplicator i3 by balassy

...l: this piece is taller, so it will not drop shadow to the nozzle, but it blocks more view. (see the photo with the black piece.)

thingiverse

free

Dual parkside x20v battery adapter by JernejL

...es.

make your own 4ah battery, or even crazyer: combine 2 4ah batteries into one 8ah battery.

posted with permission from glol.

Jaaanik

thingiverse

free

Wall Mount for SIL hybrid - Pump-Action Repeating Bow with Ammo Clips by jaaanik

...wall_hook_cover parts. you also need a steel hook, screw and wall plugs. the vertical distance between the holes should be 28 cm.

thingiverse

free

Parkside X20V Team Charger Wall Mount by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Parkside X20V Team Shelf / Wall Battery Holder by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Pistol Crossbow Bolt and Fletching by Pythonp90

...sliding legolini from jaaanikhttps://www.thingiverse.com/thing:4210059 i used the print settings jaaanik recommends for the legolini layer height of 0.2 mm...

thingiverse

free

Parkside X20V Team Wuzhi TPA3116 Portable 2x20W Bluetooth 5.0 Audio Amplifier for Speakers by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Hotend, Micro Swiss, assembly for Sapphire PLUS by runekc

...is a modified version of the piece made by https://www.thingiverse.com/jaaanik i would love to have the hotend mount made...

thingiverse

free

Sapphire pro led mount by NikNakTak

...niknaktak thingiverse i remixed slightly the design proposed by jaaanik i like the idea, i simply replaced led holder...

thingiverse

free

Crossbow Cobra Adder Original Magazin V1 Fast Refill with 6 Arrows by g1cs2009

...this time. so i want a speed loader and jaaanik design is very nice. at this moment it is...

X20V

thingiverse

free

adattatore parkside x20V a powerbank by SamueleLg

...sfruttare le batterie parkside x20v team come un powerbank utilizzando un comunissimo adattatore da accendi sigari per auto a usb

thingiverse

free

Parkside X20V Arbeitslicht by kay_1971

...es arbeitslichtes, ausgelegt für

https://www.wish.com/product/5df9c24ba0f3b408d6cb620c

und einen standard kippschalter (28*12mm)

thingiverse

free

Parkside PABH adapter x20v team by diegomax

...parkside pabh adapter x20v team by diegomax

thingiverse

adapter for parkside pbah 18 li a1

thingiverse

free

Dual parkside x20v battery adapter by JernejL

...es.

make your own 4ah battery, or even crazyer: combine 2 4ah batteries into one 8ah battery.

posted with permission from glol.

thingiverse

free

Lidl Parkside X20V Team Powerbank USB Adapter by Knuspel

...board

stackable design so that each part is easy to print. the screws are directly screwed into the material. do not overtighten.

thingiverse

free

Parkside x20v battery adapter for 12v lighter socket by GLoL

... 12v !!!

one piece print !!

the drawing was optimize to be printed upwards,no supports needed

(thingverse cant generate previews)

thingiverse

free

Lidl Parkside X20V adapter by misil

...e na kontaktech.

https://cad.onshape.com/documents/d55b391241c770a5e72bf94a/w/43fd5f1289571e1c07fb2d0d/e/631db234c99c9881fcc640d6

thingiverse

free

Parkside X20V to Parkside PDSSA 18 A1 Fixed by Alex2244

... print i need to sanding a lot on the 18v battery part. other than that, the model is very good and a big thanks to andrzejdevil!

thingiverse

free

Parkside X20V Team Charger Wall Mount by jaaanik

...the recommended orientation of the elements when printing.

walls thickness 1.6 mm (4 shells). layer height 0.2 mm. infill 25-30%.

thingiverse

free

Lidl Parkside X20V Team Battery Adapter by Knuspel

... m2 screws (~8mm length) to mount the top plate onto the bottom plate. i used hot glue to hold the cable shoes in place properly.

Parkside

thingiverse

free

PARKSIDE ACCU

...parkside accu

thingiverse

parkside accu

thingiverse

free

Parkside hammer grip

...parkside hammer grip

thingiverse

parkside hammer grip

thingiverse

free

Parkside blade by cecnet

...parkside blade by cecnet

thingiverse

parkside blade.

abs

thingiverse

free

Parkside 12 A1

...parkside 12 a1

thingiverse

parkside 12vhalterung, park 12 a1

thingiverse

free

Parkside 20V mount

...parkside 20v mount

thingiverse

parkside 20v mount, for paralell to wall mount

thingiverse

free

Parkside to SN50T6 by dejx

...parkside to sn50t6 by dejx

thingiverse

parkside vacuum hose to sn50t6 dust cyclone separator adapter

thingiverse

free

Battery PARKSIDE

...battery parkside

thingiverse

housing for lion accu.

thingiverse

free

Parkside organizer separator by hugo_sa

...parkside organizer separator by hugo_sa

thingiverse

separator for parkside organizer.

thingiverse

free

Parkside PFBS12A1 Halter by JMDesigns

...parkside pfbs12a1 halter by jmdesigns

thingiverse

parkside pfbs12a1 halter

thingiverse

free

Parkside multitool wrench by lucibrandus

...parkside multitool wrench by lucibrandus

thingiverse

parkside multitool wrench

Floodlight

turbosquid

$20

Floodlight

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Floodlight

...ts, swimming pools, soccer fields. can be used in: 3d max 2011 3d max 2012 3d max 2014 use for your works. thanks for attention:)

turbosquid

$69

Floodlight PACK

...lty free 3d model floodlight pack for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1496708)

turbosquid

$30

Floodlight RED

...alty free 3d model floodlight red for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1496705)

turbosquid

$30

Floodlight YELLOW

...y free 3d model floodlight yellow for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1496704)

turbosquid

$10

floodlight tower

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

FloodLight/WorkLight

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

led floodlight

...ted using approximate real world dimensions. thank you for purchasing this model!! click on my username to see more of my models.

turbosquid

$49

SLV OUTDOOR FLOODLIGHTS set

...slv outdoor floodlights set for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1223002)

3d_export

$30

stage light Floodlights 3D Model

...t music electric studio set movie filter-frame par lens lamp beam reflector

stage light floodlights 3d model braz 7057 3dexport

10W

3ddd

$1

Lucide Glasfi

...диаметр 80 см, высота 30 см. количество лампочек: 15xg4 10w ...

3ddd

$1

Lucide Glasfi

...диаметр 50 см, высота 68 см. количество лампочек: 14xg4 10w ...

3ddd

$1

EGLO 90737

...775 тип патрона: g4 количество ламп: 15 мощность: 15x 10w цвет: античная/бронза/белый материал: метал...

3ddd

$1

Люстра Orion 446-1555/12 satin

...австрия количество ламп: 12 цоколь: g4 мощность лампы: . 10w высота: 55 см ширина: 30 см длина: 60...

3ddd

free

Aureliano Toso / Salome 30 sospension

...+ темно-синие) арматура: хромированный металл лампы 30 x max 10w ...

3ddd

$1

3967Y-2A,09 LED СВЕТИЛЬНИК АЖУР ОРАНЖЕВЫЙ

...материал - акрил, количество ламп/тип ламп - power led 1*18w+1*10w ...

3ddd

$1

ILFARI. TEARS FROM MOON H34

...balls дизайн: coen munsters описание: 34 x g4 | 10w max. | 12v включительно светильники 4 x led 3.2w...

3d_export

$5

mid century lamp

...bar / restaurant polys: 28 838 verts: 29 464 http://m.sbc-lighting.net/table-lamps-10w100w/mid-century-marble-and-brass-lamp-with-e27.html ...

3ddd

$1

ILFARI. TEARS FROM MOON H22

...balls дизайн: coen munsters описание: 22 x g4 | 10w max. | 12v включительно светильники 3 x led 3.2w...

3ddd

$1

ESTILUZ BUTTON T-3305 / T-3306

...material: aluminium lamp type: t - 3305 - led 10w 3000k 975lm; t - 3306 - led 10w 3000k...

Team

design_connected

$13

Team

...team

designconnected

arper team computer generated 3d model. designed by lievore, alberto.

3ddd

$1

Team 7

...team 7

3ddd

team 7

моделилось с кталога team 7

3ddd

free

team 7

...team 7

3ddd

team 7

стол фабрики team 7.

типы размеров /900,1000/x/1750,2000,2250/x/750/

раздвигается +600 или +1200

3d_export

$99

basketball team

...basketball team

3dexport

basketball team 3d model. rigged. include obj, fbx files.

design_connected

$18

Team - trestle

...team - trestle

designconnected

arper team - trestle computer generated 3d model. designed by lievore, alberto.

3ddd

$1

TEAM 7 Atelier

...team 7 atelier

3ddd

team 7 , стол

производитель team 7

модель atelier

3ddd

$1

Банкетка Flex Team

... , flex team

http://www.abitant.com/products/banketka-flex-team-2014-kilt-pouf

3d_export

$65

mountaineering team

...mountaineering team

3dexport

simple rendering of the scene file

3d_export

$65

Camel team

...camel team

3dexport

simple rendering of the scene file

3ddd

$1

Стол Joha-team - BaumArt

... joha , team

стол от joha-team, под названием baumart

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Work

3d_export

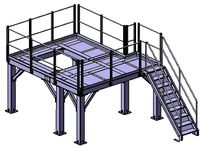

$5

WORKING PLATFORM

...working platform

3dexport

working platform 4000x3000x1500mm

design_connected

$16

Working set

...working set

designconnected

smallaccents working set computer generated 3d model.

3ddd

free

Pinao / Stelar Works

...pinao / stelar works

3ddd

stelar works , stellar works

стулья pinao от stelar works

design_connected

$13

Work Lamp

...work lamp

designconnected

design house stockholm work lamp computer generated 3d model. designed by form us with love.

turbosquid

$6

Road Works

...turbosquid

royalty free 3d model road works for download as on turbosquid: 3d models for games, architecture, videos. (1151328)

3ddd

free

Stellar Works Lumar

...llar works , lumar , барный

stellar works lumar

turbosquid

$20

Work boots

...bosquid

royalty free 3d model work boots for download as stl on turbosquid: 3d models for games, architecture, videos. (1313566)

turbosquid

$8

Desk Work

...osquid

royalty free 3d model desk work for download as blend on turbosquid: 3d models for games, architecture, videos. (1381338)

turbosquid

$5

Work Desk

...osquid

royalty free 3d model work desk for download as blend on turbosquid: 3d models for games, architecture, videos. (1435344)

turbosquid

$1

Plant for work

...uid

royalty free 3d model plant for work for download as obj on turbosquid: 3d models for games, architecture, videos. (1557514)

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...