Thingiverse

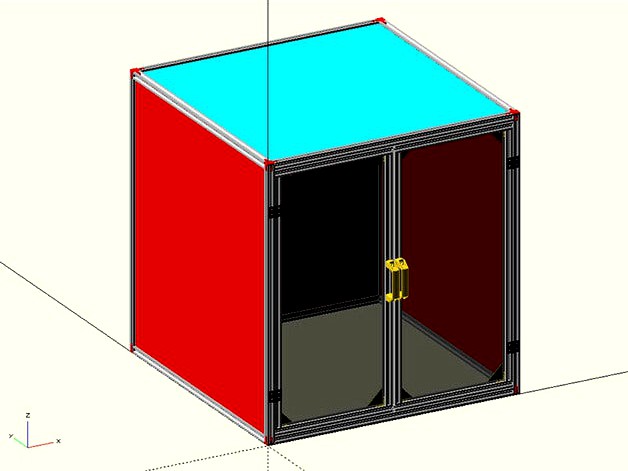

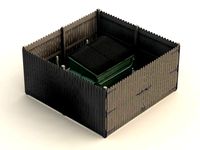

Parametric Enclosure based on Openbuilds Modular Enclosure System by GeoDave

by Thingiverse

Last crawled date: 3 years, 3 months ago

10/17/2020 Update

In Enclosure_Rev9.scad added option for 2020, 2040 or 2060 Door headers since Openbuilds changed their design to use 2060 for the door header. For smaller enclosures you might not need that, so added the 3 options.

For this option set: Hd_Size = 60; //20, 40 or 60

Also added option for 3 or 4 joining plates on the door.

For this option set: JP_Qty = 4; //Set to 3 or 4

The spreadsheet VariableModular_Enclosure_V3.xlsx was also updated by adding the variable line:

Door Header Z Height Size (20, 40 or 60)

This really only affects the cut lengths of Door Vertical Lengths & Door panels.

This is a parametric openscad program to show different size configurations of the Openbuilds Enclosure system which can be found here: https://openbuilds.com/builds/openbuilds-enclosure-series.9535/ There is also a spreadsheet that will give you all the cut sizes. The calculations used here are based on their 3 different configurations & I have not created an enclosure yet, so be aware that there could still be bugs here. That said, the cut size numbers come out correctly for the 3 different sizes Openbuilds sells.

I would like to make my enclosure a little different size that can be used on more than one machine since I will not be using the different machines at the same time. I think Openbuilds is using 1/4" boards for the sides, top & back panels, but I am thinking of just using 20x30" sheets of foam core to start with since they are only $1 each at dollar store. Using the enclosure spreadsheet if I set the Overall Length & Width to 794(mm) & Overall Height to 540(mm), I can use 20x30 foam core panels without cutting them. The top panel would be 30x30 though, so it would need a partial foam core added with the 20x30. Foam core would also might it lighter than using wood.

The door gaps I based on the 3D model of the hinges being 20.4mm between the V-Slot holes, so the side gaps are 0.4mm. The gap between the door panels I calculated based on what openbuilds had for the horizontal lengths of the Door V-Slot extrusions.

This openscad & spreadsheet file uses the 3 way brackets for the corners by default, but if you want to use the 20mm cube corners, change the variable in openscad file to Br_Thk to 20 instead of 5 (or spreadsheet line 3 way Bracket Thickness)

This openscad file uses the following STL files in the model: InHidCornBr.stl, V-Slot_DrHandle.stl & Hinge.stl. These files were converted from Openbuilds 3d models. The other parts of the openscad assembly are modules in the file.

In Enclosure_Rev9.scad added option for 2020, 2040 or 2060 Door headers since Openbuilds changed their design to use 2060 for the door header. For smaller enclosures you might not need that, so added the 3 options.

For this option set: Hd_Size = 60; //20, 40 or 60

Also added option for 3 or 4 joining plates on the door.

For this option set: JP_Qty = 4; //Set to 3 or 4

The spreadsheet VariableModular_Enclosure_V3.xlsx was also updated by adding the variable line:

Door Header Z Height Size (20, 40 or 60)

This really only affects the cut lengths of Door Vertical Lengths & Door panels.

This is a parametric openscad program to show different size configurations of the Openbuilds Enclosure system which can be found here: https://openbuilds.com/builds/openbuilds-enclosure-series.9535/ There is also a spreadsheet that will give you all the cut sizes. The calculations used here are based on their 3 different configurations & I have not created an enclosure yet, so be aware that there could still be bugs here. That said, the cut size numbers come out correctly for the 3 different sizes Openbuilds sells.

I would like to make my enclosure a little different size that can be used on more than one machine since I will not be using the different machines at the same time. I think Openbuilds is using 1/4" boards for the sides, top & back panels, but I am thinking of just using 20x30" sheets of foam core to start with since they are only $1 each at dollar store. Using the enclosure spreadsheet if I set the Overall Length & Width to 794(mm) & Overall Height to 540(mm), I can use 20x30 foam core panels without cutting them. The top panel would be 30x30 though, so it would need a partial foam core added with the 20x30. Foam core would also might it lighter than using wood.

The door gaps I based on the 3D model of the hinges being 20.4mm between the V-Slot holes, so the side gaps are 0.4mm. The gap between the door panels I calculated based on what openbuilds had for the horizontal lengths of the Door V-Slot extrusions.

This openscad & spreadsheet file uses the 3 way brackets for the corners by default, but if you want to use the 20mm cube corners, change the variable in openscad file to Br_Thk to 20 instead of 5 (or spreadsheet line 3 way Bracket Thickness)

This openscad file uses the following STL files in the model: InHidCornBr.stl, V-Slot_DrHandle.stl & Hinge.stl. These files were converted from Openbuilds 3d models. The other parts of the openscad assembly are modules in the file.

Similar models

thingiverse

free

Panel/Corner Bracket by Taalan

...dded file for pins to hold the foam core panels. i would reduce the size to 95% to make sure they will fit easily into the holes.

thingiverse

free

28mm Doors & Windows for Foam Core by kristof65

...re.

cut an appropriate size hole, and glue in place.

check back periodically, as i create new variations, i will add them here.

thingiverse

free

BI 2.5 Inexpensive enclosure 2.5 by joker55

... 1/14/15 i still need to make some flaps to fill the gap at the bottom sides & gopro mount.. will post when i can get to it.

thingiverse

free

Customizable Polygonal Picture Frame by GeoDave

...rated stl files using netfabb & i have not figured out how to fix that. i usually run my stl files thru that program anyway.

thingiverse

free

Foldable Solar Panel - 136 x 100 by n8twj

...el and i also removed the usb/dupont box option, as i already have an external enclosure for 18650s and tp4056 charge controller.

thingiverse

free

Parametric Carbon Fiber Arrow Cutting Jig for 3d Printer Delta Arms by GeoDave

...x 500mm's for the bottom & 1x 2040 x 500mm's for the top. that will give me a rod length of about 515mm by my calcs.

thingiverse

free

LED panel ceiling mounting bracket by alan_deane

...bracket by alan_deane thingiverse bracket to mount 40w (and similar led panels to a ceiling. gap for panel is...

thingiverse

free

Parametric Tetrahedron Top for Delta 3D Printer by GeoDave

...a i am building is called an emmett-delta & the build log is located here:http://www.openbuilds.com/builds/emmett-delta.3052/

thingiverse

free

Foam Core Stand by CompositionArts

...uct photography to bounce light onto your subject.

separate models for different foam core sizes:

3/32"

1/8"

3/16"

thingiverse

free

foam printer enclosure clips by jhtitan

...a set of handles and a stop for the doors as well. i will add them when i am done.

** added handle set and updated render image

Geodave

thingiverse

free

Shower Caddy accessory holder by GeoDave

... upside down on out shower caddy. i did this a few months back, but changed the design recently to make it stay in place better.

thingiverse

free

Wood Bracket with Wire Clip by GeoDave

...be either at 0 or 90 degrees to wood bracket. i included the openscad & dxf files if you want to adjust this to other sizes.

thingiverse

free

Gimbal Spinner by GeoDave

...elow 24mm for the inside width clearance distance or below 54mm for the gimbal distance. i will take a look at fixing that soon.

thingiverse

free

Spinning Top with Thumbwheel by GeoDave

... works.

https://youtu.be/fpaissfvmqm

here is the openscad source file for the thumbwheelhttps://www.thingiverse.com/thing:2407027

thingiverse

free

Parametric Shaft Coupler by GeoDave

... - m3x14mm bolts & locknuts for the 5mm to 5mm that is shown printed in yellow petg.

you can also open this in the customizer

thingiverse

free

Thumbwheel for a Jack Screw by GeoDave

...ese parts, i realized this might make a good spinning top. here is a link to that top. https://www.thingiverse.com/thing:2407034

thingiverse

free

Remix of Meade Autostar holder for LXD75/LX90 mount by GeoDave

... added 1mm extra around the holes.

i used 2 - m3x16mm screws with locknuts & printed at 40% infill with esun silver pla pro.

thingiverse

free

Parametric Tapered Spacer by GeoDave

... the larger diameter against the wheels & they did not roll at all. the 2nd & 3rd photo should show what i mean by this.

thingiverse

free

A Very Customizable Funnel by GeoDave

...gs in the openscad script.

i changed the hook_xx variable names to a more appropriate eye_xx names after a friend mentioned this.

thingiverse

free

Parametric Honeycomb containers by GeoDave

...file to varie the size of them based on 8 variables. since making this, i have made a number of containers for various purposes.

Openbuilds

3d_export

free

openbuilds lead cnc laser mount for opt lasers

...nload at:<br>to learn more about engraving and cutting cnc lasers that can be mounted with this item, click the link below:

thingiverse

free

OpenBuilds LEAD by OpenBuilds

...nyone to modify it to make it longer/taller or add attachments for adding a diode laser, a plasma an extruder among other things.

thingiverse

free

Openbuilds logo by olo2000pm

...openbuilds logo by olo2000pm

thingiverse

openbuilds logo

thingiverse

free

OpenBuilds Standard Spacer by TheMadScientist

...emadscientist

thingiverse

spacer with no offset and a 7.1mm hole for mounting openbuild slider wheels to openbuild mount plates.

thingiverse

free

Openbuilds aluminum profiles by Artu66

...openbuilds aluminum profiles by artu66

thingiverse

aluminum profiles openbuilds

thingiverse

free

Openbuilds Filament Filter by olo2000pm

...openbuilds filament filter by olo2000pm

thingiverse

openbuilds filament filter

thingiverse

free

Openbuilds Nut Block

...erted it to stl for who ever would like to use it ..again this is openbuilds not mine... use at your own risk...happy printing :)

thingiverse

free

Openbuilds CBeam End Plate

... end mount plate that was converted from grabcad.com to an stl this is openbuilds not mine use at your own risk happy printing ;)

thingiverse

free

Openbuilds M5 T-Nut

...openbuilds m5 t-nut

thingiverse

openbuilds slim t-nut with one m5 thread

thingiverse

free

Openbuilds Mountplate by TheMadScientist

...plate with regulation spaced/sized holes for openbuilds v slot rails

untested - if anyone prints, please let me know if it works!

Parametric

turbosquid

$25

Parametric

...oyalty free 3d model parametric for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1683196)

3ddd

$1

Parametric Wall

...parametric wall

3ddd

панель

parametric wall with shelf

3d_export

$5

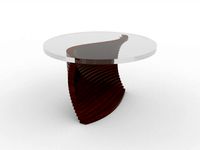

parametric table

...parametric table

3dexport

parametric table model created on rhinoceros 6. this 3d model includes: .gh, .3dm files

turbosquid

$2

parametrical chandelier

...lty free 3d model parametrical chandelier for download as dxf on turbosquid: 3d models for games, architecture, videos. (1257635)

turbosquid

$2

Parametric Seat

...id

royalty free 3d model parametric seat for download as max on turbosquid: 3d models for games, architecture, videos. (1691557)

turbosquid

$2

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1690373)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691303)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691148)

turbosquid

$19

Parametric Bench

...ty free 3d model parametric bench for download as max and max on turbosquid: 3d models for games, architecture, videos. (1713396)

turbosquid

free

Parametric wall

...ee 3d model parametric wall for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1356869)

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

Modular

3ddd

$1

MODULAR

...modular

3ddd

modular , врезной свет

modular потолочные светильники

3ddd

$1

Modular Spock

...modular spock

3ddd

modular

modular spock

3ddd

$1

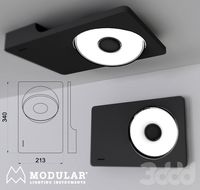

MODULAR / Spock

...modular / spock

3ddd

modular

modular/spock

design_connected

$7

Modular

...modular

designconnected

emmemobili modular shelves and storage computer generated 3d model. designed by ferruccio laviani.

3ddd

$1

Modular spock

...modular spock

3ddd

modular

spock wall led

turbosquid

$25

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570923)

turbosquid

$15

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570304)

3ddd

$1

Modular 2FLAT2C

...modular 2flat2c

3ddd

modular

modularhttp://www.supermodular.com/

3d_export

free

Modular walls

...modular walls

3dexport

modular walls for playing without materials and textures

3ddd

$1

Modular / Lighting Juliette

...modular / lighting juliette

3ddd

modular

modular lighting juliette

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Based

archibase_planet

free

Base

...base

archibase planet

base column column base

base 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base ionic - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base tuscan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$18

Base

...base

designconnected

tom dixon base computer generated 3d model. designed by dixon, tom.