Thingiverse

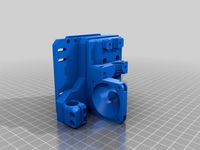

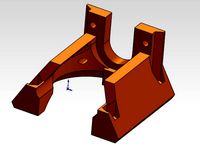

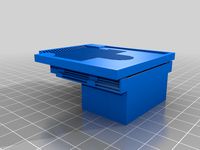

P3 Steel Direct Drive Hotend by PerfectFirstLayer

by Thingiverse

Last crawled date: 3 years ago

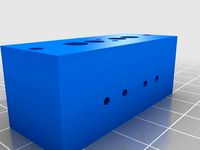

This is a modification for implementing direct drive for the P3 Steel. If you have built the AU P3 Steel you will need only two 45 mm M3 screws in addition to the original hardware. I used these:

http://www.thansen.dk/product.asp?n=511490482&pn=511491043

Secure your PTFE (bowden) tube to the top part of the printer to eliminate jerking in filament when x-axis moves. This can be done with cable ties and a glue gun (see pictures)

As extruder I used this: http://www.thingiverse.com/thing:754217 by Phil_Maddox

I reccomend printing this in PETG or ABS since the fan duct comes close to the hotend.

Things needed to make this:

PTFE tube 30 cm

PTFE tube 10 cm

Nema 17 stepper motor

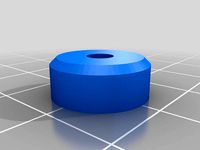

Induction probe

Radial Fan 50 mm

E3D V6 Universal hotend full kit

2 x 45 mm M3 bolts (40 mm might be enough)

3 x 10 mm M3 bolt

3 x M3 nuts

cable ties

Edit 12/7/2017

Added ver. 2 of same design with small changes.

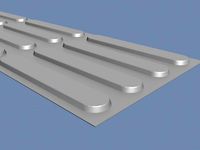

The "platform" for induction sensor made thinner to make more room for sensor threading on top and bottom. This gives more room for the nuts on sensor.

Made the fan duct a couple of mm lower (further away from heatbed) to avoid collisions with bed mounting bolts.

Edit 10/01/18:

Added version with 18 mm hole for sensor, not yet tested. Not sure if it can reach the plate.

http://www.thansen.dk/product.asp?n=511490482&pn=511491043

Secure your PTFE (bowden) tube to the top part of the printer to eliminate jerking in filament when x-axis moves. This can be done with cable ties and a glue gun (see pictures)

As extruder I used this: http://www.thingiverse.com/thing:754217 by Phil_Maddox

I reccomend printing this in PETG or ABS since the fan duct comes close to the hotend.

Things needed to make this:

PTFE tube 30 cm

PTFE tube 10 cm

Nema 17 stepper motor

Induction probe

Radial Fan 50 mm

E3D V6 Universal hotend full kit

2 x 45 mm M3 bolts (40 mm might be enough)

3 x 10 mm M3 bolt

3 x M3 nuts

cable ties

Edit 12/7/2017

Added ver. 2 of same design with small changes.

The "platform" for induction sensor made thinner to make more room for sensor threading on top and bottom. This gives more room for the nuts on sensor.

Made the fan duct a couple of mm lower (further away from heatbed) to avoid collisions with bed mounting bolts.

Edit 10/01/18:

Added version with 18 mm hole for sensor, not yet tested. Not sure if it can reach the plate.

Similar models

thingiverse

free

Hotend for Prusa P3 w/ mounts for cablechain, induction sensor, blower fan by FrederikS

...

e3 v6d

induction sensor

blower fan

led strip

cable chain

works with following cable chain:http://www.thingiverse.com/thing:11978

thingiverse

free

Direct Drive for Briss Moto Ender 3 Fang duct by wku_wake

....

future updates will include with and without cable chain mount, with and without ptfe tube connection for the filament sensor.

thingiverse

free

Cheap and simple direct extruder mount for Tronxy X5SA by DizelTH

... old hotend radiator, pneumo fitting and some cable ties.

compatible with this fan duct https://www.thingiverse.com/thing:4826662

thingiverse

free

P3 Steel hotend mount with fan and proximity sensor by hinge

...r the p3steel alu x-sled. which holds hotend, radial fan and proximity sensor in one. modified by xoffer. including the fan duct.

thingiverse

free

Inductive sensor holder by andergrin

...r for 12 mm diameter inductive sensor.

update: added holder for 18 mm diameter sensor. you can use m3 insert nut, or regular nut.

thingiverse

free

Improved fan duct and inductive probe holder for Voron X-carriage by Laurman

....2 fan duct which directs most of the air to the part and not to the hotend. it has holes for m2 screws (because of 3dsway fans).

thingiverse

free

E3D Bowden to Direct converter ( PTFE lock nut ) by rdware

...ect converter ( ptfe lock nut ) by rdware

thingiverse

a nut to lock the ptfe tube in e3d bowden hotend ad use it in direct mode.

thingiverse

free

Ender 3 Gratch Fan Duct by IgorGratch

..._duct.

increased model_fan_duct wall thickness for greater stability.

update 27.02.2021

added a mount for the left bmg extruder.

thingiverse

free

Ender 3 BTT Smart Sensor & Direct Drive Filament path mounts by skrutch

...r the extruder replacement piece could be for a closed filament system. feeding from the filament box to the direct drive system.

thingiverse

free

Hypercube E3D Titan Direct Drive Mount and Fan Duct by butchja

...m/thing:2514542

edit 14/01/2018: added x-carriage based on 1.2 version with extra nut holes.

edit 22/03/2018: added bltouch mount

P3

3d_export

$29

P3 3D Model

...p3 3d model

3dexport

3d interior cabana

p3 3d model arturrabello 3211 3dexport

3ddd

$1

Wunderlicht YL7502AB-P3

...wunderlicht yl7502ab-p3

3ddd

wunderlicht

подвес wunderlicht yl7502ab-p3 bronze cell 4xe14 60w

3ddd

free

Luce YW9988-P3 Wunderlicht

...luce yw9988-p3 wunderlicht

3ddd

wunderlicht

http://www.svet-opt.ru/catalog/lyustry/wd_yw9988-p3/

design_connected

$11

Aeon Rocket P1, P3

...aeon rocket p1, p3

designconnected

lightyears aeon rocket p1, p3 computer generated 3d model. designed by voss, morten.

3ddd

$1

Wunderlicht 9833AB-P3

...rlicht (germany)

height: 770 mm.

the diameter (width) 240 mm.

quantity and power of lamps: 3x40w e14

color: brass

material: metal

3ddd

$1

Wunderlicht Cool Lake YL7322AB-P3

...liсht yl7322ab-p3

ссылка на сайт производителя:http://www.wunderlicht.ru/catalog/podvesnye-svetilniki/yl7322ab-p3.html

cg_studio

$50

Kitchen P3 set3d model

...el

cgstudio

.3ds .lwo .max .obj .pz3 - kitchen p3 set 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Luce YW9988-P3

...luce yw9988-p3

3ddd

wunderlicht

модель под крупные ракурсы. mat vray. лампочка 3ddd.

humster3d

$40

3D model of Kitchen Set P3

...uy a detailed 3d model of kitchen set p3 in various file formats. all our 3d models were created maximally close to the original.

cg_studio

$129

Ferrari p330 P3 19663d model

...

.3ds .c4d .fbx .lwo .max .obj - ferrari p330 p3 1966 3d model, royalty free license available, instant download after purchase.

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Steel

3d_export

$10

Mask steel

...mask steel

3dexport

mask steel

turbosquid

$35

steel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

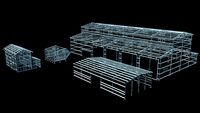

Steel Construction

...steel construction

3docean

construction frame h-beam house steel

4 models of steel construction. maya, obj, fbx

3ddd

$1

steel door

...steel door

3ddd

двери

steel door with black paint

archibase_planet

free

Steel Post

...steel post

archibase planet

fence balustrade

balustrade steel post

3d_export

$5

steel chair

...el chair

3dexport

a steel chair with leather and steel materials. 555.41 x 490.11 x 794 yes contains 4 leather materials 4.2

3d_export

$7

steel teapot

...steel teapot

3dexport

simple steel teapot. physical render. 28k polygons

3d_export

$25

tower steel

...tower steel

3dexport

steel tower 200 meters hight. autodesk revit 2019.2

3d_ocean

$4

Steel Tap

...athroom faucet green tiles shining faucet steel tap wall mounted silver tap

steel faucet mounted on green tiled wall of bathroom.

3d_export

$9

Steel Barrel

...steel barrel

3dexport

steel barrel - includes new and aged version - 4k png textures