Thingiverse

Open source bullet feeder / collator - 223/556 (Dillion 650, Hornady L&L etc) by gzcwnk

by Thingiverse

Last crawled date: 3 years ago

*April 2019

As a moron went and killed 50 people NZ is about to lose all access to AR15s etc hence no more development on 223R for this. If I do continue it will be on 308W I suspect.

December 2018

Seems to work OK. If you have issues drop me a comment on the problem.

Source code files are provided allowing you to mod parts to suit your need. Hence I will not be re-designing for you. ie step / f3d code is here to download. If you want a new calibre please copy the "source code" step or f3d file to your PC and re-design your own need.

Designed to be printed on a 200x200mmx170mm high 3D printer (specifically a Wanhao D6). Material eSun PLA+ or PETG.

223 / 556 bullet collator assembly is for 55gr flat base FMJs or BT 62gr FMJs as tested below,

Current status

7-July 2018

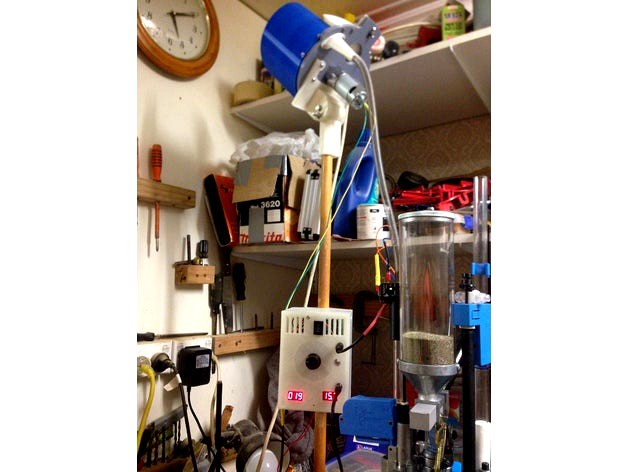

Mounted on Dillon650, functional test ie feeding bullets down to the press is good.

28th-August 2018

30cal drop tube added but note, un-tested.

https://youtu.be/zY6zK0Xbe7I

Next need to write,

i) BoM (bill of materials)

ii) Build guide

Other parts

a) Steel drive flange, you will have to tap the 3mm holes M4 yourself. https://www.aliexpress.com/item/4-Set-of-Rigid-Flange-Coupling-Motor-Guide-Shaft-Coupler-Motor-Connector-6mm-with-Wrench-and/32854922468.html

b) Suitable motor

i) (ZGB37RH 12VDC 37mm speed 15rpm (though 10rpm maybe the better choice) https://www.aliexpress.com/item/ZGB37RH-12VDC-37mm-10-15-20-30-45-50-80-100-120-200-300-800RPM-Large/32813387794.html

I have a 12volt 10rpm motor coming as this seems a better bet and cheaper, watch this space!

ii) You could try a 24volt motor of 5rpm or 10rpm and run it at 9volts or maybe less, cheaper and simpler but I have not tried it yet. https://www.aliexpress.com/item/24VDC-37mm-Large-torque-gear-motor-100RPM-ZGB37RH-Positive-inversion-ECCenter-shaft-with-ZYDT555-motor/32811176919.html

I have 24volt 5rpm motor coming as this seems a better bet and cheaper, watch this space!

c) Straight power supply or a Suitable motor controller,

i) The easiest way is find a 24volt motor instead of the 12v I have listed and a 3~12volt adjustable PSU and drop the voltage to get it to run as slow as possible, 1amp or better a 1.5amp unit.

ii) Alternatively a controller, https://www.aliexpress.com/item/Digital-display-PWM-speed-controller-DC-motor-0-100-adjustable-drive-module-Input-12V-24V-40A/32856323198.html

d) 3.3mm drills as a tap size for M4. https://www.aliexpress.com/item/High-Quality-2015-Highly-Commend10-pcs-3-3mm-HSS-Electrical-Drilling-Twist-Drill-Bit/32701217157.html

e) M3 stainless steel hex heads bolts.

i) 12mm x 6 for motor

ii) 8mm x 9 for wall

iii) 12mm x 2 for bullet damper

iv) 25mm x 2 for nose guide assembly

x) M3 SS nuts x 1

y) 3mm SS washers x ? 24?

f) brass thread inserts,

i) M3, x 11

ii) M4 x 4

y) 4mm SS washers x ? 8?

g) This design will use Mr BulletFeeder Pro 223 bullet seater to place bullet on case as its the cheapest I can find without designing my own one.

h) Bag each (50) of 3mm and 4mm washers

i) Metric HSS tap set (these are really good taps). https://www.aliexpress.com/item/Spiral-Pointed-Taps-Tapping-Thread-Forming-Tap-Titanium-Coated-Hss-5pc-Metric-Spiral-Fluted-Machine-Screw/32476583120.html

j) tap set T bar. https://www.aliexpress.com/item/Adjustable-3-8mm-T-Handle-Ratchet-Tap-Wrench-with-5pcs-M3-M8-Machine-Screw-Thread-Metric/32741340742.html

k) M4 bolts

i) 22mm SS hex screws x 4 collator to drive flange.https://www.aliexpress.com/item/100pcs-Lot-Metric-Thread-M4-6-8-10-12-14-16-18-20-22-25-30/32608294243.html

ii) 10mm SS hex screws x 4 to mount base

iii) 10mm SS hex screw x 2 to mount scraper

l) This will need a mechanism to place the bullet on the case, Hornady and RCBS to name but 2 do these.

FAQ

1) The bullets do not drop into the fed tube/shoot from the collator. This is usually down to

a) burrs or some remaining brim on the bottom of the U of the collator plate, carefully clean these off with a sharp knife.

b) Angle of unit too steep. This causes the bullets to drop slower so slow the motor down or lessen the angle.

2) Collator cant hold many projectiles. This is an issue. For the mk2 I will mod the base plate to take 2 bearings (of some sort) to go under the collator plate to take the weight off the motor. This should allow a decent amount of projectiles. Until then throw <200 in at a time.

3) What angle is best to set the unit at? This is a very good question. It is about 47Deg or a little more, 51 Degree is too much.

4) I have bigger/different bullets. You will need to take the collator plate model provided in the step file and modify it to suit. Also the nose guide design and ramp may want changing.

5) Bigger (longer) than 62gr FMJs do not un-invert reliably. Probably the collator plate needs to be made thicker so there is more support for the projectile in the U slot.

6) I have round / soft nose bullets. The 55gr FMJ collator plate will probably work best as the too thick a plate of the 62gr FMJs might cause 2 bullets to stack, or bullets may not de-invert well. I suggest a nose flipper per caliber and type of bullet, they only take about 45mins to print anyway. So set them up on the set screw and leave as is.

Notes

Updates/progress (historic notes for me mostly)

22-May-2018

Uploaded 223 bullet collator plate modded to suit drive flange.

Uploaded bullet collator base plate modded to suit drive flange.

i) Collator plate (mk2d - 22/5/2018)

ii) Nose guide plate and distance plate (mk1b - 21/4/2018)

iii) nose flip ramp (Mk1 - 20-4-2018)

iv) collator base body (mk1d - 22/5/2018)

v) Tube converter to Mr Bullet Feeder 10mm (small) slinky tube (mk1b - 21/4/2018)

25-May

i) Updated collator base body (mk1f 25-5-2018), alterations to better suit motor flange, and "thinned" to speed up printing. Added more side holes to spread load on wall.

ii) Added a spring steady to try and stop the projectile bouncing around so much (this needs work still)

30-May

i) Updated collator base body (mk1j 25-5-2018) Added more side holes to spread load on wall.

ii) New base wall, twice as thick (mk1e 29-5-2018) Will probaby need ribs to strengthen further.

iii) 223 Collator, added a 3mm recess for the screws to suit 20mm M4 bolts as 22mm are hard to get.

iv) 2x Test legs 45Deg.

4-June

i) 223 Collator re-design work. Bullets can stick on the 45Deg ramp and not drop into the "U" slot. Also when the bullet is "nose" down it looks / is unstable. Made the collator 8mm thicker and changed the angle to 70Deg, seems to have improved this issue.

Bugger notes lost...thanks thingiverse.

5-June

i) new adjustable test feet giving 45Deg+ but 45Deg is not a bad angle.

ii) Totally new (mk2) flip ramp, 11mm taller to match taller collator plate, waiting in queue to print.

6-June

i) Collator plate seems Ok on 55gr flat base but for 62gr when inverted they are to unstable. So I have left the design as is for 55gr and am trying a new 5mm deeper collator plate for 62gr fmjs.

ii) Designed a new nose guide for inverted 62gr projectiles.

7-June

i) new deeper/thicker collator plate works really well with 62gr FMJs.

ii) mk2 "improved" nose guide spacer done but may not now be needed.

iii) Scraper for inside to "scrap" any more than 1 projectile out of a U slot.

10-June

Initial testing went fine, now doing a "proper" test print. The best angle is about 53Degress. the tool shown to check this is on aliexpress for about $18US.

11-June

Base printed starting to assemble beta unit.

13-June

Beta unit ready for testing.

22-June-2018 5rpm motors arrived. However I am not sure if slower is a huge improvement. Occasional jam as bullet is slow to drop into shoot as the "right" angle is hard to find 53Deg is too steep IMHO. Added a bigger chamfer to the shute to try and fix this so base will need re-printing :(

Needs a bullet steady / plate to hold the projectile into the U.

23-June Changed angle to 47Deg, almost faultless in 1000 rounds. So its not less than 46Deg and not more than 50Deg. Currently back on the old 15rpm motor as I found my issues with speed control was down to a bad PSU and the 15rpm motor is a better motor. Currently running at 3rpm and 47Deg.

I now find with a good PSU I can run at 15% on the speed controller which is about 2~3rpm.

24-June-2018

Uploaded a mk1 standalone stand that screws to the benchtop for the bullet feeder. This way anyone can use it on any press with no changes or unique bits. Needs a 20mm round dowel of length > 1m (to be determined)

300 round test, 62gr FMJs 3 to 15rpm at 47Deg incline.

https://youtu.be/15Gr9stidR8

30-June-2018

Mounted bullet feeder "on" press using the bench stand.

1-July-2018

Working on controller case, currently printing it.

As a moron went and killed 50 people NZ is about to lose all access to AR15s etc hence no more development on 223R for this. If I do continue it will be on 308W I suspect.

December 2018

Seems to work OK. If you have issues drop me a comment on the problem.

Source code files are provided allowing you to mod parts to suit your need. Hence I will not be re-designing for you. ie step / f3d code is here to download. If you want a new calibre please copy the "source code" step or f3d file to your PC and re-design your own need.

Designed to be printed on a 200x200mmx170mm high 3D printer (specifically a Wanhao D6). Material eSun PLA+ or PETG.

223 / 556 bullet collator assembly is for 55gr flat base FMJs or BT 62gr FMJs as tested below,

Current status

7-July 2018

Mounted on Dillon650, functional test ie feeding bullets down to the press is good.

28th-August 2018

30cal drop tube added but note, un-tested.

https://youtu.be/zY6zK0Xbe7I

Next need to write,

i) BoM (bill of materials)

ii) Build guide

Other parts

a) Steel drive flange, you will have to tap the 3mm holes M4 yourself. https://www.aliexpress.com/item/4-Set-of-Rigid-Flange-Coupling-Motor-Guide-Shaft-Coupler-Motor-Connector-6mm-with-Wrench-and/32854922468.html

b) Suitable motor

i) (ZGB37RH 12VDC 37mm speed 15rpm (though 10rpm maybe the better choice) https://www.aliexpress.com/item/ZGB37RH-12VDC-37mm-10-15-20-30-45-50-80-100-120-200-300-800RPM-Large/32813387794.html

I have a 12volt 10rpm motor coming as this seems a better bet and cheaper, watch this space!

ii) You could try a 24volt motor of 5rpm or 10rpm and run it at 9volts or maybe less, cheaper and simpler but I have not tried it yet. https://www.aliexpress.com/item/24VDC-37mm-Large-torque-gear-motor-100RPM-ZGB37RH-Positive-inversion-ECCenter-shaft-with-ZYDT555-motor/32811176919.html

I have 24volt 5rpm motor coming as this seems a better bet and cheaper, watch this space!

c) Straight power supply or a Suitable motor controller,

i) The easiest way is find a 24volt motor instead of the 12v I have listed and a 3~12volt adjustable PSU and drop the voltage to get it to run as slow as possible, 1amp or better a 1.5amp unit.

ii) Alternatively a controller, https://www.aliexpress.com/item/Digital-display-PWM-speed-controller-DC-motor-0-100-adjustable-drive-module-Input-12V-24V-40A/32856323198.html

d) 3.3mm drills as a tap size for M4. https://www.aliexpress.com/item/High-Quality-2015-Highly-Commend10-pcs-3-3mm-HSS-Electrical-Drilling-Twist-Drill-Bit/32701217157.html

e) M3 stainless steel hex heads bolts.

i) 12mm x 6 for motor

ii) 8mm x 9 for wall

iii) 12mm x 2 for bullet damper

iv) 25mm x 2 for nose guide assembly

x) M3 SS nuts x 1

y) 3mm SS washers x ? 24?

f) brass thread inserts,

i) M3, x 11

ii) M4 x 4

y) 4mm SS washers x ? 8?

g) This design will use Mr BulletFeeder Pro 223 bullet seater to place bullet on case as its the cheapest I can find without designing my own one.

h) Bag each (50) of 3mm and 4mm washers

i) Metric HSS tap set (these are really good taps). https://www.aliexpress.com/item/Spiral-Pointed-Taps-Tapping-Thread-Forming-Tap-Titanium-Coated-Hss-5pc-Metric-Spiral-Fluted-Machine-Screw/32476583120.html

j) tap set T bar. https://www.aliexpress.com/item/Adjustable-3-8mm-T-Handle-Ratchet-Tap-Wrench-with-5pcs-M3-M8-Machine-Screw-Thread-Metric/32741340742.html

k) M4 bolts

i) 22mm SS hex screws x 4 collator to drive flange.https://www.aliexpress.com/item/100pcs-Lot-Metric-Thread-M4-6-8-10-12-14-16-18-20-22-25-30/32608294243.html

ii) 10mm SS hex screws x 4 to mount base

iii) 10mm SS hex screw x 2 to mount scraper

l) This will need a mechanism to place the bullet on the case, Hornady and RCBS to name but 2 do these.

FAQ

1) The bullets do not drop into the fed tube/shoot from the collator. This is usually down to

a) burrs or some remaining brim on the bottom of the U of the collator plate, carefully clean these off with a sharp knife.

b) Angle of unit too steep. This causes the bullets to drop slower so slow the motor down or lessen the angle.

2) Collator cant hold many projectiles. This is an issue. For the mk2 I will mod the base plate to take 2 bearings (of some sort) to go under the collator plate to take the weight off the motor. This should allow a decent amount of projectiles. Until then throw <200 in at a time.

3) What angle is best to set the unit at? This is a very good question. It is about 47Deg or a little more, 51 Degree is too much.

4) I have bigger/different bullets. You will need to take the collator plate model provided in the step file and modify it to suit. Also the nose guide design and ramp may want changing.

5) Bigger (longer) than 62gr FMJs do not un-invert reliably. Probably the collator plate needs to be made thicker so there is more support for the projectile in the U slot.

6) I have round / soft nose bullets. The 55gr FMJ collator plate will probably work best as the too thick a plate of the 62gr FMJs might cause 2 bullets to stack, or bullets may not de-invert well. I suggest a nose flipper per caliber and type of bullet, they only take about 45mins to print anyway. So set them up on the set screw and leave as is.

Notes

Updates/progress (historic notes for me mostly)

22-May-2018

Uploaded 223 bullet collator plate modded to suit drive flange.

Uploaded bullet collator base plate modded to suit drive flange.

i) Collator plate (mk2d - 22/5/2018)

ii) Nose guide plate and distance plate (mk1b - 21/4/2018)

iii) nose flip ramp (Mk1 - 20-4-2018)

iv) collator base body (mk1d - 22/5/2018)

v) Tube converter to Mr Bullet Feeder 10mm (small) slinky tube (mk1b - 21/4/2018)

25-May

i) Updated collator base body (mk1f 25-5-2018), alterations to better suit motor flange, and "thinned" to speed up printing. Added more side holes to spread load on wall.

ii) Added a spring steady to try and stop the projectile bouncing around so much (this needs work still)

30-May

i) Updated collator base body (mk1j 25-5-2018) Added more side holes to spread load on wall.

ii) New base wall, twice as thick (mk1e 29-5-2018) Will probaby need ribs to strengthen further.

iii) 223 Collator, added a 3mm recess for the screws to suit 20mm M4 bolts as 22mm are hard to get.

iv) 2x Test legs 45Deg.

4-June

i) 223 Collator re-design work. Bullets can stick on the 45Deg ramp and not drop into the "U" slot. Also when the bullet is "nose" down it looks / is unstable. Made the collator 8mm thicker and changed the angle to 70Deg, seems to have improved this issue.

Bugger notes lost...thanks thingiverse.

5-June

i) new adjustable test feet giving 45Deg+ but 45Deg is not a bad angle.

ii) Totally new (mk2) flip ramp, 11mm taller to match taller collator plate, waiting in queue to print.

6-June

i) Collator plate seems Ok on 55gr flat base but for 62gr when inverted they are to unstable. So I have left the design as is for 55gr and am trying a new 5mm deeper collator plate for 62gr fmjs.

ii) Designed a new nose guide for inverted 62gr projectiles.

7-June

i) new deeper/thicker collator plate works really well with 62gr FMJs.

ii) mk2 "improved" nose guide spacer done but may not now be needed.

iii) Scraper for inside to "scrap" any more than 1 projectile out of a U slot.

10-June

Initial testing went fine, now doing a "proper" test print. The best angle is about 53Degress. the tool shown to check this is on aliexpress for about $18US.

11-June

Base printed starting to assemble beta unit.

13-June

Beta unit ready for testing.

22-June-2018 5rpm motors arrived. However I am not sure if slower is a huge improvement. Occasional jam as bullet is slow to drop into shoot as the "right" angle is hard to find 53Deg is too steep IMHO. Added a bigger chamfer to the shute to try and fix this so base will need re-printing :(

Needs a bullet steady / plate to hold the projectile into the U.

23-June Changed angle to 47Deg, almost faultless in 1000 rounds. So its not less than 46Deg and not more than 50Deg. Currently back on the old 15rpm motor as I found my issues with speed control was down to a bad PSU and the 15rpm motor is a better motor. Currently running at 3rpm and 47Deg.

I now find with a good PSU I can run at 15% on the speed controller which is about 2~3rpm.

24-June-2018

Uploaded a mk1 standalone stand that screws to the benchtop for the bullet feeder. This way anyone can use it on any press with no changes or unique bits. Needs a 20mm round dowel of length > 1m (to be determined)

300 round test, 62gr FMJs 3 to 15rpm at 47Deg incline.

https://youtu.be/15Gr9stidR8

30-June-2018

Mounted bullet feeder "on" press using the bench stand.

1-July-2018

Working on controller case, currently printing it.

Similar models

thingiverse

free

Open source case feeder - 223R/556Nato or 308W (Dillion 650, Hornady L&L etc) by gzcwnk

...use aliexpress? and not say amazon or ebay?

because i am not in the usa and shipping hurts.

please note this is gpl2/3 licenced.

grabcad

free

.223 REM FMJ

....223 rem fmj

grabcad

.223 remington with full metal jacket bullet

3dwarehouse

free

5.56mm / .223 Rem.

... / .223 rem.

3dwarehouse

steel casing. copper jacket. 55gr. 5.56mm / .223 remington round. #223_rem #556mm #bullet #steel_casing

thingiverse

free

Bullet Collator Feed Plates and Guides by RickJ19Zeta8

... 5.56 62gr v-max.

the ramp is more universal but the collators are for the specific bullet design and may not work with others.

thingiverse

free

Bullet Feeder Collator Wheel - Clutch Type by davetpilot

.../2021

the .308 plate is repaired and back up.

the .308 hub is back up. (each plate has its own hub but the clutch is universal.)

thingiverse

free

Brushless 48mm cover + bracket original = joeynovak by pek

...?spm=a2g0s.9042311.0.0.27424c4dlz1gvb

7-gearhttps://www.aliexpress.com/item/33031516913.html?spm=a2g0s.9042311.0.0.27424c4dsll0v1

thingiverse

free

Ka-Radio WiFi Internet radio

...k, so i used https://www.aliexpress.com/item/32574110297.html )

2" speakers https://www.aliexpress.com/item/32593991938.html

thingiverse

free

Base v2 by JanSpiesZA

...ws the use of a screw to adjust the nose guide without removing the collator and side wall.

use this together with nose guide v2.

3dwarehouse

free

Bullet

...bullet

3dwarehouse

a .50 caliber bullet #223 #50 #556 #762 #armor #caliber #calibre #core #fmj #piercing #steel

thingiverse

free

Bluetooth speaker - " Hi-Fi stereo boombox " by Tupuh

...ml

power switchhttps://www.aliexpress.com/item/4001165826718.html

embedded nutshttps://www.aliexpress.com/item/4000585933306.html

Dillion

turbosquid

$2

Cabinet drawer handle Dillion

...del cabinet drawer handle dillion for download as fbx and dae on turbosquid: 3d models for games, architecture, videos. (1463399)

thingiverse

free

Dillion 750-650 by Dave855

...dillion 750-650 by dave855

thingiverse

thingiverse

free

Dillion Primer and Powder holder by Archer60x

...r by archer60x

thingiverse

i made a tray/holder to keep the primer and powder parts that i do not have in my dillion 550c press.

thingiverse

free

Dillion Primer Pick up Tube Holder by Archer60x

...p a lot of my reloading tools on the wall so i made this so my pick up tubes snap into it.

use pteg so it is a bit more flexible.

thingiverse

free

Dillion 550 Tool Head Holder Wall Mount by Danimal300

...ded to be reamed out a little bit to fit the pins.

here is the link to the fusion360 models for download:

http://a360.co/2ipqxne

thingiverse

free

Open source case feeder - 223R/556Nato or 308W (Dillion 650, Hornady L&L etc) by gzcwnk

...use aliexpress? and not say amazon or ebay?

because i am not in the usa and shipping hurts.

please note this is gpl2/3 licenced.

grabcad

free

Dillion Primer Tube Holder

...dillion primer tube holder

grabcad

mount to wall and holds set of primer tubes for dillion reloading equipment. 8.5mm slot width

cg_trader

$12

Dillion Harper Cute Teen Pornstar Printable | 3D

...in 2012; she has appeared in x-rated features for such notable companies as devil's film, diabolic video, and new sensations.

3dwarehouse

free

Dillion Hood

...dillion hood

3dwarehouse

Gzcwnk

thingiverse

free

6040z case upgrades by gzcwnk

...6040z case upgrades by gzcwnk

thingiverse

modification & upgrade of 6040z cnc case.

thingiverse

free

Linear Ox Openbuilds CNC by gzcwnk

...linear ox openbuilds cnc by gzcwnk

thingiverse

a conversion of the ox openbuilds cnc to linear rails and ball screws.

thingiverse

free

Bosch GCM12GLD saw to (ozito) vacuum adapter by gzcwnk

...bosch gcm12gld saw to (ozito) vacuum adapter by gzcwnk

thingiverse

adapter to vacuum

thingiverse

free

CR10S4/5 mods by gzcwnk

...e converter case (work in progress)

b) cups to go under bed springs to restore tension (finished)

c) pi holder (work in progress)

thingiverse

free

Alternative-jack-base CR10S4 by gzcwnk

...se small rework and metric m4 screw hole size and m4 nut.

a metric version of,

https://www.thingiverse.com/thing:2168244/comments

thingiverse

free

Basic Aero D-bot mount that can be modded by gzcwnk

...nt that can be modded by gzcwnk

thingiverse

works in progress.

basic design for an aero extruder mount to fit a d-bot 3d printer

thingiverse

free

Wanhao D6 short and long feet by gzcwnk

...nd 4mm perspex panels to complete. the short feet drop the internal space by 5deg c.

print 2 as is and 2 mirrored to get 4 feet.

thingiverse

free

cnc holddown clamps - various M5 size bolts by gzcwnk

... to suit m5 thread. based on similar idea to https://www.thingiverse.com/thing:1071010/files

use clamp best suited to work piece

thingiverse

free

Tongue and groove cams and Cat6 4-6 way protection shield by gzcwnk

...6 way protection shield by gzcwnk

thingiverse

jacking cams to help install tongue and groove 11mm thick (4/3/4mm) wood paneling.

thingiverse

free

Scope mounted dope chart holder for rifle ballistics by gzcwnk

... it out.

f3d files included to mod as per gpl licence.

feedback or suggested mods in comments and i will have a go.

print in abs.

Collator

3d_export

$40

CGAxis Photocopier Machine 14 3D Model

...xerox copy laser office equipment multifunction printer scanner sorter collator device appliance textures materials detailed cgaxis photocopier machine 14...

3d_export

$40

CGAxis Photocopier Machine 13 3D Model

...xerox copy laser office equipment multifunction printer scanner sorter collator device appliance textures materials detailed cgaxis photocopier machine 13...

thingiverse

free

lee case collator by Matthieu13

...lee case collator by matthieu13

thingiverse

my mini case collator for lee pro 1000

thingiverse

free

Lee APP 9mm collator by KarlLarsson

...ingle tube collator that fits the lee app 9mm case tube. refill it with ease, just dump a couple of cases and shake the collator.

thingiverse

free

Lee Case Collator by red_rider95

...even tested and works up to .270 brass (albeit slower).

inspiration for the rifle collator came from olddesertshooter on youtube.

thingiverse

free

bag sling collate by awsedr

...bag sling collate by awsedr

thingiverse

hope it's helpfull

thingiverse

free

Case Collator by Marcconi

...peration.

works excellent with 9mm, 38spec and 357mag brass.

it also works ok with 45acp but filling pipes takes a bit more time.

thingiverse

free

Bullet Collator Feed Plates and Guides by RickJ19Zeta8

... 5.56 62gr v-max.

the ramp is more universal but the collators are for the specific bullet design and may not work with others.

thingiverse

free

OpenBulletFeeder Collator Shaft for JGY-370 by timmeyb

...for my first jgy-370, but the second one needed it. this variant is also resized to fit the collator plates without modification.

thingiverse

free

Lee Loadmaster 9mm case collator modification by Dron_Broks

...r modification by dron_broks

thingiverse

modify the lee case collator so 9mm cases don't fall into the feed tubes inverted.

Hornady

3d_export

$10

17 Hornady Mach 2 Bullet

...best results in blender.<br>no extra plugins are required for this model. lights and cameras are not included in the scene.

thingiverse

free

Hornady Nozzle by Greg198

...hornady nozzle by greg198

thingiverse

thingiverse

free

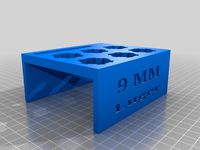

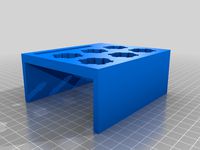

Hornady Die holder 9MM

...hornady die holder 9mm

thingiverse

this will hold 6 reloading dies with the hornady lnl bushing and the shell plate

thingiverse

free

Hornady’s Powder Trickler Funnel by commanderbeatle2

...hornady’s powder trickler funnel by commanderbeatle2

thingiverse

just a funnel for hornady’s powder trickler.

thingiverse

free

Reloading die with Hornady LNL bushing

...reloading die with hornady lnl bushing

thingiverse

for reloading dies with the hornady lnl bushing

thingiverse

free

Die Holder with a Hornady LNL bushing

...die holder with a hornady lnl bushing

thingiverse

holds 6 reloading dies with the hornady lnl bushing and shell plate

thingiverse

free

Wrench for lock ring die Hornady by Dragunov76

...wrench for lock ring die hornady by dragunov76

thingiverse

wrench for lock ring die hornady

thingiverse

free

Hornady deburring tool bit mount by bios86

...hornady deburring tool bit mount by bios86

thingiverse

drill bit mount for hornady deburring tool

thingiverse

free

Hornady die holder

...hornady die holder

thingiverse

this will hold 6 dies with the lnl bushing and the associated shell plate.

thingiverse

free

Hornady Case prep gears by imakershop

...ingiverse

replacement gears for the hornady lock-n-load case prep trio (https://www.midwayusa.com/product/1012733817?pid=245424)

556

turbosquid

$9

Rosette 556

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

Architecture 556 3D Model

...lege campus max street landscape commercial building medical hospital offices

architecture 556 3d model lotusmodel 48689 3dexport

3d_export

$160

3d building 556 3D Model

...metropolis street block detailed definition realistic skyscraper huge collection

3d building 556 3d model kanhtart 44592 3dexport

3d_export

$50

3D Home 556 3D Model

... chair furniture texture table lamp apartment rug carpet restaurant hotel sitting

3d home 556 3d model richard3015 46495 3dexport

3d_export

$10

The box is a 556 caliber cartridge of the NATO sample

...the box is a 556 caliber cartridge of the nato sample

3dexport

the box is a 5.56 caliber cartridge of the nato sample

3d_ocean

$6

Triant Harmony 556

... textures are included, but strongly resized, and cropped from top-left corner by 1:1 ration in 750×750pix. feel free to just ...

3d_export

$20

ficus benjamina trees in a flowerpot for interior design 556

...lack pots.<br>houseplants<br>exotic plants<br>tropical plants<br>ficus benjamina trees<br>white pot

3ddd

$1

Rose

...rose 3ddd роза polys: 556 792 verts: 435...

3ddd

$1

rose_2

...rose_2 3ddd роза polys: 556 682 verts: 435...

3ddd

free

Постельное белье

...постельное белье 3ddd постельное белье 376 556 poly with shell...

223

turbosquid

$18

plants 223

...

royalty free 3d model plants 223 for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1468325)

turbosquid

free

223-AMMOBOX

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Fallout Pistol 223

...bosquid

royalty free 3d model 223 for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1482082)

3d_export

$5

223 Ammo Bullets 3D Model

...223 ammo bullets 3d model

3dexport

223 ammo // bullets

223 ammo bullets 3d model nick2012 62621 3dexport

turbosquid

$7

Rug Set 223

...y free 3d model rug set 223 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497443)

turbosquid

$17

Coffee Table_ 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Geometric Shape 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Gervasoni InOut 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

223 Calhoon Round

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

LowPoly Character Male 223

...223

turbosquid

royalty free 3d model 223 for download as obj on turbosquid: 3d models for games, architecture, videos. (1242232)

650

3ddd

$2

A-650#

...a-650#

3ddd

капитоне

кресло a-650# кожа

turbosquid

$54

XS-650

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

MD10606-60-650

... черный, белый. в архиве оба варианта расцветки. + fbx для импорта.http://www.cosmorelax.ru/catalog/svet/md10606_60_650

3ddd

$1

Pioneer sx-650

... радио

one of the classic mid-range receivers offered by pioneer in the mid 70's was this pioneer sx-650.

turbosquid

$80

mclaren 650s spider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$80

mclaren 650s spider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Lumia 650 BLACK

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Arizzi 805 6 H740 650

...arizzi 805 6 h740 650

3ddd

arizzi

arizzi 805 6

h740 650

turbosquid

$25

UTB 650 - Front Rim

...d

royalty free 3d model utb 650 - front rim for download as on turbosquid: 3d models for games, architecture, videos. (1654238)

3d_export

$20

mclaren 650s gt3

....<br>headlights and taillights are modelled, doors and trunk lid can be opened.<br>the model includes modelled tires.

Feeder

3d_export

free

Feeder

...feeder

3dexport

feeder.

3d_ocean

$7

bird feeders

...bird feeders

3docean

bird feeders wood

bird feeders

3d_export

$6

bird feeder

...bird feeder

3dexport

bird feeder

3d_export

free

Bird feeder

...feeder

3dexport

a beautiful, lovely and tranquil bird feeder, which you can use for your amazing games, animations, or pictures.

turbosquid

$59

Hummingbird Feeder

... free 3d model hummingbird feeder for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1444996)

turbosquid

$2

Baby Feeder

...y free 3d model baby feeder for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1488786)

archive3d

free

Bird feeder 3D Model

...r tray feeder

bird feeder n250714 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$18

Pet feeder

...ee 3d model pet feeder for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559898)

turbosquid

$3

dog feeder

... 3d model dog feeder for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545601)

turbosquid

$29

Chicken Feeder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bullet

3d_export

$5

Bullet

...bullet

3dexport

bullet

3d_export

free

bullet

...bullet

3dexport

bullet in the context of

3d_export

$5

bullet

...bullet

3dexport

ready 3d model of a bullet.

3d_ocean

$1

Bullet

...bullet

3docean

bullet copper_material fully in blender project multi-materials weapons

bullet in 3d with multiple materials

3d_export

$5

bullet

...bullet

3dexport

bullet, created in blender there are 2 versions with and without texture.

3d_ocean

$7

Wanted Bullet

...wanted bullet

3docean

bullet wanted

wanted bullet

3d_ocean

$3

Brass Bullets

...brass bullets

3docean

brass bullet bullets gun guns rifle rifles

low-poly bullets

3d_export

$15

bullet box

...bullet box

3dexport

bullet box for 50 bullets with hinges type a

3d_export

$15

bullet box

...bullet box

3dexport

bullet box for 50 bullets with hinges tybe b

turbosquid

$1

bullet

...bullet

turbosquid

free 3d model bullet for download as c4d on turbosquid: 3d models for games, architecture, videos. (1191844)

Etc

3ddd

free

Oranges, mandarins etc.

...син , мандарин , фрукты

oranges, mandarins etc.

3ddd

$1

Bowls, dishes etc.

...bowls, dishes etc.

3ddd

посуда , сервиз

bowls, dishes etc. for contemporary kitchens

turbosquid

$30

theater for( cinema, collage, etc.)

...model theater for( cinema, collage, etc.) for download as fbx on turbosquid: 3d models for games, architecture, videos. (1258736)

3d_export

$40

stage light ETC 3D Model

...am shaper lighting concert music electric studio set movie lens lamp zoom reflector

stage light etc 3d model braz 7043 3dexport

3d_ocean

$8

Realistic TV/Blu-ray/DVD etc. remote

...3docean

blu-ray dvd realistic remote technology television tv

this is a model of a television, dvd, blu-ray, etc. remote control.

3d_ocean

$12

Desk accessories (pen, eraser, etc.)

...ats included: .c4d, .obj – the model contains 58530 polygons – not rigged, scene setup / lighting from the preview, are included.

3d_export

$5

kitchen assets - pots pans etc

...fferent material as they have a separate material id for the ability to personalise or have alternate lid types e.g. foggy glass.

3d_export

$15

bentley continental 2015 with all surroundings complete with lightmaterials etc

...als etc

3dexport

in the car model, each part as a separate object, which allows you to make animation or destruction in the game

3d_export

$12

set of 73 parts bolts nuts washers nails etc

...red with eevee. the wood texture is not included. all the other materials are procedural pbr configured in the native blend file.

3ddd

free

Suitcase

...suitcase 3ddd suitcase plastic suitcase for tools etc ...

Source

turbosquid

$30

source

...e

turbosquid

royalty free 3d model source for download as ma on turbosquid: 3d models for games, architecture, videos. (1154551)

3d_export

$7

Source

...er software such as blender, 3d max, unity in the preview you will see the model with its respective materials, textures and mesh

design_connected

$13

Master Line Source

...master line source

designconnected

piega master line source computer generated 3d model.

3ddd

$1

SodaStream Source

...sodastream source

3ddd

сифон

designed by yves béhar

сифон компании sourcestream, изготовленный в современном стиле

turbosquid

$199

Demon source files

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Water Source Animation

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

THEATRICAL LIGHT - SOURCE 4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Cross 3D print source model

... 3d print source model for download as max, max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1680597)

turbosquid

$22

Column capital source 3dsMax 001

...smax 001 3d model for download as max, max, max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1683199)

3ddd

free

Lite Source LS-21155C-WHT Table Lamps

...le lamps

3ddd

lite source

http://www.lamps-lighting.com/lite-source/ls-21155c-wht.html

3dsmax 2013+2010+obj+.fbx+.3ds

Open

3d_export

free

Opener

...r

3dexport

3d model of can opener. its my first work, if u can please show me my mistakes. this 3d model was created in autocad.

3d_export

free

Cap opener

...cap opener

3dexport

handy cap opener, more files/formats here:

3ddd

$1

Кресло, Open Oreon.

...кресло, open oreon.

3ddd

open , oreon

кресло, open oreon.

3d_ocean

$4

Open Book

...r interior max mental model open ray reading shelf text vray

open hardcover book with unique texture map on front and back cover.

turbosquid

$6

Opening Flag

...squid

royalty free 3d model opening flag for download as c4d on turbosquid: 3d models for games, architecture, videos. (1593555)

turbosquid

$10

Open book

...

royalty free 3d model open book for download as skp and obj on turbosquid: 3d models for games, architecture, videos. (1690781)

turbosquid

$2

bottle opener

...lty free 3d model bottle opener for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1621201)

turbosquid

$24

Bottle Opener

...free 3d model bottle opener for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1300948)

turbosquid

$20

Open Box

...yalty free 3d model open box for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1481218)

turbosquid

$10

Wine Opener

...ty free 3d model wine opener for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1240730)