Thingiverse

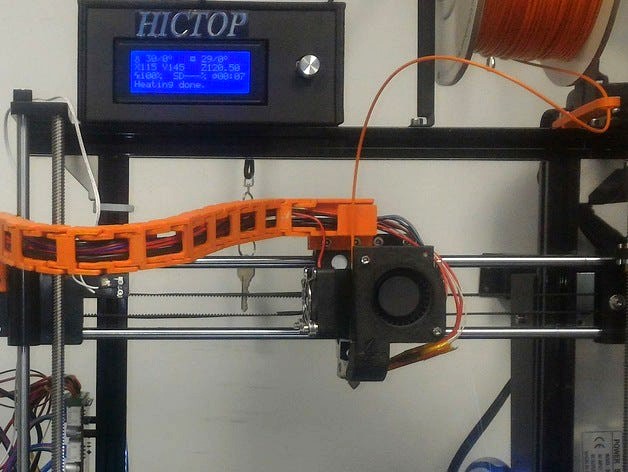

Open Cable chain set for HICTOP 3DP-11 by Klotzmando

by Thingiverse

Last crawled date: 2 years, 12 months ago

I had a problem with the wire mess on my new HICTOP and wanted a cable chain. Since I am always making changes to my printers I have to have an open chain and the ones that were presented here did not have an open side on the links. I prefer open links because you don't have to try an fish your cables in or out, you simply break the chain one link at a time and reassemble it around the cable.

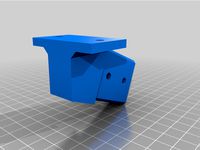

So I redesigned the terminating mounts from http://www.thingiverse.com/thing:1357884 mounting the CableChain_XCarriage a little lower and opening up the side. I redid the Cable Chain_XStepper again to make it open and added a chain mount to the back incase I figure out how to transition to a chain that will connecto to the computer board.

Finally, I took the cable chain from http://www.thingiverse.com/thing:511938 resized to fit the end mounts and group them into a set of 4 each ( your certainly will need more than one and extras come in handy)

So here you go.

Nov 2, 2016:

After some hours on the printer, I found I did not like the way the cable behaved at the X-Motor mount. I watched it for a while and realize I simply needed to make a simple change to get the cable to fold correctly. I had to make the chain end pointed so the links would fold back on the chain and therefore lay flatter. While I was at it I decided to also add a set of gate on the open side like I did for the X head mount.

Nov 13, 2016

After printing with the updated X-Motor Mount I kept noticing a POPing sound. I finally tracked this down to the shape of the point. I have converted this to a more filleted shape to make the transition easier. This form works much better. I have removed the V2 and update the original to avoid confusion. Also, I found that the chain rubbed against the lead screw when the X-head was all the way to the left. The fix for this is to simply invert the first link from the head. (The angle would normally be toward the back, except for the first link on the X-Head.

Dec 12, 2016

I was not entirely happy with the extruder/x carriage mount or the X-stepper motor mount. Some of the wires were flexing too much and I was worried that they may experience excessive strain because of it. Also, I was inspired by a YouTube video I saw, sorry I can't remember how to find it, where the circuit board case had a connector for a cable chain. So I have added support for a chain from the X-stepper motor to the circuit board case.

Finally, I redesigned the extruder/x-carriage mount to have a slot for the SN04 sensor cable and lowered the whole mount by about 8mm. This means that the screw holes for the mount are now part of the cable channel, but I added enough material to the channel to allow the screw heads to be fully counter-sunk.

Dec 13, 2016

Well, the testing of the electronics box went faster than expected so I have added it to this project. The project is now complete.

UPDATE Feb 27, 2017:

I have modified the case bottom to better handle the display cables, the USB jack and cable entry points. This version has all the entry points at the level of the board.

I also reduced the size of the cable chain mount on the top so you could use the same case with out the cable chain if you wish.

So I redesigned the terminating mounts from http://www.thingiverse.com/thing:1357884 mounting the CableChain_XCarriage a little lower and opening up the side. I redid the Cable Chain_XStepper again to make it open and added a chain mount to the back incase I figure out how to transition to a chain that will connecto to the computer board.

Finally, I took the cable chain from http://www.thingiverse.com/thing:511938 resized to fit the end mounts and group them into a set of 4 each ( your certainly will need more than one and extras come in handy)

So here you go.

Nov 2, 2016:

After some hours on the printer, I found I did not like the way the cable behaved at the X-Motor mount. I watched it for a while and realize I simply needed to make a simple change to get the cable to fold correctly. I had to make the chain end pointed so the links would fold back on the chain and therefore lay flatter. While I was at it I decided to also add a set of gate on the open side like I did for the X head mount.

Nov 13, 2016

After printing with the updated X-Motor Mount I kept noticing a POPing sound. I finally tracked this down to the shape of the point. I have converted this to a more filleted shape to make the transition easier. This form works much better. I have removed the V2 and update the original to avoid confusion. Also, I found that the chain rubbed against the lead screw when the X-head was all the way to the left. The fix for this is to simply invert the first link from the head. (The angle would normally be toward the back, except for the first link on the X-Head.

Dec 12, 2016

I was not entirely happy with the extruder/x carriage mount or the X-stepper motor mount. Some of the wires were flexing too much and I was worried that they may experience excessive strain because of it. Also, I was inspired by a YouTube video I saw, sorry I can't remember how to find it, where the circuit board case had a connector for a cable chain. So I have added support for a chain from the X-stepper motor to the circuit board case.

Finally, I redesigned the extruder/x-carriage mount to have a slot for the SN04 sensor cable and lowered the whole mount by about 8mm. This means that the screw holes for the mount are now part of the cable channel, but I added enough material to the channel to allow the screw heads to be fully counter-sunk.

Dec 13, 2016

Well, the testing of the electronics box went faster than expected so I have added it to this project. The project is now complete.

UPDATE Feb 27, 2017:

I have modified the case bottom to better handle the display cables, the USB jack and cable entry points. This version has all the entry points at the level of the board.

I also reduced the size of the cable chain mount on the top so you could use the same case with out the cable chain if you wish.

Similar models

thingiverse

free

Upgrade for Hictop 3DP-11 ATL by Klotzmando

...either the sn04 inductive sensor or the bltouch into similar designs, but first i have never had good luck...

thingiverse

free

Cable Chain Motor to Extruder head by SPWA

...x-axis on anet a8 printers. will probably work on similar machines. (update 28?10/2016 1.54pm the motor mount had a...

thingiverse

free

Anet A8 Z-axis cable chain by oh5gzr

...temperature sensor

extruder stepper motor cooling fan

extruder nozzle cooling fan

prepare yourself for some serious soldering! :)

thingiverse

free

Migbot i3 X-Axis Complete Cable Chain With Mounts by Reddrop

... can be found below:

cable chain: http://www.thingiverse.com/thing:11978

extruder clamp: http://www.thingiverse.com/thing:775684

thingiverse

free

Open Cable X-Axis Cable Chain Mount for Hictop Prusa i3 by jimmythekayaker

...oving the ends from the wiring harness.

i am currently using it with this cable chain: https://www.thingiverse.com/thing:611593

thingiverse

free

Ender 3 Electronics Case with Cable Chain Mount MKS Variant

... plan on upgrading to an mks gen l so i modified tt's case variant to also have the cable chain mount as with my other remix.

thingiverse

free

Zonestar P802M Cable Chain System by BirdJr

...(x stepper motor). used 29 chain links for the x-axis travel (extruder carriage). i would recommend re-leveling after installing.

thingiverse

free

Cable Chain Mounts for 10mm x 15mm Drag Chain

...mounts the chains.

4 - m3 x 8mm

2 - m3 x 12mm

1 - m3 x 10mm

2 - m5 x 15mm

updates:

01172020 - replaced chain mount for tool head.

thingiverse

free

I3 Clone Y-axis Chain Mounts by siskulous

...had gotten caught so many times that i had to replace them.

the mounts are designed to go with johnniewhiskey's cable chains.

thingiverse

free

X Axis Motor with cable chain mount by GeekGarage

...hain mount by geekgarage

thingiverse

updated the original bq x axis cable chain mount and ooznest x motor mount to fit together.

Klotzmando

thingiverse

free

Part for building a column of leds. by Klotzmando

...o form the leads of an led so that they may be soldered into column.

there will be more details as i finish parts of the project.

thingiverse

free

Hunter remote wall mount by Klotzmando

...ch may be screwed to the wall and holds the remote firmly but still allows for the remote to be removed and carried if necessary.

thingiverse

free

Adapter for opening in a ford fusion Hybrid by Klotzmando

...ch snaps into the dashboard mount on the back of the gps and then can be inserted into the opening on the back of the fill plate.

thingiverse

free

HICTOP LCD on the bottom by Klotzmando

... accessible (why did hictop leave that out?) and the sd slot is much cleaner and easier to "hit" when inserting a card.

thingiverse

free

Hotend Test stand by Klotzmando

... new file.

note: the extruder in the background is http://www.thingiverse.com/thing:589149. (giving credit where credit is due)

thingiverse

free

Cheerson CX10 Quad copter box. by Klotzmando

...he package is clearly marked 0.25 inch (8mm) magnets.

so i brought the project into fusion 360 and changed the size of the holes.

thingiverse

free

Case top for the Mega R3 and Newhaven Display LCD. by Klotzmando

...e same case as the mega.

i started with http://www.thingiverse.com/thing:101617 as a base, then designed this to replace the top.

thingiverse

free

Case for Waveshare 5inch HDMI LCD V2 and PI 2 by Klotzmando

...parts on my printrbot.

note:

just like my other waveshare project, this case will not work with the 5inch display from adafruit.,

thingiverse

free

Waveshare 5inch HDMI LCD (B) Simple Case by Klotzmando

...a 3d printable image of the lcd and the connectors in case you want check you printer accuracy to mine before you build the case.

thingiverse

free

30mm Fan Adapter for Rostock Max V2 by Klotzmando

...the e3d, using the proper squirrel cage fan. so i created this adapter to allow me to use the 30mm fan with the existing coolers.

Hictop

thingiverse

free

Hictop - Adjustable z Endstop by ptk21

...hictop - adjustable z endstop by ptk21

thingiverse

adjustable z endstop for hictop

thingiverse

free

Hictop 3d LCD Befestigung by festus402

...hictop 3d lcd befestigung by festus402

thingiverse

hictop 3d lcd befestigung

thingiverse

free

Cable chain HICTOP by Insani3D

...cable chain hictop by insani3d

thingiverse

iniciando la modificación de nuestra hictop, se diseña una eslabón a medida.

thingiverse

free

hictop y belt mount by polpetras

...hictop y belt mount by polpetras

thingiverse

hictop aluminum prusa y belt mount

thingiverse

free

Pen Holder for Hictop ender by basolur

...pen holder for hictop ender by basolur

thingiverse

this is a simple pen holder to use a hictop ender as a plotter.

thingiverse

free

remix for hictop mount by chibi_hero

...iverse

edit. made recesses for mounting deeper.

remixed this with http://www.thingiverse.com/thing:1323225

for my hictop 3dp-11.

thingiverse

free

Hictop 3DP-17 Parts by Adranovik

...hictop 3dp-17 parts by adranovik

thingiverse

printed parts for the hictop prusa eds-17 with auto level

thingiverse

free

Hictop xaxis clamp by Gen0idea

...oken x-axis belt clamp on the hictop printer.

printed in a different colour to the original to differentiate it as a replacement.

thingiverse

free

Hictop xaxis clamp by Gen0idea

...oken x-axis belt clamp on the hictop printer.

printed in a different colour to the original to differentiate it as a replacement.

thingiverse

free

Hictop i3 RAMPS Board Cover

...hictop i3 ramps board cover

thingiverse

cover for the stock ramps 1.3 board on the hictop i3 clone (2015 model).

3Dp

turbosquid

$15

ELEPHANT / / 3DP Animation Studio

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

GOAT / / 3DP Animation Studio

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Gandhi Salt March 3DP

...ds, dxf, lwo, obj, wrl, x, c4d, fbx, 3dm, blend, lxo, and dae on turbosquid: 3d models for games, architecture, videos. (1447208)

3d_export

free

z-morph 3dp rear hook opt lasers

...also accessible on:<br>to find out more about the functionality of laser 3d printers, take a look at the following webpage:

3d_export

free

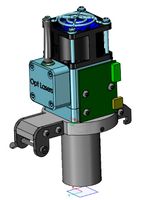

cnc 3dp laser engraving head opt lasers

...n also be found for free at:<br>if you want to take a look at the specifications of this laser head, please visit the link:

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

z-morph 3dp front hook opt lasers

...k is also available from:<br>to find out more about the 3d laser printer engraver technology, you can visit the link below:

3d_export

free

z-morph 3dp 6w engraving laser head

...e via:<br>if you want to learn the specifications of the 6w opt lasers cutting and engraving laser head, visit the website:

3d_export

$5

katar

...occlusion, curvature, world space normals, thickness, position.<br>fbx, obj, blend, 3dp 3ds, glb, ply, stl, usdc, x3d, mtl, dae,...

thingiverse

free

Robotics Feed 3DP

...ector-2

side wall extrusion 3dp connector-2

bevel box -1

l dt connector 1-2

l dt connector 2-2

arc and back plate 3dp connector-1

Chain

archibase_planet

free

Chain

...chain

archibase planet

chain chain link chain loop

chain n020708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

chain

...chain

3dexport

3d model chain

3d_export

$5

chain

...chain

3dexport

chain. obj,fbx,blend

archibase_planet

free

Chain

...se planet

chain circuit catena

chain - archicad parametrical gdl 3d model (*.gsm). regulation of the length, curvature and angle.

archibase_planet

free

Chain

...n

archibase planet

chain circuit catena

chain - archicad parametrical gdl 3d model(*.gsm). regulation of the length and angle xyz

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

turbosquid

$10

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1329200)

turbosquid

$9

chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1549461)

turbosquid

$2

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1148668)

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

$25

cable clip

...squid

royalty free 3d model cable clip for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1232374)

11

turbosquid

free

PROTOTYPE WARRIOR (11 of 11)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

11

...11

3ddd

мойка

полигональное моделирование

turbosquid

$25

11

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Bed 11

...bed 11

3ddd

постельное белье

bed 11

3ddd

$1

Pozzoli 11

...pozzoli 11

3ddd

pozzoli , круглый

итальянский столик pozzoli

модель 11

design_connected

$9

ND0410-11

...nd0410-11

designconnected

house doctor nd0410-11 computer generated 3d model.

3d_export

$12

iphone 11

...iphone 11

3dexport

iphone 11 model with exact dimensions of 150.9 mm by 75.7 mm.

3d_export

$29

iphone 11 case 11

...en the scene. units: centimeters. file formats: blender obj fbx -stl -dea info poly/verts: iphone 11 case polys: 3609 verts: 3808

design_connected

$27

Domino 11

...domino 11

designconnected

zanotta domino 11 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Kilt 11

...kilt 11

designconnected

zanotta kilt 11 computer generated 3d model. designed by progetti, emaf.

Open

3d_export

free

Opener

...r

3dexport

3d model of can opener. its my first work, if u can please show me my mistakes. this 3d model was created in autocad.

3d_export

free

Cap opener

...cap opener

3dexport

handy cap opener, more files/formats here:

3ddd

$1

Кресло, Open Oreon.

...кресло, open oreon.

3ddd

open , oreon

кресло, open oreon.

3d_ocean

$4

Open Book

...r interior max mental model open ray reading shelf text vray

open hardcover book with unique texture map on front and back cover.

turbosquid

$6

Opening Flag

...squid

royalty free 3d model opening flag for download as c4d on turbosquid: 3d models for games, architecture, videos. (1593555)

turbosquid

$10

Open book

...

royalty free 3d model open book for download as skp and obj on turbosquid: 3d models for games, architecture, videos. (1690781)

turbosquid

$2

bottle opener

...lty free 3d model bottle opener for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1621201)

turbosquid

$24

Bottle Opener

...free 3d model bottle opener for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1300948)

turbosquid

$20

Open Box

...yalty free 3d model open box for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1481218)

3d_export

$20

bank vault open

...bank vault open

3dexport

bank vault open

Set

archibase_planet

free

Setting

...setting

archibase planet

setting cover place setting

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

decorative set mens set

...decorative set mens set

3dexport

decorative set men's set

archibase_planet

free

Set

...anet

set kitchen ware kitchen set kitchen tools

set kitchen tools n281114 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

beer set bar equipment

beer set - 3d model for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

cover place setting

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

kitchen set kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

set cup glass kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

flatware cover place setting

set n311210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.