Thingiverse

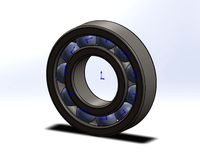

New 608 Bearing Concept: Conical Geometry Bearings by DrMcWoofies

by Thingiverse

Last crawled date: 3 years, 3 months ago

Intro

There is an old saying, "Don't reinvent the wheel". However, if we never reinvented the wheel, we would still be stuck in a Fred Flintstone society with Fred Flintstone Cars yabadabadoo'ing our way down town, walkin' fast, faces pass and we're homebound. So therefore, I am literally reinventing the wheel. Here is the latest technology in print in place bearings.

Version 2

Second Version is just a few touchups. The basic one has a clearance of 0.1 mm, the one with a tighter clearance has a clearance of 0.05mm. A 6 roller variant was also added for people with printers that can't print a 0.8mm rod.

Printing Tips

Remember, if your prints have elephant's foot, then this tiny bearing obviously will not work after printing due to parts fused or warped geometry. So if you never tuned this issue out of your printer, print with a raft. Remember this is actually a pretty difficult print with a number of small parts, it will be advisable to print slower just incase. That being said, my ender 3 pro handled this print with pretty standard print settings.

Other tips include changing Z-seam alignment to random and also lowering flow rate.

It is very simple to free this bearing. Hold the center, and roll it furiously against a bed or couch cushion until it feel's relatively free. This will wear out all the random imperfections and smooth the overall shape.

Design

So what makes this bearing so special? How is it any different from any of the other random selections out there? Well let me tell you. This bearing was designed with absolutely minimalizing contact area of the rolling elements. Most of the other bearings, except the massive herringbone gears, have 2 lines of contact on the rolling element. Normally, on a simple cylinder this doesn't affect the friction. But most designs feature cylinders shaped in a way with the housing that the parts will not fall out by changing the radius certain heights. These shaped cylinders will roll at slightly varying speeds and have areas with different speeds in contact with one another causing a lot of friction. My design only has 4 points of contact, 2 on each housing, and all those points will pretty much never have differing speeds at points in contact that cause friction.

How this is achieved comes from the shape of the rolling elements. These rolling elements work off of the same theory as the conical shape of train wheels. The conical shape when rolling down a rail will naturally self align to the center without intervention. With this in mind, the rolling elements in this bearing rolls on rails that are in the housing. There is also a built in flange in the bearing to keep the them from falling out. While not normally used in operation, the flanges keep the bearings bearing from derailing, similarly to trains. The size of the flange is still kept to the minimum to reduce friction in the event that the flanges are in use.

Another element as to why this bearing is different is the method of keeping the rolling elements in the correct positions. This design has a very off hand approach to securing the bearings, in a sense that they will only be corrected if it moves too much out of range. If the bearing was to move out of range, only a very small section at the top and bottom of the bearing will actually come into contact to keep it from moving too much. Otherwise it is highly reliant on the geometry naturally correcting itself. This further reduces friction as it reduces the amount of times the bearing is in contact with parts correcting it.

It has come to my attention that the flange is useless in the standard variants with 0.1mm of clearance between the rolling element and the rails. However the theory still stands and is actually useful in the 0.05mm clearance variants.

To everyone saying this is useless or isn't better than normal ball bearings

Of course it isn't, this is 3d printed; since when is 3d printed mechanical objects better than the standard. This is just for people who want a 3d printable bearing that has very low rolling friction and load. Nobody wants to waste premium ~1.00 USD 608 bearings which (obviously) have superiors load, thrust, speed, friction, reliability properties when all they needed was low friction and cheap.

There is an old saying, "Don't reinvent the wheel". However, if we never reinvented the wheel, we would still be stuck in a Fred Flintstone society with Fred Flintstone Cars yabadabadoo'ing our way down town, walkin' fast, faces pass and we're homebound. So therefore, I am literally reinventing the wheel. Here is the latest technology in print in place bearings.

Version 2

Second Version is just a few touchups. The basic one has a clearance of 0.1 mm, the one with a tighter clearance has a clearance of 0.05mm. A 6 roller variant was also added for people with printers that can't print a 0.8mm rod.

Printing Tips

Remember, if your prints have elephant's foot, then this tiny bearing obviously will not work after printing due to parts fused or warped geometry. So if you never tuned this issue out of your printer, print with a raft. Remember this is actually a pretty difficult print with a number of small parts, it will be advisable to print slower just incase. That being said, my ender 3 pro handled this print with pretty standard print settings.

Other tips include changing Z-seam alignment to random and also lowering flow rate.

It is very simple to free this bearing. Hold the center, and roll it furiously against a bed or couch cushion until it feel's relatively free. This will wear out all the random imperfections and smooth the overall shape.

Design

So what makes this bearing so special? How is it any different from any of the other random selections out there? Well let me tell you. This bearing was designed with absolutely minimalizing contact area of the rolling elements. Most of the other bearings, except the massive herringbone gears, have 2 lines of contact on the rolling element. Normally, on a simple cylinder this doesn't affect the friction. But most designs feature cylinders shaped in a way with the housing that the parts will not fall out by changing the radius certain heights. These shaped cylinders will roll at slightly varying speeds and have areas with different speeds in contact with one another causing a lot of friction. My design only has 4 points of contact, 2 on each housing, and all those points will pretty much never have differing speeds at points in contact that cause friction.

How this is achieved comes from the shape of the rolling elements. These rolling elements work off of the same theory as the conical shape of train wheels. The conical shape when rolling down a rail will naturally self align to the center without intervention. With this in mind, the rolling elements in this bearing rolls on rails that are in the housing. There is also a built in flange in the bearing to keep the them from falling out. While not normally used in operation, the flanges keep the bearings bearing from derailing, similarly to trains. The size of the flange is still kept to the minimum to reduce friction in the event that the flanges are in use.

Another element as to why this bearing is different is the method of keeping the rolling elements in the correct positions. This design has a very off hand approach to securing the bearings, in a sense that they will only be corrected if it moves too much out of range. If the bearing was to move out of range, only a very small section at the top and bottom of the bearing will actually come into contact to keep it from moving too much. Otherwise it is highly reliant on the geometry naturally correcting itself. This further reduces friction as it reduces the amount of times the bearing is in contact with parts correcting it.

It has come to my attention that the flange is useless in the standard variants with 0.1mm of clearance between the rolling element and the rails. However the theory still stands and is actually useful in the 0.05mm clearance variants.

To everyone saying this is useless or isn't better than normal ball bearings

Of course it isn't, this is 3d printed; since when is 3d printed mechanical objects better than the standard. This is just for people who want a 3d printable bearing that has very low rolling friction and load. Nobody wants to waste premium ~1.00 USD 608 bearings which (obviously) have superiors load, thrust, speed, friction, reliability properties when all they needed was low friction and cheap.

Similar models

grabcad

free

Rolling Element Bearings

... same principle is in work

here. rolling element bearings are used to

facilitate the free movement of parts in rotational

motion.

grabcad

free

Roller Bearings

...bearings — also known as rolling-element bearings — are similar to ball bearings in that they are designed to...

grabcad

free

Roller Bearing

...bearings — also known as rolling-element bearings — are similar to ball bearings in that they are designed to...

thingiverse

free

Slew Bearing Conic, with Spacers, parametric Design with Fusion 360 by TheGoofy

...ical - nevertheless i've exported them separately.

related video (tutorial with cylinder rolls): https://youtu.be/5o4fj8oxkb8

grabcad

free

Stacked Rolling Element Layered Radial-Axial Truncated Conical Roller Bearing

...complement tapered roller bearing, or between the rolling elements and their cage, in the case of a caged tapered roller bearing.

grabcad

free

Bearing

...earings are cost-effective and exchangeable machine elements that typically follow national or international dimension standards.

grabcad

free

Triple Rolling Element Layer Tapered Roller Axial Bearing.

...complement tapered roller bearing, or between the rolling elements and their cage, in the case of a caged tapered roller bearing.

grabcad

free

Ball Bearing

.... ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes.

grabcad

free

Ball Bearing

.... ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes.

grabcad

free

Radial Ball bearing

.... ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes.

Drmcwoofies

thingiverse

free

Coronavirus Model Remastered by DrMcWoofies

...hey are as evenly distributed as possible. this way there are no patterns and the virus is even more accurate than it was before.

thingiverse

free

Plastic Bottle Watering Spout 9000 by DrMcWoofies

...ned with drainage holes to try to remove water buildup inside due to leakage, this thing is technically resin printing compatible

Conical

3d_export

$6

conical crusher

...sher

3dexport

conical crusher designed for models, industrial equipment for the simulation of a real machine in mining companies

3ddd

$1

Cor / Conic

... обеденный , овальный

обеденный стол conic table производитель cor размеры 220*125*74 см

3d_ocean

$15

Conical juniper

...ical juniper shrub

high detalisation great for various visualization closeup because of the format *.obj great for any 3d package

turbosquid

$1

Conic Spring

...alty free 3d model conic spring for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1453633)

3d_export

free

conical pyramid

...conical pyramid

3dexport

beautiful pyramid

turbosquid

$15

Conical pinion

...el conical pinion for download as ige, obj, fbx, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1302547)

turbosquid

$5

Conical Kite

...cal kite for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1579408)

turbosquid

$5

Conical Helmet

...l helmet for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1594612)

design_connected

$13

Conic Section Light

...conic section light

designconnected

castor conic section light computer generated 3d model. designed by castor.

3ddd

$1

Allermuir Conic

...allermuir conic

3ddd

allermuir

сайт производителяhttp://www.allermuir.com

608

3d_export

$7

mb 608

...t;br>can be used wherever you want, games, commercials, billboards, everything.<br>blender<br>fbx<br>obj stl

3d_export

$60

Architecture 608 3D Model

...lege campus max street landscape commercial building medical hospital offices

architecture 608 3d model lotusmodel 48741 3dexport

3d_export

$160

3d building 608 3D Model

...metropolis street block detailed definition realistic skyscraper huge collection

3d building 608 3d model kanhtart 44669 3dexport

turbosquid

$20

Bowers & Wilkins ASW 608 Black

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$50

3D Home 608 3D Model

... chair furniture texture table lamp apartment rug carpet restaurant hotel sitting

3d home 608 3d model richard3015 46671 3dexport

turbosquid

$8

(608) Decor Element -3d STL model for CNC

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

ficus tree in pots for the interior 608

...njamina<br>howea forsteriana<br>date palm<br>banana palm<br>ravenala madagascariensis<br>strelitzia

3ddd

$1

Пуф

...пуф 3ddd пуф polys: 64 608 размеры: l-500 w- 500 h- 500 quads...

cg_studio

$100

3d building 6083d model

... building 6083d model

cgstudio

.max - 3d building 608 3d model, royalty free license available, instant download after purchase.

3d_export

$50

Jaguar XJR 14 lemans 3D Model

...xj 14 jaguar xjr 14 lemans 3d model tyio 608 ...

Bearings

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...bearing 3docean 3d engine ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic...

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Concept

3d_export

$5

concept house

...concept house

3dexport

concept house blend.

turbosquid

$20

concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Bo concept

...bo concept

3ddd

boconcept , декоративный набор

bo concept

3d_ocean

$45

Dreamcar concept

...cept cars from the past.before i became 3d modeler i sketched a lot futuristic cars.when i want it to look more realistic,i st...

3d_ocean

$49

Buggy Concept

... poly massive outdoor robust vehicle

just a model of are own buggy concept vehicle. maybe you can make a beautiful renders of it!

3d_export

free

concept s ii

...concept s ii

3dexport

concept car

3d_export

free

concept s iii

...concept s iii

3dexport

concept car

Geometry

design_connected

$7

Geometry Stool

...geometry stool

designconnected

ligne roset geometry stool computer generated 3d model. designed by ducru, jacques.

turbosquid

free

Abstract geometry

...rbosquid

free 3d model abstract geometry for download as c4d on turbosquid: 3d models for games, architecture, videos. (1340199)

turbosquid

$1

Geometry Box

...oyalty free 3d model geometry box for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1608060)

turbosquid

$10

Geometry Chair

...ree 3d model geometry chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1699186)

turbosquid

$3

icecream ( geometry )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Web Geometry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

infinite geometry

...e geometry for download as 3ds, obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1272938)

turbosquid

$4

the geometry of the cubes

...nload as 3ds, max, dxf, obj, wrl, fbx, w3d, pwc, dwg, and dae on turbosquid: 3d models for games, architecture, videos. (1368178)

design_connected

$11

Geometry Made Easy

...geometry made easy

designconnected

micromacro geometry made easy computer generated 3d model. designed by bernardi, sara .

turbosquid

$5

Geometry Nesting table

...alty free 3d model geometry nesting table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1655135)

New

turbosquid

$119

New New Beetle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

New-feather

...new-feather

3dexport

new-feather

3d_export

$6

new style

...new style

3dexport

new style room

3ddd

free

New Items

...ew items

3ddd

new items , барный

барный стул от китайского производителя фирмы new items

3d_export

$6

Logo new

...logo new

3dexport

new american style logo

3d_export

$10

New jersey

...new jersey

3dexport

new jersey stp and stl format

design_connected

$20

New Deal

...new deal

designconnected

new deal computer generated 3d model.

3d_ocean

$15

New bed

... for this bed all this file format include in zip file 3ds,obj,max,zip file change material and re-size very easy very for render

3ddd

free

Sofa-New Classic

...sofa-new classic

3ddd

new classic

sofa,new classic

design_connected

$13

New Antiques

...new antiques

designconnected

cappellini new antiques computer generated 3d model. designed by wanders, marcel.