Thingiverse

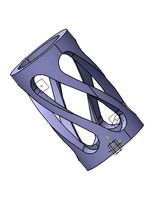

NeoDue Part 2 - 5" PanelDue Display for GRR Neo by Mechanotronikum

by Thingiverse

Last crawled date: 3 years ago

Part 2 of the NeoDue upgrade - a 5" display case that fits onto the Neo (and can be printed on it despite its print size limitations).

You need:

one of each parts

7x 3 mm x 14 mm plastic screws (four for the display, three for assembling the base pieces together)

1x 3 mm x 6 mm plastic screw for the adapter board of the display

4x 3 mm x 8 mm plastic screws for mounting the display onto the base

2x M4 x 20...30 mm screws for mounting the complete display onto the Neo (i used some leftovers from Ikea with a large head). Preferrably you might want cut the thread for these screws ont the Neo metal base, otherwise you will need two M4 nuts to scure the screws.

Additionally you will need a drill for the holes (screws and cable) in the printer itself.

Prio to assembly:

try to assemble the parts, slightly sand the connecting geometries if needed.

surface finish all parts as you like

remove adapter board from touchscreen

Assembly:

assemble display frame and display by using the two connector rods and the four 14mm screws. Take care you place the connector rods correctly.

place base parts onto Neo printer and check if they fit correctly. The connection surfaces are partially cut out so that they can easily be sanded down one mm were needed to accomodate for manufacturing tolerances of the frame. Both pieces should fit snugly over their whole contact surface (visible from the sides).

assemble both base parts by screwing them together with the remaining 14mm screws. Carefully align them in this process.

check the correct seating on the Neo frame once more, slide the base to the left until it touches the left wall of the Neo case.

with the base seated, mark the holes for the M4 screws and the holes for the wire. The hole for the wire facing the display should be rather on the right side of the cable channel to enable the sliding movement needed for seating.

drill the holes, cut the M4 thread, very carefully remove any burrs and sharp edges from the cable holes.

assemble base part and display and secure with the four 8mm screws

guide cable through holes in Neo base, slide display into place and secure with M4 screws.

plug cable into your Duet electronics and enjoy your upgraded 3D printer with Wifi and display :-)

The hole nearby the "E" of the Neo logo in the display frame can be used to push the "Erase" button of the display. The hole inside the Duet Logo can be used to reset the display if needed. The USB port for updating the display firmware is accessible from the side.

You need:

one of each parts

7x 3 mm x 14 mm plastic screws (four for the display, three for assembling the base pieces together)

1x 3 mm x 6 mm plastic screw for the adapter board of the display

4x 3 mm x 8 mm plastic screws for mounting the display onto the base

2x M4 x 20...30 mm screws for mounting the complete display onto the Neo (i used some leftovers from Ikea with a large head). Preferrably you might want cut the thread for these screws ont the Neo metal base, otherwise you will need two M4 nuts to scure the screws.

Additionally you will need a drill for the holes (screws and cable) in the printer itself.

Prio to assembly:

try to assemble the parts, slightly sand the connecting geometries if needed.

surface finish all parts as you like

remove adapter board from touchscreen

Assembly:

assemble display frame and display by using the two connector rods and the four 14mm screws. Take care you place the connector rods correctly.

place base parts onto Neo printer and check if they fit correctly. The connection surfaces are partially cut out so that they can easily be sanded down one mm were needed to accomodate for manufacturing tolerances of the frame. Both pieces should fit snugly over their whole contact surface (visible from the sides).

assemble both base parts by screwing them together with the remaining 14mm screws. Carefully align them in this process.

check the correct seating on the Neo frame once more, slide the base to the left until it touches the left wall of the Neo case.

with the base seated, mark the holes for the M4 screws and the holes for the wire. The hole for the wire facing the display should be rather on the right side of the cable channel to enable the sliding movement needed for seating.

drill the holes, cut the M4 thread, very carefully remove any burrs and sharp edges from the cable holes.

assemble base part and display and secure with the four 8mm screws

guide cable through holes in Neo base, slide display into place and secure with M4 screws.

plug cable into your Duet electronics and enjoy your upgraded 3D printer with Wifi and display :-)

The hole nearby the "E" of the Neo logo in the display frame can be used to push the "Erase" button of the display. The hole inside the Duet Logo can be used to reset the display if needed. The USB port for updating the display firmware is accessible from the side.

Similar models

thingiverse

free

Picture Frame Case for 5" Raspberry Pi Display (Joy-IT RB-LCD-5) by CaptSL

...it fits into a albrunna frame from ikea or similar you need to cut away the holes for the...

thingiverse

free

X carriage mounted extruder filament guide by jwass

...to the bearing mount to go from your spool to the guide to keep your filament from touching your work surface an picking up dirt.

thingiverse

free

Hole Grommet for Cable Passage in Desk or Enclosure by psdesign

...th a 64mm hole saw. insert hard plastic base, then insert the rubber part, pass cables.

if you make one please post your photos!

thingiverse

free

Z-limit endstop switch support for FLSUN Cube by tato_713

...u need to screw the endstop with the original m2.5 sets, this part is attached by force in one side carry bar.

version 5 assembly

thingiverse

free

Lerdge Display Panel Mount with USB Connector by darwin-de

...ed frames with m3 screws from the rear side,

they fit directly into the correspondending holes,

no threaded inserts are required.

thingiverse

free

Cable chain brackets for Tevo Tarantula bed by alejandrosnz

...a printer.

you will need to glue the bed part, hot glue will be enough. for the frame bracket you will need a m4 screw and t-nut.

thingiverse

free

CYBERPUNK AR DISPLAY STAND (Airsoft ONLY) by gumo_design

...e recommended.

you can adjust the balancing by sliding the part a.

there's a 0.36 hole in the bottom for a m4 stopping screw.

thingiverse

free

Hero Me Fan Duct for Ender 3 (2019) Full OEM. No other parts needed

...an to secure part cooler duct on base.

insert original part cooler and secure with the two longer part cooler fan screws to duct.

thingiverse

free

NeoDue Part 1 - Duet Wifi for GRR Neo by Mechanotronikum

..., just add a bat43 diode as mentioned in the duet wiki.)

the steppers work fine on my machine if i let them run with 500...600ma.

thingiverse

free

IKEA SIGNUM replacement part by Cacodaemon

...unting hole distance is nearly the same as the distance from the original holders.

you need four m4 screws and nuts for mounting.

Mechanotronikum

thingiverse

free

Bondtech BMG direct drive extruder for GRR Neo by Mechanotronikum

...dapter.

at least on my printer, this upgrade did wonders to print quality relative to the original bowden design. happy printing!

thingiverse

free

NeoDue Part 1 - Duet Wifi for GRR Neo by Mechanotronikum

..., just add a bat43 diode as mentioned in the duet wiki.)

the steppers work fine on my machine if i let them run with 500...600ma.

Grr

3dfindit

free

GRR

...grr

3dfind.it

catalog: festo

3dfindit

free

GRR

...grr

3dfind.it

catalog: festo

thingiverse

free

GRR-RIPPER Heel

...ush block.

these are disposable parts; print your own replacement!

this variant has a couple of holes for a jig fitting i needed.

thingiverse

free

E3D FAN GRR X400 Bauteilkühler by Kernfusion

...r x400 bauteilkühler by kernfusion

thingiverse

this is a remix of https://www.thingiverse.com/thing:1591912

a little bit shorter

thingiverse

free

GRR NEO Extruder tool by NitroXpress

...ool to de-tension the pressure roll of the german reprap neo filament extruder.

much easier to thread the filament.

have fun...

thingiverse

free

LCD display cover for GRR Protos V3 by kloberujo

...b of the lcd-display of german reprap's protos v3 - it just looks nicer like that. if precisly printed fits without fixtures.

thingiverse

free

Messuhrhalter für der GRR Neo by Helisinus

...ötigt.

english:

dial indicator for grr neo.

you need to extend the dial indicator and you need 6 x neodymium magnets 5mm x 2mm

thingiverse

free

Bondtech BMG direct drive extruder for GRR Neo by Mechanotronikum

...dapter.

at least on my printer, this upgrade did wonders to print quality relative to the original bowden design. happy printing!

thingiverse

free

Microjig GRR-RIPPER Gravity Heel Kit

...1.0.0.4a004c4dcjk0si

all in, parts should be less than $3.00

when fully retracted, the heel is about 1mm above the surface plane.

thingiverse

free

NeoDue Part 1 - Duet Wifi for GRR Neo by Mechanotronikum

..., just add a bat43 diode as mentioned in the duet wiki.)

the steppers work fine on my machine if i let them run with 500...600ma.

Paneldue

thingiverse

free

PanelDue enclosure by dc42

... version 2.0 in customizer.

new! this design now supports the integrated 5" and 7" versions of paneldue in customizer.

thingiverse

free

PanelDue 5" Back Cover for RailcoreII by kraegar

... railcoreii

does not fit the paneldue 5i

use with dc42's 5" paneldue case here: https://www.thingiverse.com/thing:656884

thingiverse

free

PanelDue 7i by kamikazer2

...paneldue 7i by kamikazer2

thingiverse

you need 4 m3x30 + nuts and 1 m3x6

thingiverse

free

Prusa PanelDue mount

... mount was inspired by https://www.thingiverse.com/thing:3286954 mount.

the back panel has a hole to fit the 4 pin cable through.

thingiverse

free

PanelDue 4.3" Compact Enclosure by SlimShader

...losure by slimshader

thingiverse

a compact enclose for the paneldue 4.3" display, frame mountable complete with back plate.

thingiverse

free

Ormerod PanelDue mounting bracket by 3jimd

...acket by 3jimd

thingiverse

this is a bracket and hinge for mounting dc42's paneldue lcd control panel on the reprap ormerod.

thingiverse

free

Sapphire plus duet paneldue mount by Szwalkiewicz

... the factory location

i use the paneldue lcd case form lumberjackengineering to completehttps://www.thingiverse.com/thing:2799628

thingiverse

free

PanelDue 5i encloser by danny_v1

...er for the front, without any holes for the sd card or something else.

it can be mounted with one screw to a 2020 or 3030 frame.

thingiverse

free

Case for PanelDue 4.3 duet3d by drbit

...for paneldue 4.3 duet3d by drbit

thingiverse

compact case for paneldue 4.3 duet3d

need m3 bolts

added support lerdge screen size

thingiverse

free

Bracket for a PanelDue by stephenrc

...ne for the 4.3" and in the scad file there is a version with a tab on one end for mounting above or below a horizontal 2020.

Neo

design_connected

$18

Neos

...neos

designconnected

wilkhahn neos computer generated 3d model. designed by wiege.

design_connected

$7

Neos

...neos

designconnected

gruppo feg neos computer generated 3d model. designed by nunziati, matteo.

turbosquid

$7

NEO

...

royalty free 3d model neo for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219070)

turbosquid

$30

Neo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Neo chair

...neo chair

3ddd

кресло

http://www.ufficidea.com/schedaprodotto_2720_seduta-direzionale-neo-chair.php

3ddd

$1

Riho NEO

... угловая

угловая акриловая ванна neo 140л.

фабрика изготовитель - riho

страна производитель: чехия

размер: 140 x 140 см

3ddd

$1

DUNE - NEO

... панель

186536 neo

29x29 cm./ 11,42”x11,42” d935

8 mm. de espesor/thicknesshttp://www.dune.es

3ddd

$1

Neo

...neo

3ddd

3d max 2009,vray 1.5 sp2+fbx

3ddd

$1

Russion neo classic

...russion neo classic

3ddd

lustra russion neo classic

3d_export

$7

neo matrix 1999

...neo matrix 1999

3dexport

neo matrix 1999 под печать

Display

3ddd

$1

Display

...display

3ddd

терминал

display computer 3d model

3d_export

$5

Display

...display

3dexport

display<br>verts 2.262<br>faces 3.928

turbosquid

$8

Display

...turbosquid

royalty free 3d model display for download as fbx on turbosquid: 3d models for games, architecture, videos. (1634534)

3ddd

$1

Display cabinet

...display cabinet

3ddd

витрина

display cabinet

turbosquid

$50

display

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

DISPLAY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Display

...e 3d model display for download as ma, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1387472)

3d_export

$6

display stand

...display stand

3dexport

super market display stand

3d_ocean

$12

Display Case

...rnishing furniture glass storage vetrinetta white

a 3d model of a display case. the texture for the back of the case is provided.

3d_export

$30

Vehicle display

...vehicle display

3dexport

vehicle display consists of podium and vehicle cover no vehicle there is a veiled vehicle silhouette

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.

Part

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур