Thingiverse

MPCNC - Strengthened parts by randysteck

by Thingiverse

Last crawled date: 3 years ago

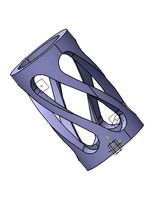

In assembling and running the MPCNC, I had to strengthen two parts and create another for wire management. I inherited this build from a friend who had a student put it together. Needless to say there were many errors, and not a few broken parts. But, this pointed out some weak spots in the design.

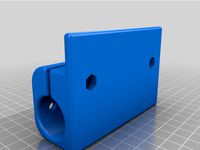

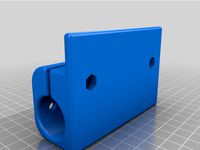

The clamps for the gantry on the original MPCNC use friction to hold the stepper assembly and bearing to the upright rails. This slips, especially if the holders have been overtightened or cracked, which is easy to do with PLA. In fact, this was so bad that the vibration of an early mill allowed the gantry to slip completely out of the holders and punch a hole through the workpiece and bed with the router still running. This design uses an 8/32 screw to hold the clamps to the rail vertically. This screw can either be of the self-tapping variety, or you can do as I did and just tap a hole in the side of the rail. The bonus on this is that it appeared to reduce vibration of the stepper rod with no real increase in mass. I created two versions of this part: a 23.5mm version and a 25.4 version.

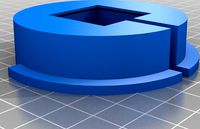

The roller plates on each of the 4 horizontal steppers broke very easily when tightening the bearings, especially with PLA. I increased the thickness and printed in ABS to solve the problem.

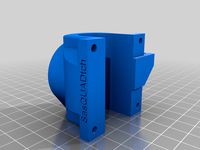

I was very uncomfortable with the wire management going into the Z-axis stepper. Repeated movement tends to bend the wires at the stepper body, assisted by gravity, of course. I designed and printed a wire channel holder to eliminate this problem and this will be part of a better wire management scheme with a drag chain in the not too distant future also.

Designs done in Fusion 360 from imported MPCNC STL files.

Happy milling.

The clamps for the gantry on the original MPCNC use friction to hold the stepper assembly and bearing to the upright rails. This slips, especially if the holders have been overtightened or cracked, which is easy to do with PLA. In fact, this was so bad that the vibration of an early mill allowed the gantry to slip completely out of the holders and punch a hole through the workpiece and bed with the router still running. This design uses an 8/32 screw to hold the clamps to the rail vertically. This screw can either be of the self-tapping variety, or you can do as I did and just tap a hole in the side of the rail. The bonus on this is that it appeared to reduce vibration of the stepper rod with no real increase in mass. I created two versions of this part: a 23.5mm version and a 25.4 version.

The roller plates on each of the 4 horizontal steppers broke very easily when tightening the bearings, especially with PLA. I increased the thickness and printed in ABS to solve the problem.

I was very uncomfortable with the wire management going into the Z-axis stepper. Repeated movement tends to bend the wires at the stepper body, assisted by gravity, of course. I designed and printed a wire channel holder to eliminate this problem and this will be part of a better wire management scheme with a drag chain in the not too distant future also.

Designs done in Fusion 360 from imported MPCNC STL files.

Happy milling.

Similar models

thingiverse

free

CNC 3018 Pro bearing holders

..., they have a tenancy to vibrate loose. these bearing clamps, slip over the housing the bearing rests in and holds them in place.

thingiverse

free

Long Dual Bushing Holder by PETFlasche

...d some problems with wobble and vibration in my x gantry .

so i decide to make a longer bushing holder.

for me it works perfekt !

thingiverse

free

MPCNC 525 Roller Clamp by lostpig

....

designed as part of my plan to add a powered drop table to my mpcnc build with an overly tall leg.

only works with 525 rollers!

thingiverse

free

Z Axis Holder for Igus Bearing by Slater2k2

...y 75°c with the rod inserted. after that they run perfectly smooth.

update: added a version with bearing grooves for better grip.

thingiverse

free

Feet and Rails made for Bearing Spool Holder for stabilization. by Serachja

...to clamp the two bearing-spool holders together. maybe something similar already exists, but today i was out of luck...

thingiverse

free

CNC gantry corner clamp part by sanderspaul

...cnc gantry corner clamp part by sanderspaul

thingiverse

corner clamp for cnc gantry

needs to be tapped for bolts

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

Hypercube X Gantry LM8UU bearing clamp with wire terminal block by neoh

...lock for hypercube x gantry.

requires

10 m3 (3mm) x 8mm screws

10 m3 nuts

10 m3 washers

best printed on its side with supports...

thingiverse

free

MPCNC End-stop switch holder, 25mm rail by Deveraux

...n m4 bolt clamps it to the rail.

i've only tried printing it in pla with 30% infill, works quite well. needs minimal support.

thingiverse

free

XYZ Davinci 1.0 bearing holder

... bearing holder failed and i found i couldn't get parts shipped to nz. works well, still running this holder with no problems

Randysteck

thingiverse

free

Zenwatch Printed Watchband by randysteck

...kle of the semi transparent material and at least my wrist is semi-fashionable now (even if it doesn't match the watch body).

thingiverse

free

Power Meter Box by randysteck

... how this came out and both boxes are working very well for some iot experiments.

designed in fusion 360, sliced with simplify3d.

thingiverse

free

Nexus 7 Charger Stand by randysteck

...notch in the top piece; it allows the power cord plug space, along with a channel for the power cord under the plaque at the top.

thingiverse

free

Shower door Handle and Towel holder by randysteck

...e short side of the towel rack which needs about 1.5". set up for 8-32 screws and nuts; holes will have to reamed as usual.

thingiverse

free

Horizontal Phone Holder/Charger by randysteck

...lug opening on the top of each side as well as the top of the arc, but it seems to print in abs without too much trouble without.

thingiverse

free

Nosecone Mount Altimeter/Tracker by randysteck

...ing flight, probably at drogue chute ejection which saw a very large impulse due to a likely excess black powder ejection charge.

thingiverse

free

Modified Secret Heart Box by randysteck

...ed.

it's the first time i'd seen or used scad and i was blown away by emmett's ingenuity and clear spatial reasoning.

thingiverse

free

Hold Down Clamp V2 by randysteck

...which is expected with these plastics. picture of stress analysis attached (i could not attach a video showing the progression).

thingiverse

free

MPCNC Drag Chain System by randysteck

...sion for a terminal block for spindle power connection, which seemed to work better than any connector option i'd considered.

Mpcnc

thingiverse

free

MPCNC Laser Mount

...mpcnc laser mount

thingiverse

custom laser mount for mpcnc.

thingiverse

free

MPCNC Remix

...mpcnc remix

thingiverse

test

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

thingiverse

free

MPCNC Y PLATE

...mpcnc y plate

thingiverse

ender 3 printable y plate for mpcnc lowrider 2

thingiverse

free

MPCNC adapter for pen holder

...mpcnc adapter for pen holder

thingiverse

adapter to mpcnc

thingiverse

free

MPCNC Higher Feet

...mpcnc higher feet

thingiverse

extra height and width feet to minimize wobbling on higher mpcnc 2.5mm configurations.

thingiverse

free

MPCNC 30x30 Laser by DariusO

...mpcnc 30x30 laser by dariuso

thingiverse

mpcnc lasermodul in 30x30

thingiverse

free

mpcnc penholder

...mpcnc penholder

thingiverse

a quick remix of two different ideas

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

MPCNC Proxxon Mount by CNC_Fan

...mpcnc proxxon mount by cnc_fan

thingiverse

this is my proxxon mount for use mpcnc

Strengthened

archive3d

free

Bracing 3D Model

...

holder bracing strengthening

bracing 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...

bracing strengthening holder

bracing 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

free

Walk in tub 32х38

...x 38"(h) color: white faucet included acrylic shell / strengthened with a fiberglass backing safety action return double seal...

3d_ocean

$89

Subaru Impreza WRX STI 2006

...2003 fhi has been strengthening its support of the subaru world rally team (swrt), which takes part in the fia world rally cha...

3ddd

$1

Maestrale Desk & Eva Chair by Zanotta

...2268 chromium plated steel legs. body in integral polyurethane strengthened with a steel insert in the shade of white...

3d_export

$6

maestrale desk eva chair by zanotta

...eva 2268<br>chromium plated steel legs. body in integral polyurethane strengthened with a steel insert in the shade of white...

3d_export

$8

French WWI Model 1916 Trench Dagger

...br>dimensions (lxwxh): 28.18x2.54x7.86.<br>textures: 4096x4096, base, metallic, ao, normal, roughness + unreal 4 packed.

3d_export

$5

lawn lattice braer meba

...quot;<br>in the archive files:<br>3dsmax 2017,<br>3dsmax 2014,<br>3dsmax 2011,<br>fbx,<br>obj

Parts

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)

turbosquid

$8

Drum parts

...bosquid

royalty free 3d model drum parts for download as max on turbosquid: 3d models for games, architecture, videos. (1631178)