Thingiverse

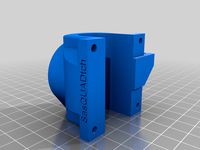

MPCNC foam-cutter attachment by dkj4linux

by Thingiverse

Last crawled date: 3 years ago

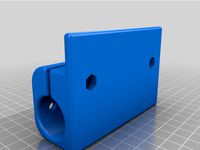

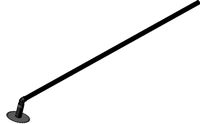

Simple foam cutter for Ryan "allted" Zellars' Mostly Printed CNC (http://www.thingiverse.com/thing:724999). Cut foam planes and figures from $tree foamboard or 1/4" fanfold foam insulation board. Uses DC motor salvaged from inkjet printer or battery-powered drill/screwdriver, .025" music-wire needle, small ball-bearing with 3mm bore, and sports-ball inflation needle for guide. Vary motor voltage to get good cut action -- 10-15 strokes/perforations per mm cleanly cuts paper and foam. Form needle loop around drill bit shank to be just under bearing OD. Mount bearing with 3x10mm screw in off-center hole, put small washer between inner race and plastic wheel, and lightly groove outer race with Dremel and cutoff wheel to retain wire needle loop. Dress the needle point with a fishhook sharpener to remove burrs and barbs. Needle exposure below end of guide should be material thickness plus 2-3 mm. Works well at feedrate of 1000 mm/min and cutter speed of 10000 rpm (strokes/min).

Originally inspired from "A Foam Cutting Machine" by Tom McGuire -- http://makeict.org/wiki/Foam_Cutting_Machine

Foam cutter in action --https://www.youtube.com/watch?v=kRLBNsZTKgM

UPDATE: I have created a version 2 foam-cutter that uses a smaller, higher-rpm motor (27mm X 38mm body and 2.3mm shaft). This resulted in improved cutting action especially when using a piano-wire (rather than Mig-wire) needle. The smaller motor lacks the torque of the larger however so am still cutting at 24-30 in/min feedrate... it tends to bog/drag a bit with attempts to increase the feedrate so far.

UPDATE 11/29: Version 3 has gone to more powerful motor from a cheap battery-powered drill that had been discarded. The motor holding fixture has also been adjusted to make mounting the completed cutter head assembly easier.

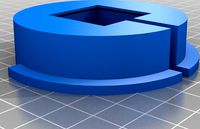

UPDATE 12/03: Improved flywheel/eccentric replaces old "shaft_eccentrics". Holes around periphery allow short 3mm screws to be placed strategically to balance the ball-bearing on the other side. Ran very smoothly to near 10000 rpm in configuration shown.

Originally inspired from "A Foam Cutting Machine" by Tom McGuire -- http://makeict.org/wiki/Foam_Cutting_Machine

Foam cutter in action --https://www.youtube.com/watch?v=kRLBNsZTKgM

UPDATE: I have created a version 2 foam-cutter that uses a smaller, higher-rpm motor (27mm X 38mm body and 2.3mm shaft). This resulted in improved cutting action especially when using a piano-wire (rather than Mig-wire) needle. The smaller motor lacks the torque of the larger however so am still cutting at 24-30 in/min feedrate... it tends to bog/drag a bit with attempts to increase the feedrate so far.

UPDATE 11/29: Version 3 has gone to more powerful motor from a cheap battery-powered drill that had been discarded. The motor holding fixture has also been adjusted to make mounting the completed cutter head assembly easier.

UPDATE 12/03: Improved flywheel/eccentric replaces old "shaft_eccentrics". Holes around periphery allow short 3mm screws to be placed strategically to balance the ball-bearing on the other side. Ran very smoothly to near 10000 rpm in configuration shown.

Similar models

thingiverse

free

Needle foam cutter for mpcnc by moebeast

... at the top in the bearing pocket.

update 9/20/2017 added new version of the needle holder with less mass in 10mm and 8mm sizes.

thingiverse

free

MPCNC 2826/2822 Brushless RC Motor Foam Cutter by dkj4linux

...173

mpcnc brushless foam cutter v2 in action:https://youtu.be/hvbnpgin62chttps://youtu.be/qo3jcprphcuhttps://youtu.be/blyrvlnocb0

thingiverse

free

Improved Needle Cutter 525 By Jason Hitesman For 2822 by Michael763

....php?24251-cutting-foam-sheets-with-a-needle!&p=356850&viewfull=1#post356850. mine remix can be seen in subsequent posts.

3dwarehouse

free

Shorter Needle Cutter

... the standard tool mount on an mpcnc. the distance from the motor to the guide bearings has been shortened to reduce needle slop.

thingiverse

free

Foam Ripper by moebeast

...work with 60 mm wheels from vicious1.com.

update 10/11/2017: added some thickness to the lower printed bearing on the z-carriage.

grabcad

free

6V-24V Mini Electric Drill DIY 385 DC Motor

...min @24v

-with 385 ball bearing motor

-round shaft: 3.175mm(1/8")

-with jt0 precision drill chuck, clamping range: 0.3 ~ 4mm

grabcad

free

Linear bearing with 3mm balls

...linear bearing with 3mm balls

grabcad

linear bearing with 3mm balls and 200mm stroke

thingiverse

free

MPCNC Needle cutter guide block by Basscor

...mpcnc needle cutter guide block by basscor

thingiverse

this is a bearing block for a needle cutter attachment.

thingiverse

free

ZMR250 3mm Motor Hole Guide by rogueqd

...zmr250 3mm motor hole guide by rogueqd

thingiverse

a drill guide for drilling 3mm holes for 2204 size motors.

thingiverse

free

MPCNC Needle Cutter by TEAJR66

...t the printed cutter.

10 oct 18

added the pen holder v2. holes in the side allow for tap or zip ties to secure the pen or marker.

Dkj4Linux

thingiverse

free

Foam Cutter by dkj4linux

...be found in my thread on the flitetest forum...http://forum.flitetest.com/showthread.php?24251-cutting-foam-sheets-with-a-needle!

thingiverse

free

CoreXY Laser Engraver by dkj4linux

...tps://www.youtube.com/watch?v=ppj-wbvnacm

https://www.youtube.com/watch?v=_l-yyxgziy4

https://www.youtube.com/watch?v=zoddbtyh3_q

thingiverse

free

Mostly Printed CamSlider by dkj4linux

...here...

http://forum.flitetest.com/showthread.php?24251-cutting-foam-sheets-with-a-needle!&p=315967&viewfull=1#post315967

thingiverse

free

Improved Needle Cutter 525 By Jason Hitesman For 2822 by Michael763

...keeper files to this item. the flywheel comes from dkj4linux https://www.thingiverse.com/thing:1211039, and the needle keeper comes from dkj4linux, https://www.thingiverse.com/thing:2528032....

thingiverse

free

MPCNC 2826/2822 Brushless RC Motor Foam Cutter by dkj4linux

...173

mpcnc brushless foam cutter v2 in action:https://youtu.be/hvbnpgin62chttps://youtu.be/qo3jcprphcuhttps://youtu.be/blyrvlnocb0

thingiverse

free

![X-Carve Brushless RC Motor Foam Cutter [EMAX MT2206-1500KV] by AustinSaintAubin](/t/8819823.jpg)

X-Carve Brushless RC Motor Foam Cutter [EMAX MT2206-1500KV] by AustinSaintAubin

...of mpcnc 2826 brushless rc motor foam cutter by dkj4linux designed for use with x-carve by mounting to x-carve...

thingiverse

free

Needle foam cutter for mpcnc by moebeast

...mash together of ryan's blank tool mount and the dkj4linux needle cutter. for full development of the tool, visit...

thingiverse

free

Improved Needle Cutter by jhitesma

...stretched to 52mm to allow more motor options with dkj4linux#39;s original "prop saver" mount style...

thingiverse

free

Foam Ripper by moebeast

...from "mpcnc 2826/2822 brushless rc motor foam cutter by dkj4linuxquot; and the pineapple coupler from "mostly printed cnc 525...

Mpcnc

thingiverse

free

MPCNC Laser Mount

...mpcnc laser mount

thingiverse

custom laser mount for mpcnc.

thingiverse

free

MPCNC Remix

...mpcnc remix

thingiverse

test

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

thingiverse

free

MPCNC Y PLATE

...mpcnc y plate

thingiverse

ender 3 printable y plate for mpcnc lowrider 2

thingiverse

free

MPCNC adapter for pen holder

...mpcnc adapter for pen holder

thingiverse

adapter to mpcnc

thingiverse

free

MPCNC Higher Feet

...mpcnc higher feet

thingiverse

extra height and width feet to minimize wobbling on higher mpcnc 2.5mm configurations.

thingiverse

free

MPCNC 30x30 Laser by DariusO

...mpcnc 30x30 laser by dariuso

thingiverse

mpcnc lasermodul in 30x30

thingiverse

free

mpcnc penholder

...mpcnc penholder

thingiverse

a quick remix of two different ideas

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

MPCNC Proxxon Mount by CNC_Fan

...mpcnc proxxon mount by cnc_fan

thingiverse

this is my proxxon mount for use mpcnc

Foam

3d_export

$5

cylinder foam does not fall stand polyurethane foam

...cylinder foam does not fall stand polyurethane foam

3dexport

cylinder foam does not fall stand.<br>polyurethane foam

turbosquid

$1

Foam Gun

...urbosquid

royalty free 3d model foam gun for download as fbx on turbosquid: 3d models for games, architecture, videos. (1659619)

turbosquid

$39

Foam Hand

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Shaving Foam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Foam Glider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Foam Brush

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Foam fire extinguisher

...alty free 3d model foam fire extinguisher for download as max on turbosquid: 3d models for games, architecture, videos. (1700116)

design_connected

$7

TORK Foam Soap Dispenser

...tork foam soap dispenser

designconnected

tork foam soap dispenser computer generated 3d model.

turbosquid

$29

Sierra Foam Sofa

...e 3d model sierra foam sofa for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1575076)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

Cutter

archibase_planet

free

Cutter

...cutter

archibase planet

cutter mill milling cutter

cutter 2 n050712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$10

pipe cutter

...pipe cutter

3dexport

pipe cutter

3d_export

$8

Grass Cutter

...grass cutter

3dexport

grass cutter

turbosquid

$5

Cutter

...alty free 3d model cutter for download as ige, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1505202)

turbosquid

$29

Cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cutter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Attachment

turbosquid

$20

M4A1 + Attachements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Attached House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Attache case

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$75

Attached House3d model

...d model

cgstudio

.3ds .fbx .max .obj - attached house 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

M416 AR with attachments

... model m416 ar with attachments for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1614294)

turbosquid

$10

M16A2 with M203 Attachment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

bench attached to greenery

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Modern 1911 with Attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Mercedes Sprinter sun visor attachment

...mercedes sprinter sun visor attachment

3dexport

mercedes sprinter sun visor attachment

turbosquid

$14

Residential building with attached shop

...l residential building with attached shop for download as max on turbosquid: 3d models for games, architecture, videos. (1482935)