Thingiverse

Mounting Plate for 2 in 1 out Switch Hotend for Geeetech Prusa I3 by DougInAZ

by Thingiverse

Last crawled date: 3 years ago

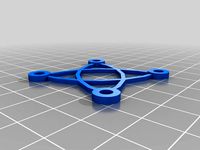

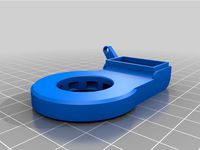

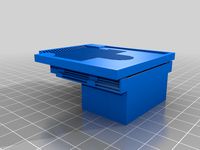

Update 12/6/17 I AM PLANNING ON CHANGING THE COOLING SCHEME FROM AN AXIAL FAN TO A RADIAL FAN. I ADDED THE FIRST CUT AT THE DUCT AND A TEMPORARY TRANSITION PIECE USING A 30 MM AXIAL FAN . THE DUCT MOUNTS ON THE BACK, NEAREST THE LINEAR BEARINGS, SO IT DOESN'T INTERFERE WITH THE LAYER FAN AND MAKES IT EASY TO CHANGE HOT-ENDS. I HAVEN'T TRIED IT YET, AND IT MAY BE IN-PROCESS FOR SEVERAL MONTHS. PLS LET ME KNOW IF YOU TRY THIS AND HAVE ANY SUGGESTIONS.

Update 4/16/17 Added link to information on using a Y-block hotend. 4/19 https://1drv.ms/w/s!AoMNMLsOFAgFj-AnywOk94qGBizVrg

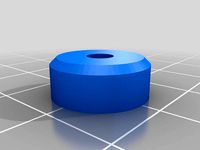

Update 3/30 Changed spacer and plate with closed bottom to 3 hole version.

Update 3/15 I found that this hotend requires a higher filament temp than the one I had been using. Also, the extruder PIDs needed adjustment to keep the temperature more constant than the larger one I had been using. I used to get good results with one PLA type at 193 deg. Now I believe something over 200 is required for the same filament. The following PIDs seem to work well at a print temp of 202 C: Kp 13.5 Ki 0.8 Kd 57.6. The heater block is uninsulated at this time. I've found it's worthwhile to add some insulation to the block. I use cereal box paper secured with kapton tape.

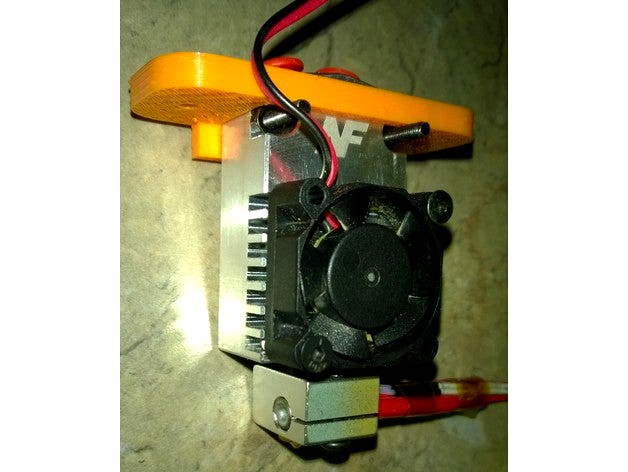

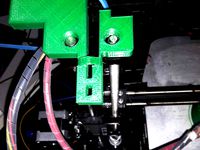

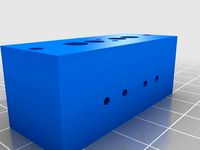

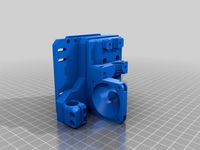

Update 3/13/17 Added a couple photos of the part installed in a very thin test print of the bracket. The part looks very good. So far, I've only used it as a single extruder. The heat break is very effective. The upper part of the block stays very cool when printing PLA, even without the fan running. There are holes on the back of the upper block for a layer cooling fan. I've removed my cooling fan temporarily from the extruder bracket while I'm testing things. More updates as I figure out the scripts required to make it function as a switcher.

Update 2/27 minor tweak in cavity dimensions. Added 2 mm Spacer.

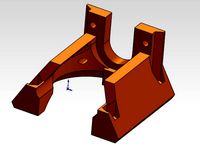

updated 3/17 I only printed this part as a lite-weight test-prototype. It is for mounting a new 2-to-1 hot end that is similar to a Cyclops, but permits two filaments to be switched between one output. It will not mix two filament streams and does not have the backflow problem if you only load one filament in the block. ==============================================================

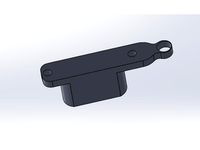

The plate is intended to mount on a single extruder mounting plate like that furnished with the Geeetech I3 Pro B printer with 50 mm mounting centers. When this design is proven, I expect to be able to switch between the Cyclops/Chimera clone setup I have on this printer and this 2 to 1 switch hotend with minimal readjustment of the printer. That means I will adjust the bracket as necessary to get close to the same vertical height as I currently have on my Cyclops clone using the mounting plate and spacer I designed. I expect the plate will mount on top surface of the extruder bracket with the hotend mounting holes below the mounting plate.

I recently received the part, but have done little testing. I found it on AliExpress. I also found it on eBay when I was researching a new extruder today. You can probably find it as I did by searching for: HOTEND 2 IN 1 OUT.

A first look at the part shows that it runs much cooler than expected in the area of the mounting holes, so PLA will probably be what I'll use for the final bracket. The part mounts through the rectangular hole in the plate, but the .STL file has a thin surface covering this hole. The purpose of the surface is to keep the plate bonded to the bed during printing if you use ABS; being only 0.6 mm thick, it can be easily cut out when finished. I also added a version with the hole open.

I have high hopes for this part for use as an easy way to switch between filaments during a print. My Cyclops setup is OK as a mixer but tricky when trying to use it as a switcher with high ratios between the two filaments. The printer manager will require some code to retract the unused filament back into the cool zone and advance the other filament when the extruder is switched.

Update 4/16/17 Added link to information on using a Y-block hotend. 4/19 https://1drv.ms/w/s!AoMNMLsOFAgFj-AnywOk94qGBizVrg

Update 3/30 Changed spacer and plate with closed bottom to 3 hole version.

Update 3/15 I found that this hotend requires a higher filament temp than the one I had been using. Also, the extruder PIDs needed adjustment to keep the temperature more constant than the larger one I had been using. I used to get good results with one PLA type at 193 deg. Now I believe something over 200 is required for the same filament. The following PIDs seem to work well at a print temp of 202 C: Kp 13.5 Ki 0.8 Kd 57.6. The heater block is uninsulated at this time. I've found it's worthwhile to add some insulation to the block. I use cereal box paper secured with kapton tape.

Update 3/13/17 Added a couple photos of the part installed in a very thin test print of the bracket. The part looks very good. So far, I've only used it as a single extruder. The heat break is very effective. The upper part of the block stays very cool when printing PLA, even without the fan running. There are holes on the back of the upper block for a layer cooling fan. I've removed my cooling fan temporarily from the extruder bracket while I'm testing things. More updates as I figure out the scripts required to make it function as a switcher.

Update 2/27 minor tweak in cavity dimensions. Added 2 mm Spacer.

updated 3/17 I only printed this part as a lite-weight test-prototype. It is for mounting a new 2-to-1 hot end that is similar to a Cyclops, but permits two filaments to be switched between one output. It will not mix two filament streams and does not have the backflow problem if you only load one filament in the block. ==============================================================

The plate is intended to mount on a single extruder mounting plate like that furnished with the Geeetech I3 Pro B printer with 50 mm mounting centers. When this design is proven, I expect to be able to switch between the Cyclops/Chimera clone setup I have on this printer and this 2 to 1 switch hotend with minimal readjustment of the printer. That means I will adjust the bracket as necessary to get close to the same vertical height as I currently have on my Cyclops clone using the mounting plate and spacer I designed. I expect the plate will mount on top surface of the extruder bracket with the hotend mounting holes below the mounting plate.

I recently received the part, but have done little testing. I found it on AliExpress. I also found it on eBay when I was researching a new extruder today. You can probably find it as I did by searching for: HOTEND 2 IN 1 OUT.

A first look at the part shows that it runs much cooler than expected in the area of the mounting holes, so PLA will probably be what I'll use for the final bracket. The part mounts through the rectangular hole in the plate, but the .STL file has a thin surface covering this hole. The purpose of the surface is to keep the plate bonded to the bed during printing if you use ABS; being only 0.6 mm thick, it can be easily cut out when finished. I also added a version with the hole open.

I have high hopes for this part for use as an easy way to switch between filaments during a print. My Cyclops setup is OK as a mixer but tricky when trying to use it as a switcher with high ratios between the two filaments. The printer manager will require some code to retract the unused filament back into the cool zone and advance the other filament when the extruder is switched.

Similar models

thingiverse

free

K8200 E3D V5 Mount and nozzle fan by abrooksdavis

...v5 mount allowing for a hotend fan duct.

this uses the original 30mm fan from the e3d extruder and a 40mm fan for the fan duct.

thingiverse

free

Hotend mount spacer for Wades Extruder by carbochip

...d jam.

use concentric infill for smoother top surface (still had to file it down).

use 2mm drill bit to clear the filament hole.

thingiverse

free

Bulldog XL / E3D-V6 cooling fan mount (60mm) by markusbart

...ing here. the circuit switches on when the hotend gets power and switches off after it is left without power for like 10 minutes.

thingiverse

free

Anycubic Kossel Linear Plus Cyclops Effector by Joe021

...end mount as well as widened the hole that the hotend goes into. the fan shroud has been updated so less air blows on the nozzle.

thingiverse

free

Mounting Plate for 2 to 1 Mixing Extruder for Geeetech Prusa I3 by DougInAZ

...eams of fluid filament by retracting the unused filament back into the cool zone when the tool is switched to the other extruder.

thingiverse

free

Ormerod Parts Cooling Fan Mount - E3D hotend by dapol

....

use m3x20 bolts to attach the parts cooling fan. i have m3x70 as the top mount bolts for the head cooling fan and this bracket.

thingiverse

free

Compact and Silent E3D v6 Fan Box by Dvogonen

...s.

the fan box was constructed using freecad and the design file is available for download together with the printable stl files.

thingiverse

free

Cyclope afterburner tri-fan by DannyGi

...swiss plate.

i'm thinking of a version with 50mm fan for extruded cooling mounted horizzontally to the bed. work in progress.

thingiverse

free

Layer Cooling Fan Bracket for Geeetech Prusa I3 by DougInAZ

...to a geeetech prusa i3 printer or others with similar extruder brackets. the fan duct is not included in...

grabcad

free

ACi3M X Carriage Plate and Hotend Bracket

...ccurate. this is useful when designing accessories for your aci3mega such as hotend brackets and part cooling fans. more to come.

Douginaz

thingiverse

free

Simple Fan Guard by DougInAZ

...original, but other than that should do about the same job as the original. if you want it thicker, scale it in the z direction.

thingiverse

free

Super Glue Holder by DougInAZ

...se for super glue before i had a 3d printer. now, i find it an essential item to assmeble and patch pla and some other plastics.

thingiverse

free

Soap Tray for Kitchen or bathroom by DougInAZ

...version without drain holes, let me know and i'll add one.

note: the models are sized @ 10x. scale to 0.1 for original size.

thingiverse

free

Nose Clip for anti COVID mask by DougInAZ

...nother version(s) right away.

update 4/17/21 i added a version that fits tighter on my face and is twice as thick in the arms.

thingiverse

free

Holder for X10 Clock by DougInAZ

...the rear feet of the stand. it was really not needed for my use, and probably doesn't need to be used for most applications.

thingiverse

free

Joy Stick Handle for Power Chair by DougInAZ

...meter, with a 11.5 mm circular stop below.

the part has a thin internal brim built into it that has to be removed prior to use.

thingiverse

free

Base for Enermax EAS02S Bluetooth Speaker by DougInAZ

...ne perimeter for the base, and the infill moved the printed thread where they were adjacent. however, it was surprisingly rigid.

thingiverse

free

Tray for Pills, etc. by DougInAZ

...two colors using a y-switching extruder and patched g-code. there is also a small foot. print four and glue them on the bottom.

thingiverse

free

Tether for Drill Chuck Key by DougInAZ

...asy to heat them with a hair dryer and slip them around the 90 deg bend when they were hot. upon cooling, they are a shrink fit.

thingiverse

free

Steering Wheel Spinner Knob for 29x36 mm Wheel by DougInAZ

...ings like this, the question of legality and the risk imposed by having this attached to the steering wheel is borne by the user.

Geeetech

3d_export

free

part right for geeetech acrylic i 3

...part right for geeetech acrylic i 3

3dexport

the engine can be shifted

3d_export

free

cable holder

...cable holder 3dexport for geeetech acrylic i...

thingiverse

free

geeetech a10 by Igor_garbuz

...geeetech a10 by igor_garbuz

thingiverse

model geeetech a10 ( solidworks).

thingiverse

free

geeetech calibration by muffler1979

...geeetech calibration by muffler1979

thingiverse

just a calibration test for the bed on a geeetech

thingiverse

free

Fan for Geeetech proB

...fan for geeetech prob

thingiverse

this is my fan for the geeetech pro b i3.

thingiverse

free

Chain for Geeetech A30

...chain for geeetech a30

thingiverse

this is my personal review of chain for geeetech a30.

thingiverse

free

Zugentlastung Hotend Geeetech A30T / Strain relief Geeetech A30T by 3DDennis1983

...zugentlastung hotend geeetech a30t / strain relief geeetech a30t by 3ddennis1983

thingiverse

zugentlastung hotend geeetech a30t

thingiverse

free

Kettenhalter i3x geeetech by Autark

...kettenhalter i3x geeetech by autark

thingiverse

geeetech i3x

thingiverse

free

Geeetech A10 Fanduct by stefan177gr

...geeetech a10 fanduct by stefan177gr

thingiverse

fanduct for geeetech a10

thingiverse

free

Geeetech filament guide by RicardoZ2018

...geeetech filament guide by ricardoz2018

thingiverse

desing for geeetech i3x

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

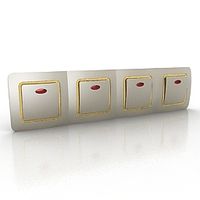

Switch

archibase_planet

free

Switch

...switch

archibase planet

switch cluster switch

light switch 1 - 3d model for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

switches switch

switch 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

closer button switch cluster switch

switch - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

switch closer

light switch 2 - 3d model for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

closer button switch

switch n300808 - 3d model (*.gsm+*.3ds) for interior 3d visualization

archibase_planet

free

Switch

...switch

archibase planet

closer button switch

switch n141108 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

cluster switch closer

switch n260609 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

button switch closer

switch 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

button switch closer

switch n070510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

switch

...switch

3dexport

3d model of a low-poly switch

Plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

plate

...plate

3dexport

plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate kitchen ware

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plates

...plates

archibase planet

plate plates and dishes crockery

plates 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plate

...plate

archibase planet

dinner-plate plate kitchen ware

plate n070808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$6

plate

...plate

3dexport

design of plate

3d_export

$5

plate

...plate

3dexport

plate lowpoly

archibase_planet

free

Plates

...plates

archibase planet

plate dish kitchen-ware

plate - 3d model for interior 3d visualization.

3ddd

$1

Plates

...plates

3ddd

полка , тарелка

african plates

archibase_planet

free

Plate

...plate

archibase planet

plate kitchen ware

plate - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mounting

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.