Thingiverse

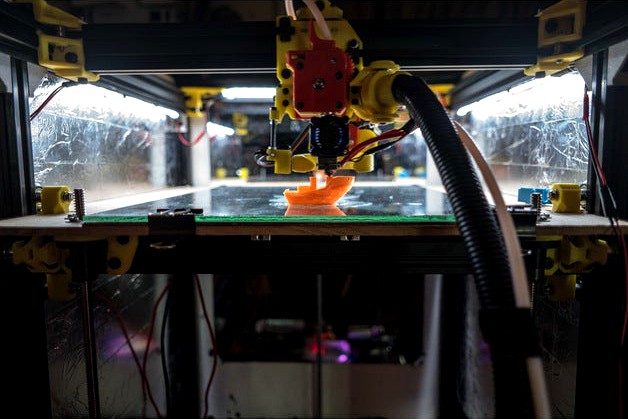

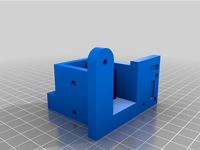

Mortar Bot v.2 CoreXY 3D Printer by MortarArt

by Thingiverse

Last crawled date: 3 years ago

Deprecated; see here:

M-bot v.1; https://www.thingiverse.com/thing:2386365/

M-bot v.3; https://www.thingiverse.com/thing:3134348

M-bot v.3.5; https://www.thingiverse.com/thing:3889891

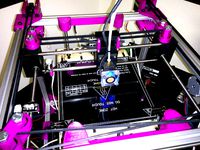

THIS IS A WORKING PRINTER

Current Status:

BOM lists all required hardware, though it hasn't been double checked, and I haven't found good sources for everything yet.

The printer is functioning, within an enclosure, and printing both ABS and PLA at a high standard.

I'm still to confirm whether or not this design will be compatible with the e3d toolchanger, but that is the intent.

List of key design changes implemented from the M-Bot v1 (itself a D-Bot remix) - https://www.thingiverse.com/thing:2386365

Wider implementation of aluminium brackets, including the full replacement of some printed corners.

Mirror of the 3 leadscrew design to improve space efficiency

Additional of MGN-9 rails for Y axis.

Lengthening of Y axis, shortening of X axis to reduce weight of moving components.

Reduction of extrusion usage, increase of structural use of enclosure.

Usage of full sized delrin wheels on Z axis.

Bed base to act as enclosure floor.

Use of precut lengths from RobotDigg for almost all extrusions

Features as designed:

400x300mm heatbed.

400mm build height.

Tight enclosure for heat retension.

Compatibility with e3d extruder and hot end options (v6, Volcano, Titan, Aero, Pitan)

Space for user's choice of electronics.

Rigid frame.

Light moving components.

Reduction in sources required for suppliers

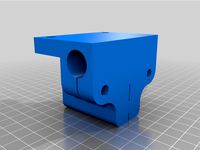

Printed Part descriptions (assumes D-bot knowledge):

Recommended to print all in solid ABS, in an enclosure. PET-G would work as a substitute, but some tolerances may be off.

Z Axis:

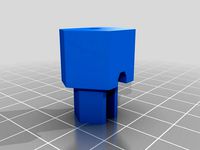

Two-wheel-carriage-portion-x2 - Part to be bolted to side of 2040 main Z extrusion

One-wheel-carriage-part-x2 - Part to be bolted to opposite side of 2040 main Z extrusion

Z-leadscrew-front-mount-x2 - Mounted next to One-wheel-carriage

Z-leadscrew-rear-mount - Mounted at end of 2040 T-bar

! Z-leadscrew parts available with either 4 bolts or 3 bolts for leadscrew nuts.

XY Frame corners:

back-right-bearing-mount & back-left-bearing-mount - 2020 X extrusion at rear mounted on top.

Right-motor-bracket & Left-motor-bracket - 2020 X extrusion mounted directly under 2040 Y extrusions

Base pieces:

z-motor-mount - Raised motor, to make space for electronics

Rubber-foot-m5 (x4) - Printed feet, to save buying them. Use TPU. Print close to solid.

Rail carriages:

linear-rail-carriage - Mounted on two linear rail blocks, supports incorporated into STL.

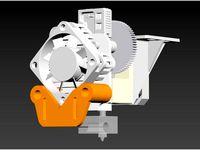

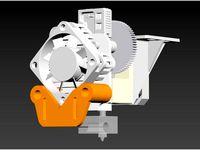

Effector carriage:

v-wheel-top-clamp - mounts a full sized delrin V wheel, clamps with 4x M3 bolts to the carriage body

Carriage_Front_bdige_rotated & Carriage_Rear_for_Longer_Stepper - mount two mini v wheels, and the motor for either a Titan or Aero extruder

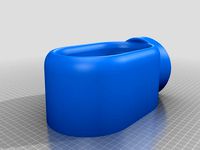

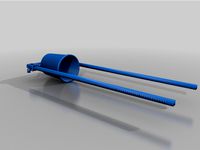

e3d-v6-cooling-fan-extension - lowers the cooling fan for a full V6 heatbreak.

AC-Bot-fan-shroud-improved-placement - is for a left hand side titan / aero

IR-guide & ir-cover for mounting DC42 ir probe. Requires M3x40mm bolts for regular Titan, and M3x50mm bolts for Volcano. Much shorter for Titan Aero.

Extruder:

Pitan parts adjusted to fit 5x14x5mm bearings for the hob, and a 4x13x4 grooved bearing on the lever, plus a new 5x14x5mm bearing on the motor shaft for the lever.

Optional Pitan body parts with holes for airflow. Suggested to mount with a 40mm fan for use in the enclosure.

Electronics enclosures:

Duet Wifi enclosure, with one major cable hole, and holes for screw down terminals, USB, wifi antenna etc. Requires 12mm M3 stand offs, and stand offs of any length for mounting to aluminium sheet, as well as 5 M3 bolts, and a 40mm blower fan for cooling.

PSU cable cover, to protect from accidental exposure to live lines.

Enclosure instructions / suggestions:

Cut MDF panels to size

Paint exterior

Line interior with aluminium tape

Drill holes for mounting on extrusions

Front panel requires cut corners to fit front motor mounts

Bed panel requires cuts for Z axis wheel carriage and extrusions

Roof panel requires gasket sealant such as silicone along contact points

Suggest installing a handle on the roof panel

Back enclosure corner should be installed over rear panel's top screw mounts as a guide for the roof panel

Consider mounting mirror on rear panel

M-bot v.1; https://www.thingiverse.com/thing:2386365/

M-bot v.3; https://www.thingiverse.com/thing:3134348

M-bot v.3.5; https://www.thingiverse.com/thing:3889891

THIS IS A WORKING PRINTER

Current Status:

BOM lists all required hardware, though it hasn't been double checked, and I haven't found good sources for everything yet.

The printer is functioning, within an enclosure, and printing both ABS and PLA at a high standard.

I'm still to confirm whether or not this design will be compatible with the e3d toolchanger, but that is the intent.

List of key design changes implemented from the M-Bot v1 (itself a D-Bot remix) - https://www.thingiverse.com/thing:2386365

Wider implementation of aluminium brackets, including the full replacement of some printed corners.

Mirror of the 3 leadscrew design to improve space efficiency

Additional of MGN-9 rails for Y axis.

Lengthening of Y axis, shortening of X axis to reduce weight of moving components.

Reduction of extrusion usage, increase of structural use of enclosure.

Usage of full sized delrin wheels on Z axis.

Bed base to act as enclosure floor.

Use of precut lengths from RobotDigg for almost all extrusions

Features as designed:

400x300mm heatbed.

400mm build height.

Tight enclosure for heat retension.

Compatibility with e3d extruder and hot end options (v6, Volcano, Titan, Aero, Pitan)

Space for user's choice of electronics.

Rigid frame.

Light moving components.

Reduction in sources required for suppliers

Printed Part descriptions (assumes D-bot knowledge):

Recommended to print all in solid ABS, in an enclosure. PET-G would work as a substitute, but some tolerances may be off.

Z Axis:

Two-wheel-carriage-portion-x2 - Part to be bolted to side of 2040 main Z extrusion

One-wheel-carriage-part-x2 - Part to be bolted to opposite side of 2040 main Z extrusion

Z-leadscrew-front-mount-x2 - Mounted next to One-wheel-carriage

Z-leadscrew-rear-mount - Mounted at end of 2040 T-bar

! Z-leadscrew parts available with either 4 bolts or 3 bolts for leadscrew nuts.

XY Frame corners:

back-right-bearing-mount & back-left-bearing-mount - 2020 X extrusion at rear mounted on top.

Right-motor-bracket & Left-motor-bracket - 2020 X extrusion mounted directly under 2040 Y extrusions

Base pieces:

z-motor-mount - Raised motor, to make space for electronics

Rubber-foot-m5 (x4) - Printed feet, to save buying them. Use TPU. Print close to solid.

Rail carriages:

linear-rail-carriage - Mounted on two linear rail blocks, supports incorporated into STL.

Effector carriage:

v-wheel-top-clamp - mounts a full sized delrin V wheel, clamps with 4x M3 bolts to the carriage body

Carriage_Front_bdige_rotated & Carriage_Rear_for_Longer_Stepper - mount two mini v wheels, and the motor for either a Titan or Aero extruder

e3d-v6-cooling-fan-extension - lowers the cooling fan for a full V6 heatbreak.

AC-Bot-fan-shroud-improved-placement - is for a left hand side titan / aero

IR-guide & ir-cover for mounting DC42 ir probe. Requires M3x40mm bolts for regular Titan, and M3x50mm bolts for Volcano. Much shorter for Titan Aero.

Extruder:

Pitan parts adjusted to fit 5x14x5mm bearings for the hob, and a 4x13x4 grooved bearing on the lever, plus a new 5x14x5mm bearing on the motor shaft for the lever.

Optional Pitan body parts with holes for airflow. Suggested to mount with a 40mm fan for use in the enclosure.

Electronics enclosures:

Duet Wifi enclosure, with one major cable hole, and holes for screw down terminals, USB, wifi antenna etc. Requires 12mm M3 stand offs, and stand offs of any length for mounting to aluminium sheet, as well as 5 M3 bolts, and a 40mm blower fan for cooling.

PSU cable cover, to protect from accidental exposure to live lines.

Enclosure instructions / suggestions:

Cut MDF panels to size

Paint exterior

Line interior with aluminium tape

Drill holes for mounting on extrusions

Front panel requires cut corners to fit front motor mounts

Bed panel requires cuts for Z axis wheel carriage and extrusions

Roof panel requires gasket sealant such as silicone along contact points

Suggest installing a handle on the roof panel

Back enclosure corner should be installed over rear panel's top screw mounts as a guide for the roof panel

Consider mounting mirror on rear panel

Similar models

thingiverse

free

MGN12H Hermera Carriage for 2040 extrusion with V slot Wheel Stabiliser

...2h carriage on a 20* profile extrusion..

you can mount a stabilising v slot wheel to the bottom if you mount on a 2040 extrusion.

thingiverse

free

2040 Extrusion Mount for 37mm Anti Backlash Nut by kwirky

...axis leadscrew nut for my dbot. the original d-bot part doesn't work for the 37mm version so i designed this using openscad.

thingiverse

free

Titan Aero bracket for D-Bot by muz64

...int carriage.

i don't think you can get the titan aero any closer to the rail. it's a nice compact and very rigid mount.

thingiverse

free

Tevo Tarantula Z axis inverted leadscrew holder by SuperSushi3000

...for the connection to the motor axis, those worked very well:https://www.thingiverse.com/thing:602481

fusion files are included.

thingiverse

free

MGN12 Carriage Reverse Mount by ChrisT88

...he front side z axis on a c/d-bot. mounts to 20mm extrusion via two 5mm bolt holes and the four carriage holes are of course 3mm.

thingiverse

free

Eryone Thinker S - Dual Extruder Stepper Mount

... 5mm bolts for the right-hand side z-axis wheels and 5mm nuts and washers on the rear to hold the new mount down to the carriage.

thingiverse

free

Titan Aero IR mount by MortarArt

...ount by mortarart

thingiverse

a fitting for mounting an ir sensor to a titan aero.

the updated mount is for the duet3d ir mount.

thingiverse

free

Aus3D IR Z Probe mount for E3D Titan Aero by ChrisBarr

... aero extruder.

this will hold the ir probe at the correct height from the titan aero's nozzle for use as a bed sensor/probe.

thingiverse

free

ANET A8 2020 X Axis with Titan Aero BLTouch by markalunwinn

...s tight, file it down a bit. if it's loose, you can put a piece of paper between the joints to secure it.

bltouch offsets

tbd

thingiverse

free

Titan direct drive carriage front plate for C-Bot by ian_in_the_midlands

...owden option\c-bot bowden carriage rear plate (x1) ).

for the cooling fan ducts and bracket to mount the fans, see thing 2830838.

Mortarart

thingiverse

free

Until we all belong. by MortarArt

...until we all belong. by mortarart

thingiverse

https://untilweallbelong.com/

thingiverse

free

Titan Aero IR mount by MortarArt

...ount by mortarart

thingiverse

a fitting for mounting an ir sensor to a titan aero.

the updated mount is for the duet3d ir mount.

thingiverse

free

Leg for Logitech y-r0015 keyboard by MortarArt

...15 keyboard by mortarart

thingiverse

printed in petg. needed a little post-processing to get the nodules to fit in the recesses.

thingiverse

free

E3d Titan Idler Arm redesign by MortarArt

...edesign by mortarart

thingiverse

basically provides space for a bearing on the motor arm, and a grooved bearing against the hob.

thingiverse

free

Hex Adapter for screwdriver by MortarArt

...r

m3 nut

adapts a 1/4" hex on a screwdriver to 3, 4 & 5mm hex keys.

printed in solid abs, supportless. heated enclosure.

thingiverse

free

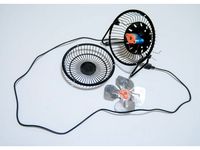

RS Components USB fan rebuild by MortarArt

...erse

a bracket to install a motor recovered from a cd/dvd drive to replace a broken motor in a usb powered fan by rs components.

thingiverse

free

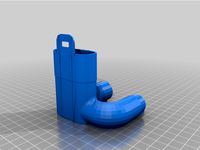

Charlotte Valve with minimal manual support by MortarArt

...r more rapid production. thicker walls where the part joins the mask, and manual support for the remaining parts that require it.

thingiverse

free

Near-supportless Bladless Fan by MortarArt

...required, but only in internal areas. printing now ... hopefully it won't fail as it's a 24 hour print on a replicator 2.

thingiverse

free

Micro Lift by MortarArt

...ls, so that it can easily be moved along the formwork.

components could be a mix of aluminium or steel plates, and printed parts.

thingiverse

free

Greenhouse sprinkler (pour from outside) by MortarArt

...oviding a funnel on one end, and an outlet on the other, so that watering can be done without opening or entering the greenhouse.

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Mortar

turbosquid

$19

Mortar

...uid

royalty free 3d model mortar for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1197208)

3d_ocean

$5

Mortar and Pestle

...mortar and pestle

3docean

brass brazen kitchen medicine mortar pestle

a brazen mortar and a pestle with some scratches

3d_export

$5

mortar

...mortar

3dexport

3d_ocean

$5

Mortar and Pestle

...mortar and pestle

3docean

alchemist cooking crush kitchen mortar pestle silver witch

a silver mortar and pestle set

turbosquid

$48

Mortar

...oyalty free 3d model mortar for download as max, max, and 3ds on turbosquid: 3d models for games, architecture, videos. (1589238)

3d_export

$15

mortar 80mm

...mortar 80mm

3dexport

mortar 4k textures uvw

turbosquid

$50

Mortar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Mortar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Mortar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Mortar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bot

turbosquid

$19

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

scanner bot

...scanner bot

3dexport

cool scanner bot who scans for fixing things...

3d_ocean

$9

Apc Bot

...n bot games toys

an all-purpose-constructo-bot. for cartoon purposes. the model is not rigged. please use vray adv for rendering.

3d_export

$75

Bot 3D Model

...bot 3d model

3dexport

robot bot man kiborg character

bot 3d model evgen 19504 3dexport

turbosquid

free

Eye Bot

...eye bot

turbosquid

free 3d model eye bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1514059)

turbosquid

$29

Gorill-bot

...bosquid

royalty free 3d model gorill-bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1239456)

turbosquid

$25

Lamp Bot

...bosquid

royalty free 3d model lamp bot for download as blend on turbosquid: 3d models for games, architecture, videos. (1230121)

turbosquid

$10

Spectre Bot

...osquid

royalty free 3d model spectre bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1616378)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V

design_connected

$16

V Chair

...v chair

designconnected

v chair computer generated 3d model.

design_connected

$11

V Hanglamp

...v hanglamp

designconnected

arturo alvarez v hanglamp computer generated 3d model. designed by alvarez, arturo .

turbosquid

$25

Borbet V

...v

turbosquid

royalty free 3d model borbet v for download as on turbosquid: 3d models for games, architecture, videos. (1381618)

turbosquid

free

Saturn V

...rn v

turbosquid

free 3d model saturn v for download as blend on turbosquid: 3d models for games, architecture, videos. (1651098)

turbosquid

$40

V motor

...turbosquid

royalty free 3d model v motor for download as max on turbosquid: 3d models for games, architecture, videos. (1379483)

turbosquid

$7

V for Van

...rbosquid

royalty free 3d model v for van for download as max on turbosquid: 3d models for games, architecture, videos. (1695889)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408535)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408534)

turbosquid

$15

BonePile V

...oyalty free 3d model bonepile v for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546310)

turbosquid

$2

FONT V

...quid

royalty free 3d model font v for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549450)

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.